A flat-type solid oxide electrolytic cell stack bottom air intake test device

A technology of solid oxide and testing equipment, which is applied in the direction of measuring equipment, reactors, nuclear power generation, etc., to achieve stable testing, easy assembly, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

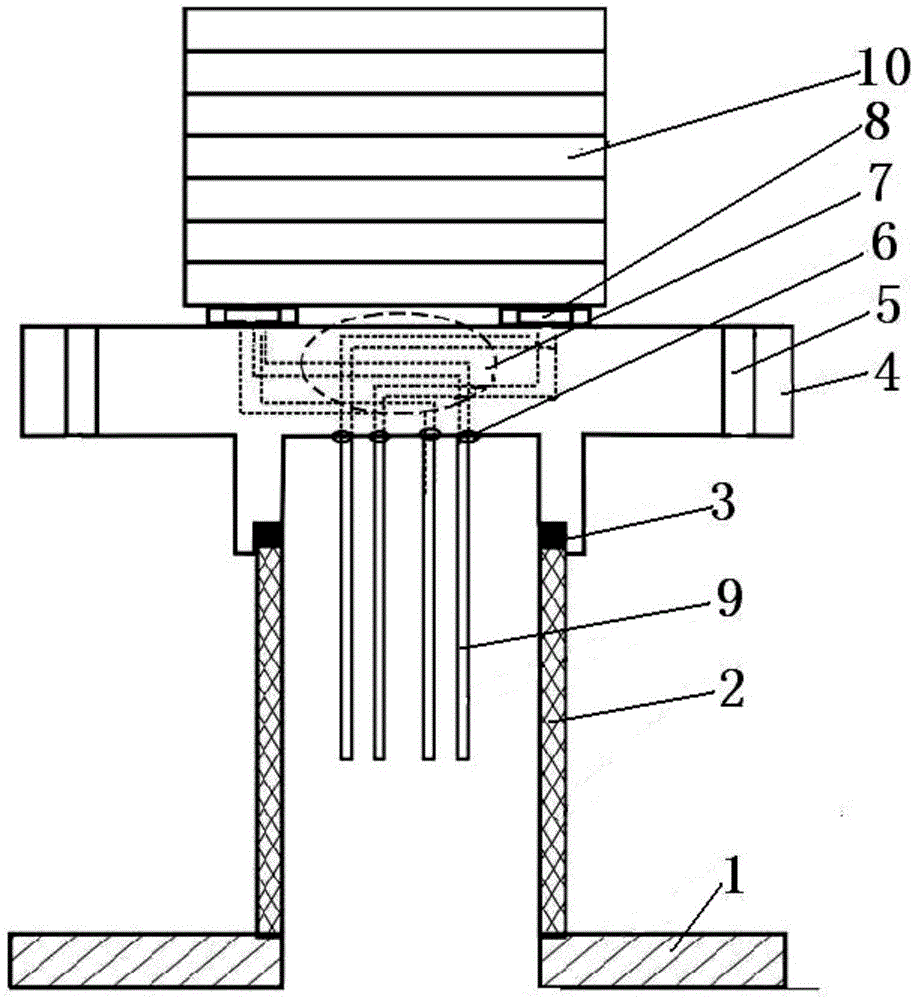

[0022] The present invention provides a flat-type solid oxide electrolytic cell stack bottom air intake test device, which is used for the operation and performance test of the solid oxide electrolytic cell stack. The present invention will be further described below in conjunction with the accompanying drawings.

[0023] figure 1 It is a schematic diagram of the structure of the air inlet test device at the bottom of a flat solid oxide electrolytic cell stack. The test device is composed of a support substrate 1, a ceramic support tube 2, a buffer gasket 3, a test base 4 and 4 stainless steel gas pipes 9. The shape of the test base 4 is that the upper part is a cuboid with a square cross section, the lower part is a torus, the axis of the torus coincides with the longitudinal centerline of the cuboid, and there is a circular step on the inner wall of the lower end of the torus.

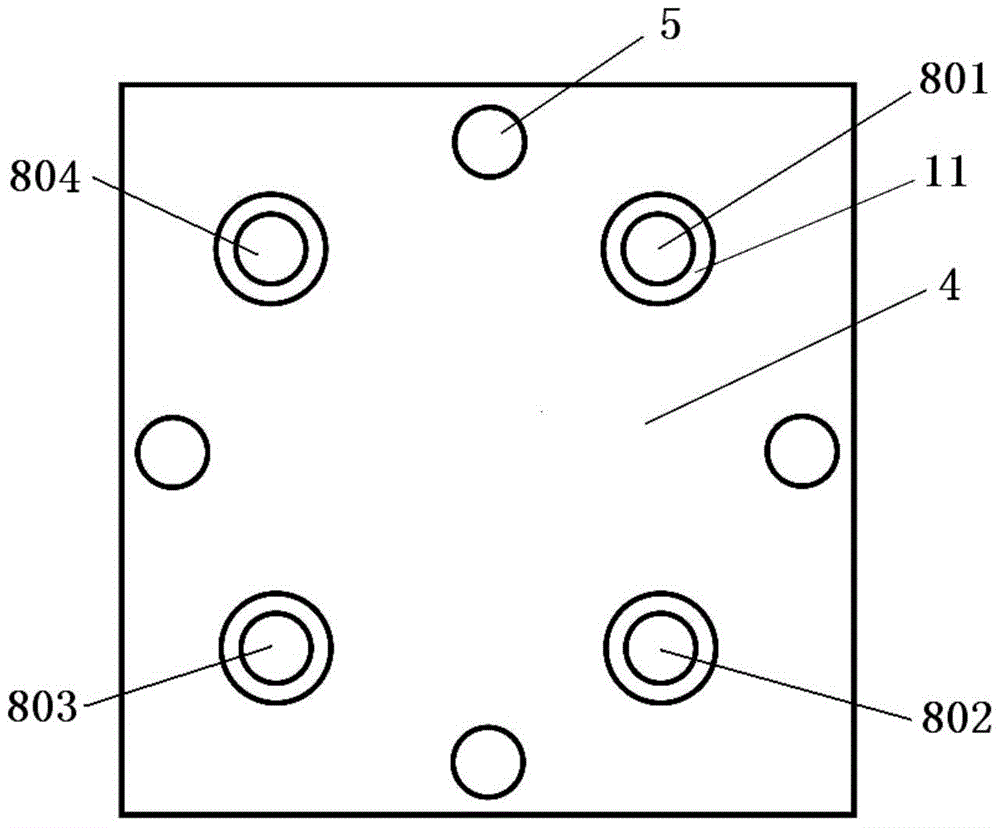

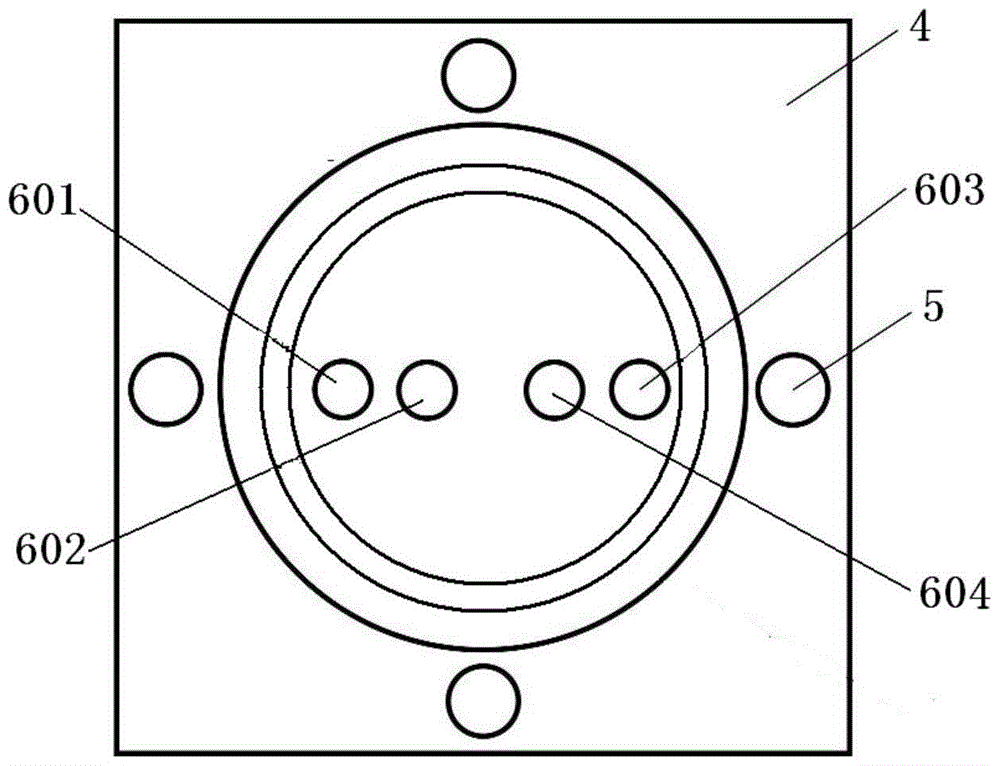

[0024] Such as figure 2 As shown in the top view of the test base, on the top surface of the te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com