Patents

Literature

70results about How to "Play a warm-up role" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and device for controlling residual stress on stir friction welding surface

InactiveCN101774079AAvoid Welding Quality DeteriorationRealize full CNC controlNon-electric welding apparatusEngineeringControl equipment

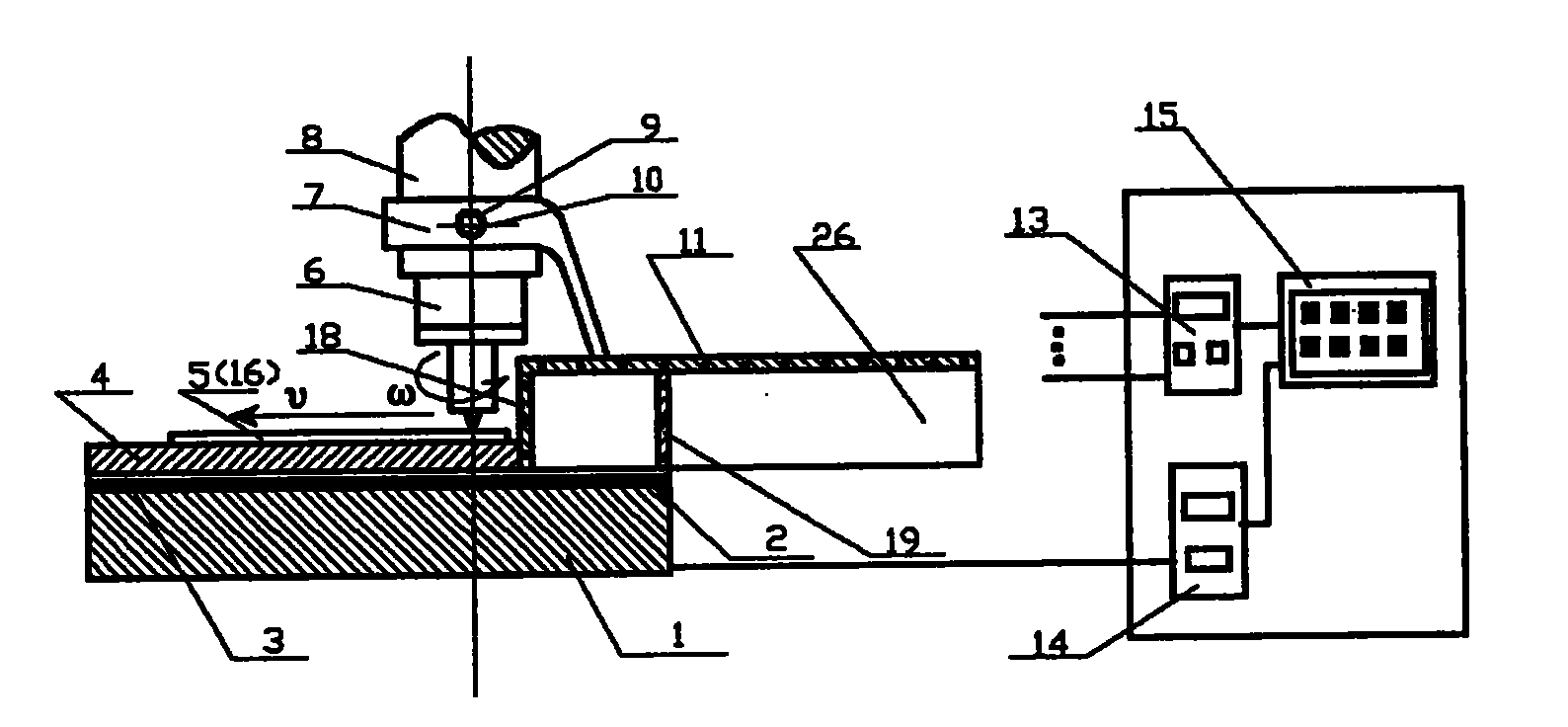

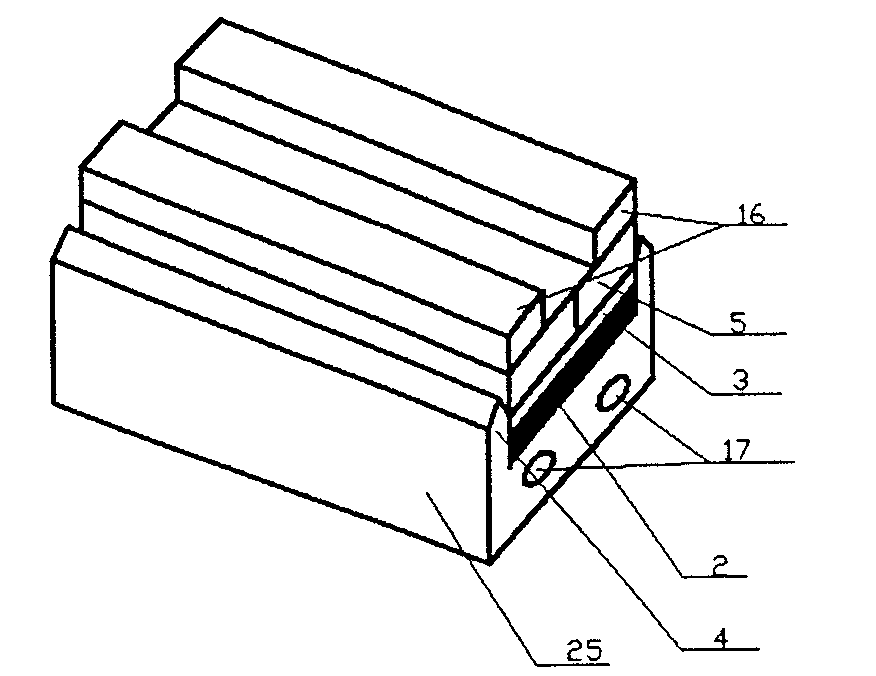

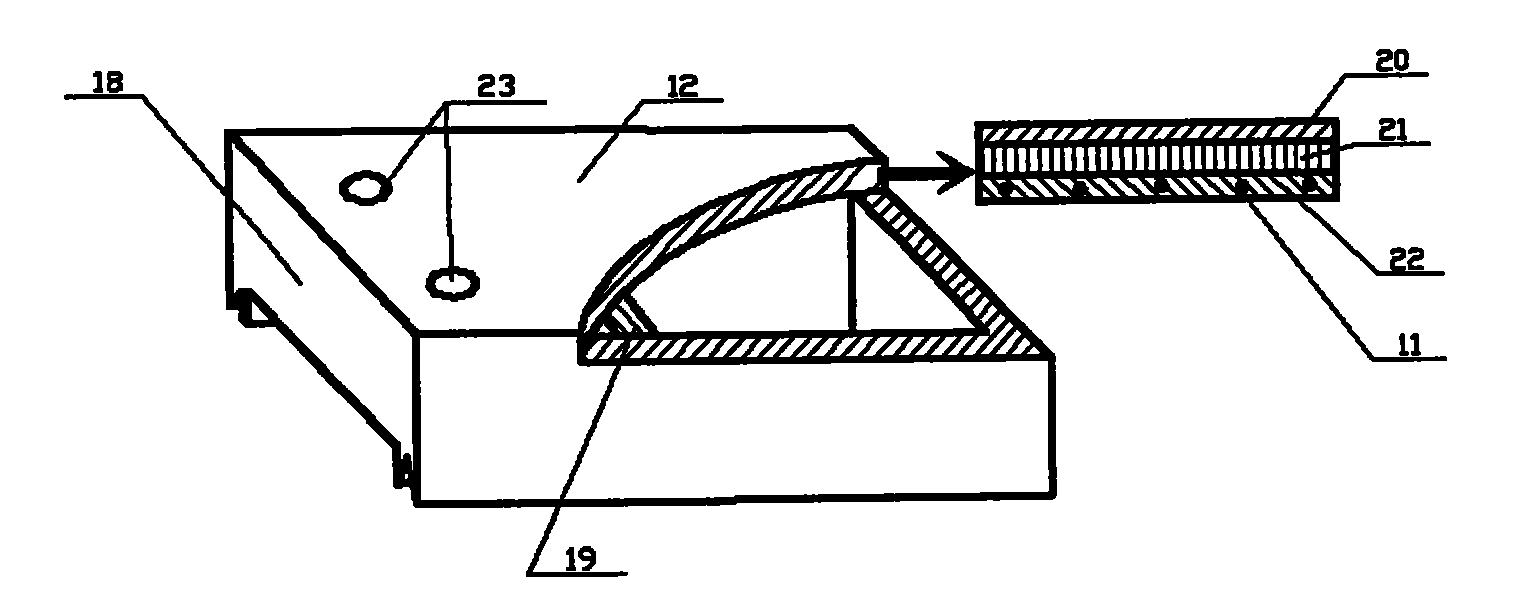

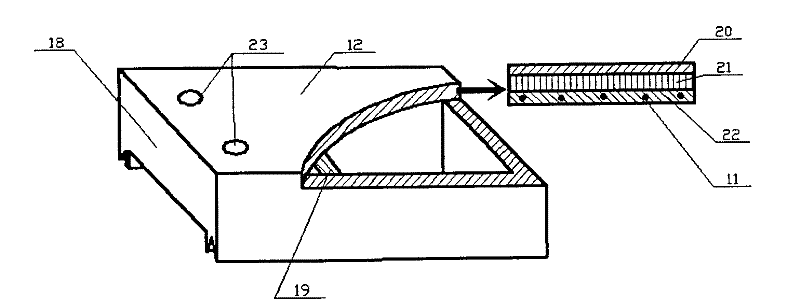

The invention relates to a method and a device for controlling a residual stress on a stir friction welding surface. According to the method, an insulation box capable of moving along a stirring head is adopted to insulate the weld joint and parent metal after welding, and then furnace cooling is performed so as to reduce the residual stress on the stir friction welding surface. The device mainly comprises a sucking-disc type fixture, the insulation box and control equipment, wherein the insulation material mainly comprises fire bricks, asbestos and steel plates. During welding, the insulation box moves along the stirring head and insulates the welded workpiece continuously; and after the welding, the whole workpiece enters the insulation box to be insulated and is cooled with the furnace after being insulated for a certain time so as to control the residual stress on the welding surface and the deformation, wherein the insulating temperature is the critical temperature of the heat treatment of the materials. The device realizes full automation in the whole welding process and avoids the reduction in the welding quality due to a human factor. The method and the device have the advantages of simple device, convenient operation, high technical economic benefit, and high welding quality of the stir friction welding.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Slimming warm-up oil

InactiveCN102895134APlay a warm-up roleCosmetic preparationsHydroxy compound active ingredientsChemistryPropanolamine

The invention discloses a slimming warm-up oil, which is prepared by mixing 10-20 parts of lecithin,10-20 parts of polyoxyethylene, 10-20 parts of octadecyl hydroxyl betaine, 0.8-1 part of low molecular weight polyacrylamide, 10-15 parts of glycerol, 0.5-1.5 parts of tallow alkyl propanolamine and 30-40 parts of cation water. The slimming warm-up oil provided by the invention can be applied to the body before exercise, and has warm-up effect as well as slimming effect.

Owner:启东市中远机械有限公司

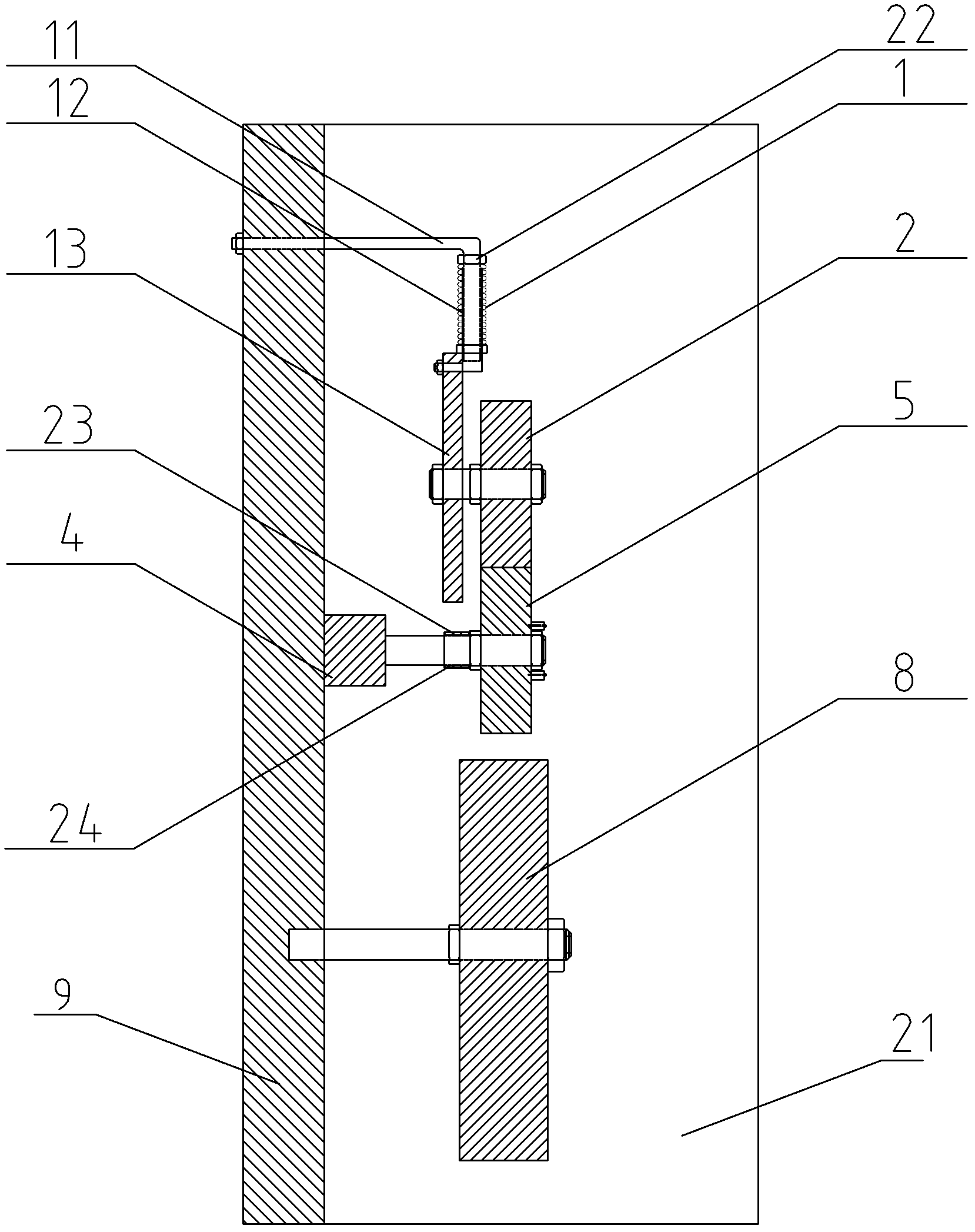

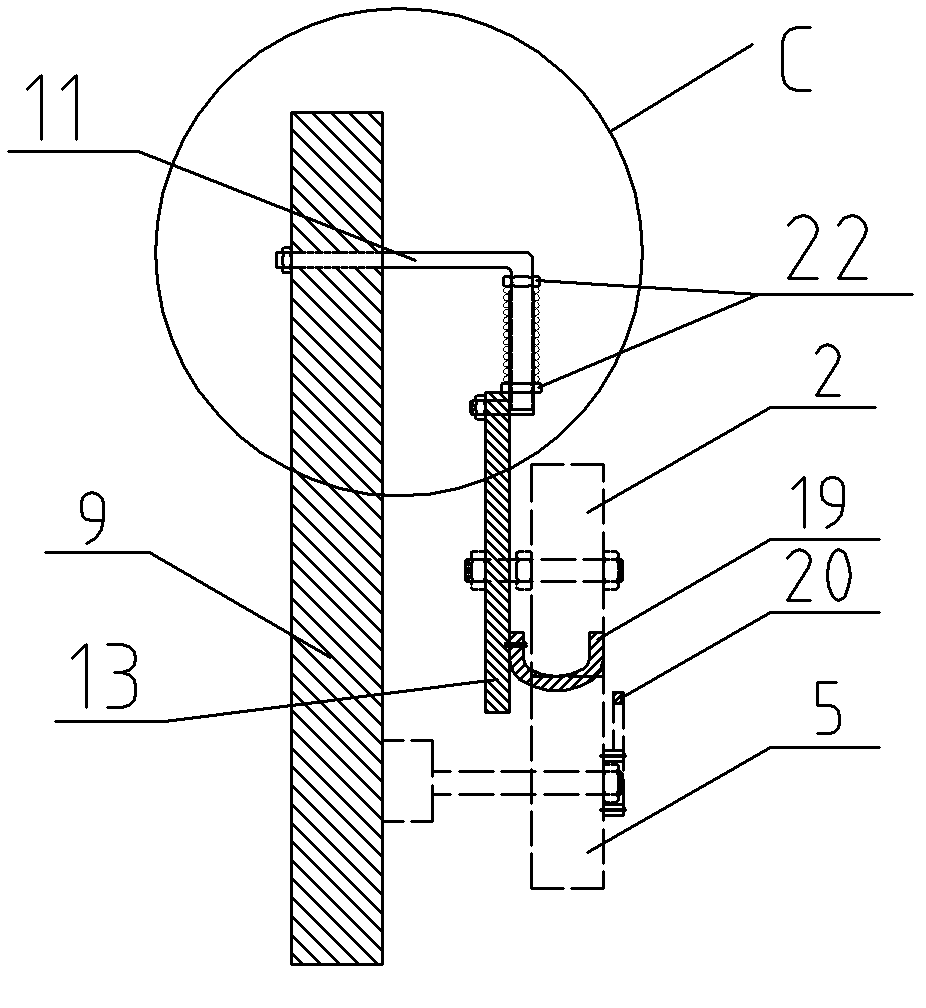

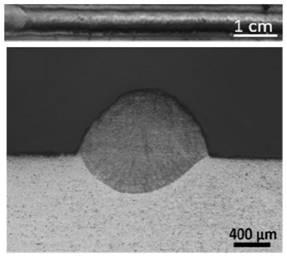

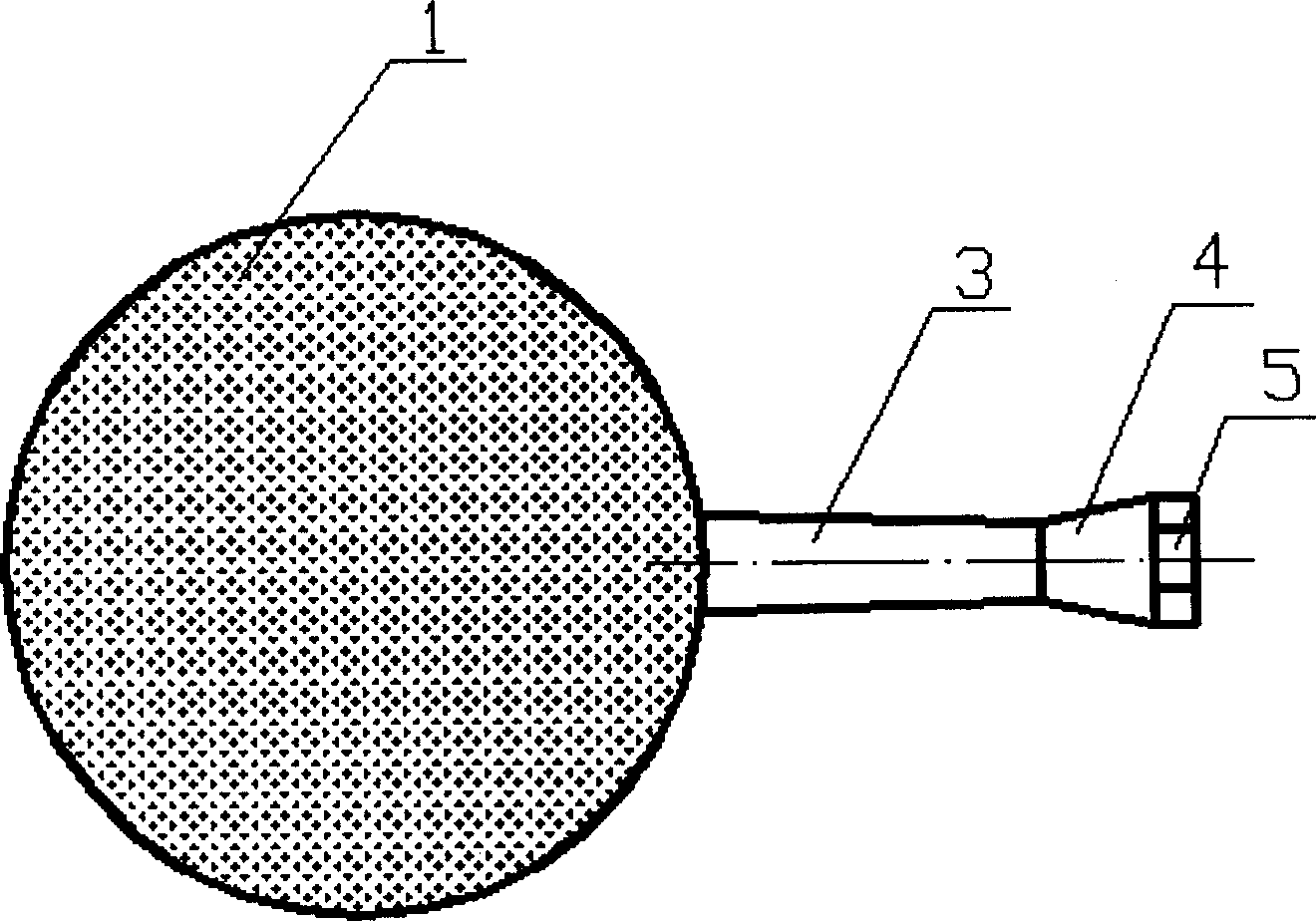

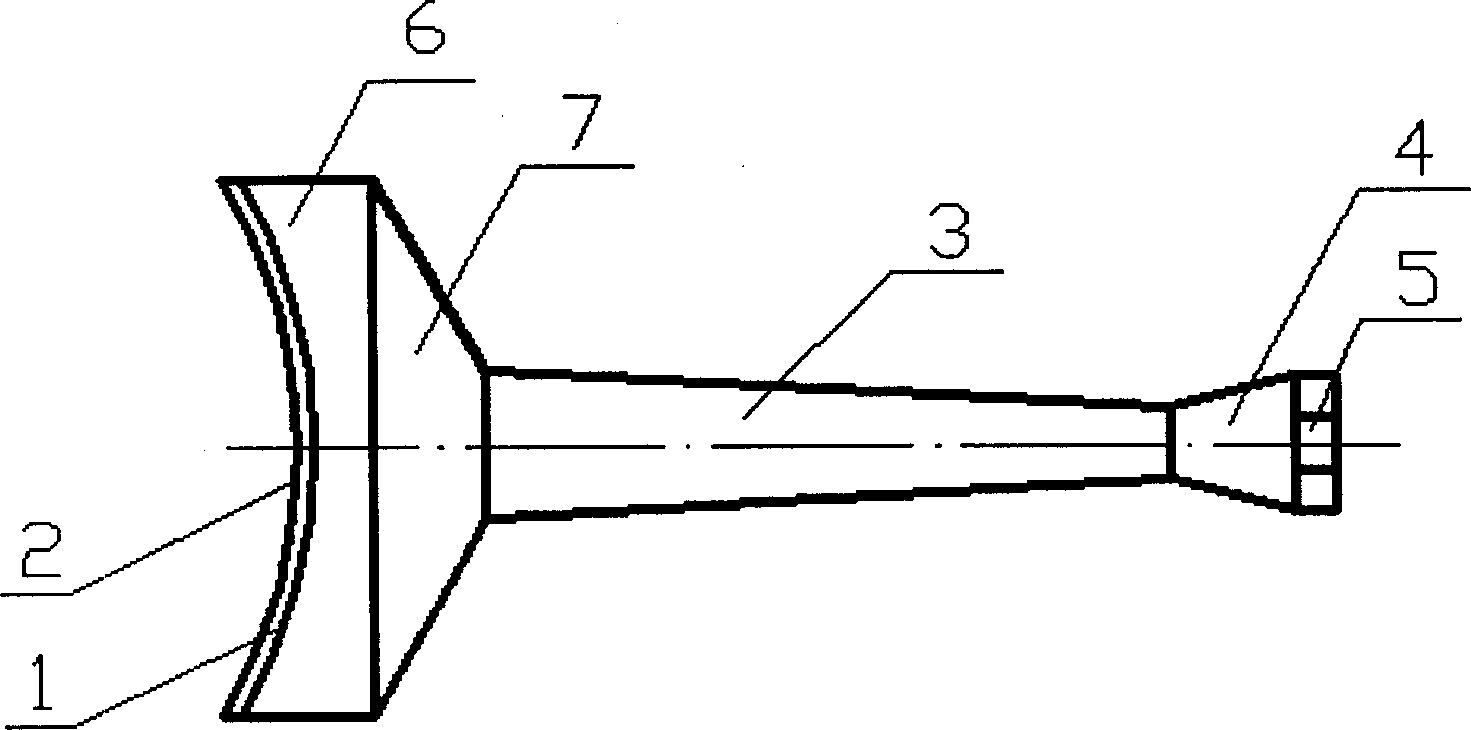

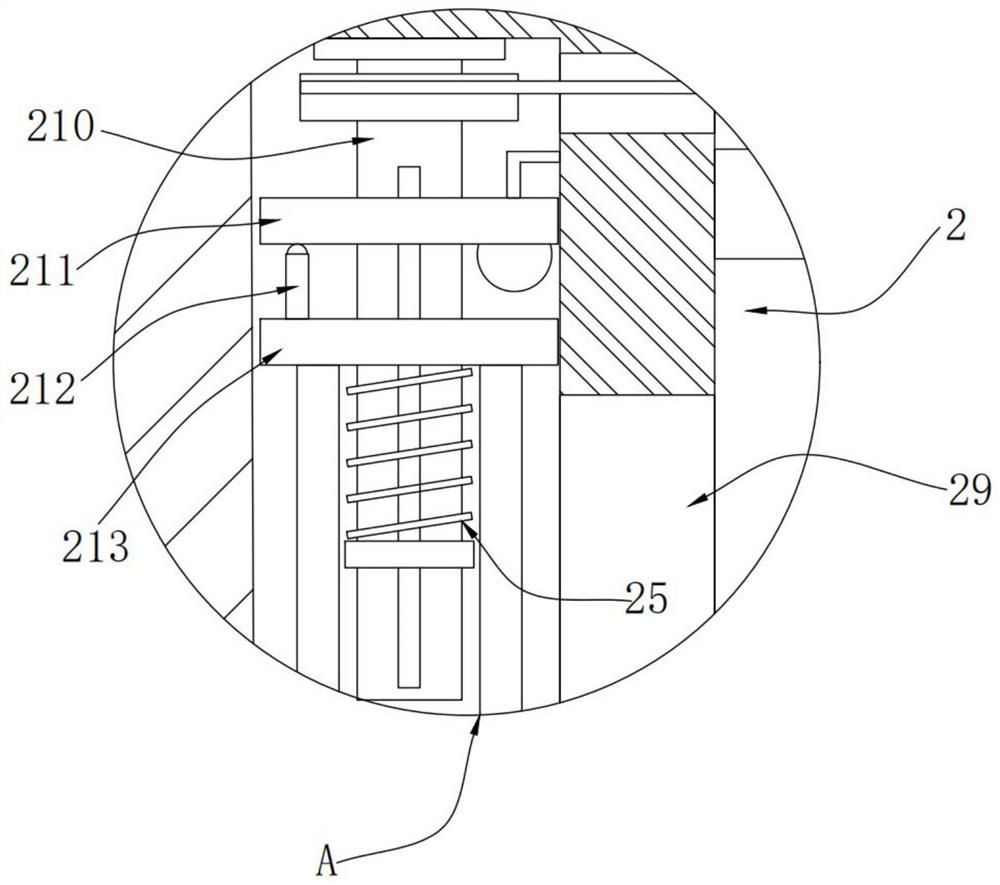

Four-roller connection-rod vacuum electron beam wire feeder

InactiveCN102357731AStable structureSimple structureElectron beam welding apparatusSelf formingWeld seam

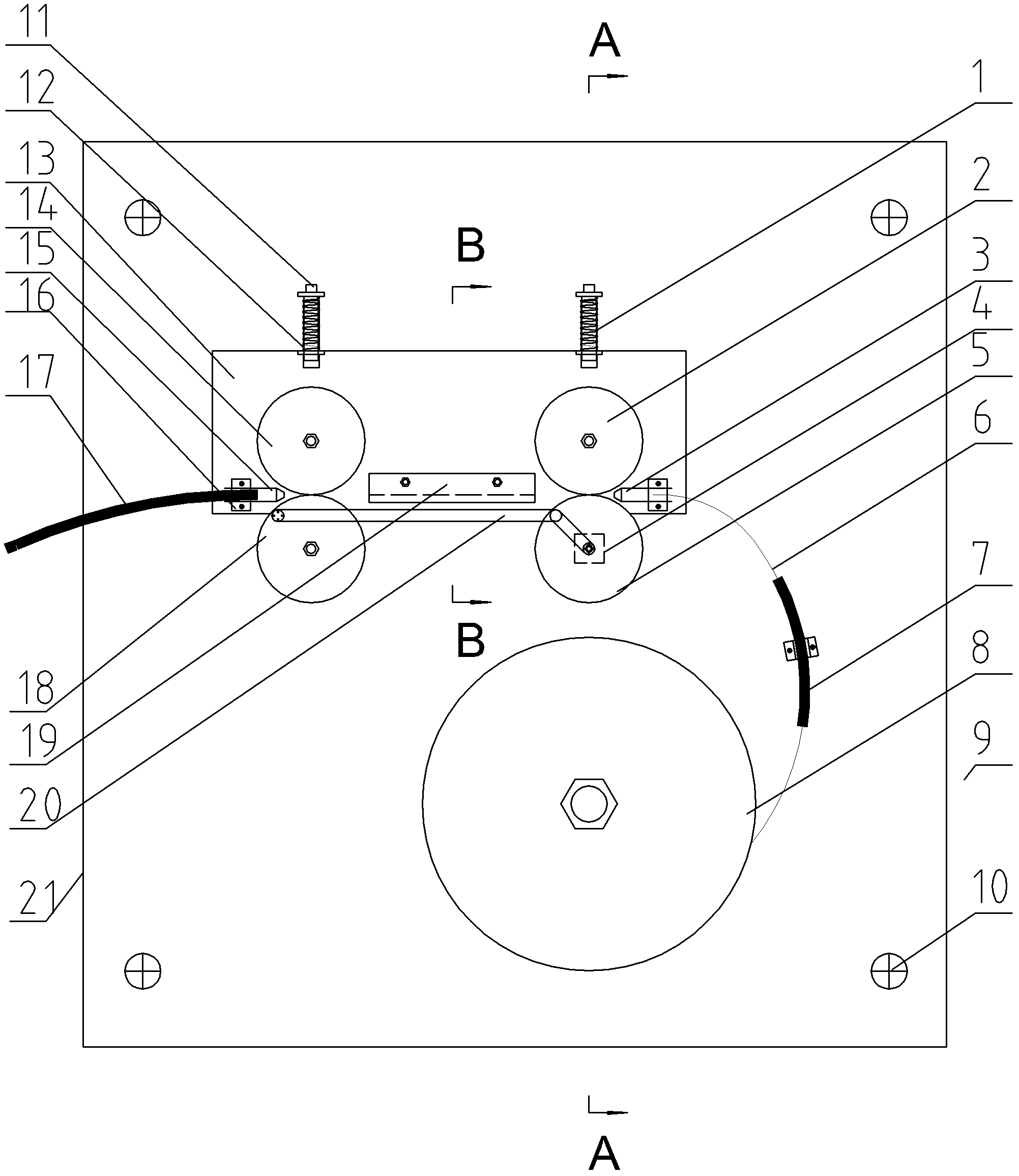

The invention provides a four-roller connection-rod vacuum electron beam wire feeder, relates to a vacuum electron beam wire feeder, and belongs to the field of the welding machinery. The invention aims to solve the problems of the existing vacuum electron beam wire feeder that wire feeding rollers and wire pressing rollers are easily worn, the distance between the wire feeding rollers and the wire pressing rollers can not be automatically adjusted according to the diameter of welding wires, etc. The main structure of the four-roller connection-rod vacuum electron beam wire feeder comprises a servo motor, two wire feeding rollers, two wire pressing rollers, a connection rod, a U-shaped groove and spring limit mechanisms, wherein, one wire feeding roller is fixed on the rotating shaft of the servo motor, the wire feeding roller rotates as the motor rotates, power is supplied for the other wire feeding roller through the connection rod; the two wire pressing rollers are fixed on a support through studs and nuts; the four rollers are coplanar; the two wire pressing rollers supply pressing forces for the wire feeding operation; and the four rollers and the connection rod jointly form the four-roller connection-rod vacuum electron beam wire feeder. The four-roller connection-rod vacuum electron beam wire feeder provided by the invention is mainly applied in the fields such as dissimilar material vacuum electron beam welding, self-forming technology, material surface cladding, efficient optimization of the performances of welding seams, defect control and the like.

Owner:HARBIN INST OF TECH

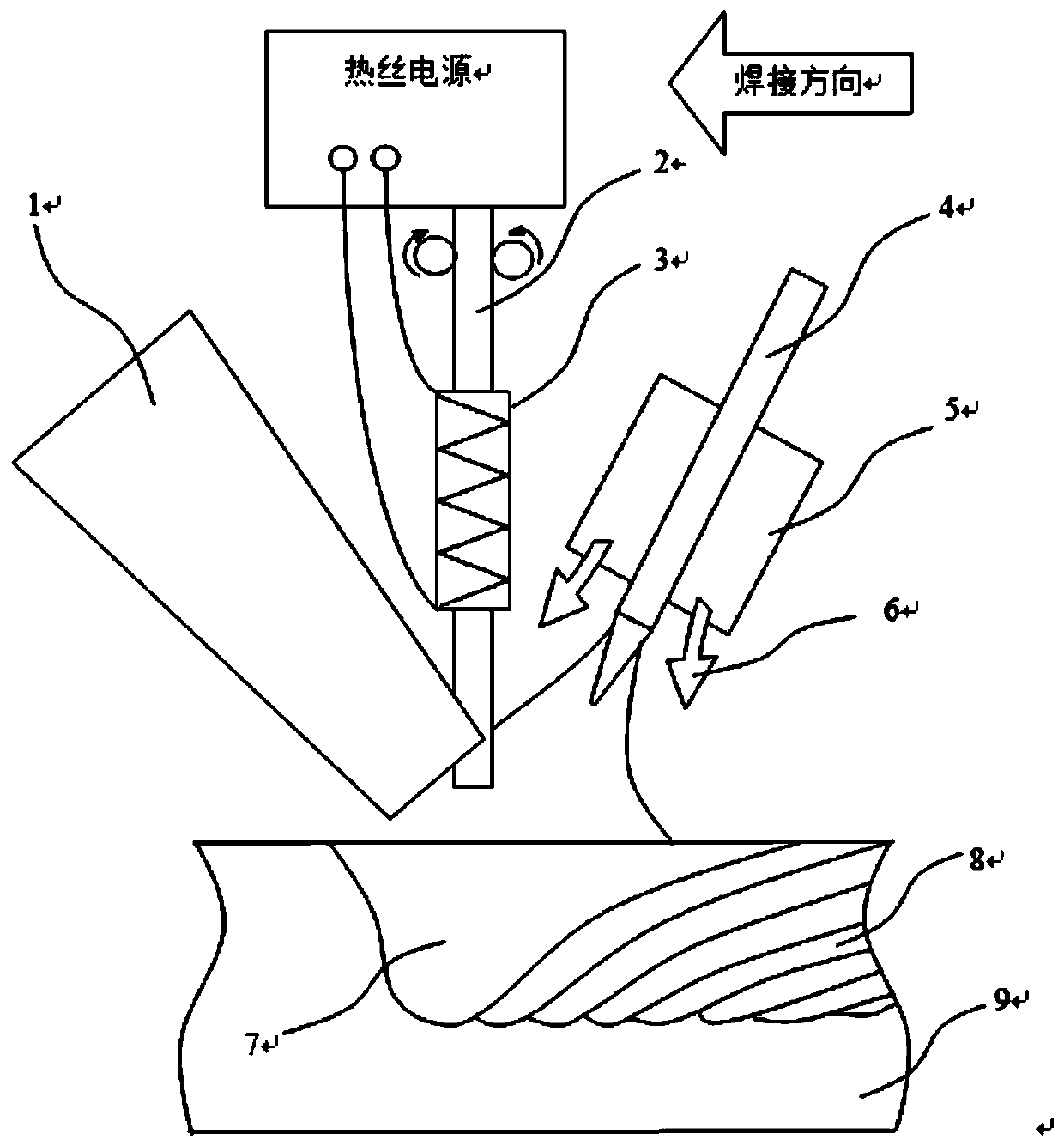

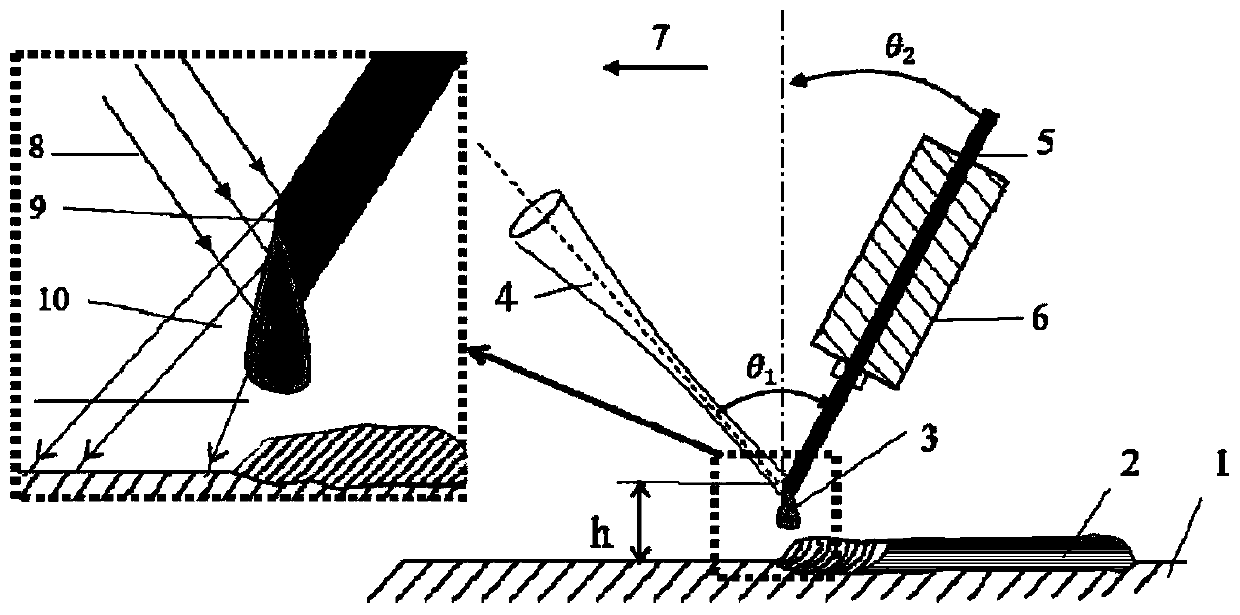

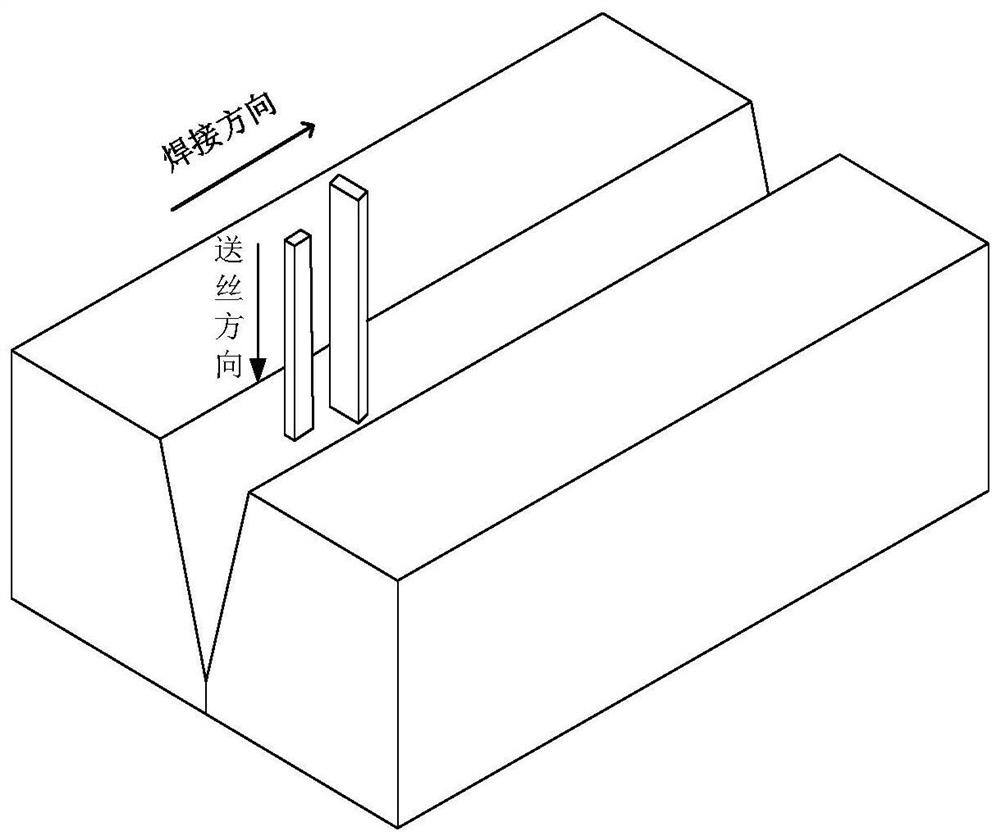

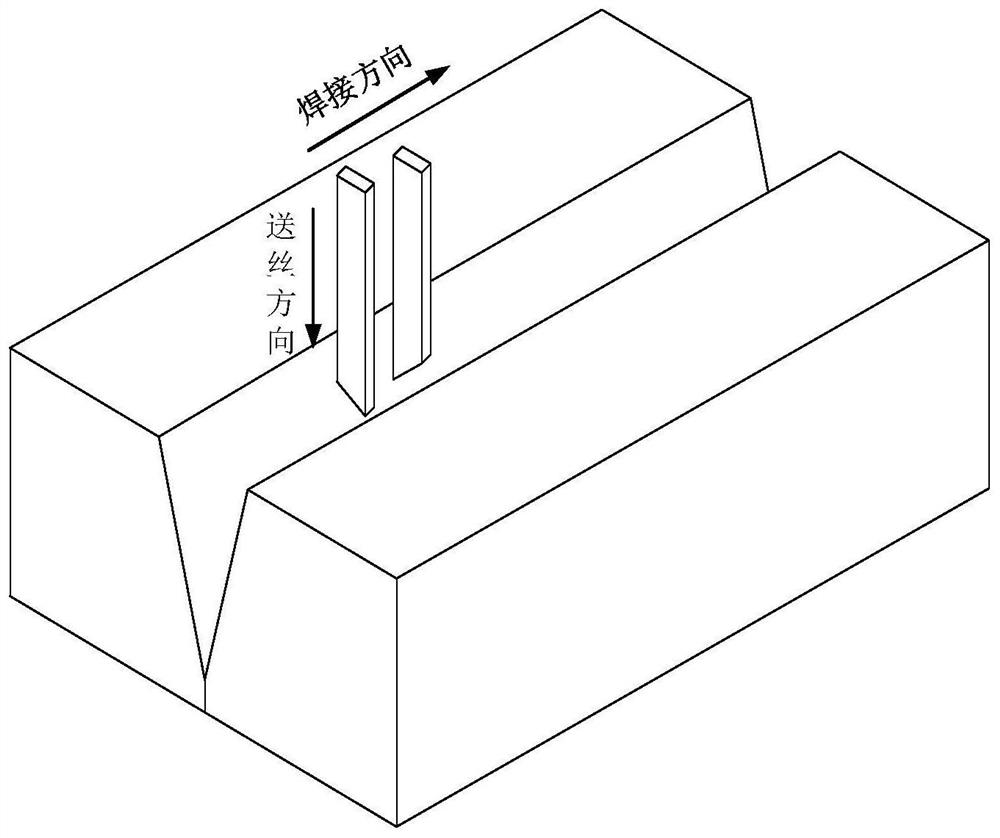

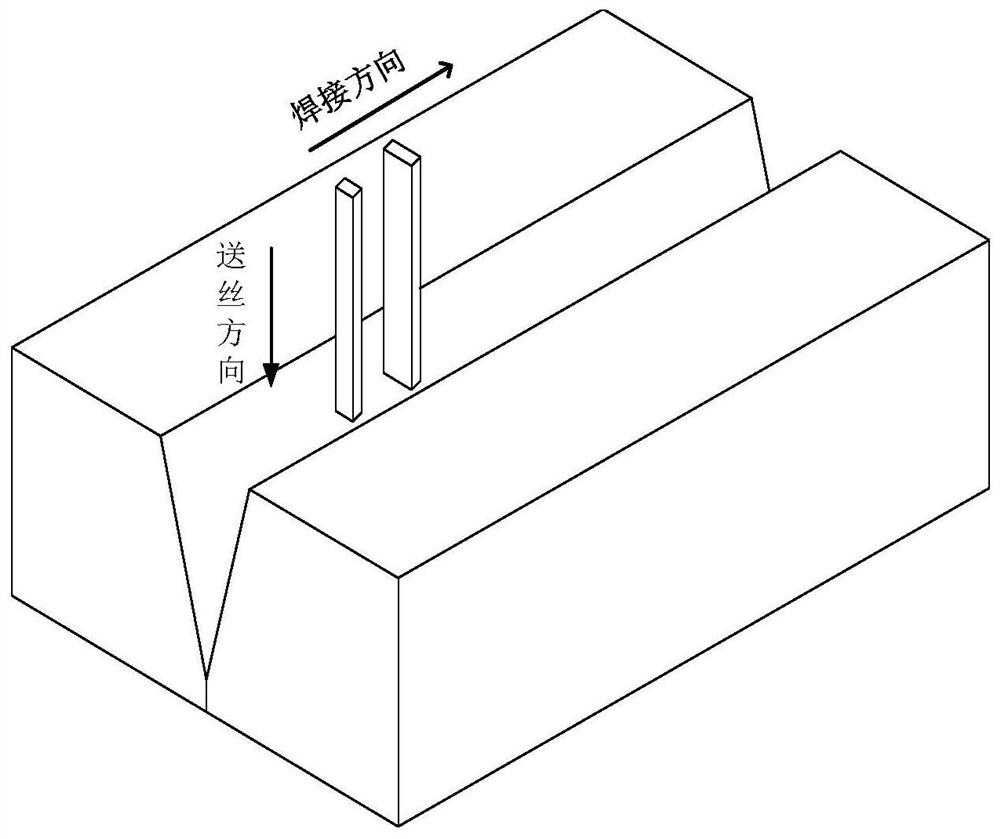

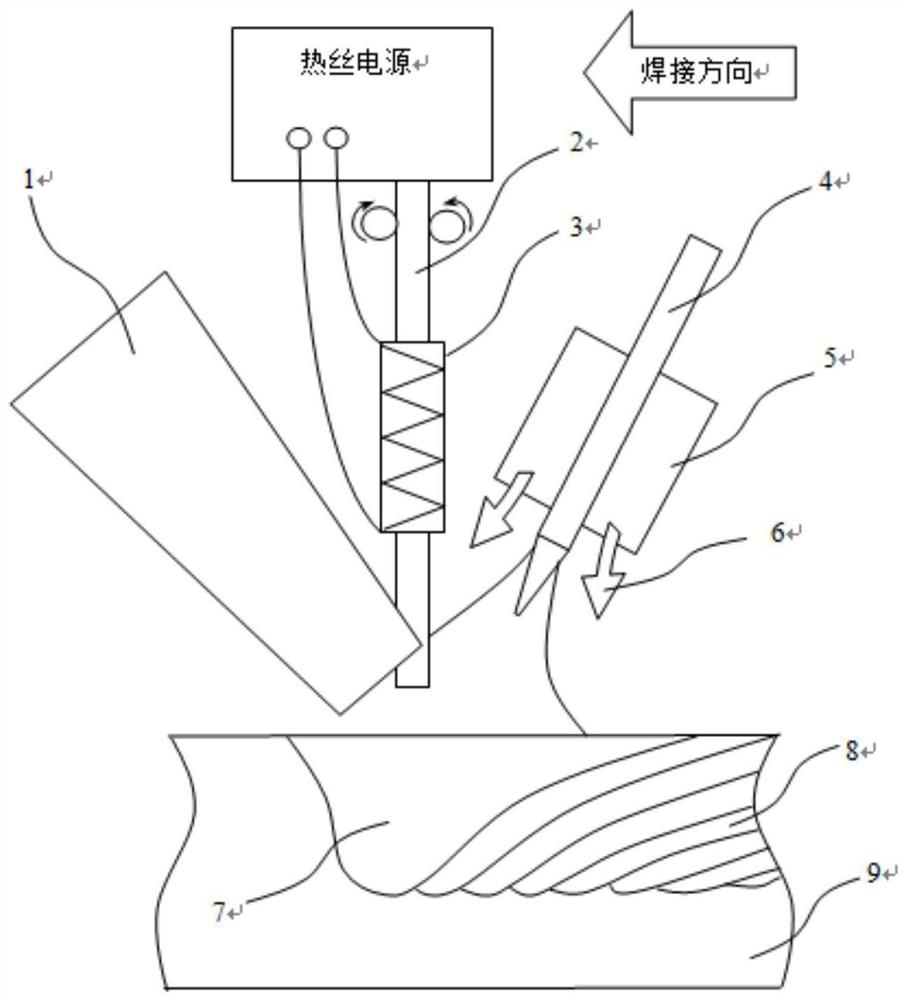

Laser-heat wire TIG composite welding method achieving normal wire feeding

ActiveCN110238528ASuppress heat lossIncrease temperatureLaser beam welding apparatusHigh power lasersGas protection

The invention relates to a laser-heat wire TIG composite welding method achieving normal wire feeding. The method comprises the steps that a welding groove is designed out on the welding portion of a welded thick plate, and backing welding of the root face through high-power laser deep melting penetration welding; layer-by-layer filling welding is carried out on the groove of the welded thick plate in a manner of compounding a laser beam, a non-molten electrode and a welding wire achieving continuous heating, in the welding process, a composite welding torch should be adjusted to the height position of a molten bath according to the single-layer filling thickness, the welding wire is induced and heated through a heat wire heating device, in the welding feeding direction, the laser beam is arranged in front of the welding wire, and the non-molten electrode is arranged behind the welding wire and is put in an inert gas shielding shroud; and the groove weld of the welded thick plate is subjected to cosmetic welding through the above composite welding manner, and compose welding is completed.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

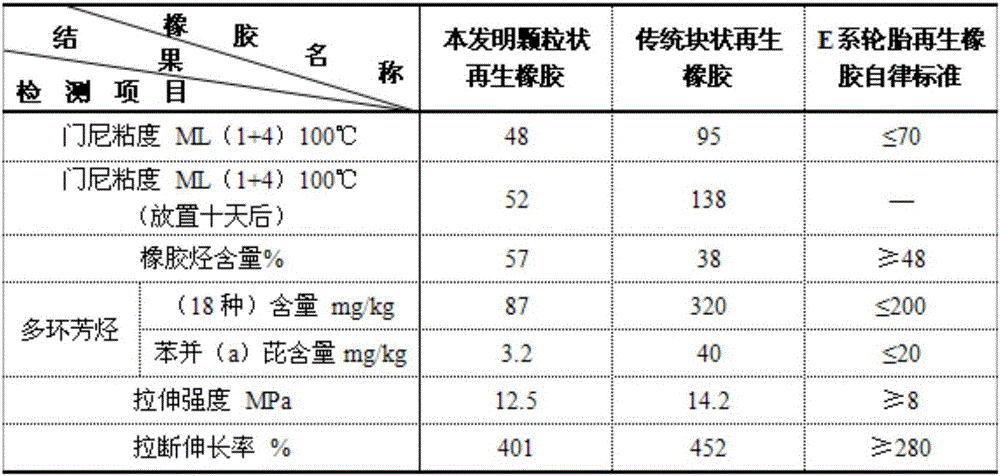

Supercritical-CO2-assisted ozone desulfurization regeneration technique of waste rubber

InactiveCN106380623ARealize selective green sulfur removal and regenerationAvoid Uncontrollable DefectsPlastic recyclingBulk chemical productionGreen environmentAfter treatment

The invention discloses a supercritical-CO2-assisted ozone desulfurization regeneration technique of waste rubber. The technique comprises the following steps: waste tires are subjected to crushing and separation by an automatic-linkage crushing line to obtain 20-50-mesh rubber powder, the rubber powder is sent into a co-rotating full-engagement double screw extruder and subjected to compounding plasticizing and preheating, and supercritical CO2 is introduced to the rear section of the double screw extruder so that the preheated plasticized rubber powder is subjected to the strong permeation and swelling actions of the supercritical CO2; in the auger delivery process, an ozone generator emits ozone which acts on the swollen plasticized rubber powder, and the crosslinked network structure of the swollen plasticized rubber powder is selectively destroyed under the ozonization action, thereby implementing the selective desulfurization regeneration; the rubber powder is subjected to complete desulfurization and extrusion forming by a screw extruder, and finally, subjected to after-treatment to obtain the green environment-friendly granular regenerated rubber; and the granular regenerated rubber is packaged and warehoused. The whole regeneration process does not need any chemical aid, and the obtained product is green and environment-friendly and has superior performance.

Owner:ANHUI GVG NEW MATERIAL CO LTD

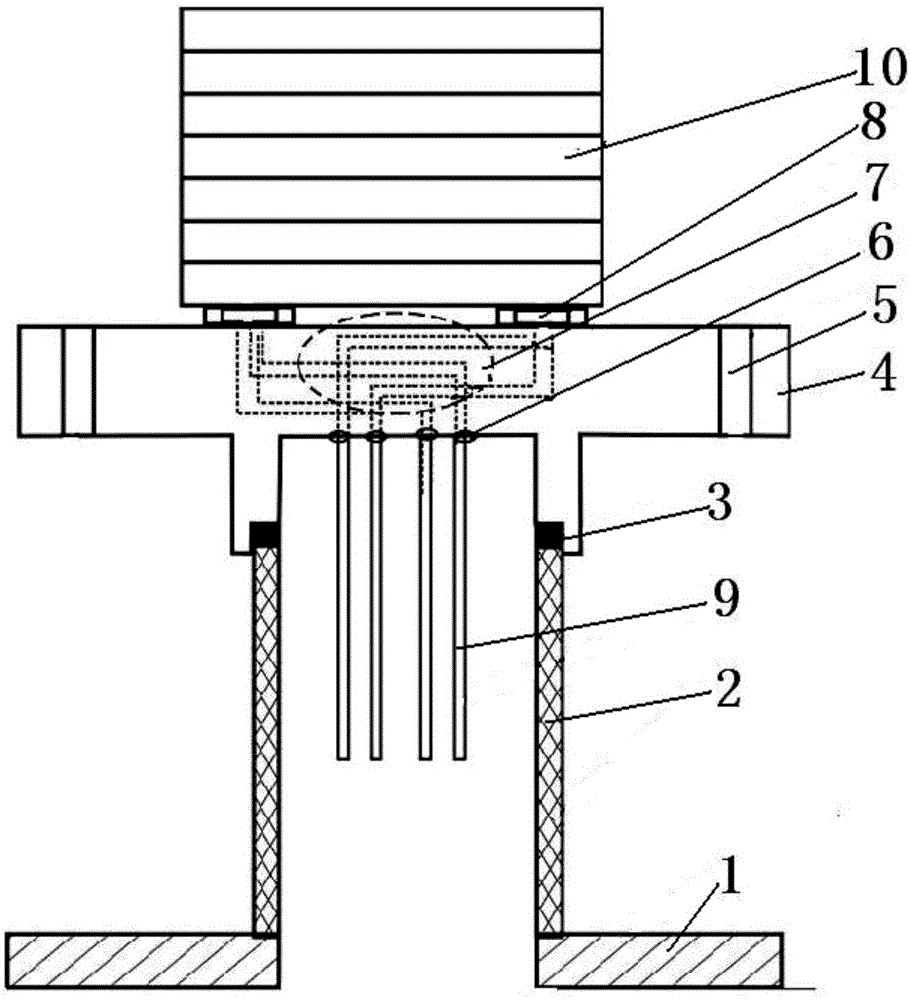

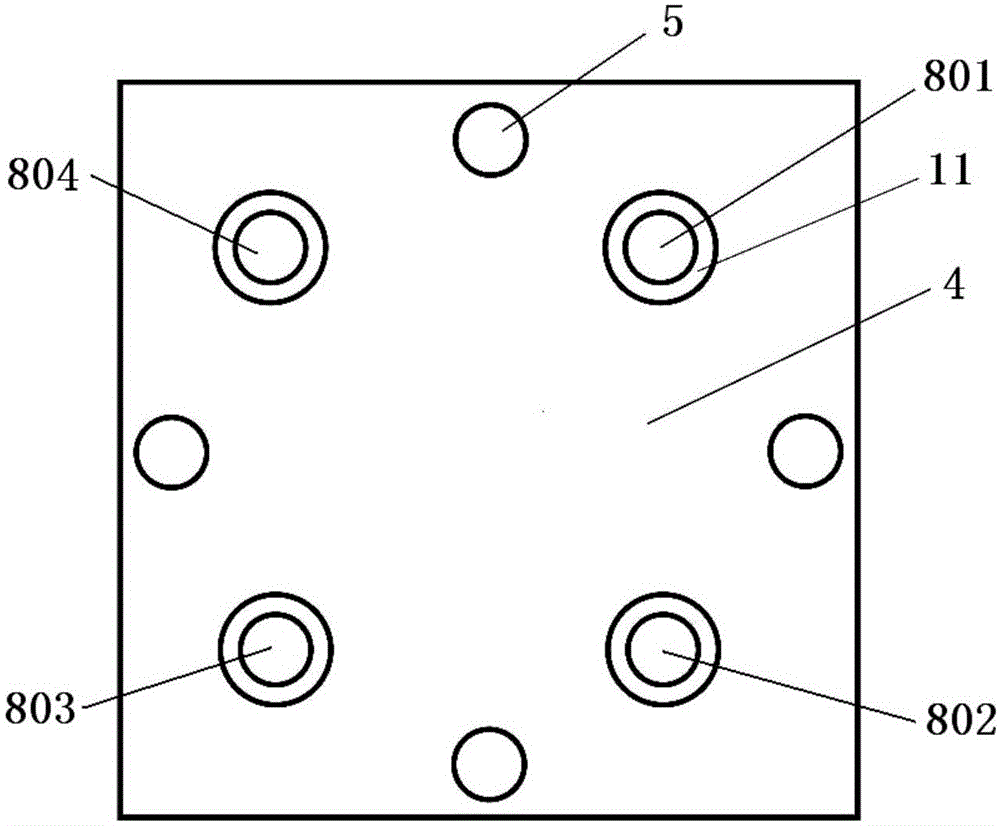

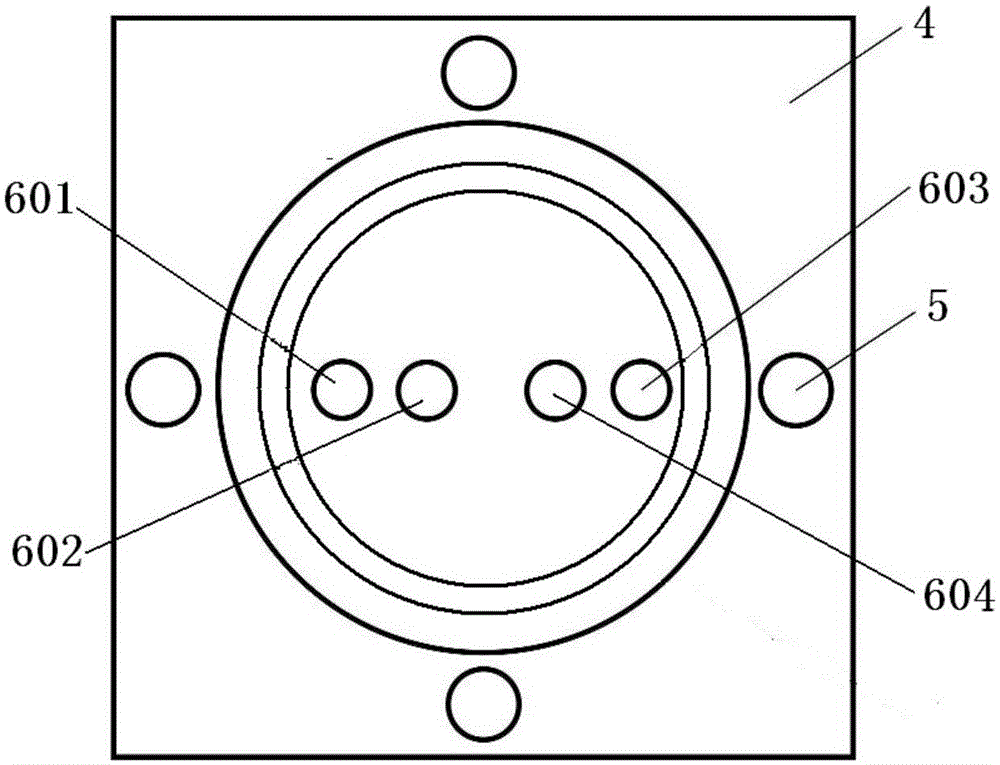

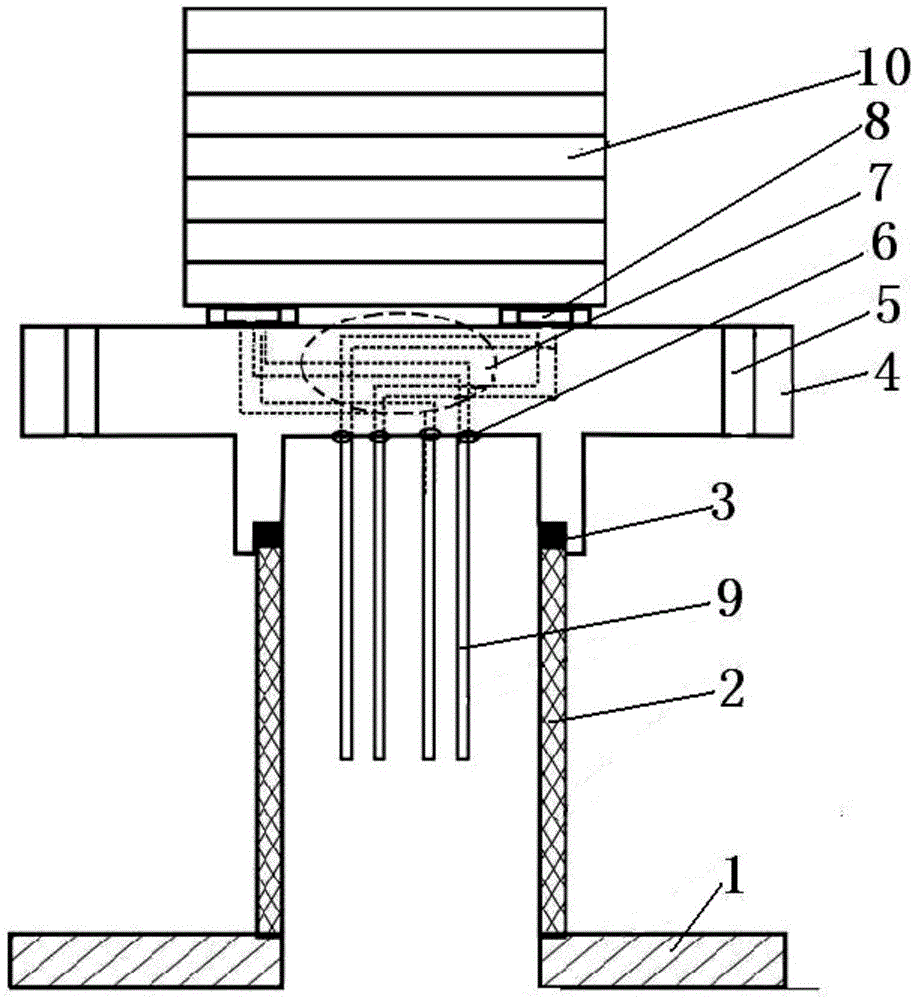

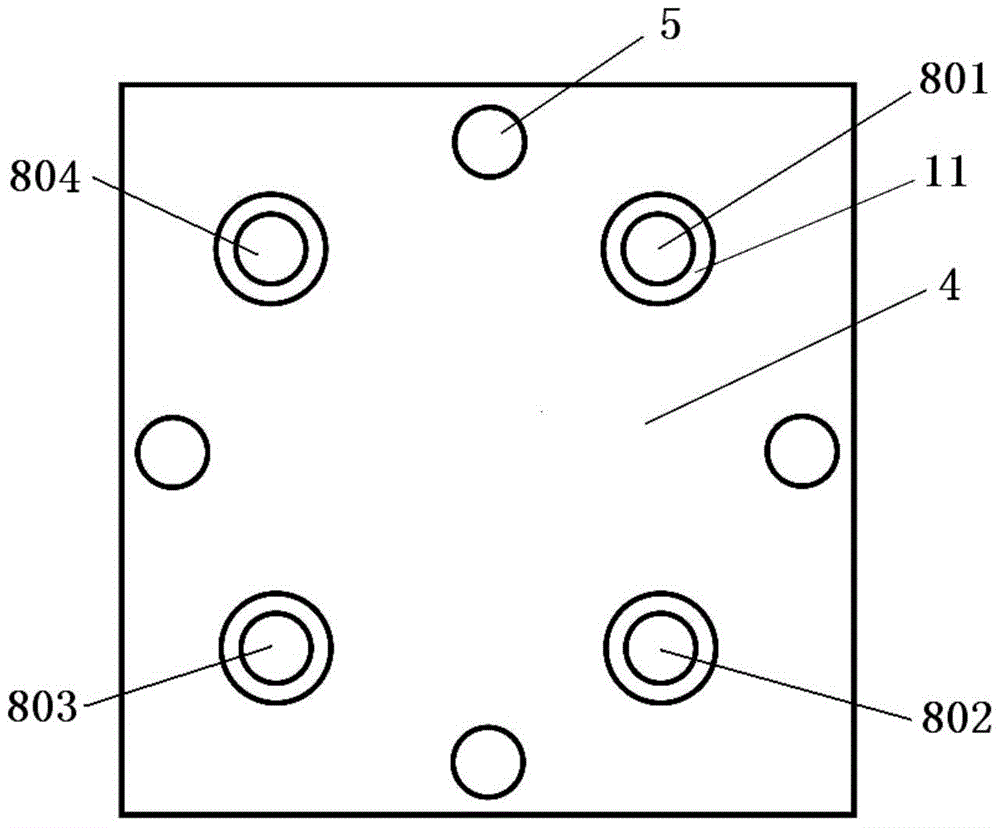

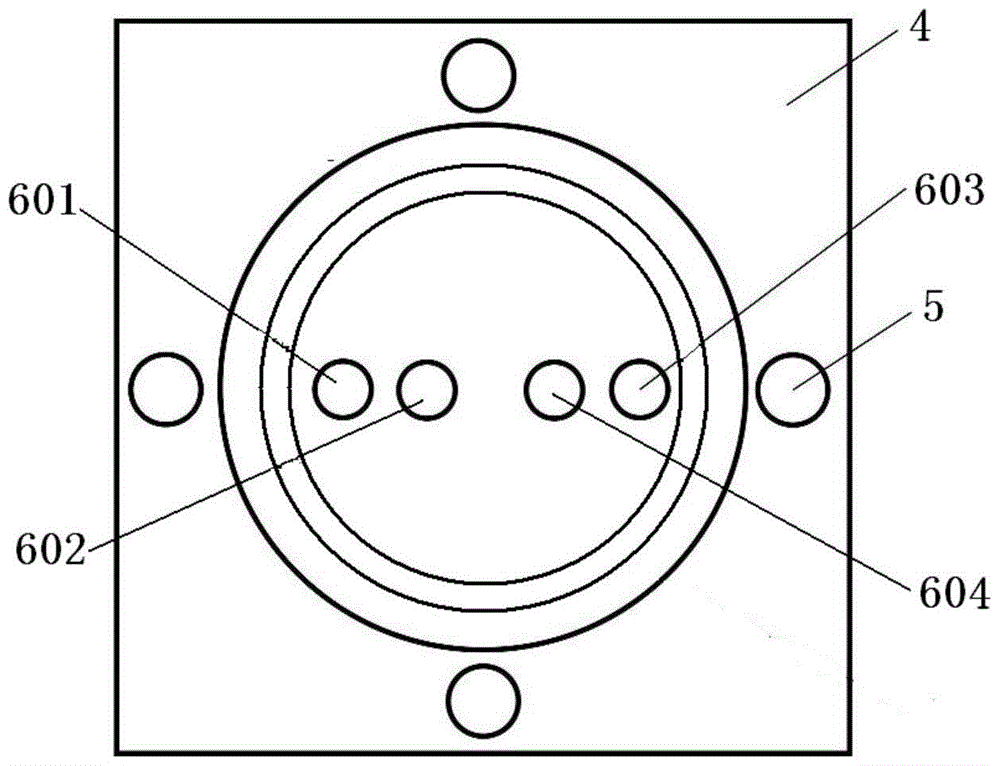

Bottom entering gas testing device for planar SOEC (solid oxide electrolyzer cell) stack

ActiveCN105161146ASolve the problem of air leakageTemperature resistantMeasurement devicesNuclear energy generationElectricityElectrolysis

The invention belongs to the technical field of high-temperature steam electrolysis for hydrogen production and relates to a bottom entering gas testing device for a planar SOEC (solid oxide electrolyzer cell) stack. The testing device comprises a support base plate, a ceramic support pipe, a buffer gasket, a testing base and four stainless steel gas path pipes, wherein 4 gas flow distribution hole channels are formed in a cuboid of the testing base and communicate four base bottom gas holes with four base top gas holes pairwise. The testing device is used as a testing platform for a high-temperature SOEC stack and has the characteristics of stable testing, practicality, convenience, easiness in assembly, simplicity in operation and the like; the testing device adopts a design mode for combining the ceramic material and the high-temperature-resistant stainless steel material and has the performance of temperature resistance, heat insulation and electric insulation; the gas flow distribution hole channels formed in the testing base adopt inside roundabout design, heat in a high-temperature furnace is used directly for preheating entering gas, and the problems of gas pipe cracking and gas leakage of pipe joints at a high temperature are solved. The testing device is applicable to stable operation and performance testing of the SOEC stack.

Owner:TSINGHUA UNIV

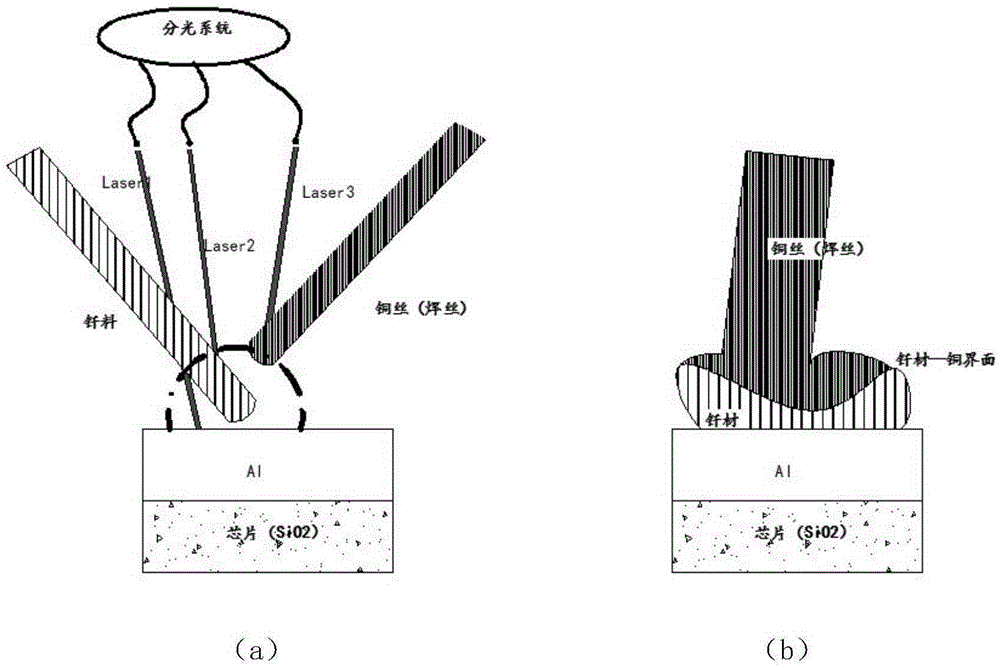

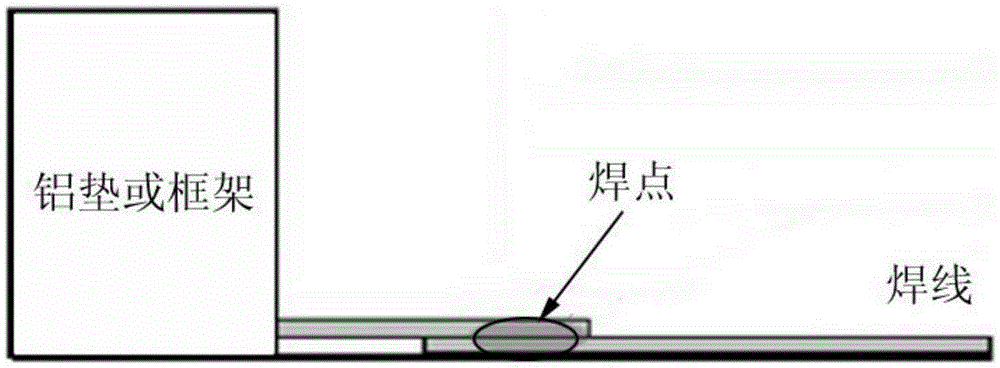

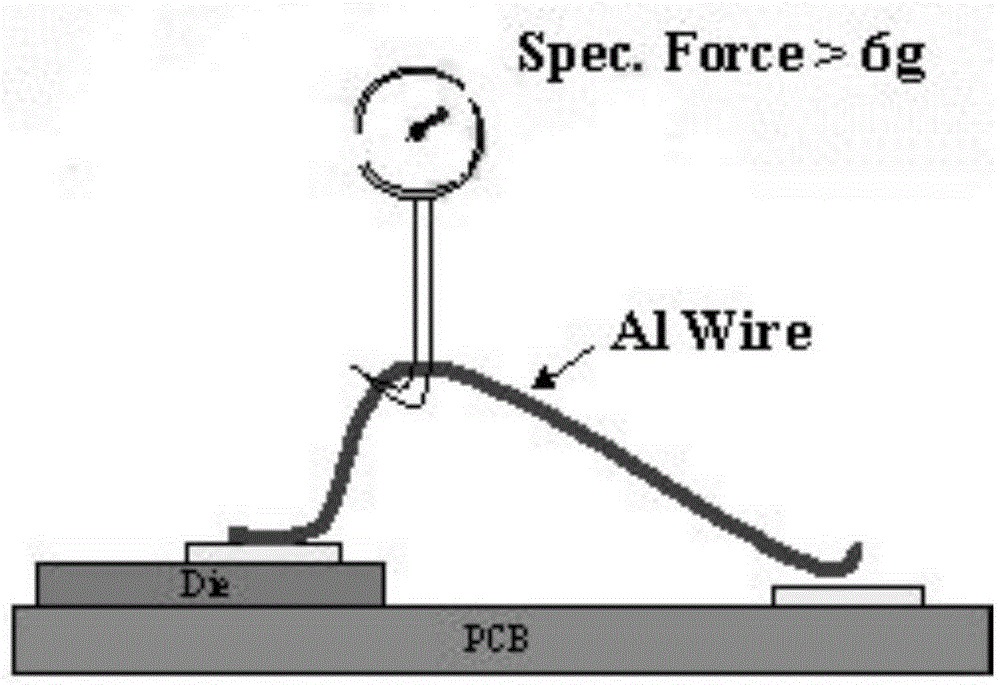

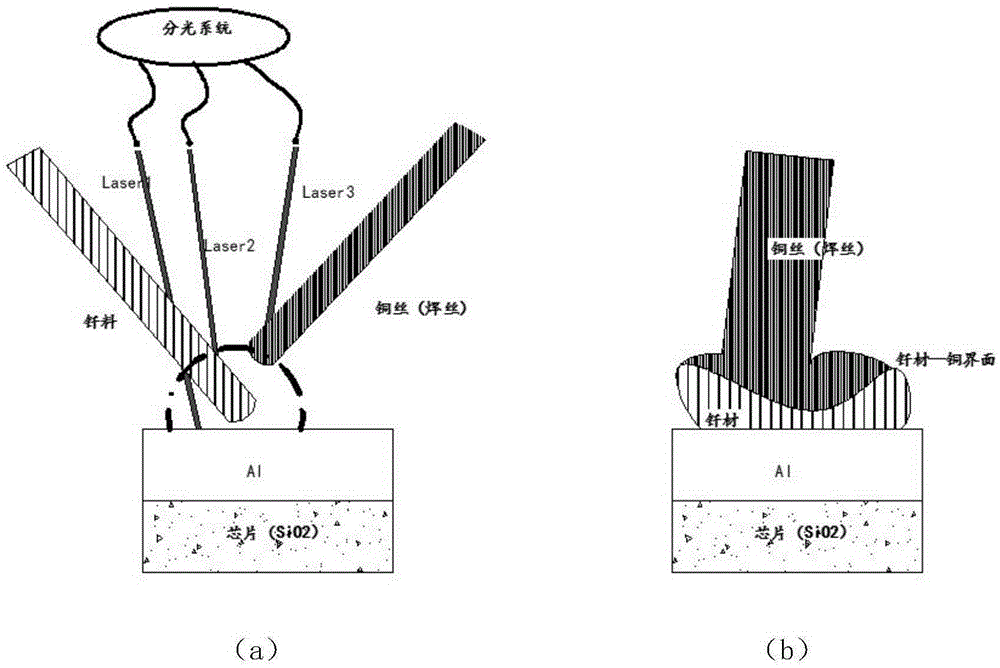

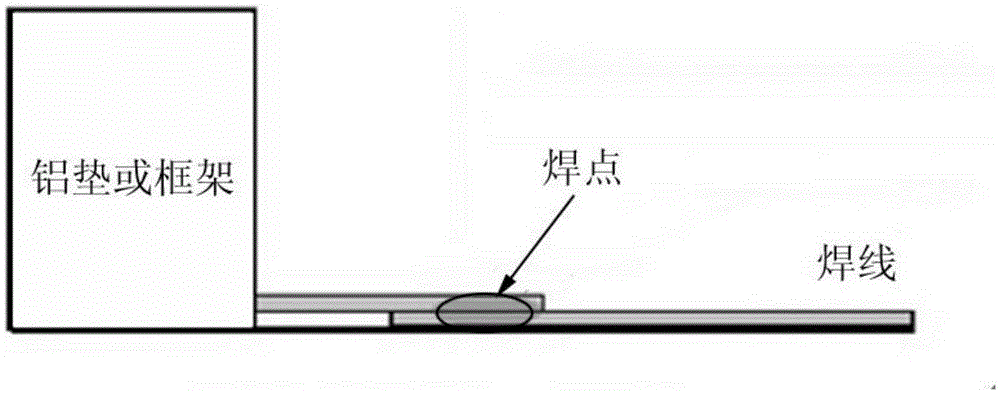

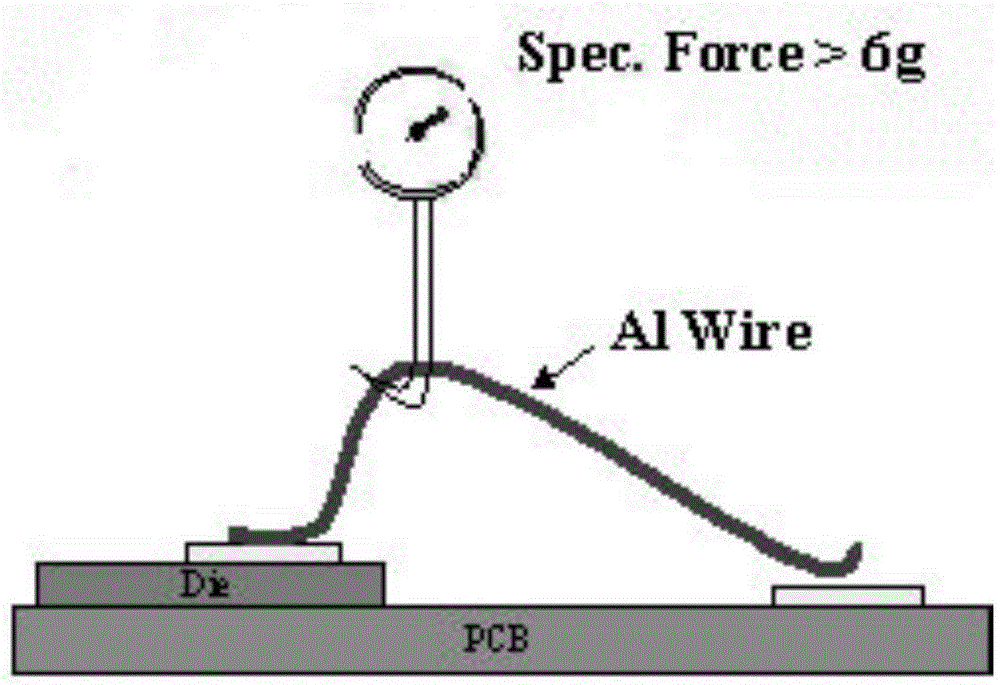

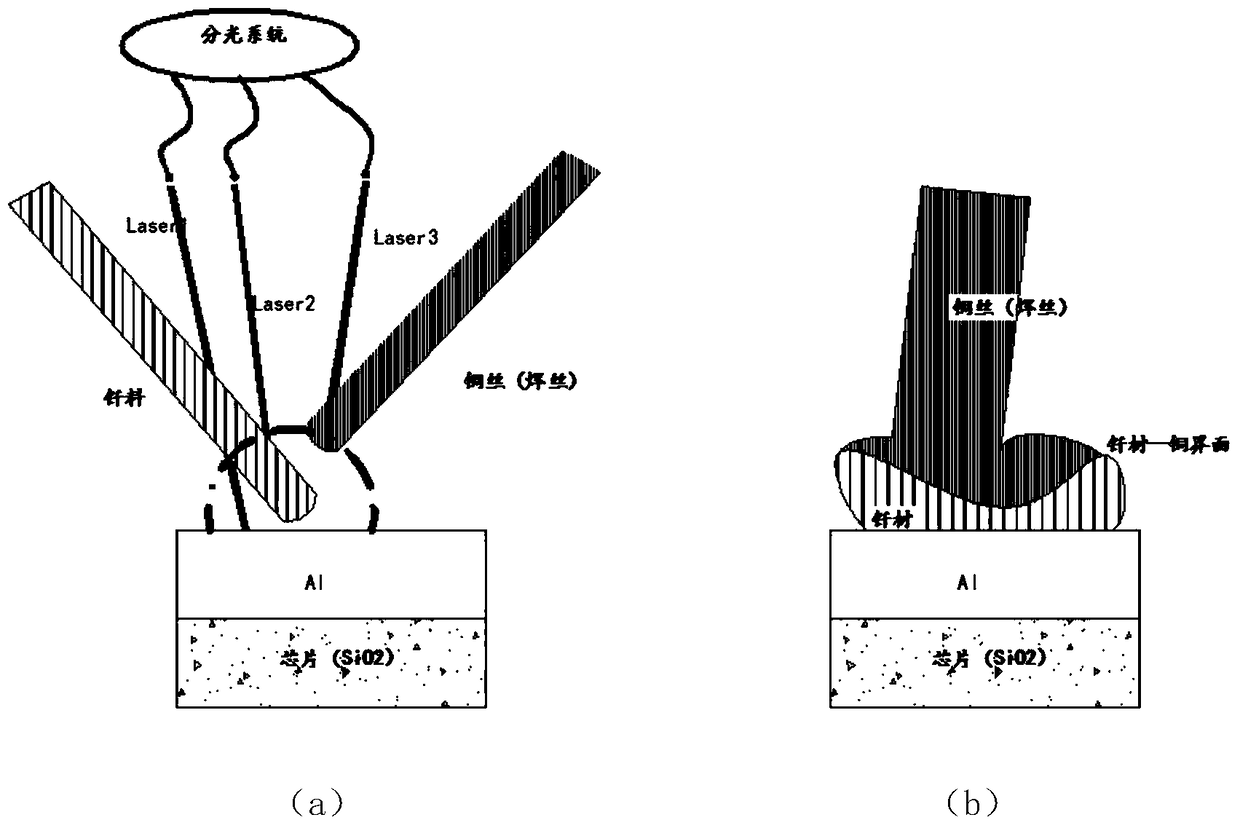

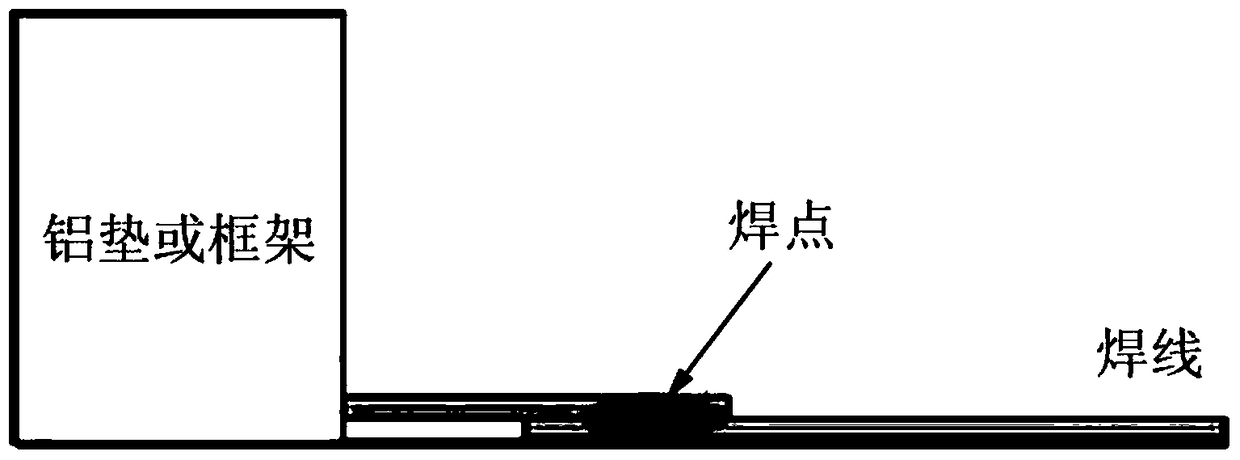

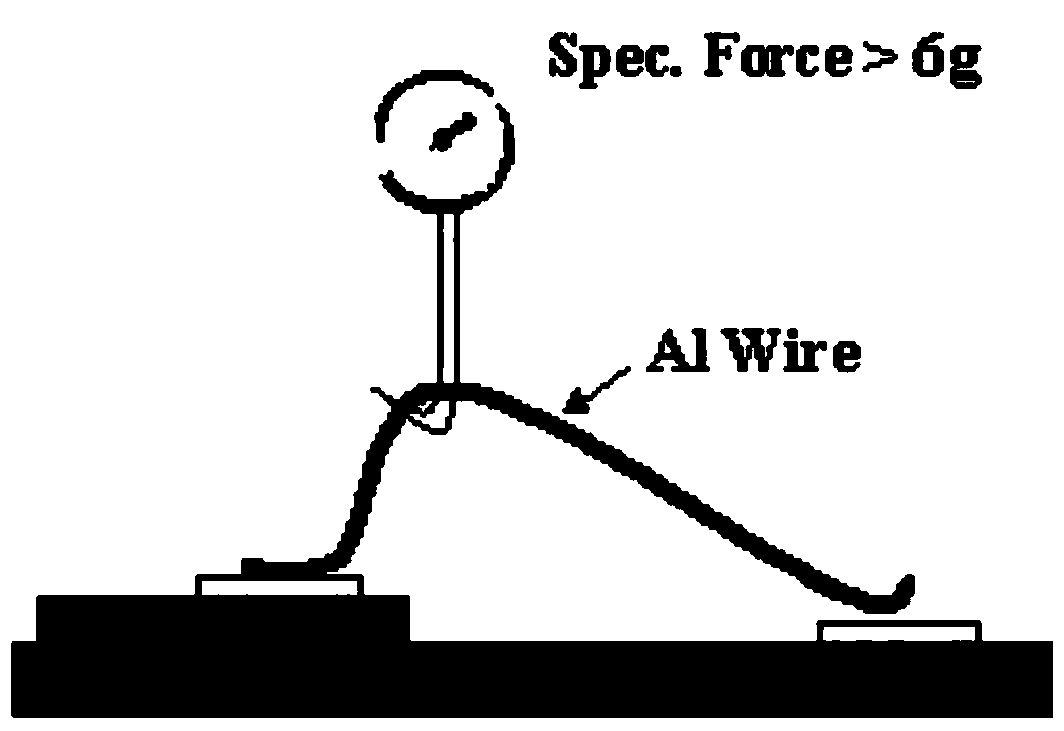

Lead welding technique for packaging semiconductor power device

ActiveCN105458434ANo stress damageIncrease flow resistanceWelding/cutting media/materialsMetal working apparatusManufacturing technologyStress Problem

The invention discloses a lead welding technique for packaging a semiconductor power device and belongs to the technical field of semiconductor power device packaging and manufacturing. According to the technique, lead connection is achieved through a brazing technique, and the brazing process is achieved through lasers, wherein lead connection refers to the completion of the welding process of a lead and a chip and the welding process of the lead and two welding points of a frame. In the welding process, the lead, the frame and a chip welding pad are preheated through direct laser spot radiation, the diameter of laser spots is 1 mm, and laser radiation time is 10 ms; and a brazing wire is heated through direct laser spot radiation, the diameter of the laser spots is 1 mm, and laser radiation time is 10 ms. By the adoption of the technique, the wet aluminum pad and the frame can be melted directly to achieve stable and reliable connection of the lead, the chip and the frame, the aluminum pad and the frame cannot be melted due to the fact that the temperature does not reach the melting point, and the aluminum pad and the frame are just preheated, so that the surfaces are stretched fully to assist in combination of the aluminum pad and liquid brazing filler metal and combination of the frame and the liquid brazing filler metal, and therefore mechanical damage, thermal damage and the stress problem existing in a traditional routing technique are avoided.

Owner:王伟

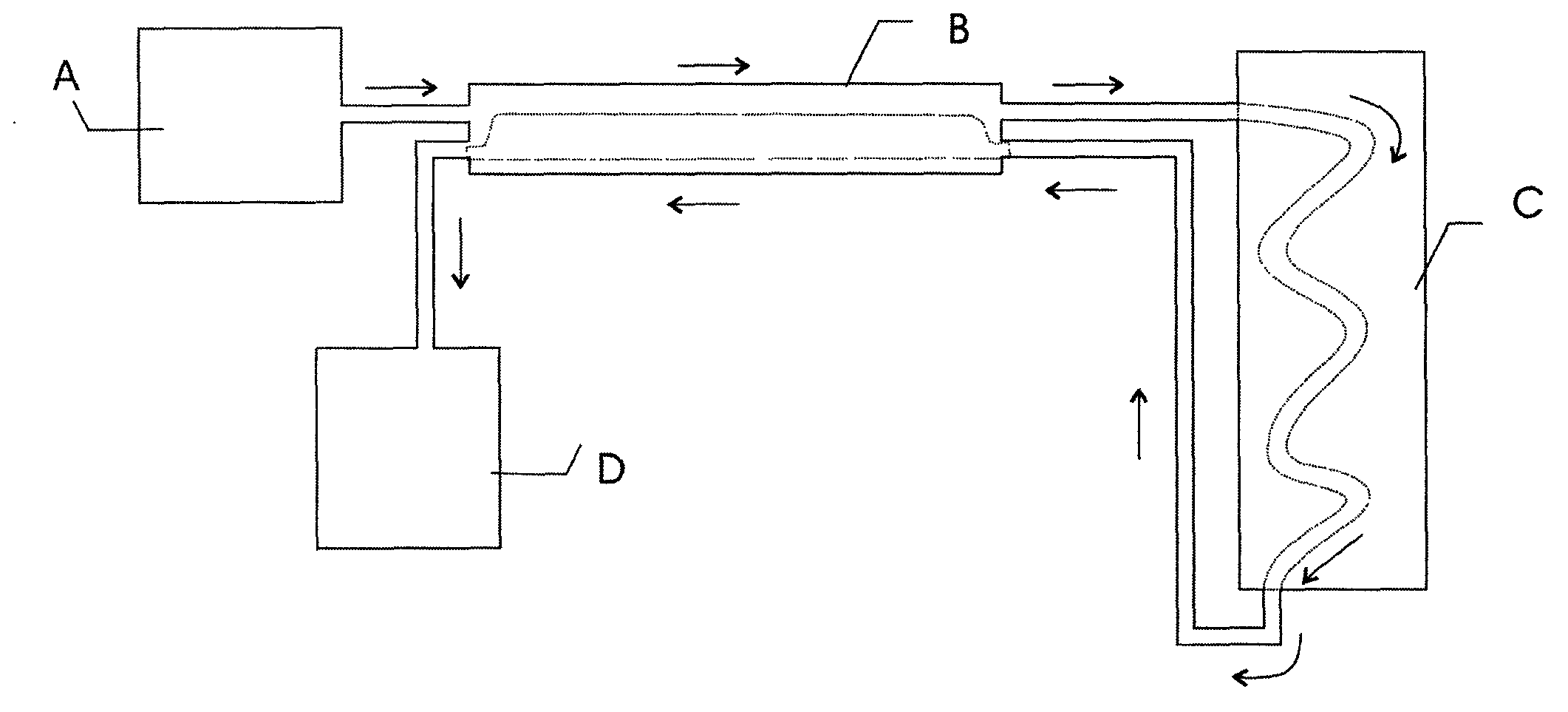

Technology for producing cooled boiled water by alternatively using cold energy and heat energy

InactiveCN103393353AGood energy saving effectPlay a warm-up roleBeverage vesselsPotable waterWater quality

The invention discloses a technology for producing cooled boiled water, wherein the technology is a method for scientifically producing cooled boiled water in an energy-saving mode and is a method for producing potable water which can be widely used in families and potable water producing manufacturers. Most importantly, the technology of alternatively using cold energy and heat energy is adopted, and the inlet water flow of a water heater and the outlet water flow of the water heater are combined together through a water barrel or a pipeline so that the temperature of the inlet water (cold water) and the temperature of the outlet water (hot water) can be exchanged through the wall of the water barrel or the wall of the pipeline even though the inlet water and the outlet water are not compatible due to different water qualities. The experiment shows that the technology for producing the cooled boiled water can save about 90% of energy compared with a traditional technology for producing the cooled boiled water. As the technology for producing similar products, in the time when potable water producing enterprises use chemical sanitizers for disinfection, the technology for producing the cooled boiled water directly solves the problem that conventionally, cost is high when the cool water is produced and indirectly solves the problems of safety and health of the potable water drunk by people are indirectly solved at the same time.

Owner:叶于安

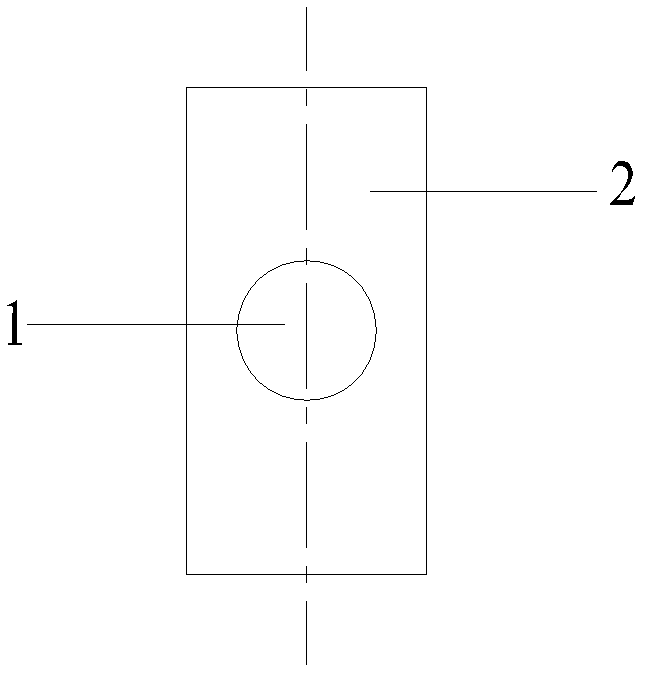

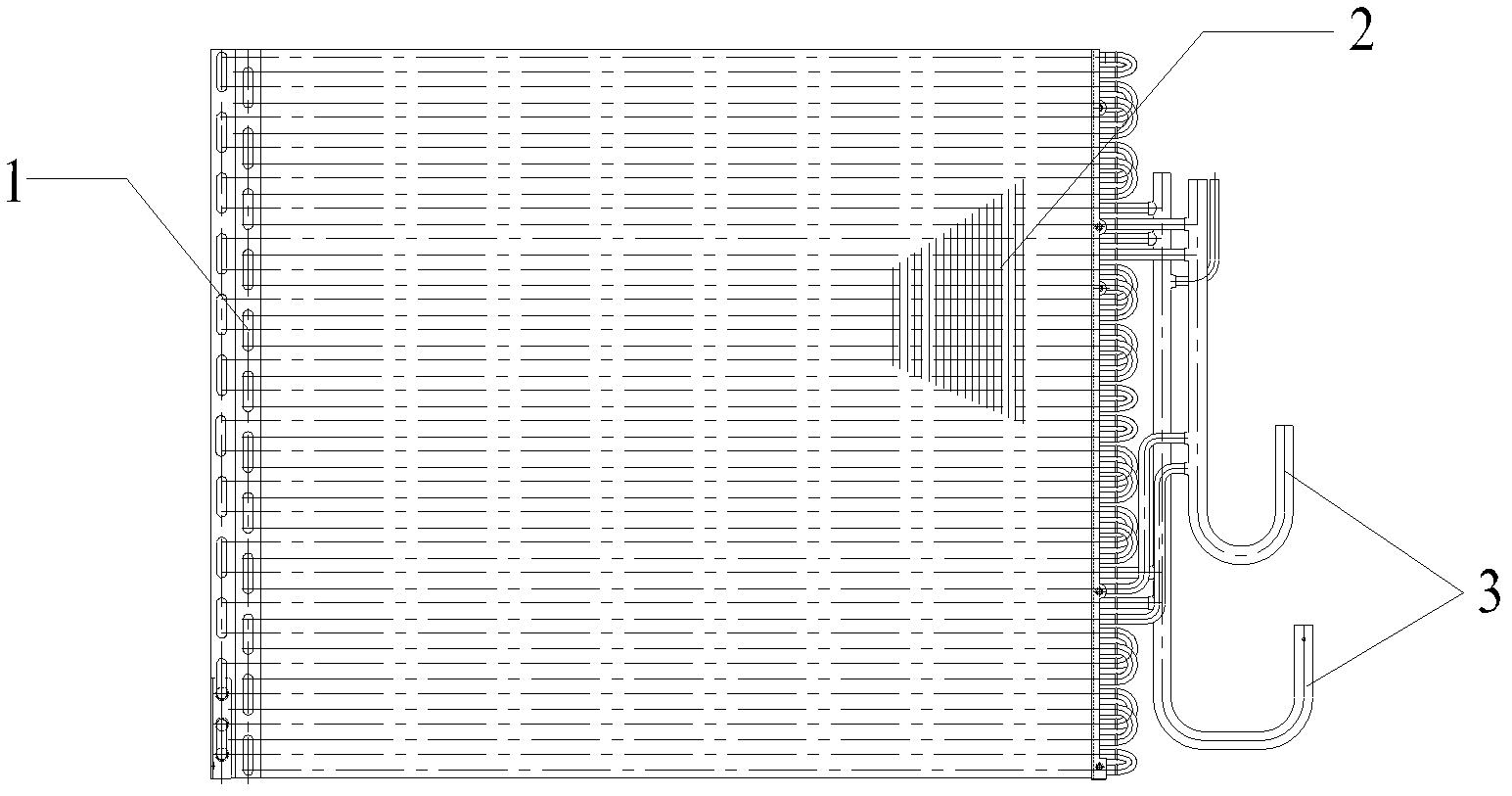

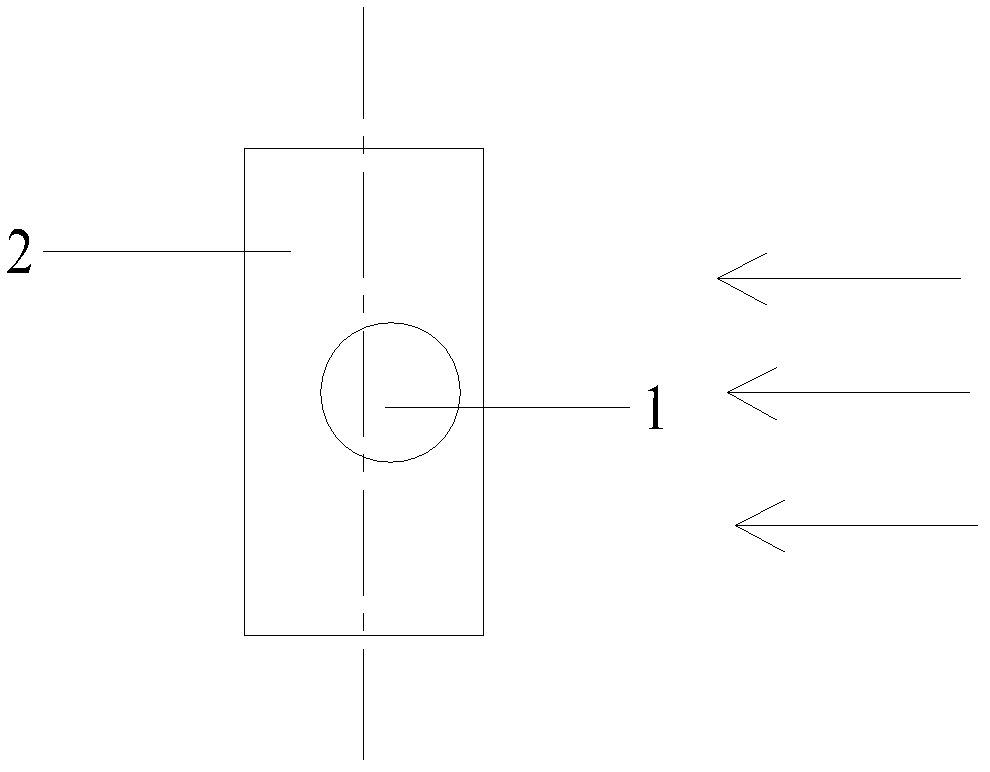

Outdoor heat exchanger of air conditioner

InactiveCN102607157ADoes not affect the overall performanceImprove wind resistanceLighting and heating apparatusSpace heating and ventilation detailsPlate heat exchangerEngineering

The invention discloses an outdoor heat exchanger of an air conditioner, comprising a heat exchanger copper pipe, heat exchanger fins and a flow splitting pipe, wherein the heat exchanger fins are asymmetrically sleeved on the heat exchanger copper pipe; the circle center of the peripheral section of the heat exchanger copper pipe deviates from the central line of the heat exchanger fins by 1 / 8-3 / 8 of the width of the heat exchanger fins; and the deviation direction of the circle center of the peripheral section of the heat exchanger copper pipe is opposite to the air inlet direction of the heat exchanger. Compared with the prior art, the outdoor heat exchanger of the air conditioner, disclosed by the invention, can improve the heat exchanging efficiency and can reduce the consumption of copper and aluminum materials by the air conditioner under the condition of not influencing the performance of the air conditioner, so that the material cost of the air conditioner is reduced.

Owner:GUANGDONG CHIGO AIR CONDITIONING

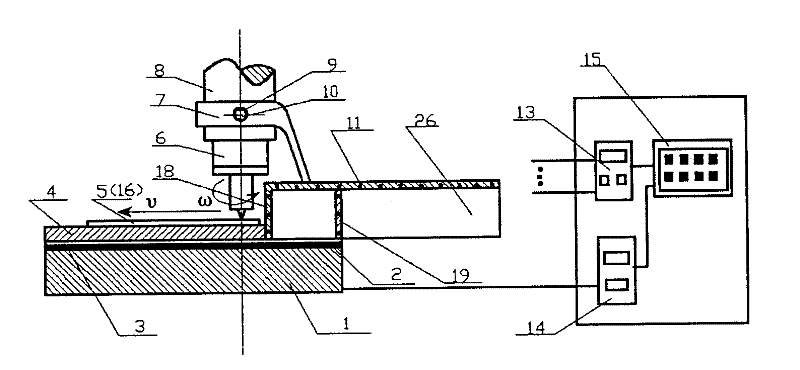

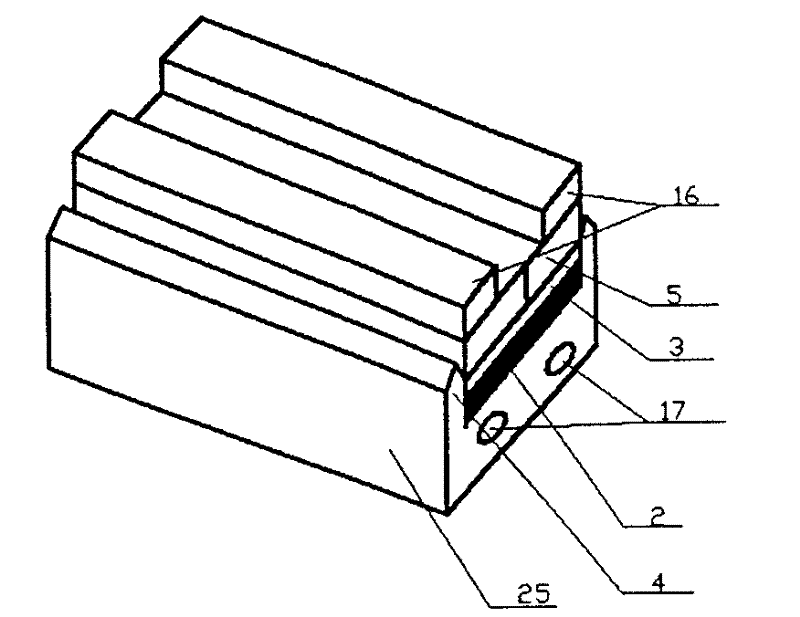

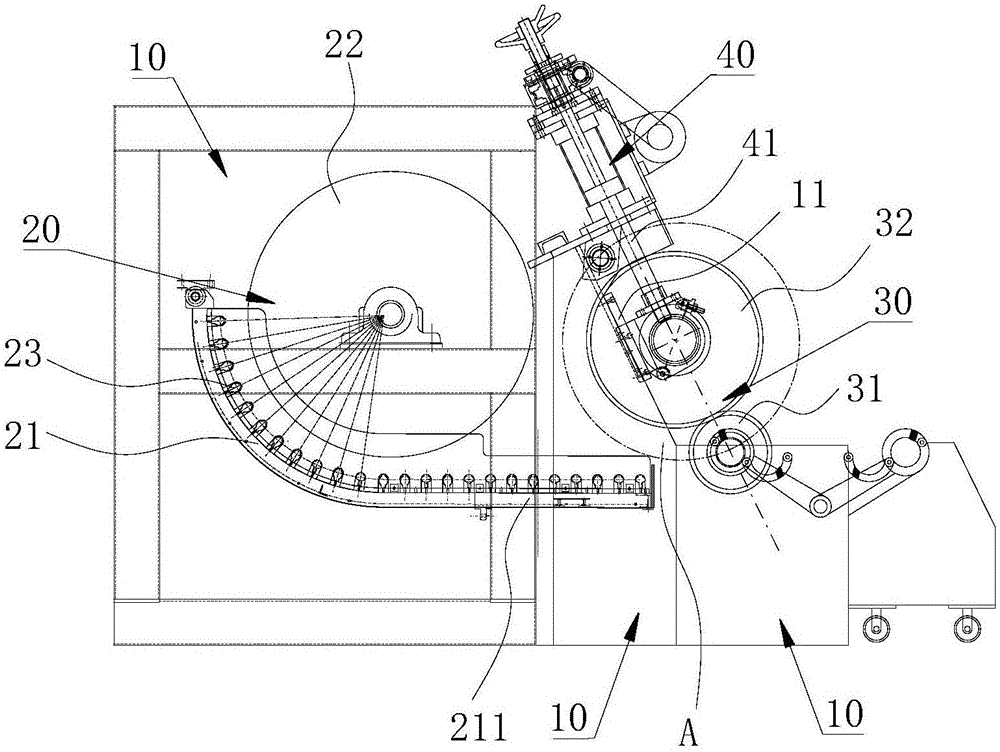

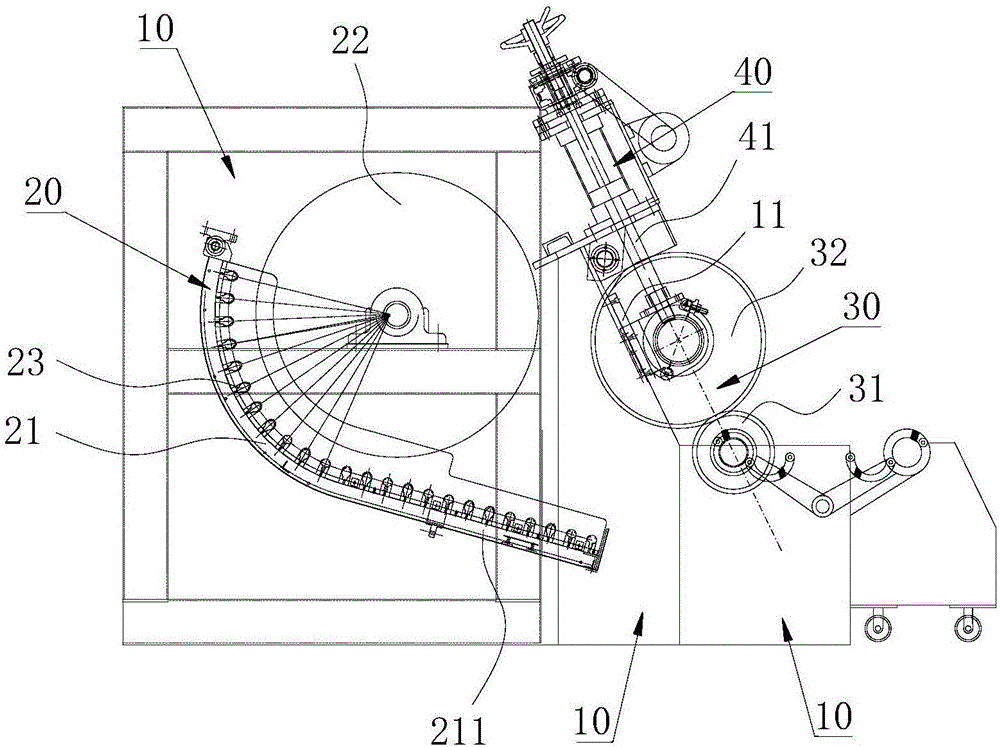

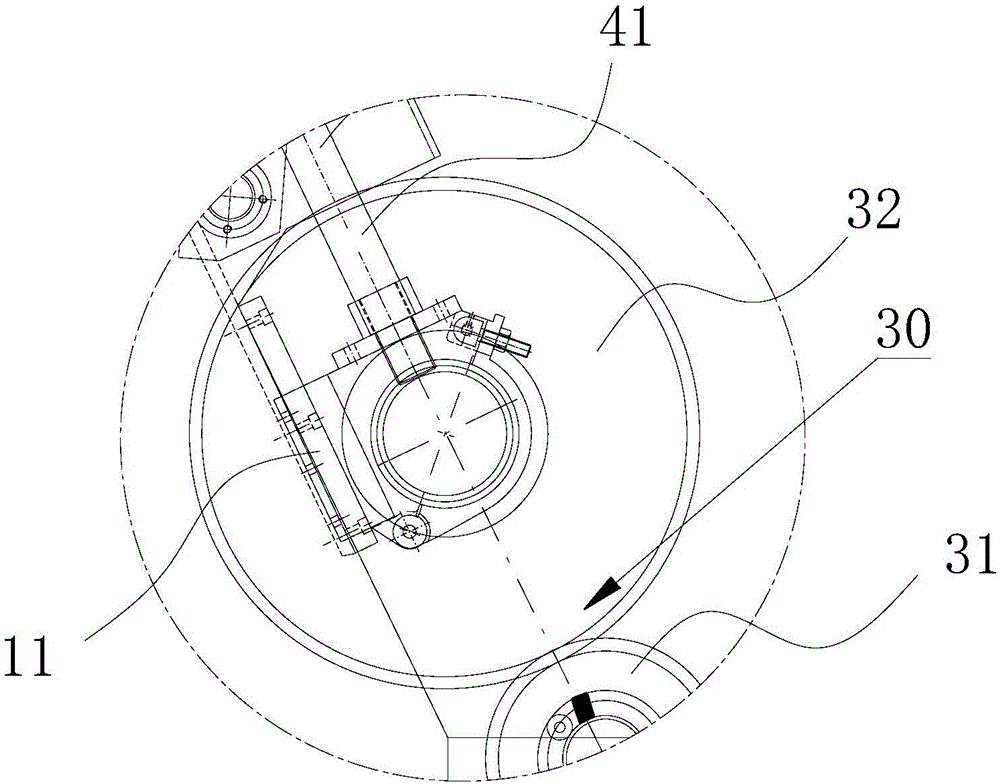

Lead welding device and technique for packaging semiconductor power device

ActiveCN105458435AImprove efficiencySmall heat affected zoneWelding/cutting media/materialsMetal working apparatusManufacturing technologyStress Problem

The invention discloses a lead welding device and technique for packaging a semiconductor power device and belongs to the technical field of semiconductor power device packaging and manufacturing. The device is a laser wire welding machine and comprises a computer main board, a laser generator, a chip and frame image identification system, a feeding system and an XY workbench. The computer main board is used for controlling all the actions of the laser wire welding machine to achieve the whole automatic and accurate wire welding technique process; the laser generator is used for outputting laser spots of the required power and the required diameter; and the feeding system is used for accurately conveying a frame, a lead and a brazing wire to the work position before welding actions are executed. According to the technique, lead connection is achieved through a brazing technique, and the brazing process is achieved through lasers. By the adoption of the device and technique, a wet aluminum pad and a frame are directly melted to achieve the stable and reliable connection of the lead, a chip and the frame, and therefore mechanical damage, thermal damage and the stress problem existing in a traditional routing technique are avoided.

Owner:王伟

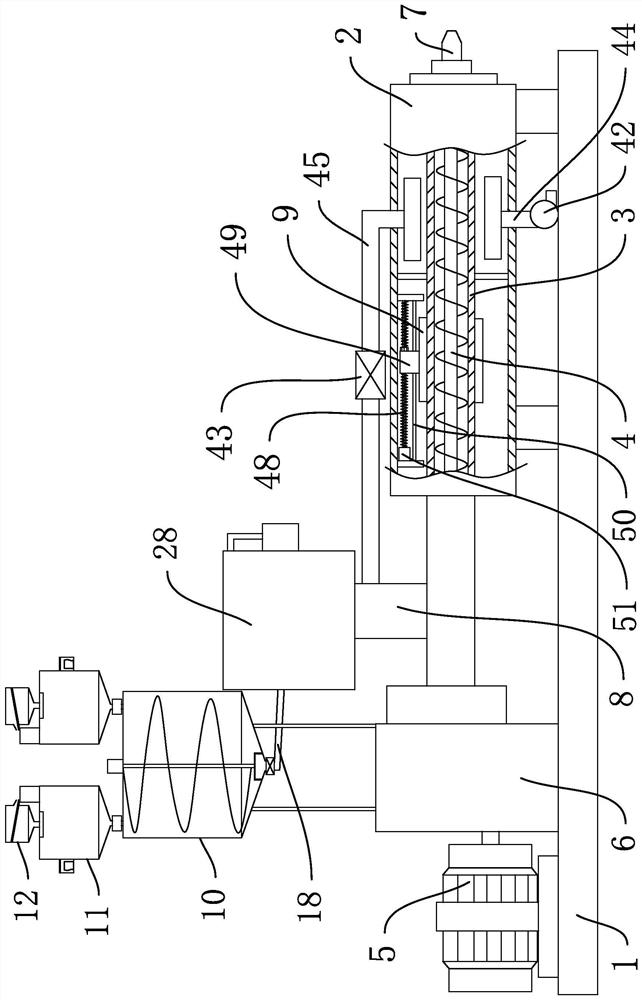

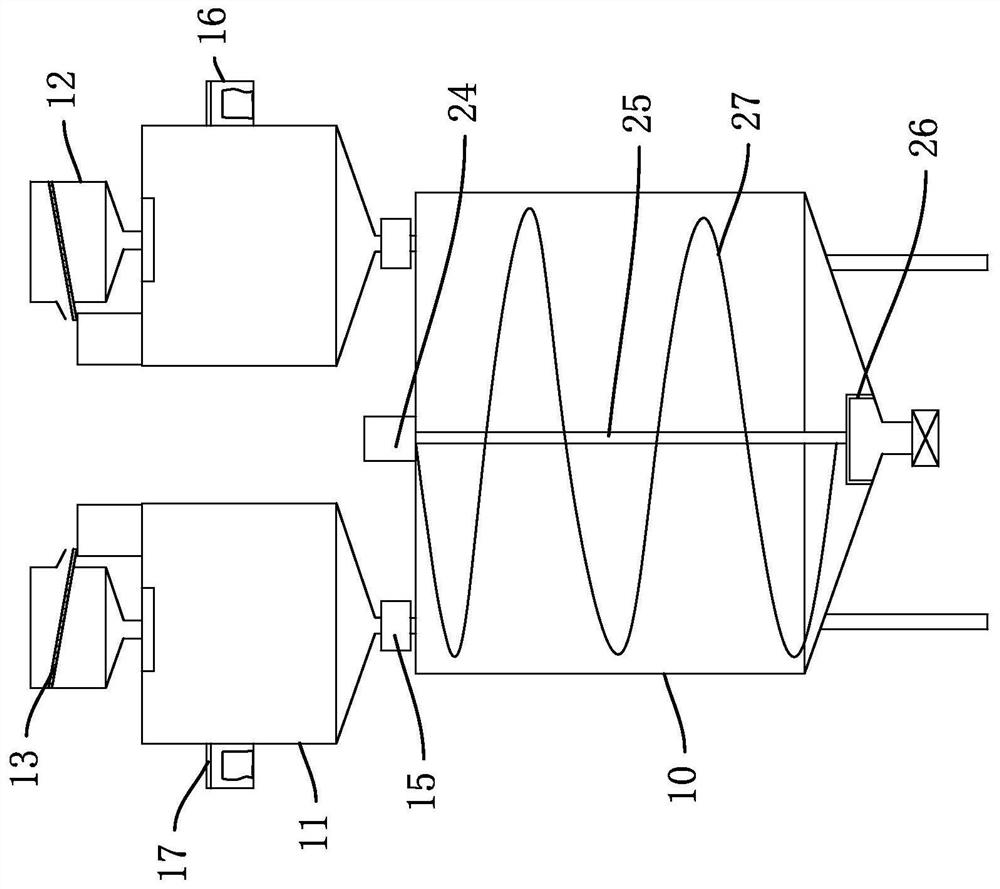

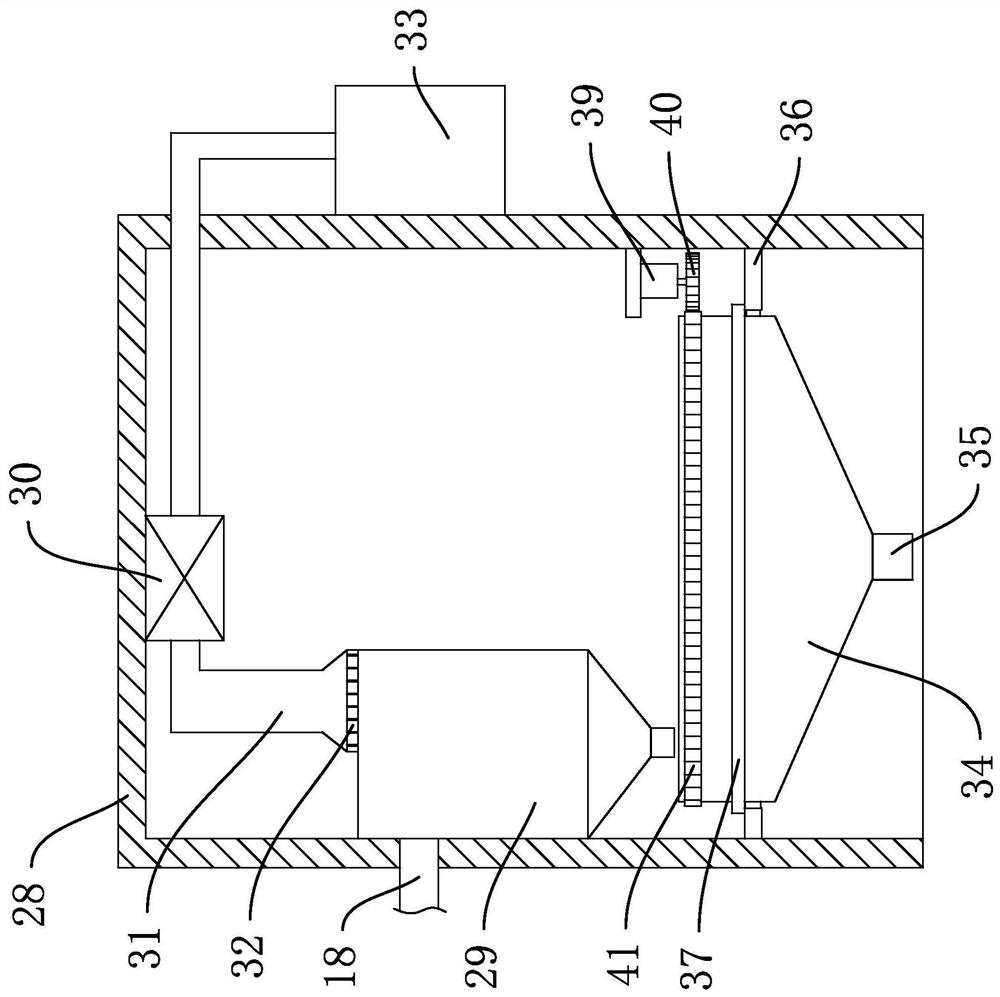

PE pipe three-section metering high-speed single-screw extruder

The invention provides a PE pipe three-section metering high-speed single-screw extruder, and belongs to the technical field of machinery. The PE pipe three-section metering high-speed single-screw extruder solves the technical problems that an existing screw extruder is troublesome in feeding and the like. The PE pipe three-section metering high-speed single-screw extruder comprises a base, and is characterized in that a working barrel and a blending device are arranged on the base, a machining barrel is arranged on the working barrel, a screw is rotationally arranged in the machining barrel,a first power motor is further arranged on the base, the screw is connected with an output shaft of the first power motor through a reduction gearbox, a first feeding port is formed in one end of themachining barrel, the other end of the machining barrel is connected with a discharging nozzle, a feeding device is further arranged on the machining barrel, the feeding device communicates with thefirst feeding port through a drying box, the feeding device communicates with the blending device, a heating device is further arranged on the working barrel, the heating device is connected with a moving structure, and a heat circulation mechanism is further arranged on the base. The PE pipe three-section metering high-speed single-screw extruder has the advantage of high working efficiency.

Owner:浙江振飞塑业有限公司

Efficient laser additive manufacturing method based on wire thermal conductivity welding

InactiveCN111299837AImprove energy utilizationReduce lossesAdditive manufacturing apparatusLaser beam welding apparatusLaser additive manufacturingLaser beams

The invention discloses an efficient laser additive manufacturing method based on wire thermal conductivity welding, and belongs to the field of laser material machining. The method is characterized in that the action position of a laser beam and a rear wire is located above a molten pool; a wire material is melted in a heat conduction welding mode to form molten drops, a base material below the molten drops is preheated by reflected light of the wire material, and meanwhile, metallurgical connection is performed between the molten drops and the base material; and metal parts of various structures are manufactured through ascending and descending of a workbench or a laser head according to a point-line-plane-body route. Compared with a three-dimensional heat transfer type laser additive manufacturing method, the method adopts the laser melting wire located above the molten pool, which belongs to one-dimensional heat transfer, the heat conduction loss of the material can be greatly reduced, the melting efficiency is improved, on the other hand, the preheating of the base material by the reflected light can promote spreading of the molten drops on the base material, and the utilization rate of laser energy is further increased, in addition, the disturbance of violent evaporated steam of the material can be avoided by adopting the heat conduction welding mode, the stability of theadditive manufacturing process is improved, and splashing particles and air holes are prevented from being formed.

Owner:BEIJING UNIV OF TECH

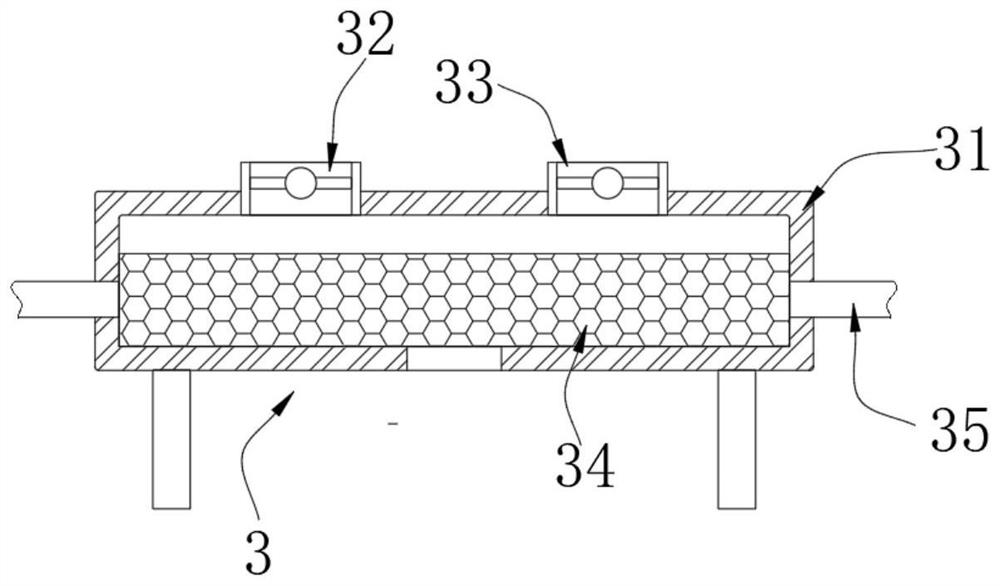

Method and device for controlling residual stress on stir friction welding surface

InactiveCN101774079BGuaranteed levelnessAchieve the double function of clamping and fixingNon-electric welding apparatusEngineeringControl equipment

The invention relates to a method and a device for controlling a residual stress on a stir friction welding surface. According to the method, an insulation box capable of moving along a stirring head is adopted to insulate the weld joint and parent metal after welding, and then furnace cooling is performed so as to reduce the residual stress on the stir friction welding surface. The device mainlycomprises a sucking-disc type fixture, the insulation box and control equipment, wherein the insulation material mainly comprises fire bricks, asbestos and steel plates. During welding, the insulation box moves along the stirring head and insulates the welded workpiece continuously; and after the welding, the whole workpiece enters the insulation box to be insulated and is cooled with the furnaceafter being insulated for a certain time so as to control the residual stress on the welding surface and the deformation, wherein the insulating temperature is the critical temperature of the heat treatment of the materials. The device realizes full automation in the whole welding process and avoids the reduction in the welding quality due to a human factor. The method and the device have the advantages of simple device, convenient operation, high technical economic benefit, and high welding quality of the stir friction welding.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

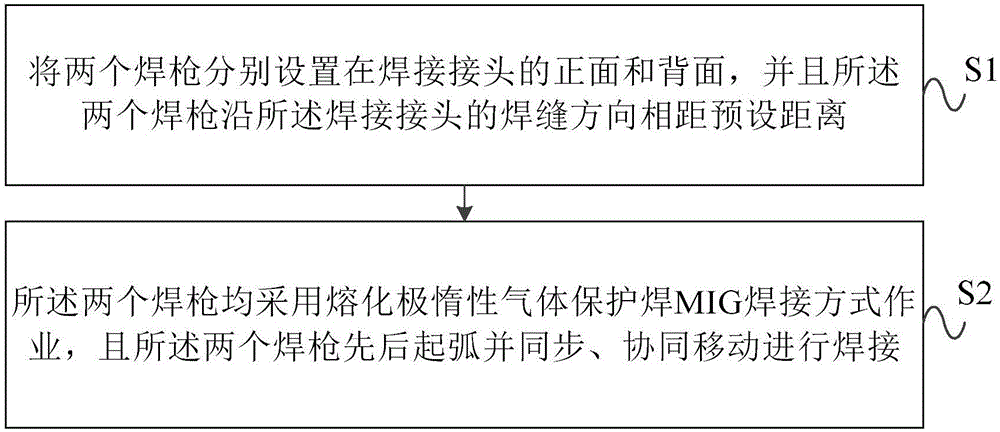

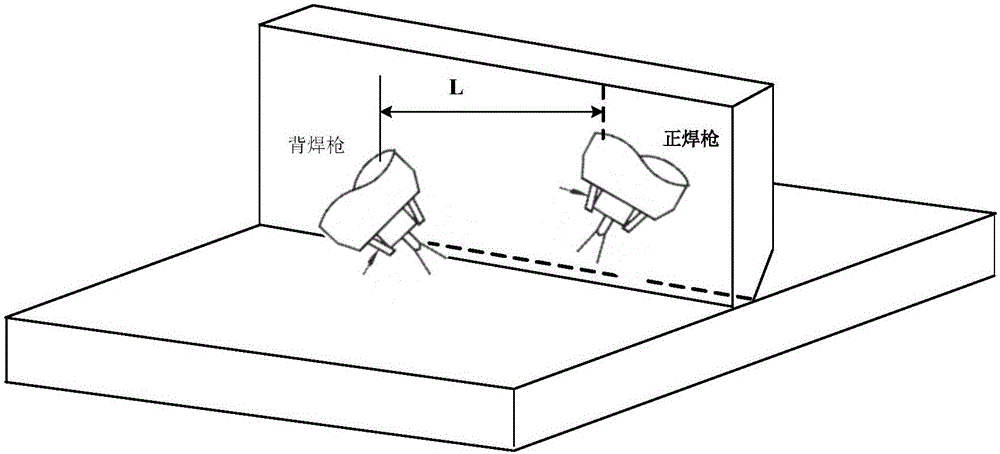

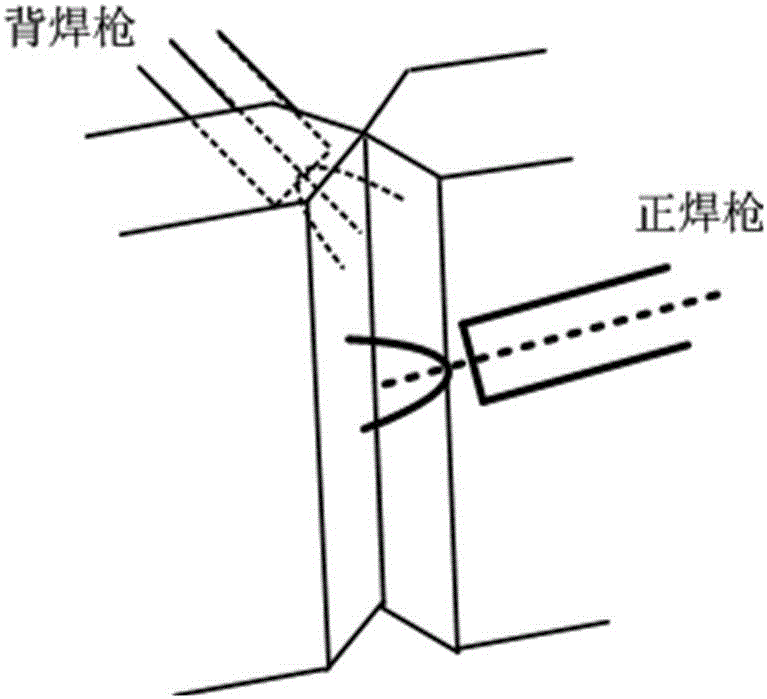

Aluminum and aluminum alloy double-gun double-face collaborative welding method

InactiveCN107520528AReduce heatExtended service lifeArc welding apparatusWelding/soldering/cutting articlesMaterials scienceMetal

The embodiment of the invention provides an aluminum and aluminum alloy double-gun double-face collaborative welding method. The aluminum and aluminum alloy double-gun double-face collaborative welding method comprises the steps that two welding guns are arranged on the front face and the back face of a welding joint correspondingly with a preset distance in the weld direction of the welding joint; and the two welding guns both operate in a metal inert-gas (MIG) welding mode, strike arcs successively and move synchronously and collaboratively to conduct welding. According to the aluminum and aluminum alloy double-gun double-face collaborative welding method, full penetration of a root of aluminum and aluminum alloy under the zero clearance condition is achieved, the welding joint with the large thickness can be welded through MIG welding, the quality of the welding joint of the aluminum and aluminum alloy is improved, and the service life of a weldment is prolonged.

Owner:CRRC QINGDAO SIFANG CO LTD

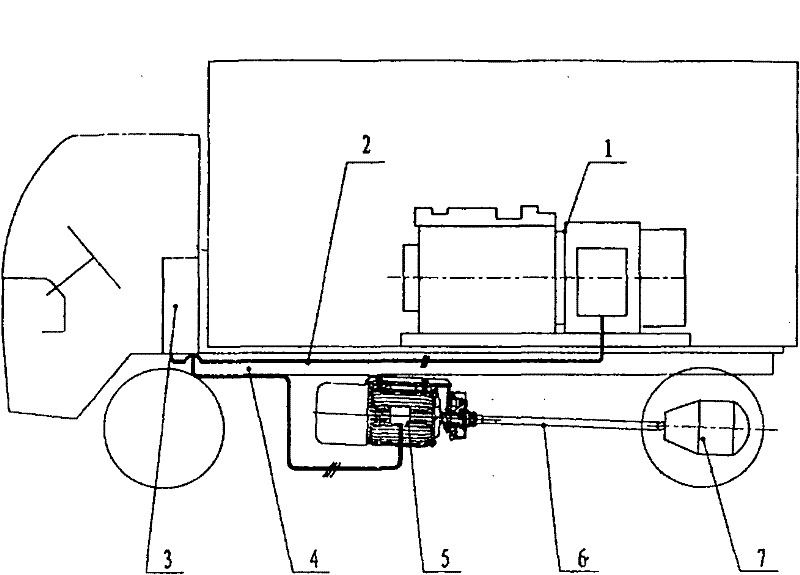

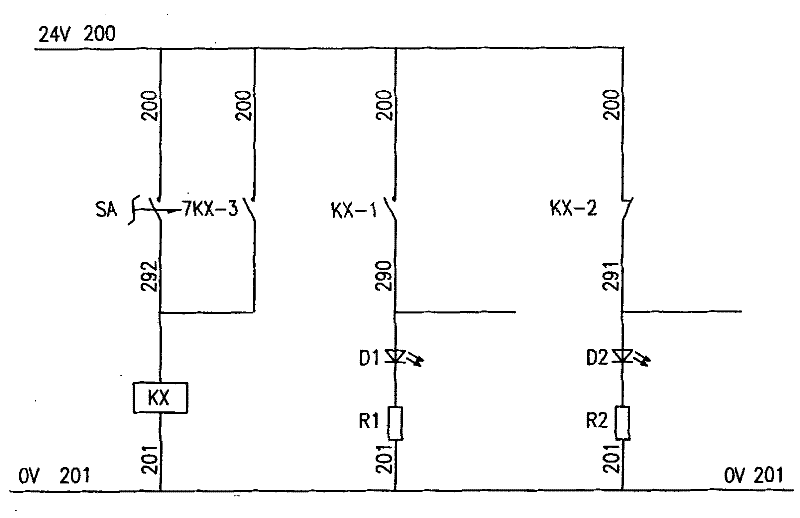

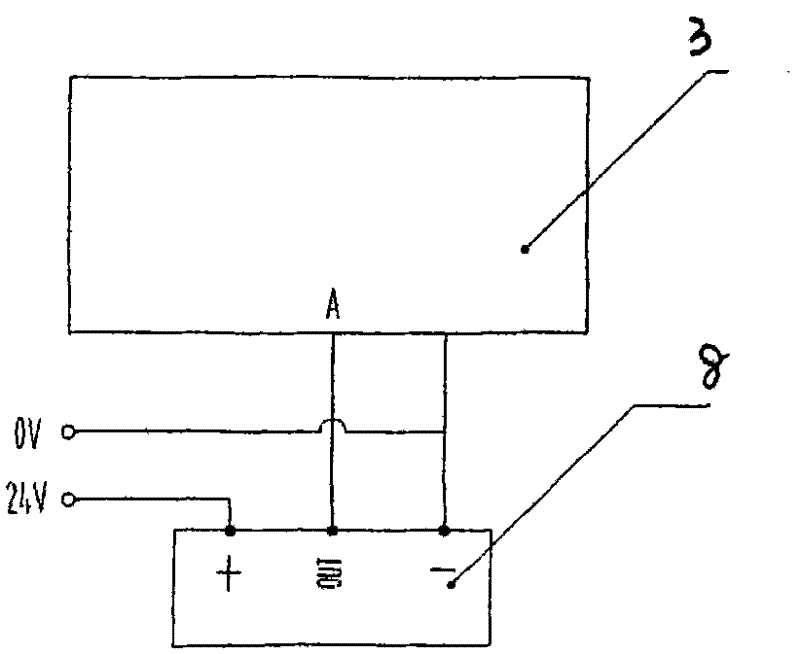

Mobile aviation ground equipment with shared power source

The invention provides mobile aviation ground equipment with shared power source, which solves the problems of required two sets of power sources, complex structure and high cost in mobile aviation ground equipment, such as airplane ground air-conditioned car, airplane ground air / power source all-in-one machine and the like. In the equipment, a wagon box of a chassis is provided with a diesel (orgas) electric generating set (1); output of the electric generating set is connected with input of a transducer (3) via a first cable (2); output of the transducer is connected with a pulling motor (5) via a second cable (4); power take-off shaft (6) of the pulling motor (5) is connected with one end of a transmission shaft (6); the other end of the transmission shaft (6) is connected with a driving axle (7); or power take-off shaft of the pulling motor (5) is connected with a hydraulic pump or a hydraulic motor.

Owner:四川华盛强航空地面设备有限公司

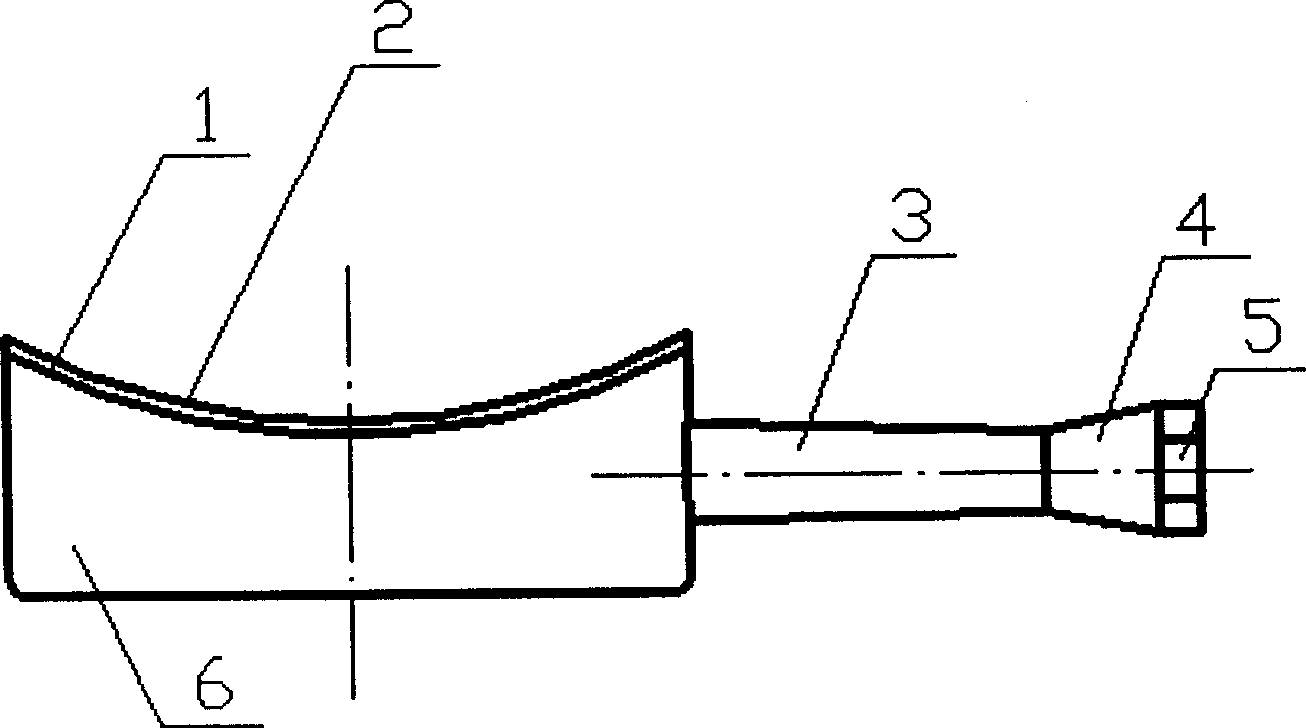

Spherieal radiation gas fuel burner

The invention relates to partial premixing type flue gas burner. Face of fire layer is in spherical surface prepared by splicing one or more cambered fireproof honeycomb panel. Angle between tangent of point, which is cutting point between faces of fire layer and mixing chamber, and horizontal line is 5-10 degrees. In the invention, particular surface shape reduces too large radiation heat dissipation from face of fire layer, raises thermal efficiency 20% higher than efficiency of traditional burner. Central temperature is higher than 900deg.C. Discharge of carbon monoxide and Nox is less than traditional burner.

Owner:TSINGHUA UNIV

A wire bonding process for semiconductor power device packaging

ActiveCN105458434BNo stress damageIncrease flow resistanceWelding/cutting media/materialsMetal working apparatusManufacturing technologyStress Problem

The invention discloses a lead welding technique for packaging a semiconductor power device and belongs to the technical field of semiconductor power device packaging and manufacturing. According to the technique, lead connection is achieved through a brazing technique, and the brazing process is achieved through lasers, wherein lead connection refers to the completion of the welding process of a lead and a chip and the welding process of the lead and two welding points of a frame. In the welding process, the lead, the frame and a chip welding pad are preheated through direct laser spot radiation, the diameter of laser spots is 1 mm, and laser radiation time is 10 ms; and a brazing wire is heated through direct laser spot radiation, the diameter of the laser spots is 1 mm, and laser radiation time is 10 ms. By the adoption of the technique, the wet aluminum pad and the frame can be melted directly to achieve stable and reliable connection of the lead, the chip and the frame, the aluminum pad and the frame cannot be melted due to the fact that the temperature does not reach the melting point, and the aluminum pad and the frame are just preheated, so that the surfaces are stretched fully to assist in combination of the aluminum pad and liquid brazing filler metal and combination of the frame and the liquid brazing filler metal, and therefore mechanical damage, thermal damage and the stress problem existing in a traditional routing technique are avoided.

Owner:王伟

Reverse embossing machine

The invention discloses a reverse embossing machine. The reverse embossing machine comprises a machine frame, a heating device, an embossing device and a position-adjusting device. The heating device comprises a lampshade, a heat-conducting oil heating wheel used for preheating a non-embossing face and a heating lamp tube used for heating an embossing face; the heat-conducting oil heating wheel can be connected to the machine frame in a rotating mode; the heating lamp tube is installed below the heat-conducting oil heating wheel and wrapped by the lampshade; the lampshade is detachably and fixedly arranged on the machine frame; the embossing device comprises an embossing wheel used for pressing patterns and a pressure wheel used for clamping; the embossing wheel can be connected to the machine frame in a rotating mode; the pressure wheel is located above the embossing wheel and can be connected to the machine frame in a rotating mode; one end of the position-adjusting device is connected to the machine frame, the other end of the position-adjusting device is connected to the pressure wheel, and the position-adjusting device is used for adjusting the distance between the pressure wheel and the embossing wheel. The reverse embossing machine can effectively utilize hot gas and improve preheating energy efficiency.

Owner:QINGYUAN QILI SYNTHETIC LEATHER

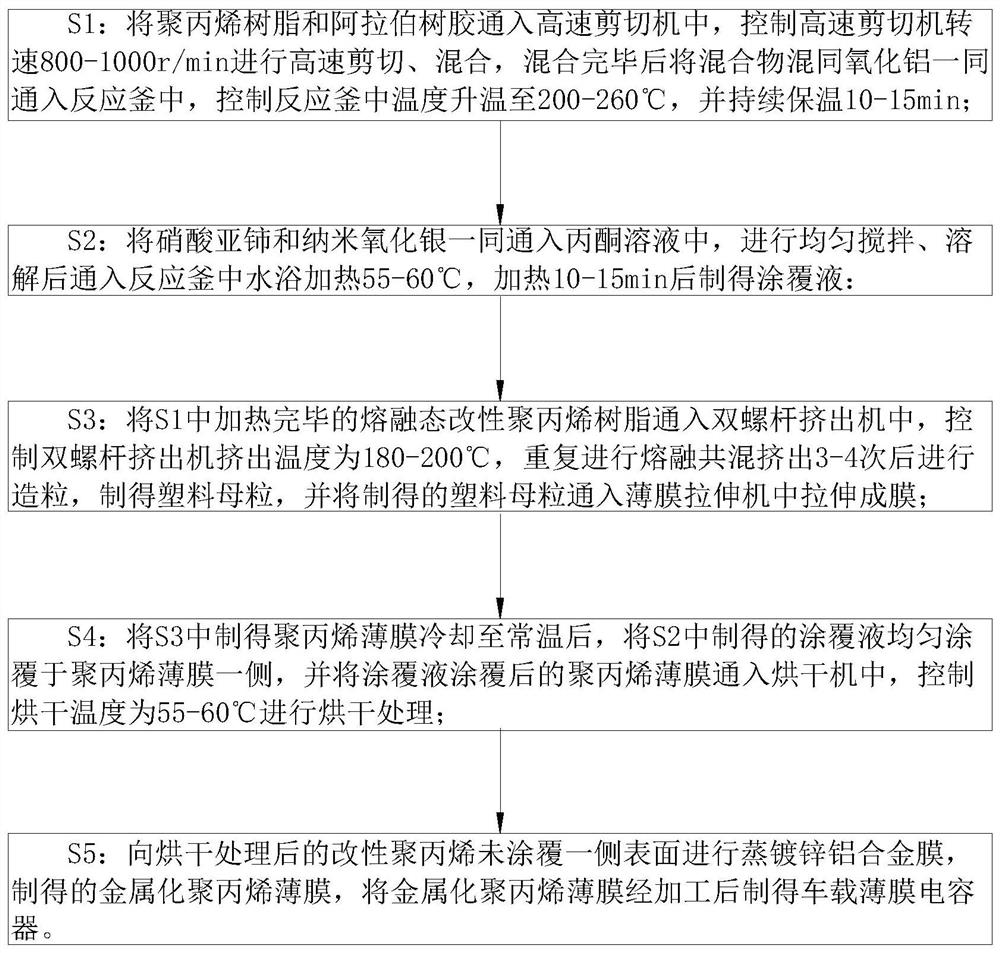

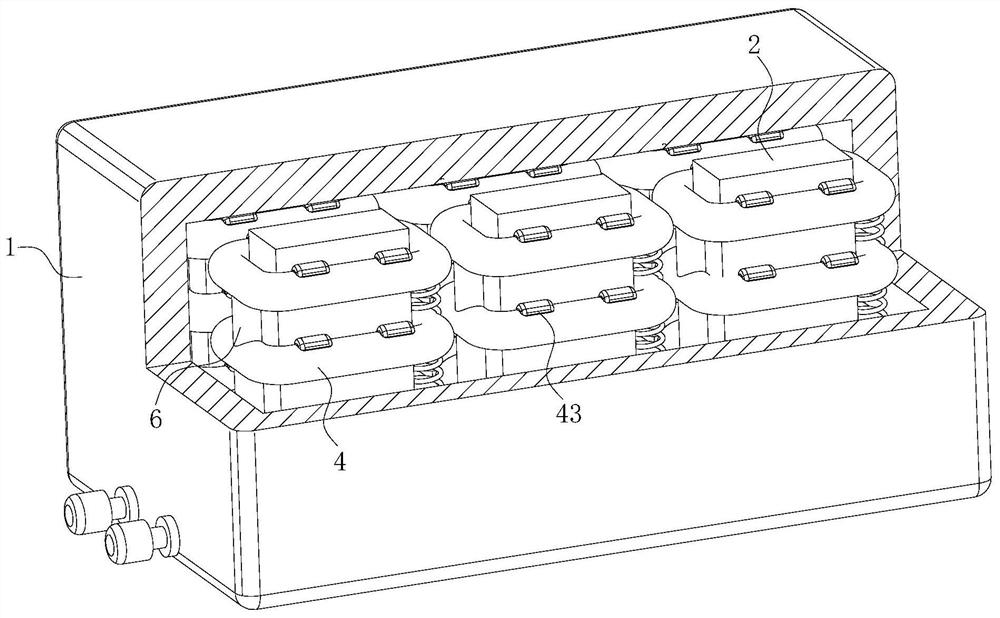

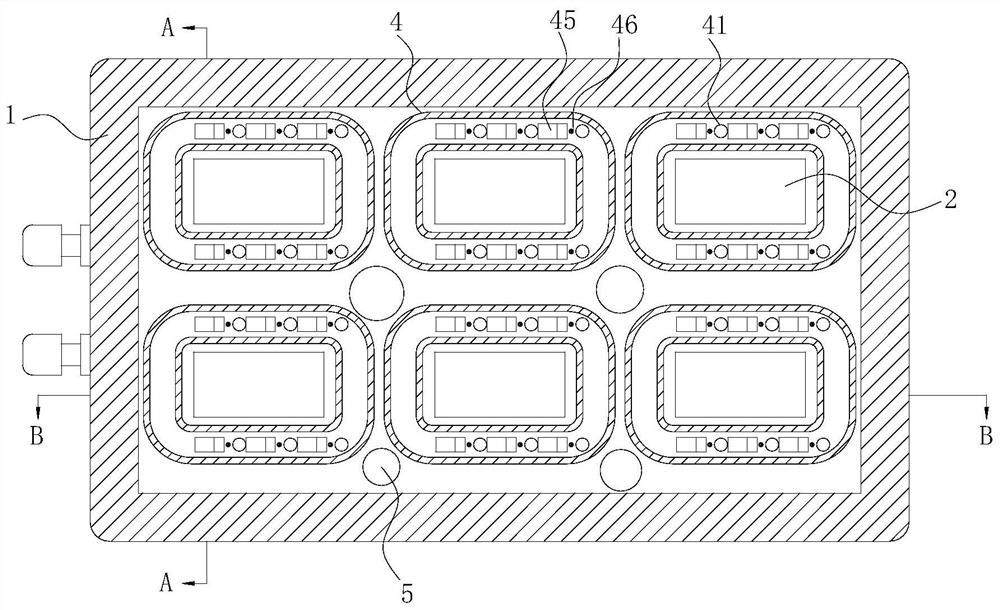

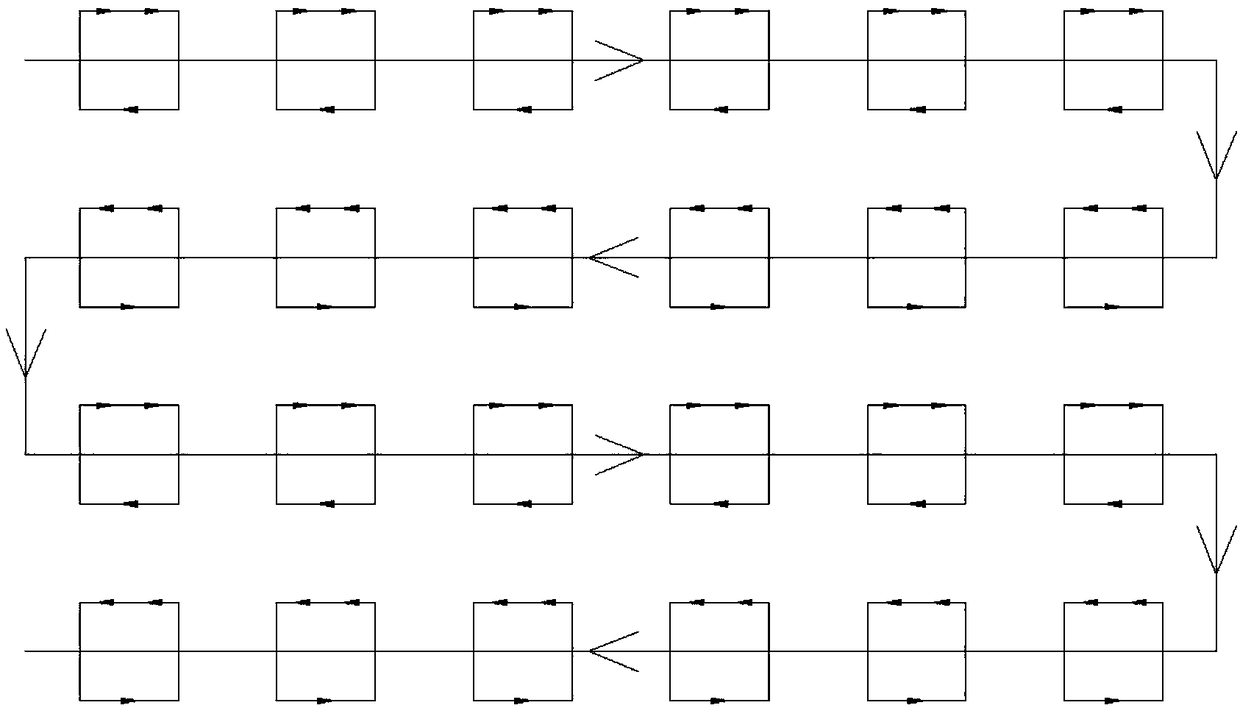

Polypropylene film

InactiveCN111635548ALow yieldLow cold shrinkageThin/thick film capacitorStacked capacitorsPolymer scienceManganese oxide

The invention belongs to the technical field of high polymer materials, and particularly relates to a polypropylene film which comprises a shell, a core and leading-out lines. The core comprises a substrate layers, metal film layers and a heat conduction layer. The two substrate layers are made of modified polypropylene resin films; the metal film layers are fixedly connected to both sides of thesubstrate layers through evaporation, and the area of the metal film layers is smaller than that of the substrate layers; the heat conduction layer is made of a heat conduction silicone grease material; the surfaces, away from the heat conduction layer, of the metal film layers are coated with an insulating paint layer; the metal film layers on two adjacent substrate layers are in a staggered state; the leading-out wires are respectively conducted with the metal film layers on the two substrate layers; the MAH graft modified polyethylene wax and the active manganese dioxide are added into thepolypropylene film, so that the softness of the prepared polypropylene film is effectively and remarkably enhanced, meanwhile, the active manganese dioxide is self-decomposed to release oxygen ions togenerate an aluminum oxide film, and the service life of a film capacitor is further prolonged.

Owner:孔维恒

Multiple laser composite scanning process

InactiveCN108339982APlay a warm-up roleSmall temperature differenceAdditive manufacturing apparatusIncreasing energy efficiencyOptoelectronicsMetal powder

The invention discloses a multiple laser composite scanning process. According to the multiple laser composite scanning process, two total laser generators of a first laser and a second laser are adopted to perform laser melting on metal powder, when melting in performed, firstly scanning preheating is performed on a metal powder area by the first laser adopting a first power, then scanning melting is performed on the metal powder area by the second laser adopting a second power, finally scanning modification is performed on the metal powder area by the first laser or the second laser adoptinga third power, the first power is less than the third power, and the third power is less than the second power. By means of the multiple laser composite scanning process, a large number of cracks andpores can be reduced, each layer surface of a workpiece is made to be sintered sufficiently, the workpiece molding quality is good, and the fatigue life is significantly prolonged.

Owner:ANHUI TUO BAO ADDITIVE MFG TECH CO LTD

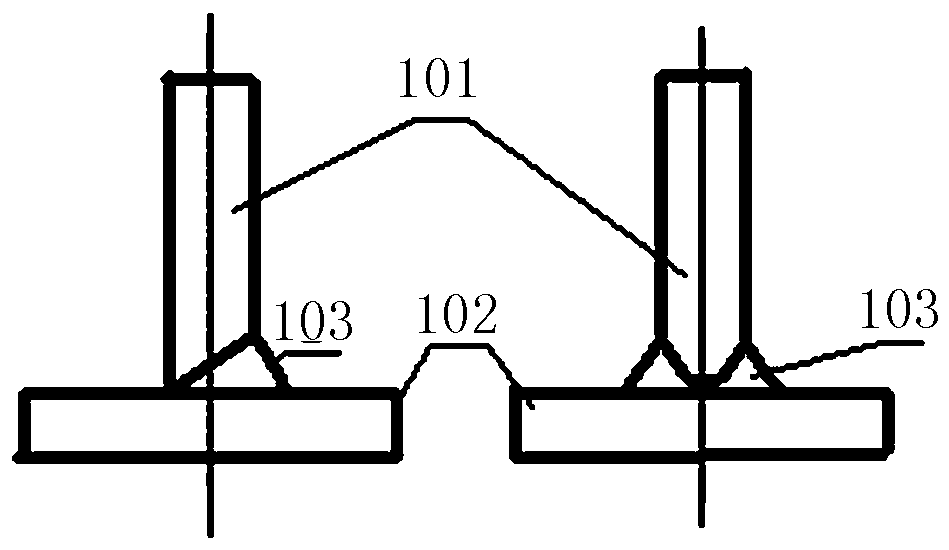

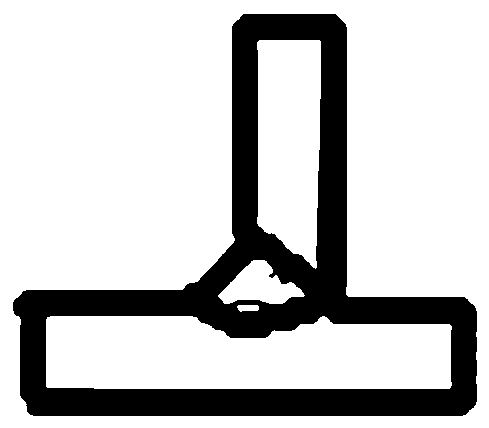

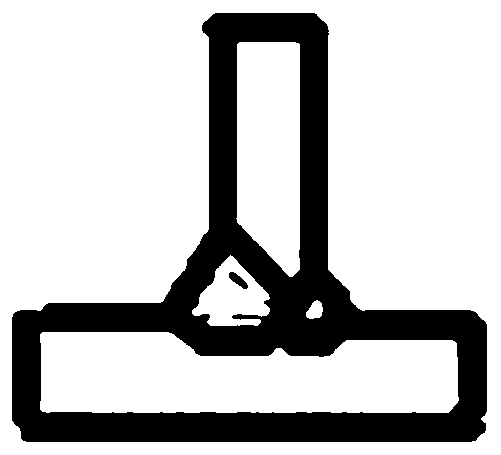

Composite welding technology method of aluminum and aluminum profile thereof

ActiveCN110587165ALow heat inputImprove thermal conductivityWelding apparatusProduction lineFriction welding

The invention relates to a composite welding technology method of aluminum and an aluminum profile thereof. Heat inputs of two welding methods are adopted for being mutually complemented and utilized.According to the first kind, electric arc welding is carried out on fillet seams on the two sides of a web, and after a certain distance is kept, stirring friction welding is carried out for weldinga middle wing plate. According to the second kind, middle stirring friction welding is carried out firstly, so that a T-shaped connector is formed, and then fusion welding is carried out on the two sides. According to the composite welding technology method, by means of integrated composite welding, an automatic profile welding production line with high efficiency, high quality and relative low cost can be achieved.

Owner:抚顺创德机械设备有限公司

Large thick plate welding method and system based on double strip-shaped welding wires

ActiveCN112809138AEfficient and high-quality weldingStrong weld adaptabilityElectrode supporting devicesElectrode accessoriesThick plateWelding process

The invention provides a large thick plate welding method and system based on double strip-shaped welding wires. The method works on the basis of the double-welding-wire arc welding principle. In the welding process of a large thick plate, a welding bead layer is divided into backing welding, filling welding and cosmetic welding; and according to the characteristics of different welding bead layers, size selection and arrangement are carried out on the strip-shaped welding wires. The system comprises a double strip-shaped welding wire welding gun A, a double strip-shaped welding wire welding gun B and a welding control center. The double strip-shaped welding wire welding gun A is provided with two strip-shaped welding wires with the same width; the double strip-shaped welding wire welding gun B is provided with two strip-shaped welding wires with different widths; and the welding control center is used for presetting a welding program and controlling the double strip-shaped welding wire welding gun A and the double strip-shaped welding wire welding gun B to work according to the preset welding program. The preset welding program comprises selection of welding modes including a backing welding mode, a filling welding mode, a cosmetic welding mode I and a cosmetic welding mode II. By adopting the method and the system, high-efficiency and high-quality welding of large thick plates can be realized.

Owner:SOUTHWEST JIAOTONG UNIV

Stretch mark removing warming-up oil

InactiveCN108653007AEfficient removalPlay a warm-up roleCosmetic preparationsToilet preparationsSulfateGlycerol

The invention discloses stretch mark removing warming-up oil. The stretch mark removing warming-up oil is prepared by mixing lecithoprotein, polypropylene oxide, sodium lauryl octohydroxy sulfate, low-molecular-weight polyamide, glycerinum, tallow alkylethanolamine and deionized water and comprises the components of, by weight, 10-20 parts of lecithoprotein, 10-20 parts of polypropylene oxide, 10-20 parts of sodium lauryl octohydroxy sulfate, 0.8-1 part of low-molecular-weight polyamide, 10-15 parts of glycerinum, 0.5-1.5 parts of tallow alkylethanolamine and 30-40 parts of deionized water. The stretch mark removing warming-up oil can be smeared on a body before motion, the warming-up effect can be achieved, and stretch marks of mother athletes can further be removed effectively.

Owner:方季群

A flat-type solid oxide electrolytic cell stack bottom air intake test device

ActiveCN105161146BSolve the problem of air leakageTemperature resistantMeasurement devicesNuclear energy generationElectricityWater vapor

Owner:TSINGHUA UNIV

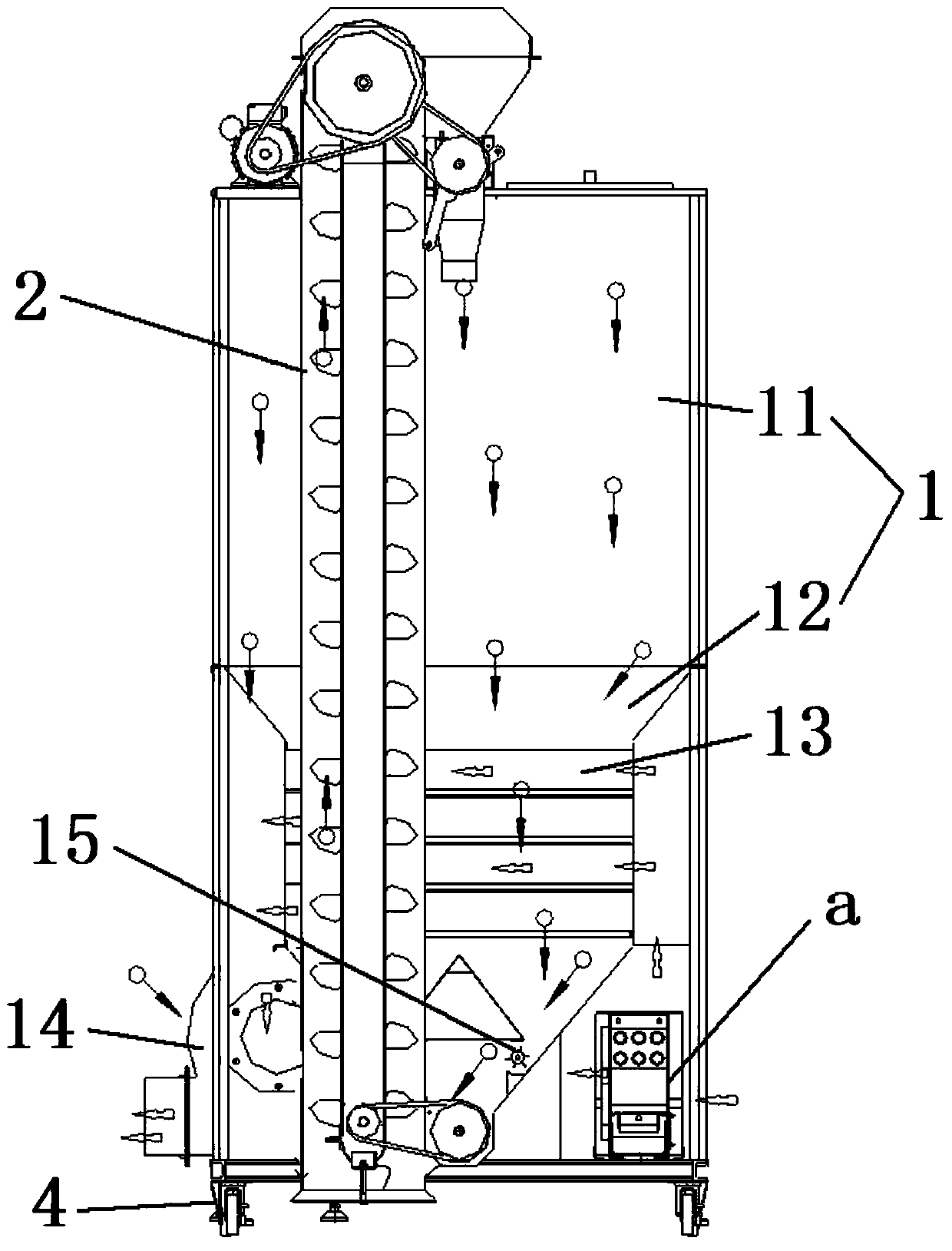

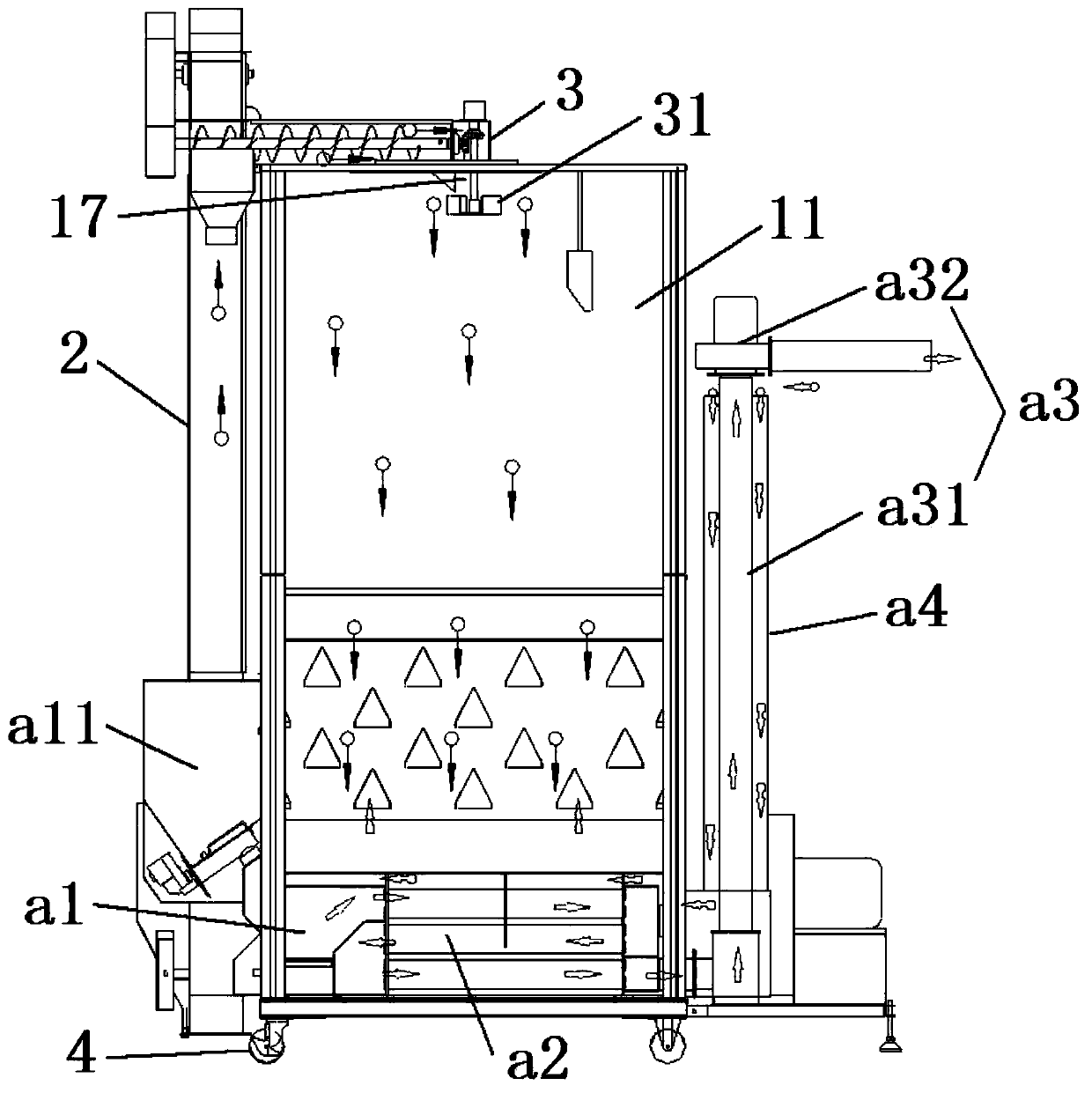

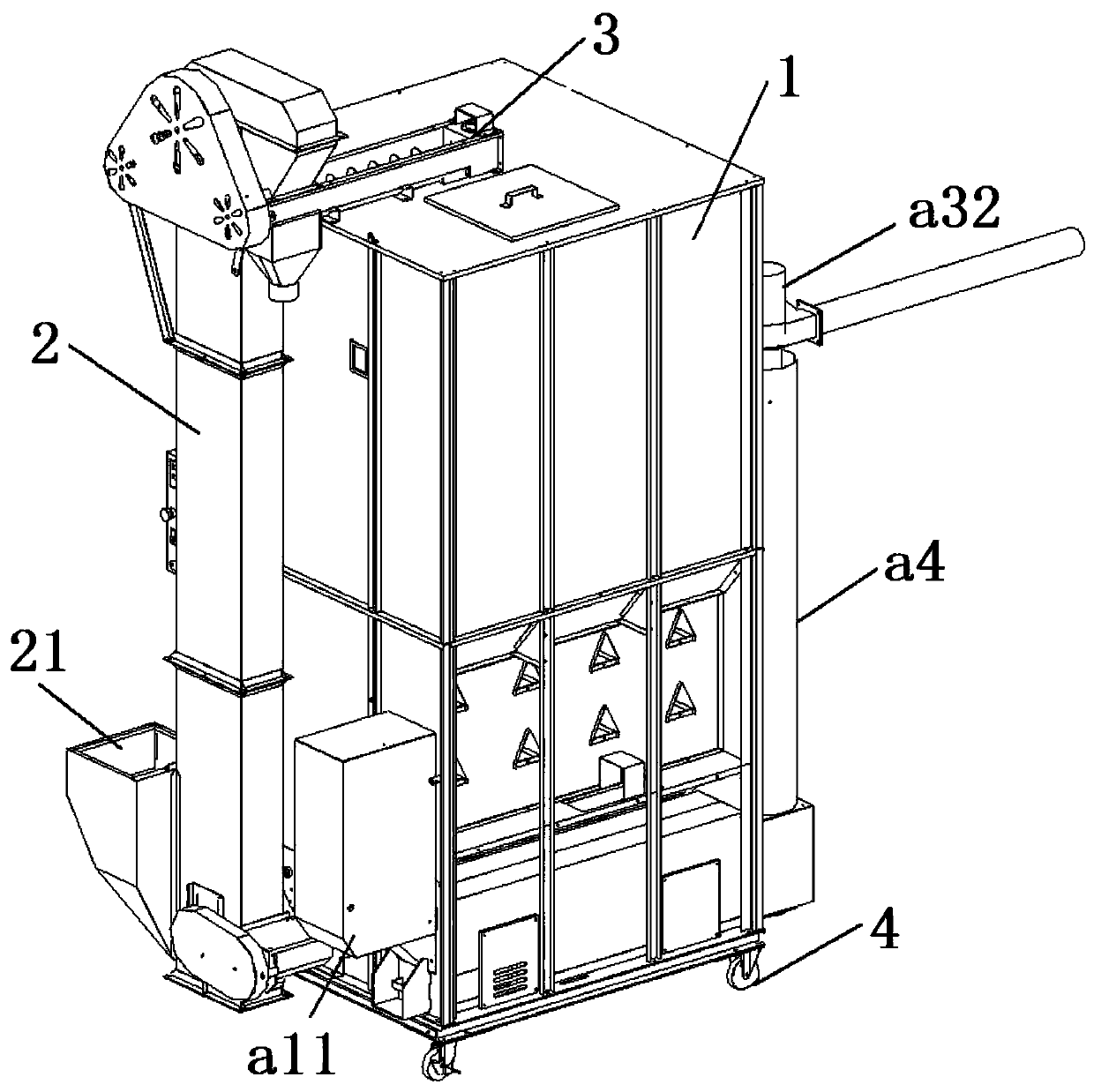

Integrated drying machine

PendingCN110793306AReduce lossesEasy to dryDrying gas arrangementsDrying solid materialsThermodynamicsHot air oven

The invention discloses an integrated drying machine which comprises a box body (1), a lifting device (2) and a hot blast stove (a). The box body (1) is divided into an upper tempering cavity (11) anda lower drying cavity (12); the lifting device (2) is used for conveying grains into the box body (1) for drying the grains and driving the grains to circulate in the box body (1); and the hot blaststove (a) is arranged in the box body (1) and used for providing hot air, and the hot air enters the drying cavity (12) to dry the grains. The integrated dryer is compact in structure, small in occupied area, convenient to arrange, capable of meeting requirements of mobile operation and capable of fully utilizing heat and reducing the heat loss.

Owner:HUNAN NONGYOU MACHINERY GRP

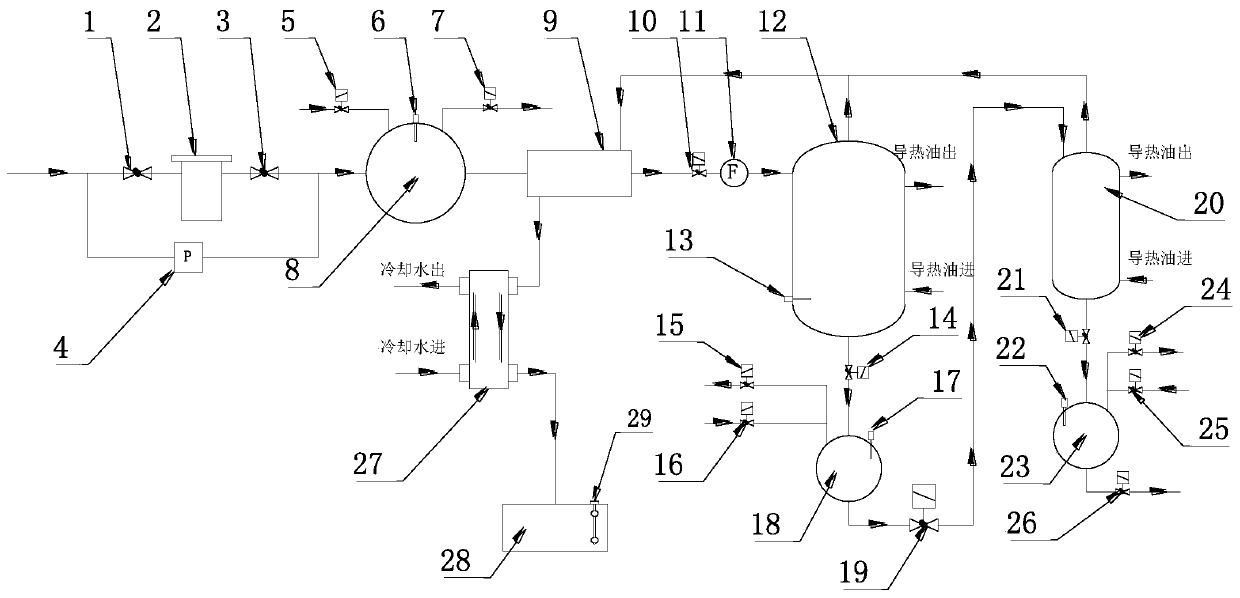

A novel distillation system of a hydrocarbon cleaning machine

PendingCN109771979APlay a warm-up roleTake advantage ofDistillation regulation/controlProcess engineeringDistillation

A novel distillation system of a hydrocarbon cleaning machine is provided. The system include a filter, a transit tank, a first heat exchanger, a second heat exchanger, a first-grade distillation tank, a second-grade distillation tank, a pure liquid tank and a drainage tank. Hydrocarbon sewage is filtrated through a filter tank to obtain a hydrocarbon filtrate; the hydrocarbon filtrate is temporarily stored in the transit tank; the hydrocarbon filtrate in the transit tank is fed into the first heat exchanger, preheated by the first heat exchanger and then fed into the first-stage distillationtank; hydrocarbon steam obtained by distilling the hydrocarbon filtrate through the first-stage distillation tank is fed into the first heat exchanger for heat exchange with the hydrocarbon filtrate,and is then cooled in the second heat exchanger to obtain pure liquid, with the pure liquid being fed into the pure liquid tank; hydrocarbon sewage obtained by distilling the hydrocarbon filtrate in the first-stage distillation tank is fed into a sewage tank, and then fed into the second-grade distillation tank, and recovered hydrocarbon steam obtained after distillation and the hydrocarbon steamobtained by distillation with the first-grade distillation tank are combined and cooled by the two heat exchangers in order to obtain pure liquid, with the pure liquid being fed into the pure liquid tank; and the hydrocarbon sewage obtained after distillation in the second-stage distillation tank is fed into the drainage tank.

Owner:江苏金色工业炉股份有限公司

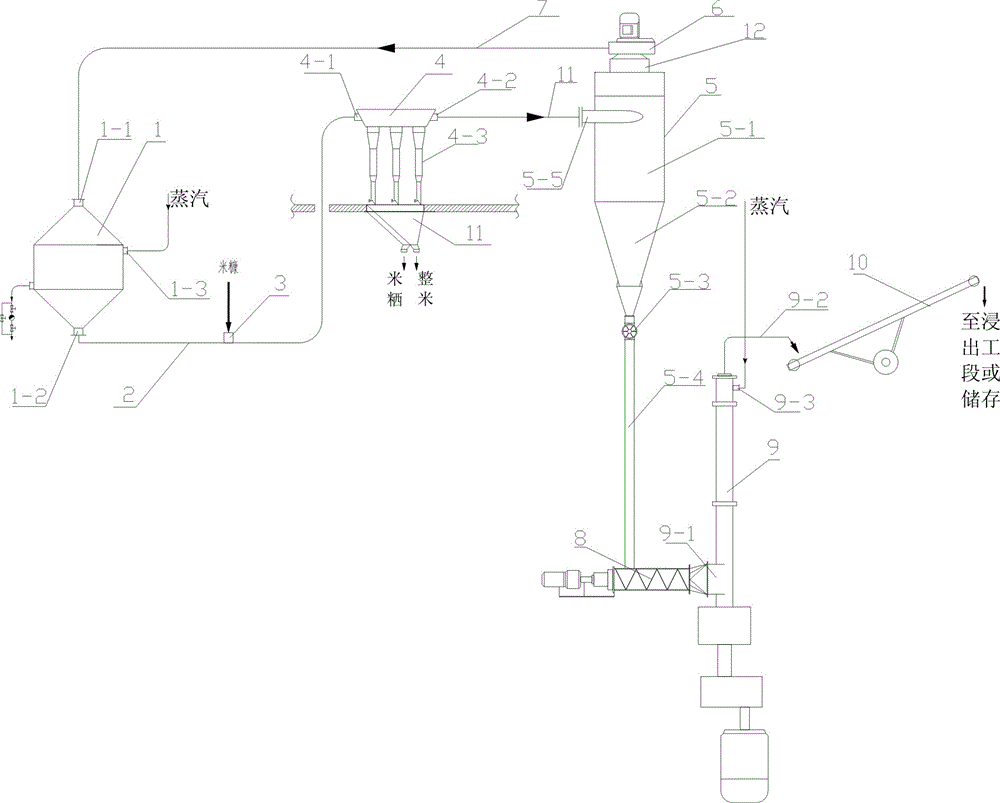

Fresh rice bran pretreatment process and matched device thereof

The invention discloses a fresh rice bran pretreatment process and a matched device thereof, belonging to the field of oil pretreatment. The process comprises the following steps: (1) performing floury product separation treatment on fresh rice bran so as to obtain purified rice bran of which the fine broken rice content is lower than 1 percent; and (2) collecting the purified rice bran, and performing sterilization, inactivation and forming treatment on the purified rice bran. The matched device comprises a floury product separator, a collecting cyclone separator, a sterilization forming machine and an air heater, wherein an air inlet of the floury product separator is communicated with a hot-air conveying pipeline; the other end of the hot-air conveying pipeline is connected with an air outlet of the air heater; a fresh rice bran inlet is formed in the hot-air conveying pipeline between the air heater and the floury product separator; an upper air outlet of the floury product separator is connected with an air inlet of the collecting cyclone separator through a pipeline; a discharge opening of the collecting cyclone separator is connected with a feeding hole of the sterilization forming machine through a feeding auger. The fresh rice bran is pretreated by utilizing the process and the device provided by the invention, the obtained rice bran is suitable for being stored for more than one month at room temperature, the acid value of leached crude rice bran oil is maintained on a low level, and the storage acid value is slowly raised.

Owner:郑州远洋油脂工程技术有限公司

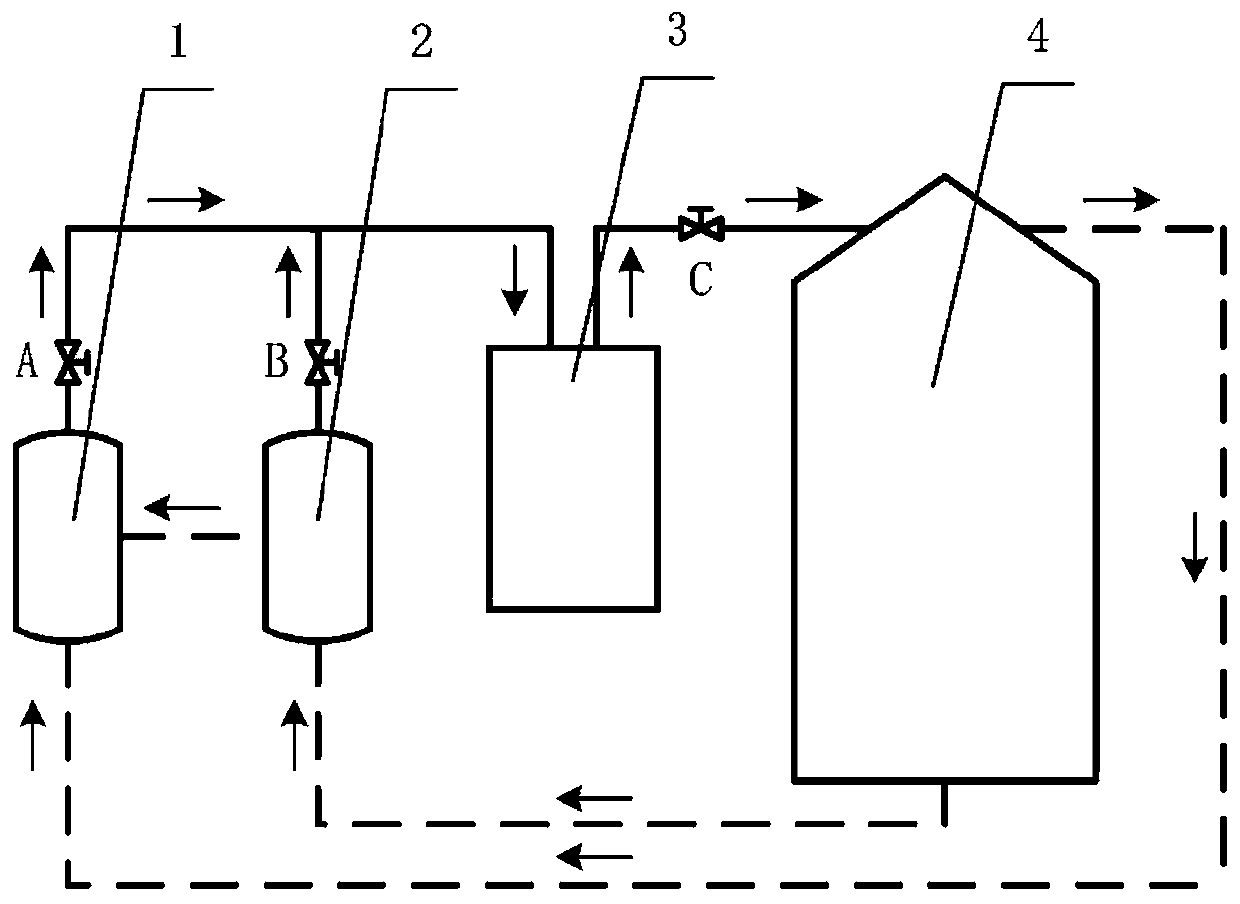

Method and system capable of using waste heat for supplying hydrogen to HCNG engine power system

ActiveCN110836153AAchieve clean and efficient useImprove thermal efficiencyNon-fuel substance addition to fuelInternal combustion piston enginesMetallic hydrogenEngineering

The invention belongs to the field of HCNG engine application, and particularly relates to a method and system capable of using waste heat for efficiently and precisely supplying hydrogen to an HCNG engine power system. The system comprises a medium-high temperature solid metal hydride hydrogen storage reactor, a low-temperature solid metal hydride hydrogen storage reactor, a fuel mixing cavity, and an SI engine. The medium-high temperature solid metal hydride hydrogen storage reactor and the low-temperature solid metal hydride hydrogen storage reactor can achieve efficient releasing of hydrogen through waste heat of the HCNG engine, meanwhile, a dual-hydrogen source can be precisely regulated to provide needed mixed hydrogen for a natural gas internal combustion engine, and stable hydrogen supply and mixed hydrogen combustion are achieved. According to the system, the waste heat of the HCNG engine is used for driving the solid-state dual-hydrogen source system to achieve efficient, precise and stable hydrogen supply, the comprehensive heat efficiency of the natural gas engine can be improved, the pollutant emission amount of the natural gas engine can be effectively reduced, and the clean and efficient use of the natural gas can be achieved.

Owner:XI AN JIAOTONG UNIV

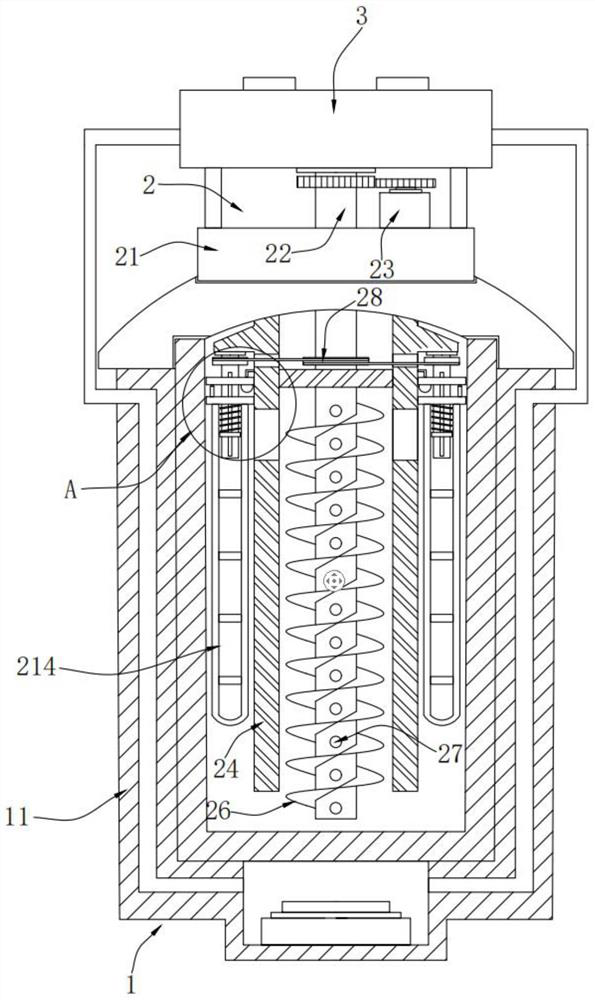

Graphite reaction kettle for hydrogen chloride production

PendingCN114192098AWell mixedImprove response qualityChemical/physical/physico-chemical reactor detailsChemical/physical/physico-chemical stationary reactorsSpiral bladeGear wheel

The present invention provides a graphite reaction kettle for hydrogen chloride production, which comprises: a base assembly, which comprises a heat transfer type graphite reaction cylinder and an exhaust port; the mixing assembly comprises a supporting seat fixedly embedded in the top of the cover plate, a hollow shaft movably penetrates through the middle of the supporting seat up and down, a spiral blade is arranged at the position, below the base plate, of the outer wall of the hollow shaft, and a plurality of sets of seepage holes are formed in the position, below the base plate, of the circumferential outer wall of the hollow shaft at equal intervals from top to bottom; and the air inlet assembly comprises an air inlet assembly which is arranged at the top of the supporting seat through a bracket. The mixing assembly is arranged, the hollow shaft rotates through the driving device and the gear set, then materials circularly flow from bottom to top through the spiral blades, hydrogen chloride gas seeps out of the seepage holes, the materials and the hydrogen chloride gas are evenly mixed, and the reaction quality is improved.

Owner:CHINA WANBAO ENG

A laser-hot wire tig composite welding method with normal wire feeding

ActiveCN110238528BSuppress heat lossIncrease temperatureLaser beam welding apparatusThick plateLaser beams

The invention relates to a laser-hot wire TIG composite welding method with normal wire feeding. The method includes: designing a welding groove on the welding part of the thick plate to be welded, and using high-power laser deep penetration welding to realize the rooting welding of the blunt edge of the groove; using laser beams, non-melting electrodes and continuously heated welding wire Composite method is used to perform layer-by-layer filling welding on the groove of the welded thick plate. During the welding process, the height position of the composite welding torch to the molten pool should be adjusted according to the thickness of the single-layer filling. In the direction of welding feed, the laser beam is set in front of the welding wire, the non-melting electrode is set behind the welding wire, and placed in an inert gas shield; The groove weld of the plate is covered by welding to complete the composite welding.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com