Large thick plate welding method and system based on double strip-shaped welding wires

A welding method and technology for large and thick plates, applied in welding equipment, electrode characteristics, arc welding equipment, etc., can solve the problems of low welding efficiency and large groove size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0057]This example gives a large plate welding method based on a binding wire and its system.

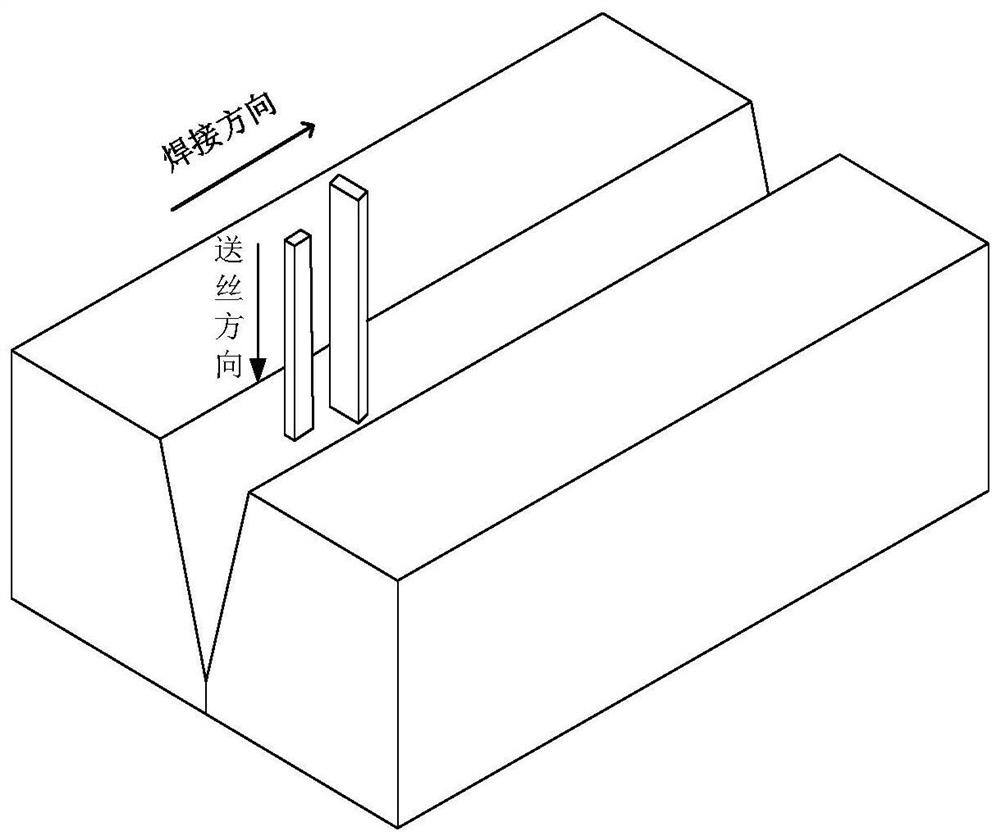

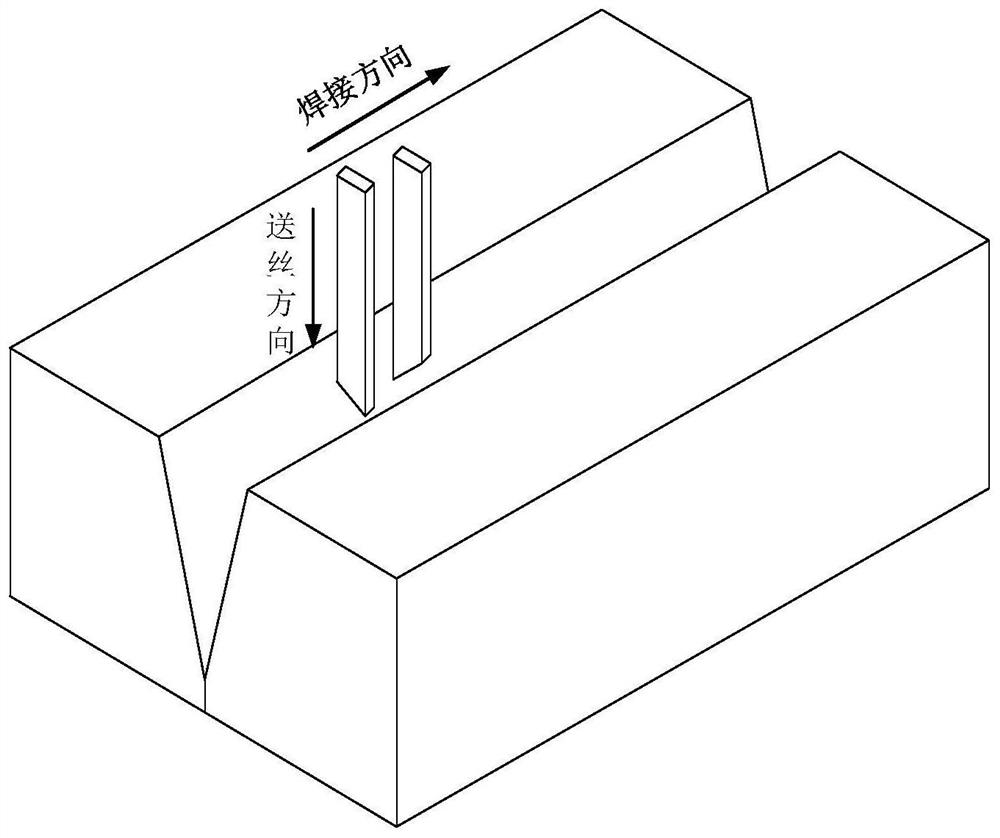

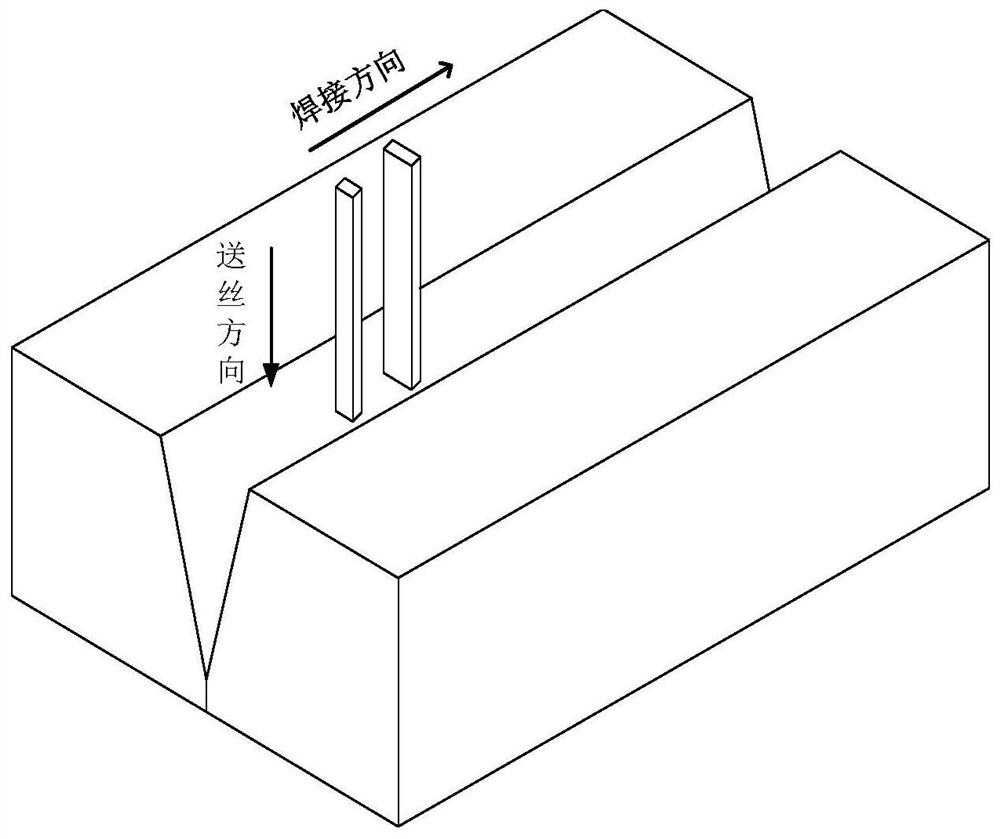

[0058]The welding method used in this example is based on the principle of the double wire arc welding. The welding wire is a strip-shaped welding wire; during the welding of the plate, the soldering tunle is divided into bottom welding, filling welding, cover welding; according to different welding The characteristics of the road layer are selected and arranged for strip-shaped wires, including:

[0059]The length and width of the strip-shaped wire is a wide surface, the length of the strip welding wire and the thickness of the thickness are narrow, and the width of the strip-shaped wire is greater than its thickness; during the welding process, the two strip-shaped welding wires The strip-shaped welding wire before the welding direction is called a front strip-shaped welding wire, and the backward wire is referred to as a rearband welding wire.

[0060]Bottling double strip welding wire selectio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com