Purifying method for hepatitis B e antigen

A purification method, hepatitis B technology, applied in the biological field, can solve problems such as cumbersome operation, and achieve the effect of simple and convenient operation and no impact on structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

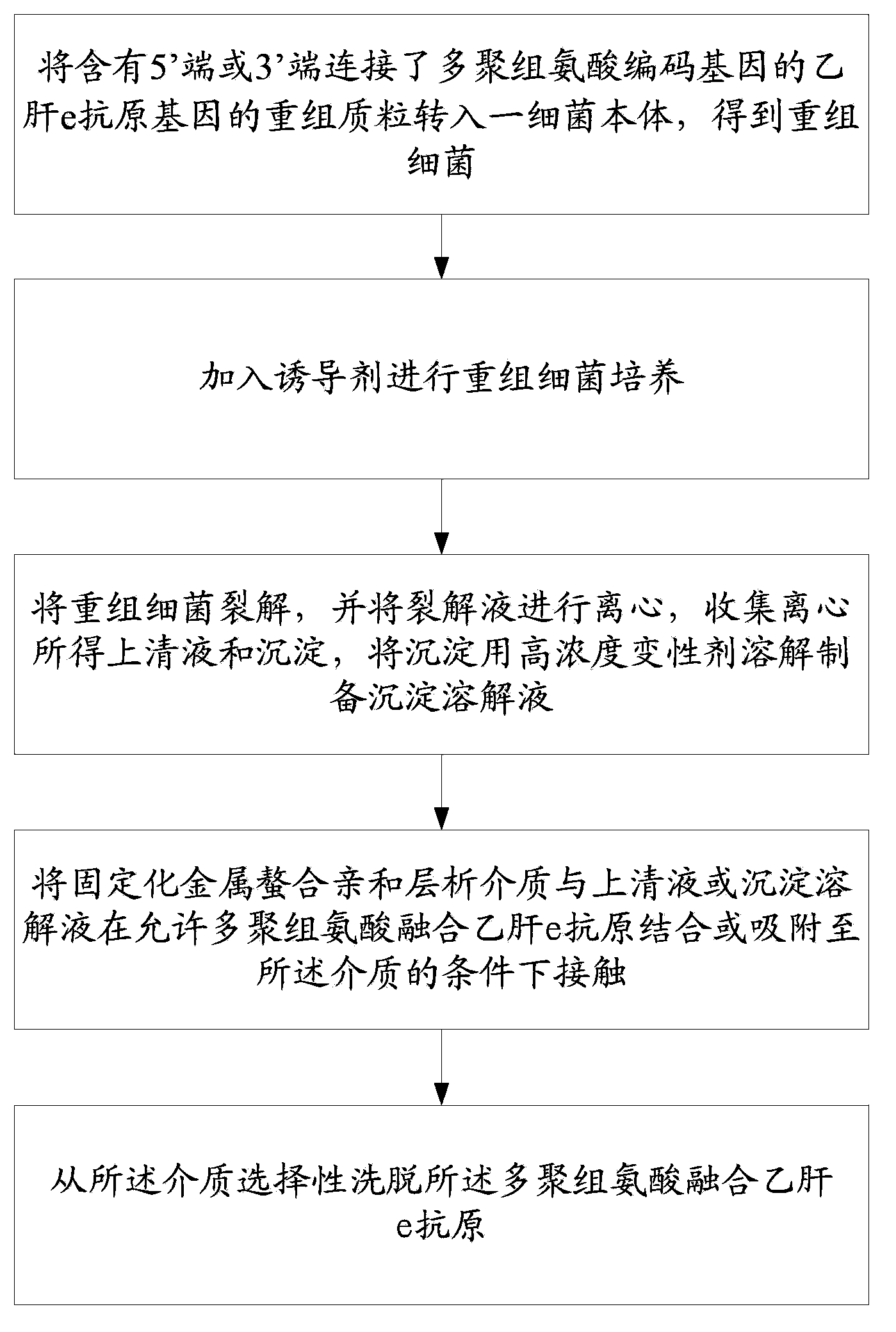

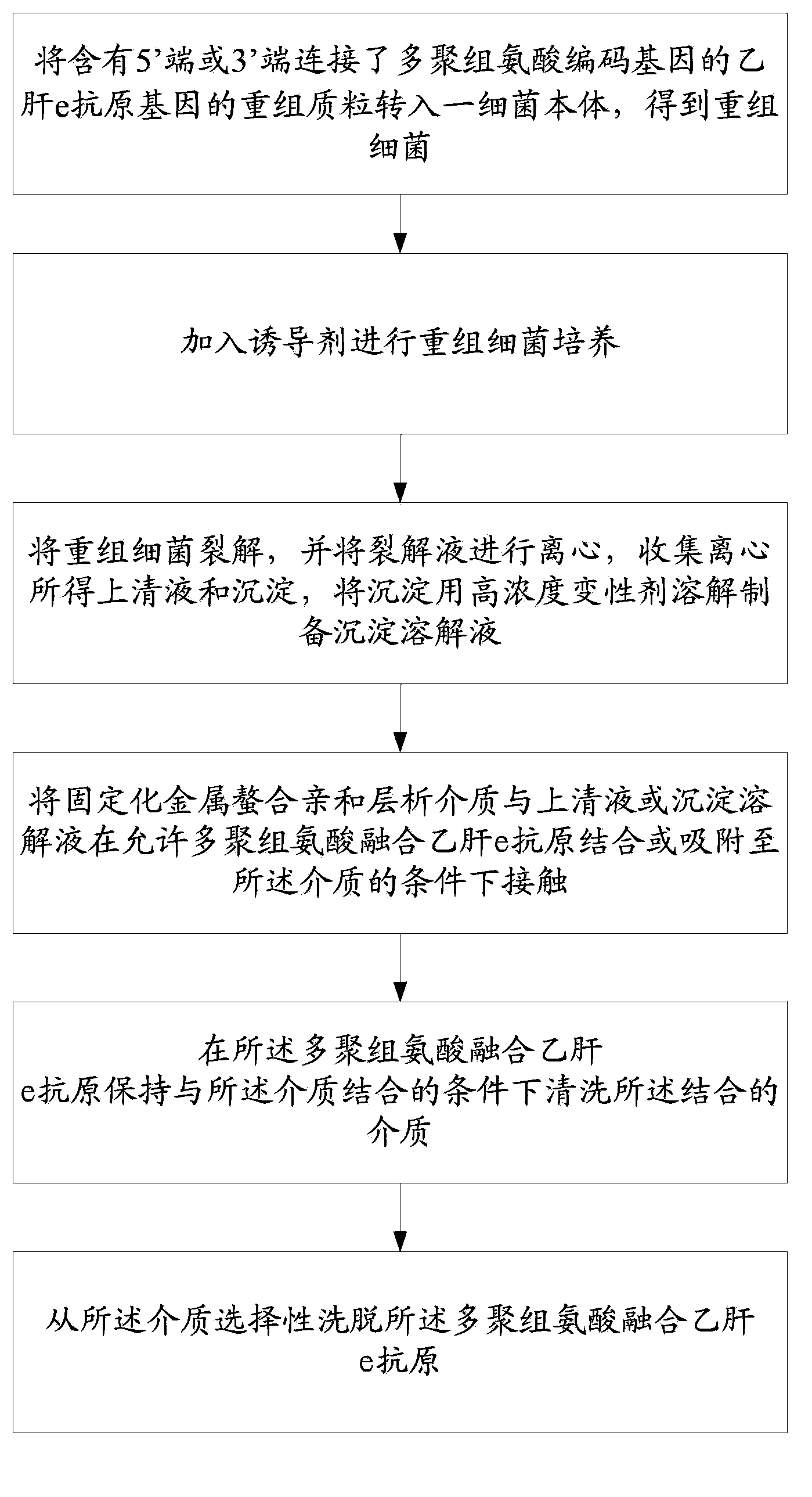

Method used

Image

Examples

Embodiment 1

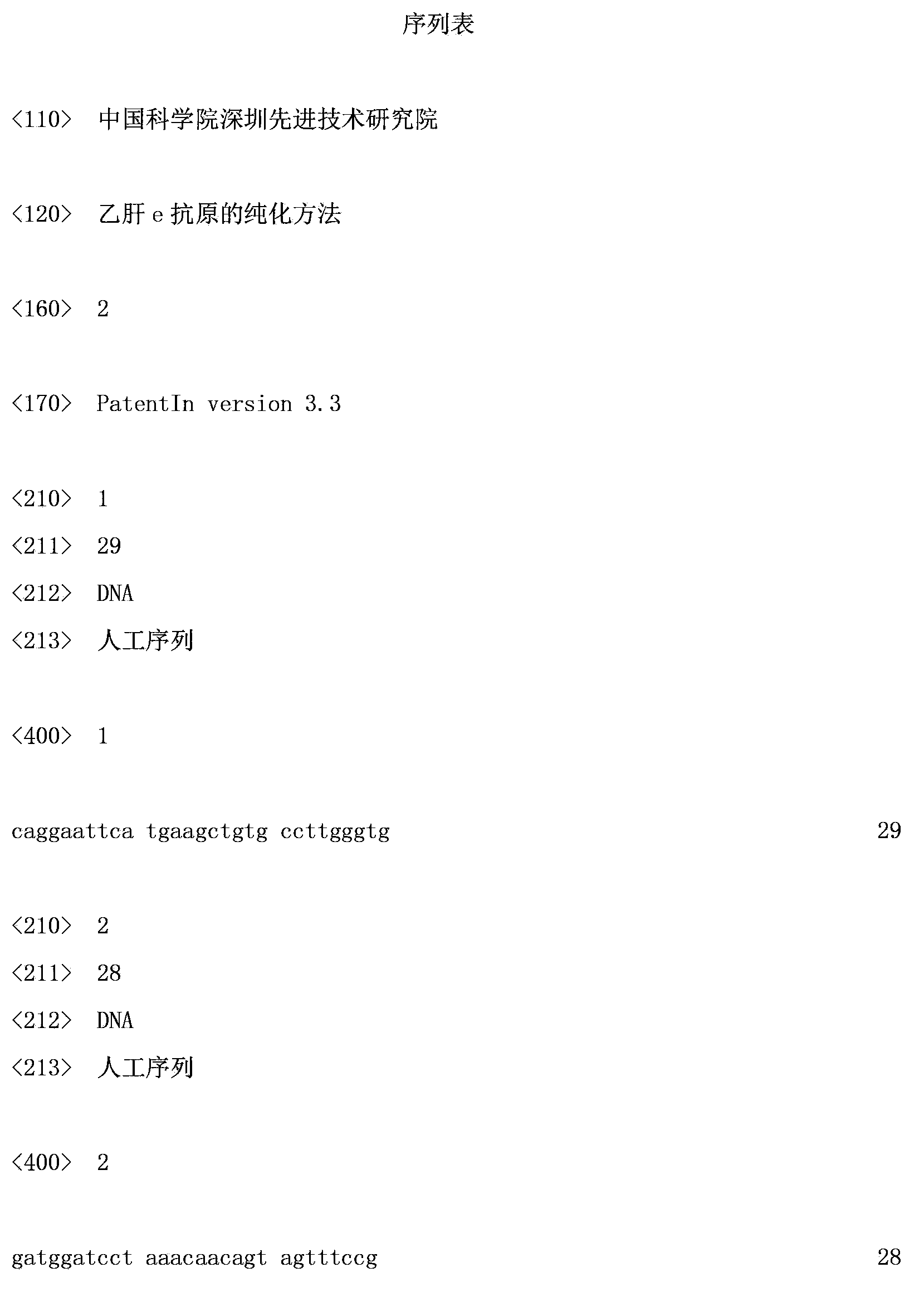

[0060] Acquisition of target sequence of hepatitis B e antigen (HBeAg) gene

[0061] Using the pADR-1 plasmid containing the HbeAg gene stored in the laboratory as a template, using SEQ ID No.1 containing the XmaI restriction site as the upstream primer, and using SEQ ID No.2 containing the Not I restriction site as the downstream primer PCR amplification was performed to obtain the HBeAg gene. After recovery and purification of the amplified product, a hexahistidine-encoded gene was introduced at the 3' end of the HBeAg gene to form a recombinant HBeAg gene, and the recombinant HBeAg gene was digested with Xma I and Not I, and then inserted into pET-28a that was also digested In -c(+), the recombinant plasmid pET-28a-c(+)-HBeAg containing the recombinant HBeAg gene was obtained. The recombinant plasmids were transformed into Escherichia coli for preservation.

[0062] Induced expression of recombinant plasmids

[0063] The recombinant bacteria were cultured by shaking,...

Embodiment 2

[0075] Acquisition of target sequence of hepatitis B e antigen (HBeAg) gene

[0076] Using the pADR-1 plasmid containing the HbeAg gene stored in the laboratory as a template, using SEQ ID No.1 containing the XmaI restriction site as the upstream primer, and using SEQ ID No.2 containing the Not I restriction site as the downstream primer PCR amplification was performed to obtain the HBeAg gene. After the amplified product is recovered and purified, a hexahistidine-encoding gene is introduced at the 5' end of the HBeAg gene to form a recombinant HBeAg gene, and the recombinant HBeAg gene is digested with Xma I and Not I, and then inserted into pET-28a that has also undergone double digestion In -c(+), the recombinant plasmid pET-28a-c(+)-HBeAg containing the recombinant HBeAg gene was obtained. The recombinant plasmids were transformed into Escherichia coli for preservation.

[0077] Induced expression of recombinant plasmids

[0078] The recombinant bacteria were cultur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com