A roller laminating machine

A laminating machine and roller technology, applied in lamination device, lamination auxiliary operation, lamination and other directions, can solve the problems of large environmental pollution and high manufacturing cost, and achieve simple gluing process, low pollution lamination, high efficiency fit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

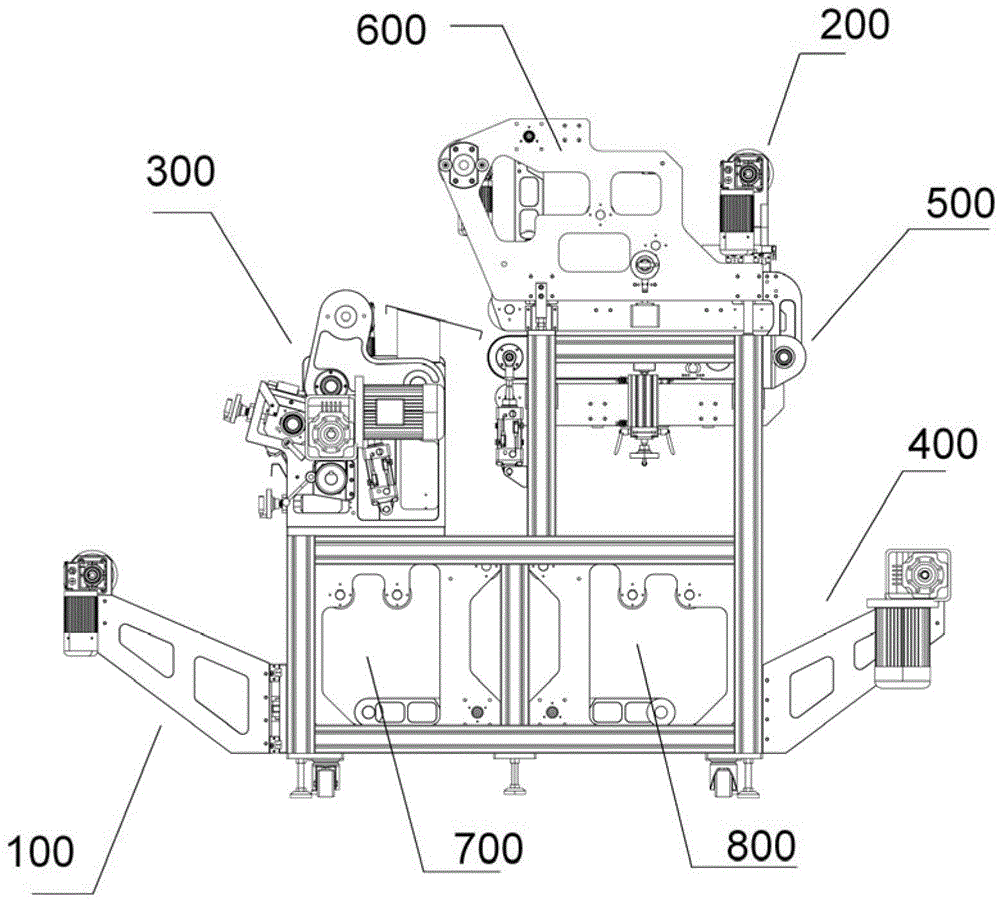

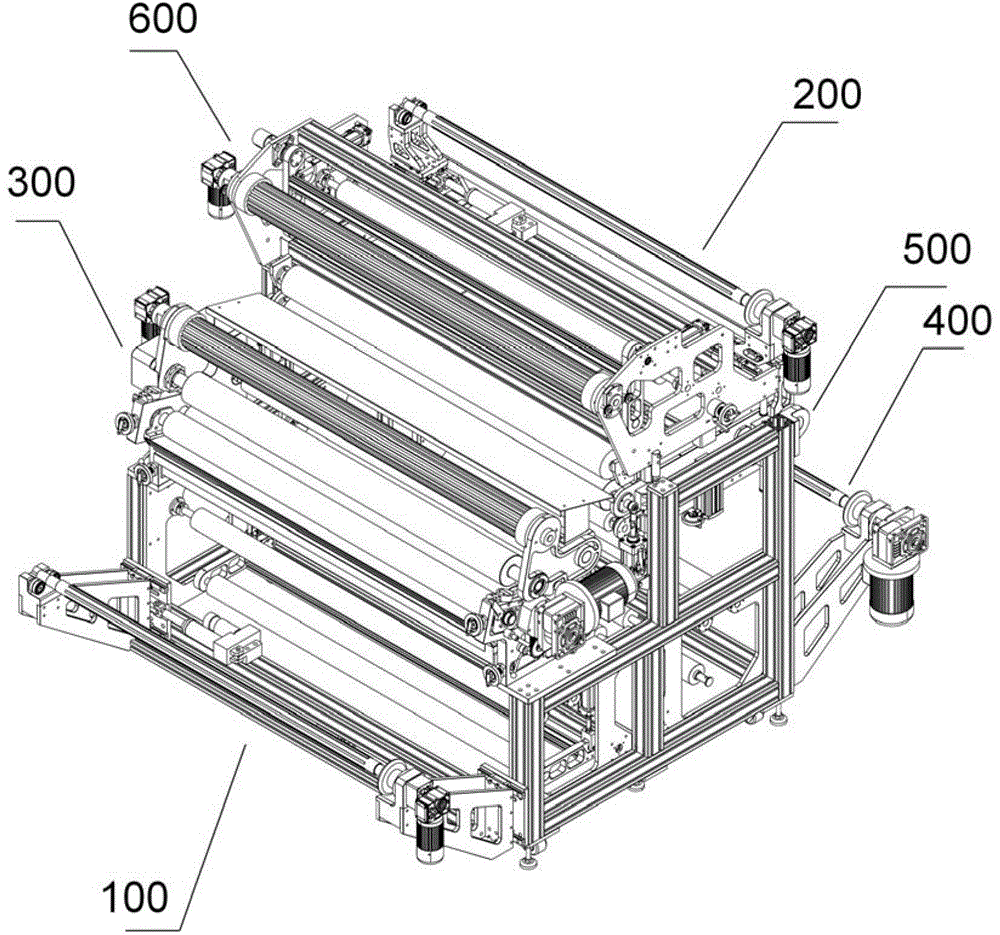

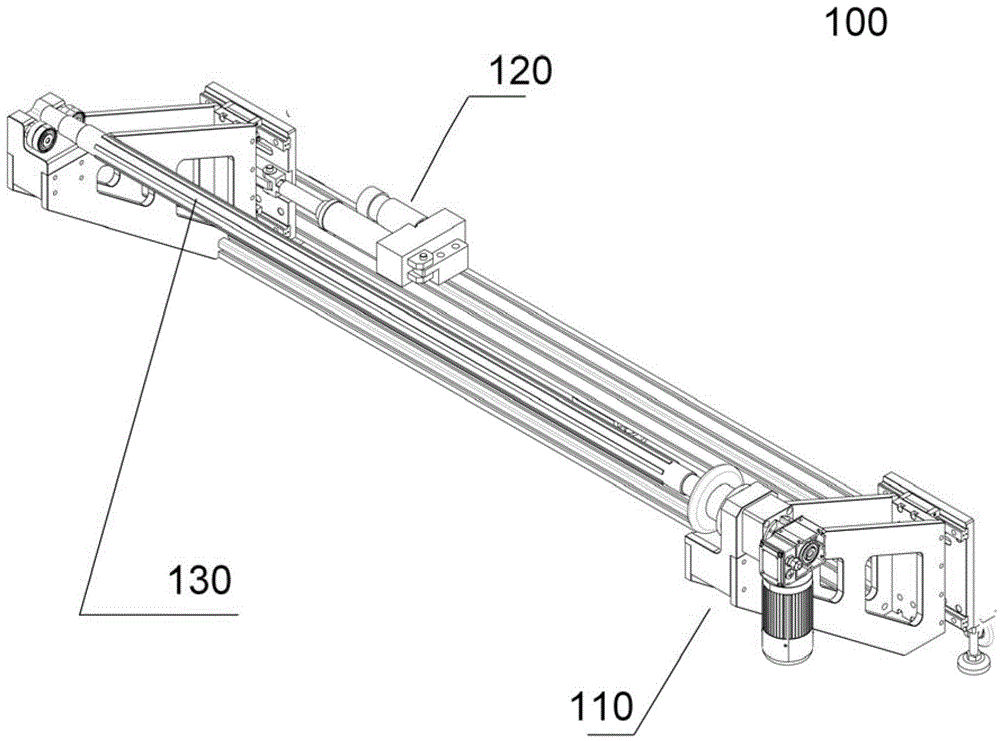

[0040] Such as figure 1 and figure 2 Shown are a side view and a perspective view of the roll laminating machine of the present invention. The roller laminating machine of the present invention includes a first unwinding mechanism 100 and a second unwinding mechanism 200, respectively provided with flexible substrates to be laminated. After the first substrate is released from the first unwinding mechanism, it enters the first floating roller system 700, and the first floating roller system 700 changes the tension degree of the first substrate after being discharged through the internal adjustable floating roller.

[0041] After passing through the first floating roller system 700, the first base material enters the glue roller system 300 for gluing. The gluing roller system 300 accurately coats the water-based glue on the first substrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com