Glass lens laminator and automatic glass lens laminating method

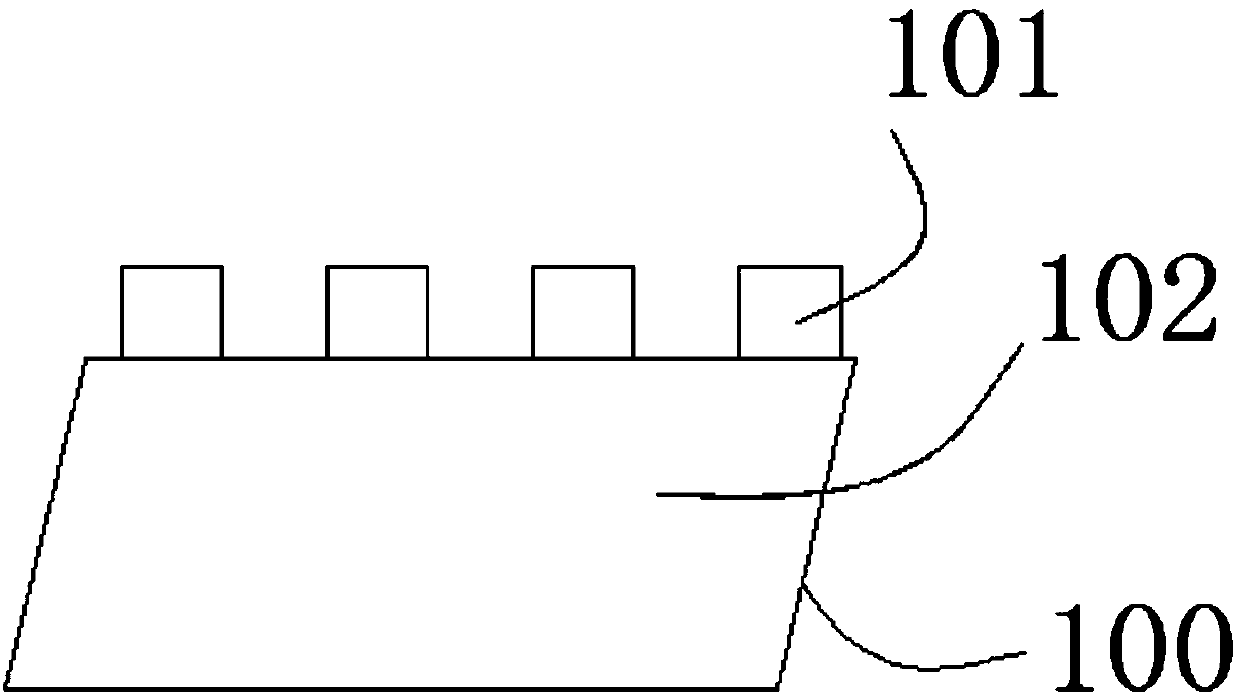

A glass lens, laminating machine technology, applied in the direction of material gluing, mechanical equipment, connecting components, etc., can solve the problem that the parallelism of products A101 and B102 cannot be guaranteed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0037] In the optical field, when the two lenses are in a state of extremely high parallelism, after the two lenses are bonded, an optical interference ring will be generated when the light is irradiated. Applying this principle, the glass lens can be bonded with a high pass rate;

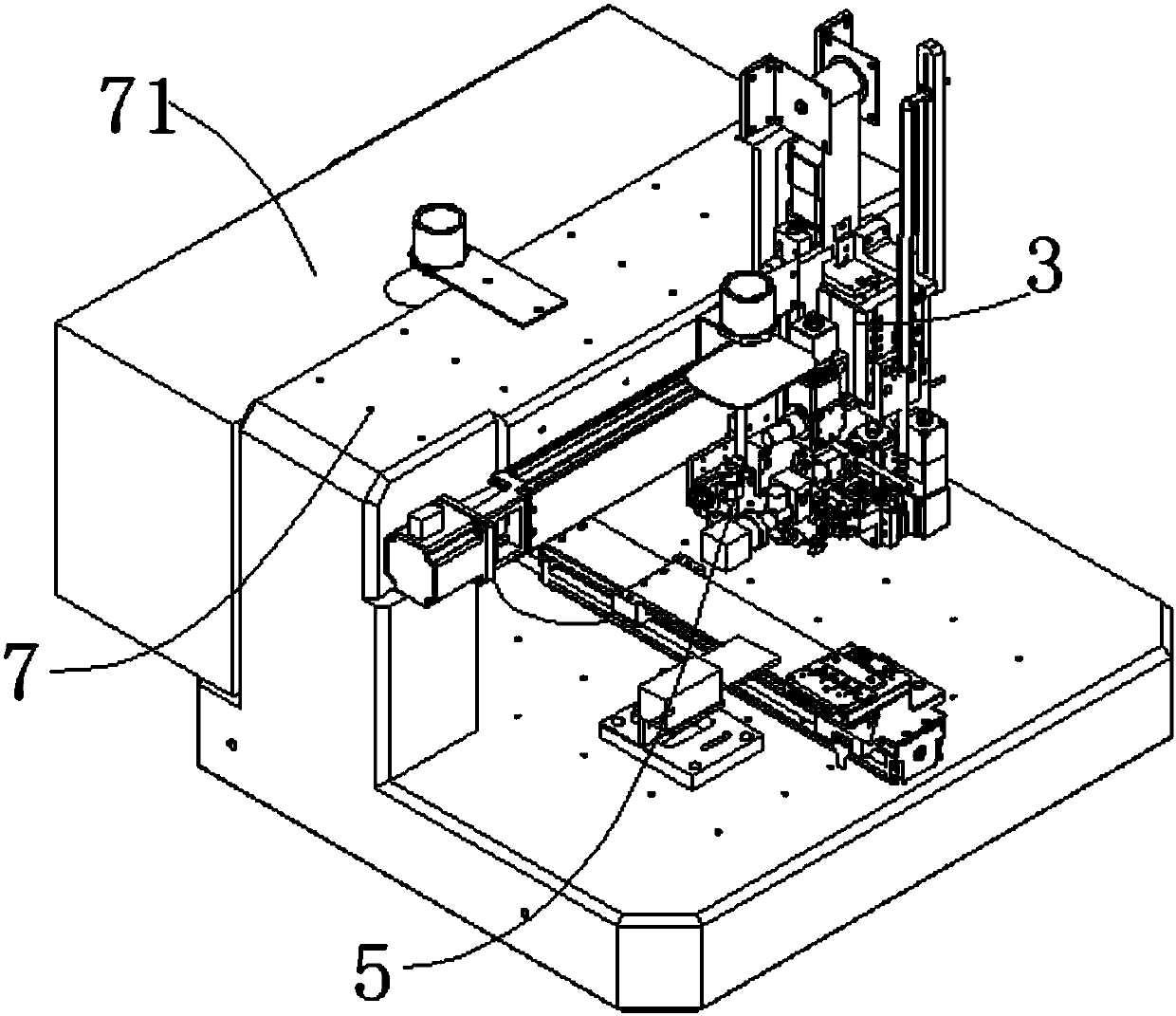

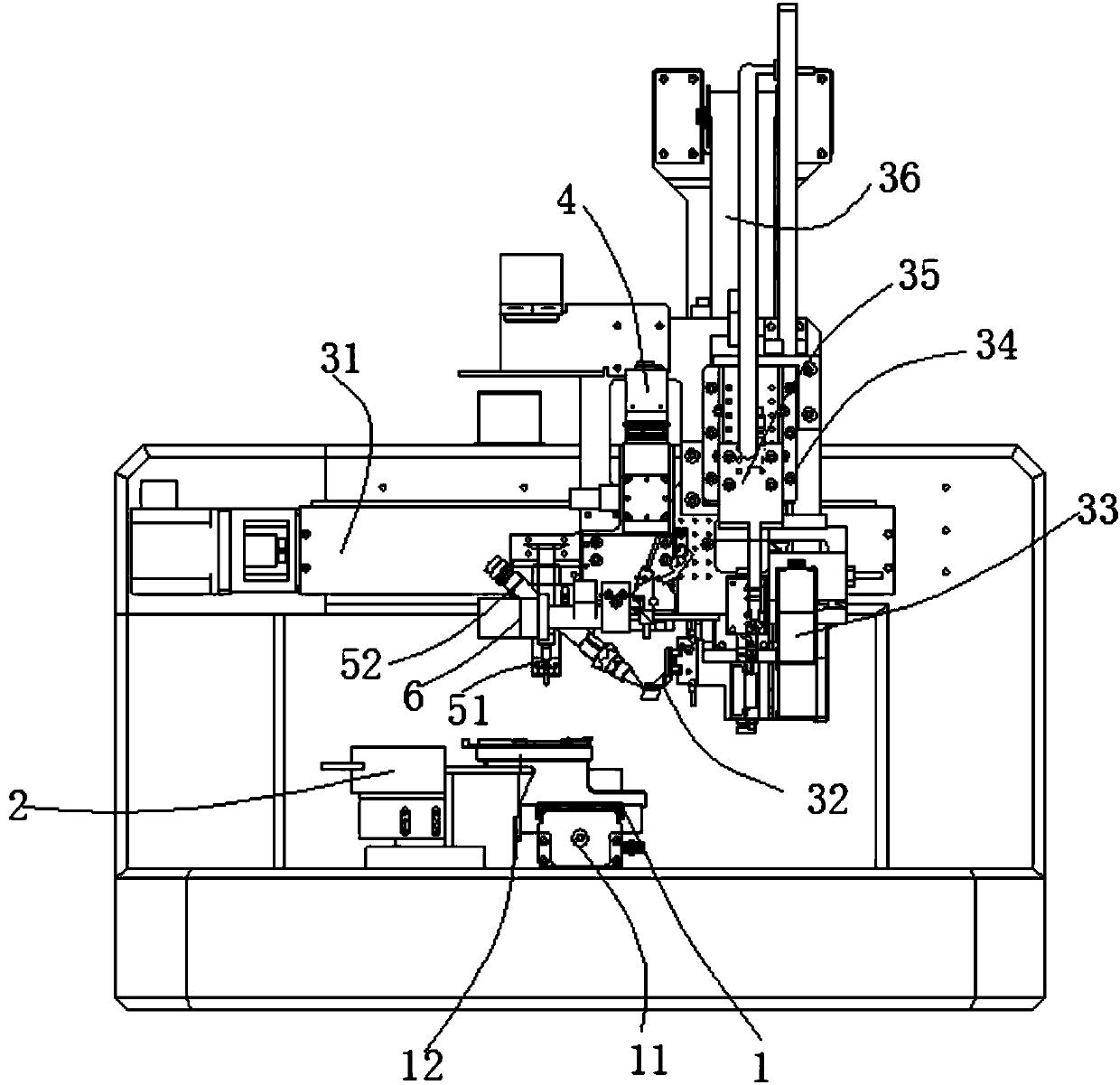

[0038] see Figure 2 to Figure 5 , this embodiment shows a method for automatic bonding of glass lenses:

[0039] It uses a glass lens automatic laminating machine for automatic lamination of glass lenses;

[0040] The glass lens bonding machine includes a carrier assembly 1 for loading product A 101 and product B 102, a light source 2 corresponding to the carrier assembly 1, a grabbing assembly 3 arranged above the carrier assembly 1, and a The collimator 4 on the grasping component 3 and used in conjunction with the carrier component 1, the UV dispensing and curing component 5 used in conjunction with the carrier component 1 that is arranged corresponding to the grasping component 3, and the car...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com