Device and method for sticking vacuum heat-insulating plate

A technology of vacuum insulation panels and side panels, applied in lamination devices, chemical instruments and methods, layered products, etc., can solve the problems of VIP board installation interference, large amount of hot melt adhesive, and high cost, and achieve widespread promotion. Application value, improve production efficiency, ensure the effect of thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

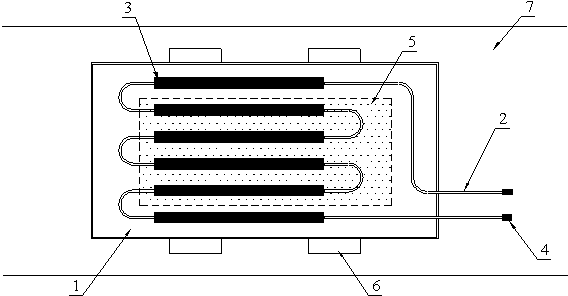

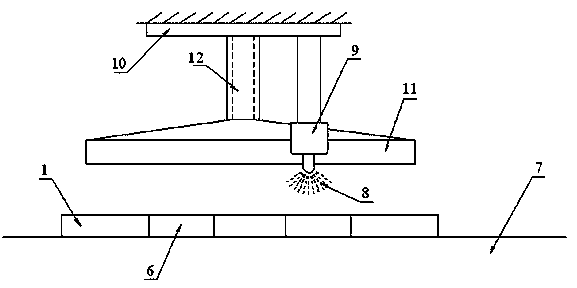

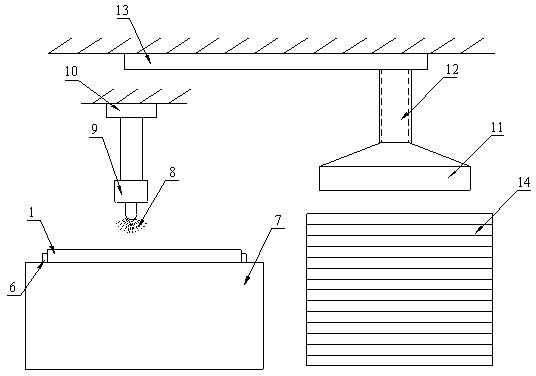

[0031] Such as Figure 1 to Figure 4 The device for pasting vacuum insulation panels of the present invention includes an assembly line platform 7 for placing refrigerator side panels 1, a spray gun head 9 arranged above the assembly line platform 7, and a vacuum insulation panel 14 that can be clamped from the pile and moved to Glue position 5 and press crimping device 11. The assembly line platform 7 is provided with a positioning block 6 for adjusting the position of the side panel 1 of the refrigerator.

[0032] figure 1 Among them, the side plate 1 of the refrigerator that has been installed and pasted with the condenser is placed on the assembly line platform 7, of which 2 is the condenser tube, 3 is the aluminum foil tape, 4 is the plug of the condenser tube, 5 is the pasting position, and 6 is the section refrigerator side plate 1 Position block.

[0033] figure 2 , is a vacuum insulation panel sticking device structure, the spray gun head 9 is movable, and it is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com