Molybdenum/steel dissimilar metal laser melt-brazing welding method

A technology of dissimilar metals and welding methods, applied in welding equipment, metal processing equipment, auxiliary equipment, etc., can solve the problems of limited size and form of joints, limited application range, slow welding speed, etc., and achieve no thermal influence on the molybdenum side of cracks zone, reduce residual stress, high-efficiency and high-quality welding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

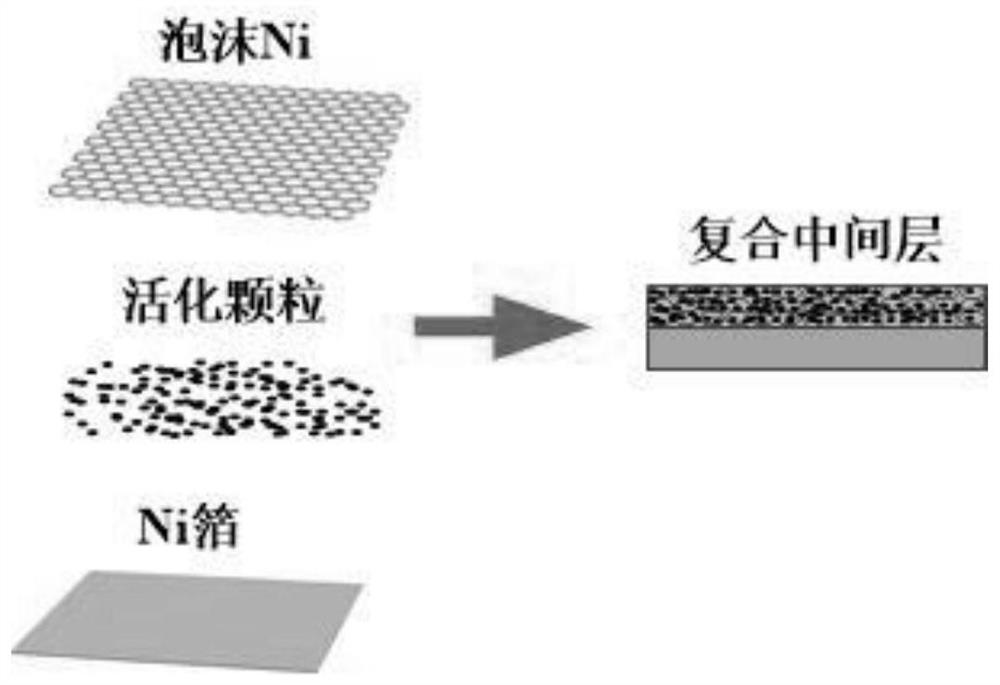

[0031] Example 1: Preparation of active element doped three-dimensional network composite interlayer

[0032] Lay 0.1mm-thick foam Ni and 0.1mm-thick Ni foil, and connect local areas with laser spot welding to form a Ni skeleton; mix activated element B powder into 50ml of ethanol, and the amount of B powder is the mass of the composite middle layer 0.2% of the solution is uniformly dispersed by ultrasonic stirring, and the solution is evenly poured onto the Ni skeleton, and dried or dried to form an activated element-doped three-dimensional network composite middle layer.

Embodiment 2

[0033] Example 2: Preparation of active element doped three-dimensional network composite interlayer

[0034] Lay 0.2mm-thick foam Ni and 0.2mm-thick Ni foil, and connect local areas with laser spot welding to form a Ni skeleton; mix activated element B powder into 80ml ethanol, and the amount of B powder is the mass of the composite middle layer 1%, ultrasonically stirred to disperse evenly, the solution was evenly poured onto the Ni skeleton, and dried or dried to form an activated element-doped three-dimensional network composite middle layer.

Embodiment 3

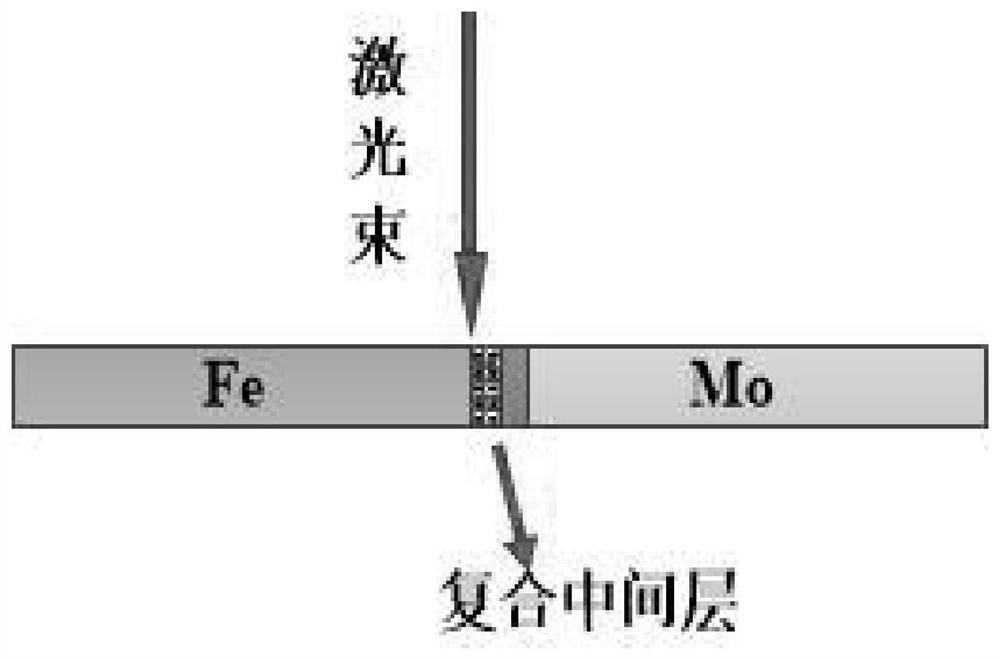

[0035] Example 3: Molybdenum / steel dissimilar metal laser welding

[0036] In order to obtain high-quality molybdenum / steel dissimilar metal joints, pure Mo and 301 stainless steel are laser welded. The pure Mo plate is the same size as the 301 stainless steel plate, which is 200mm (length) × 100mm (width) × 1mm (thickness). The 0.2mm thick activating element is doped with a three-dimensional network composite middle layer (prepared in Example 1, figure 1 ) placed between the pure Mo plate and the 301 stainless steel plate, the welding consumables are clamped by the fixture, and the welding heat source is placed at the composite intermediate layer / steel interface, such as figure 2 shown. Welding is performed under an argon protective atmosphere. Among them, the pulse laser welding process parameters are: laser power 800W, welding speed 1200mm / min, defocus amount 0mm, protective gas flow rate of 12L / min for the front and 10 / min for the back.

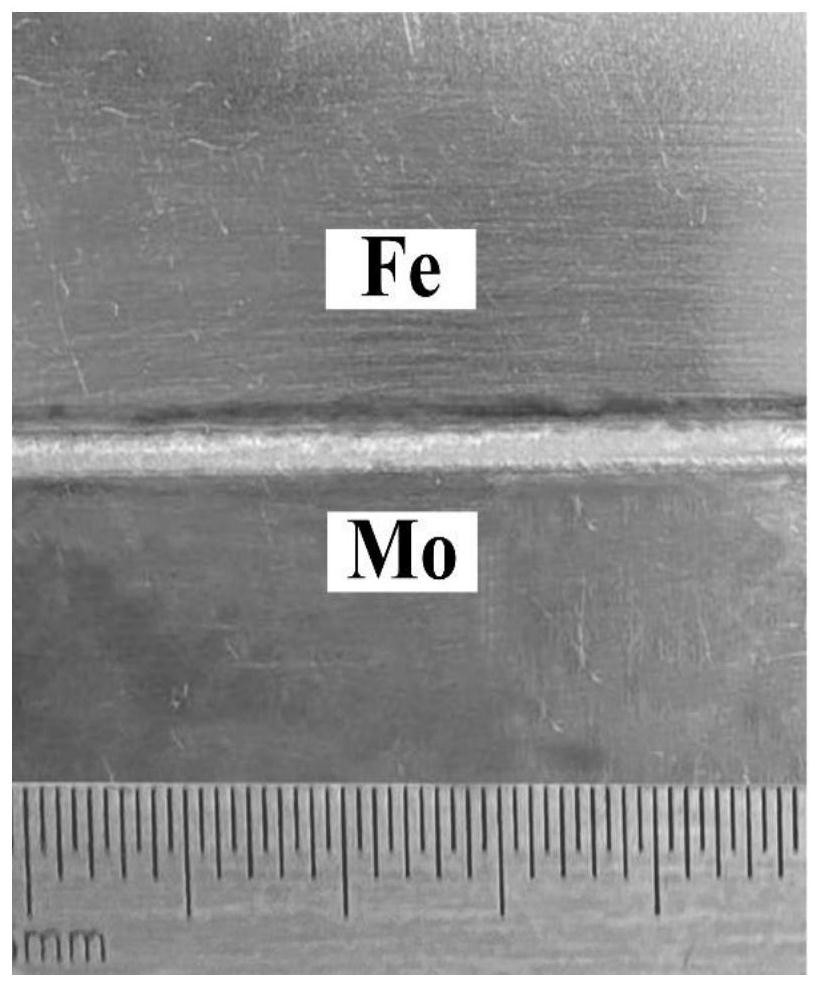

[0037] The resulting molybdenum / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com