Patents

Literature

30results about How to "Reduced propensity to form" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for eliminating cracks of hot processed surface of 2205 dual-phase stainless steel middle plate

InactiveCN106391704AQuality improvementNo crackWork treatment devicesMetal rolling arrangementsReduction rateMetallurgy

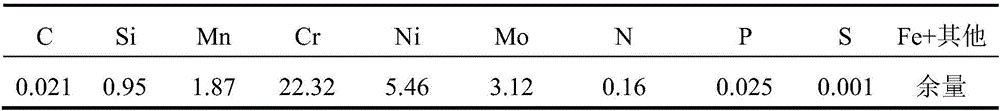

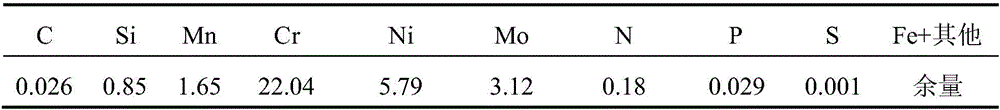

The invention belongs to the technical field of stainless steel rolling, and particularly discloses a method for eliminating cracks of a hot processed surface of a 2205 dual-phase stainless steel middle plate. The method is characterized by comprising the steps that blank selection and grinding are carried out; a cast blank is heated, specifically, the temperature of a preheating section is 1100-1150 DEG C, the temperature of a heating section is 1150-1240 DEG C, the temperature of a soaking section is 1220-1240 DEG C, and for every 10 mm of the cast blank thickness, the furnace standing time is 9-10 min; scale removal is carried out with water of high pressure of 20-25 MPa; the initial rough rolling temperature is higher than 1150 DEG C, the reduction rate is smaller than 25%, rolling is carried out for 8-11 passes, and the thickness of an intermediate blank is 35-45 mm; and the initial finish rolling temperature is larger than 1050 DEG C, the final rolling temperature is larger than 950 DEG C, the reduction rate is smaller than 18%, and rolling is carried out for 8-12 passes. The method has the advantages that the blank specifications are selected reasonably, parameters such as rolling temperature and reduction rate are matched reasonably after grinding and optimal heating, and the surface crack defect of the 2205 dual-phase stainless steel middle plate is effectively avoided.

Owner:NORTHEASTERN UNIV

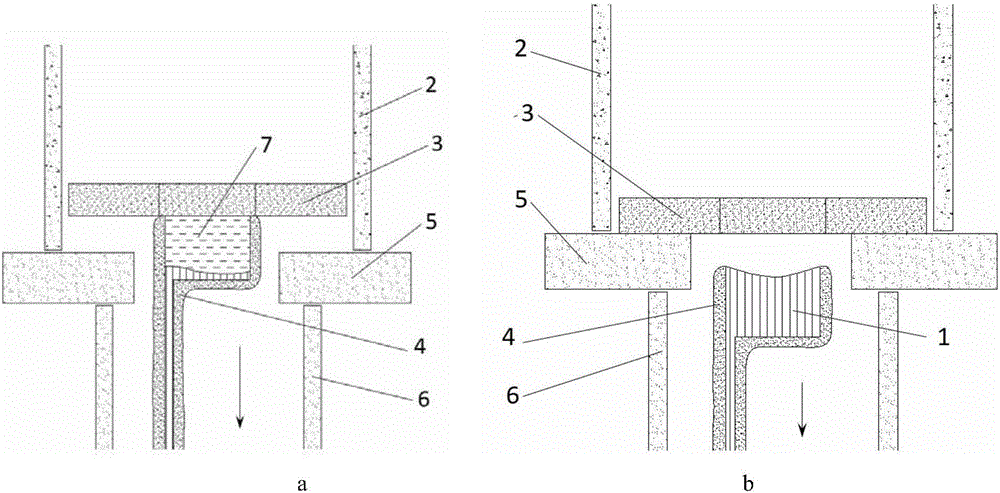

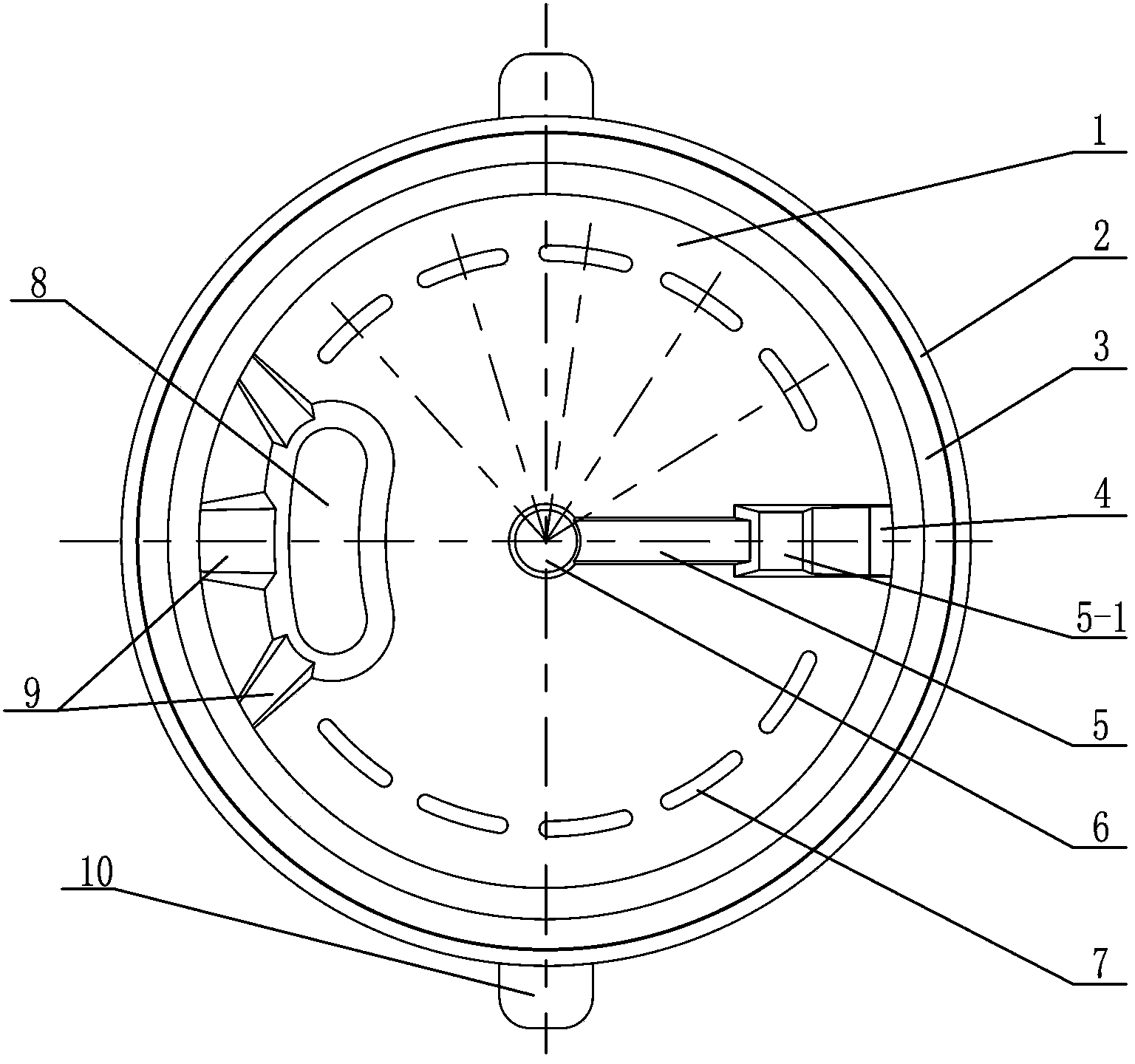

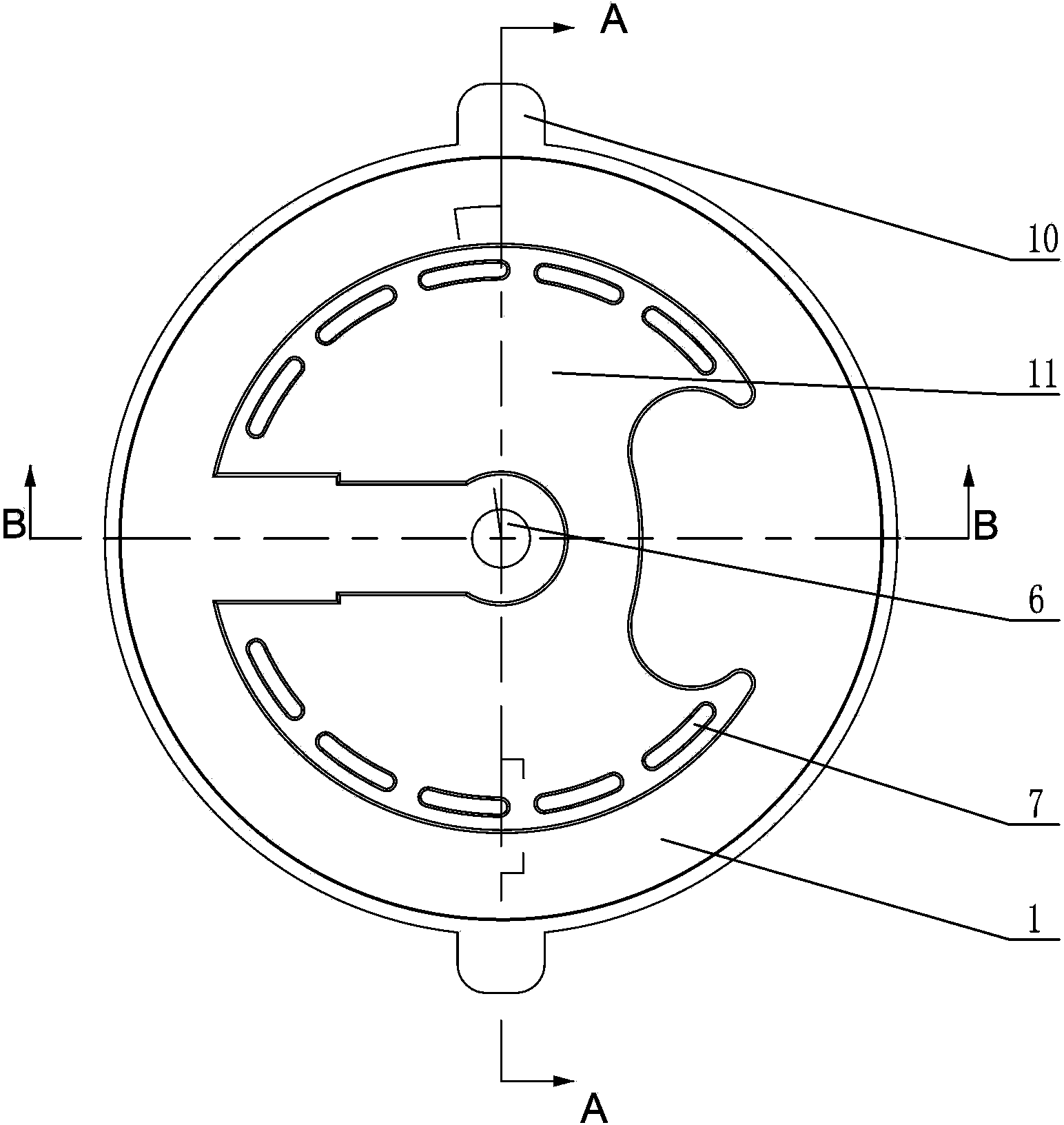

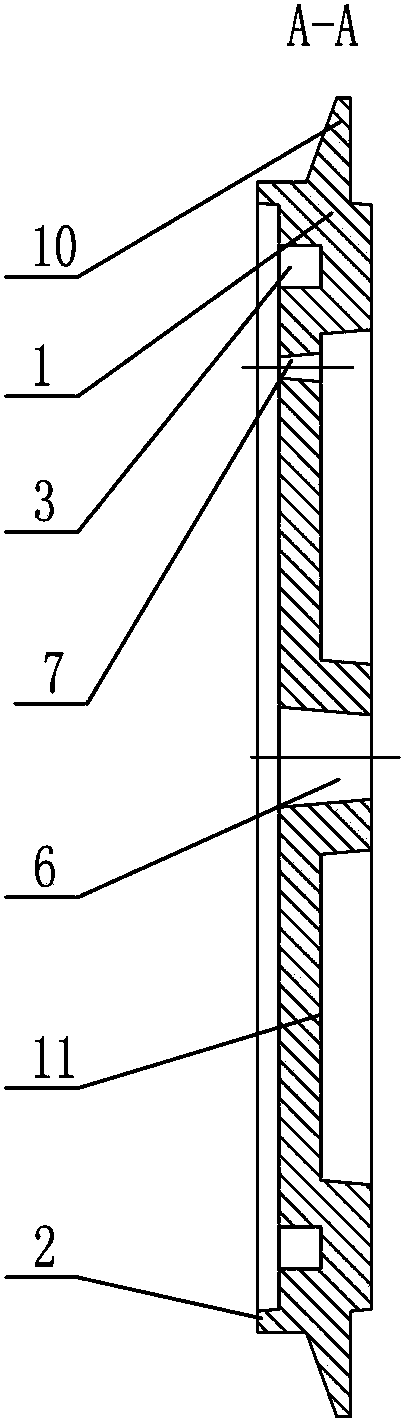

Sand mould of precoated sand for casting single piston ring and manufacturing method of sand mould

ActiveCN102699280AStable qualityGood internal qualityFoundry mouldsFoundry coresMaterials scienceProcessing cost

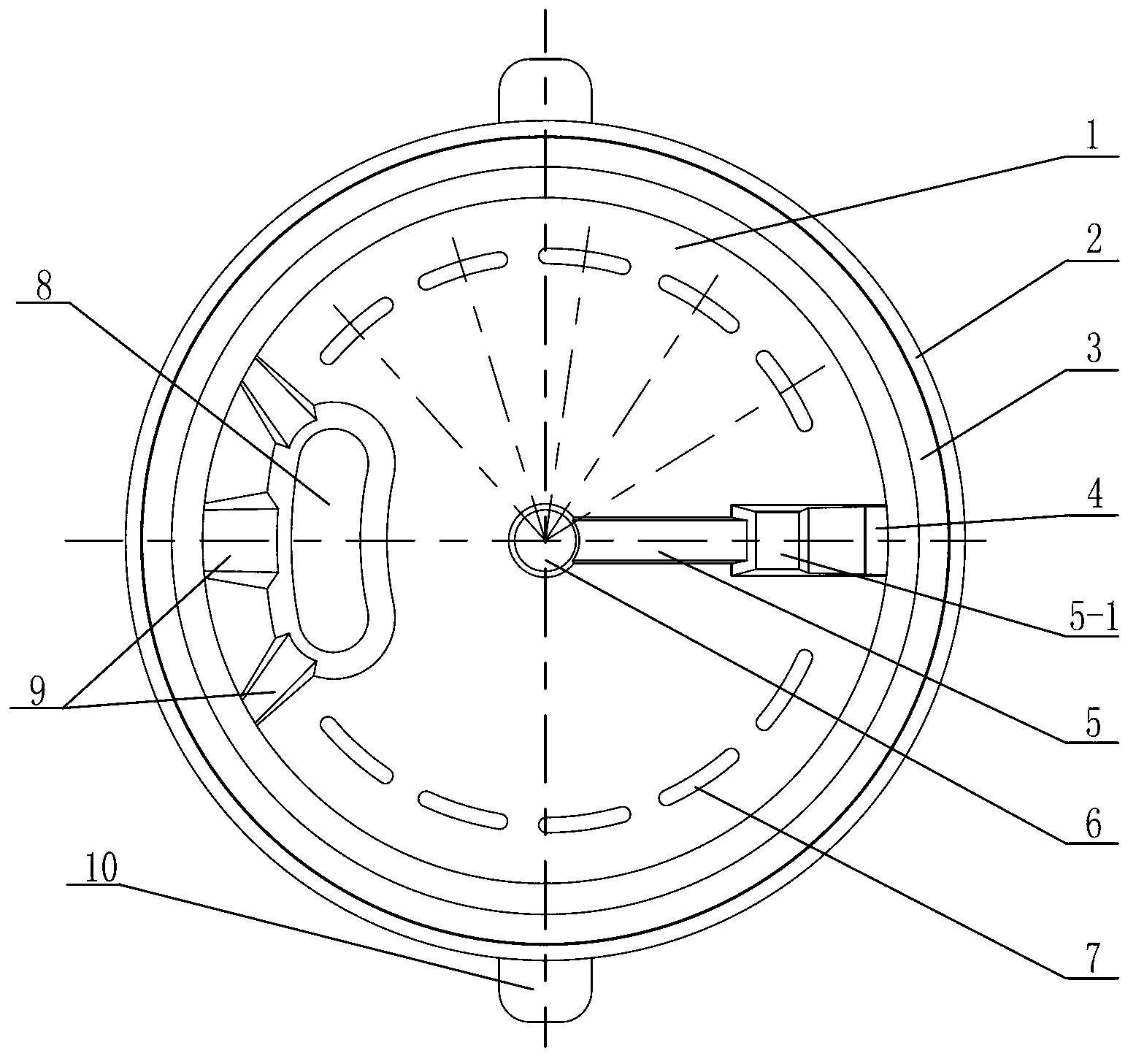

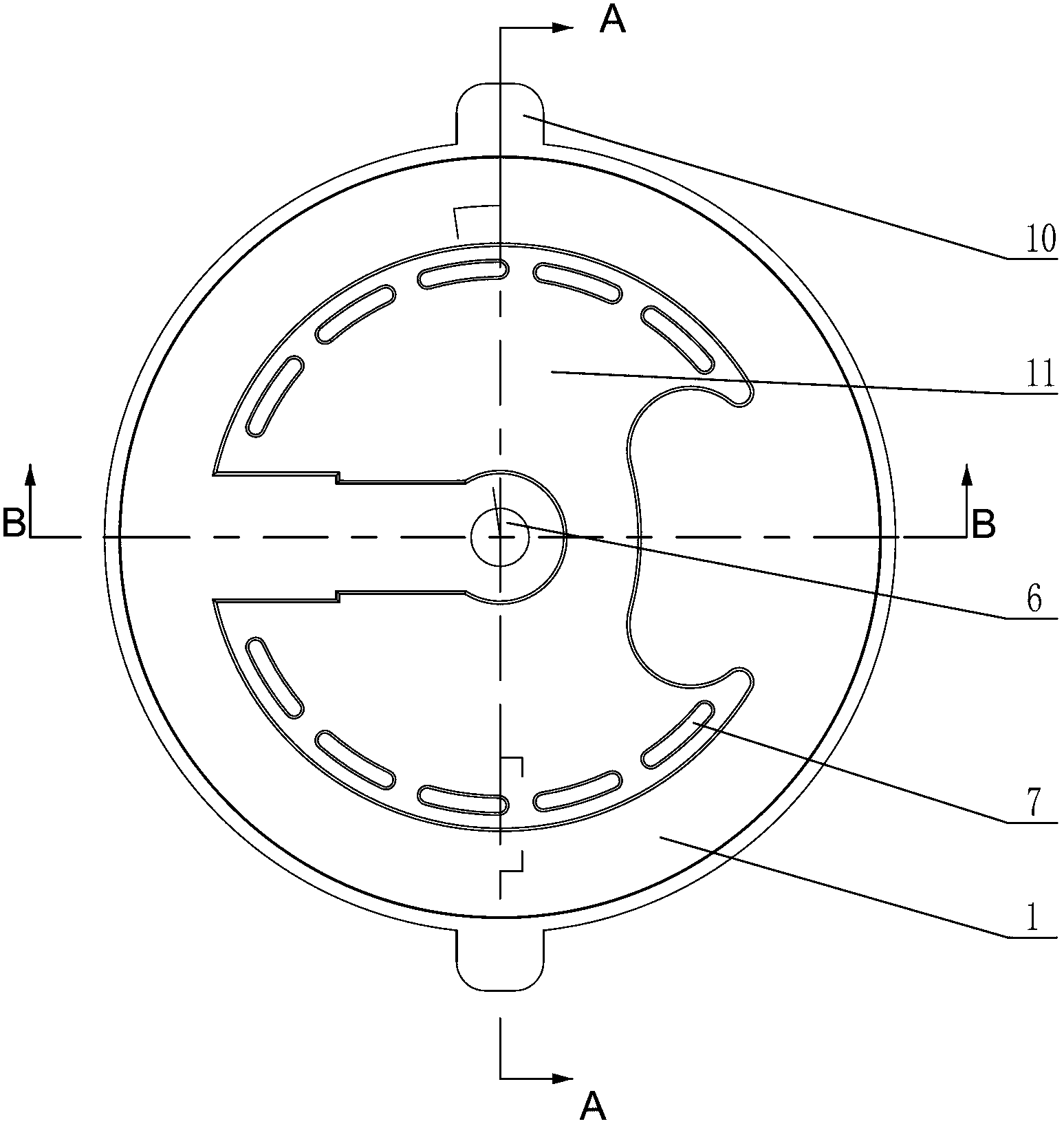

The invention relates to a sand mould of precoated sand for casting single piston ring and a manufacturing method of the sand mould. The sand mould comprises a circular tray body, a pouring system arranged on the circular tray body, a retainer ring and air outlet holes, wherein the pouring system comprises a downsprue, a flow gate, a cross gate and a dead head, the downsprue penetrates through the middle part of the circular tray body, the flow gate arranged on the facade of the circular tray body is communicated with the downsprue through the cross gate, the flow gate is communicated with a ring body groove, the dead head is arranged to be opposite to the flow gate, and the dead head is communicated with the ring body groove through more than two inclined pouring gates; and the retainer ring higher than the surface of the sand mould is arranged on the periphery of the facade of the circular tray body, and more than four air outlet holes passing through the circular tray body are symmetrically arranged on the inner side of the ring body groove between the cross gate and the dead head along the axial line of the cross gate. The piston ring processed by the invention is stable in quality and high in yield, the piston ring casting has the advantages of clear outline, high dimension precision and good surface quality, and the piston ring casting is liable to clean, thereby reducing the processing allowance, reducing the successive processing cost and improving the production efficiency.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

Diffusion welding connecting method adopting Cu foil and Ti foil as composite interlayer

ActiveCN109014549AForm to avoidFully consider compatibilityWelding/soldering/cutting articlesNon-electric welding apparatusRoom temperatureHeating furnace

The invention relates to a method for connecting a nickel-based superalloy with a Ti2AlNb alloy or a Ti3Al-based alloy, in particular to a diffusion welding connecting method adopting Cu foil and Ti foil as a composite interlayer. The diffusion welding connecting method comprises the steps that the nickel-based superalloy and the Ti2AlNb alloy or the Ti3Al-based alloy are processed into the neededsizes, ground and polished; the Cu foil and the Ti foil are subjected to oxidation film removing, and are placed into acetone with a welded base material to be subjected to ultrasonic cleaning; and the Cu foil makes contact with the nickel-based superalloy, the Ti foil makes contact with the Ti2AlNb alloy or the Ti3Al-based alloy, and thus a welded test piece with the structure of the Ti2AlNb alloy or the Ti3Al-based alloy / the Ti foil / the Cu foil / the nickel-based superalloy is obtained, a welded workpiece is placed into a vacuum heating furnace, the pressure is applied, and welding is completed after heating, heat preservation and cooling heat circulating. The welding temperature can be lowered, forming of a brittle phase of a joint is controlled, and the property of the joint is improved; and the obtained shearing strength of the joint at the room temperature reaches 240-310 MPa.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

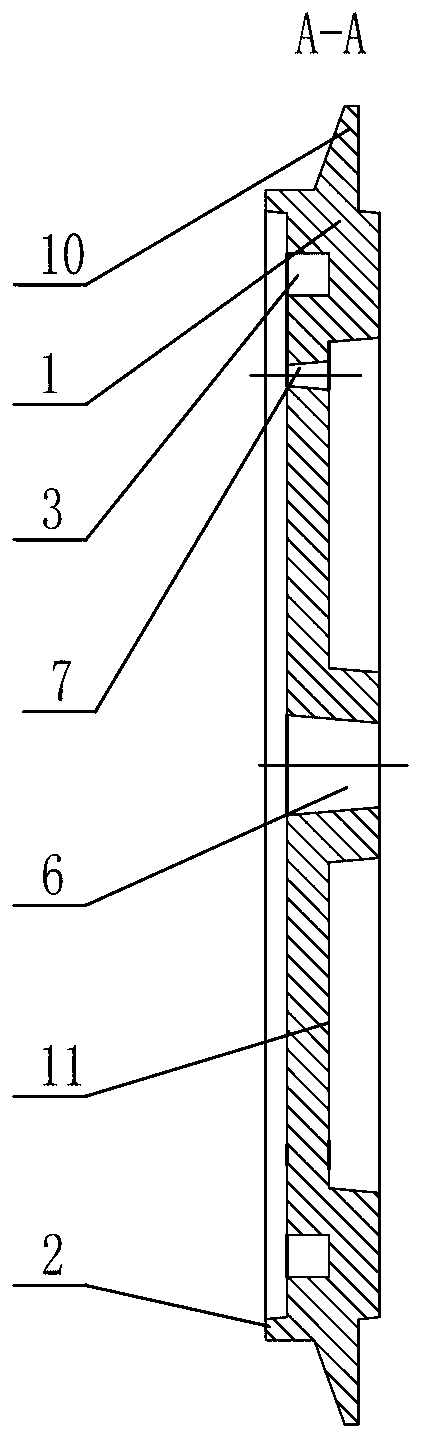

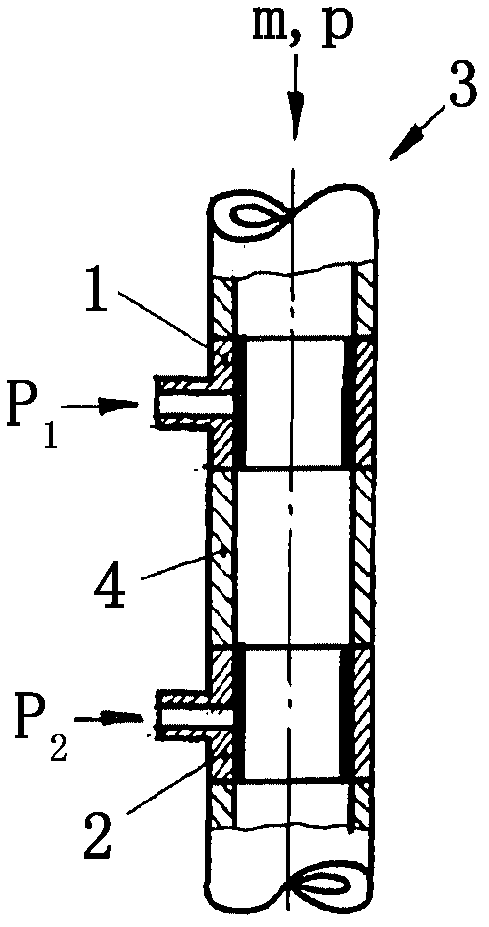

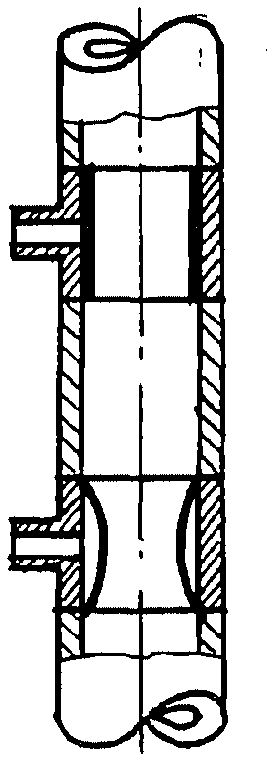

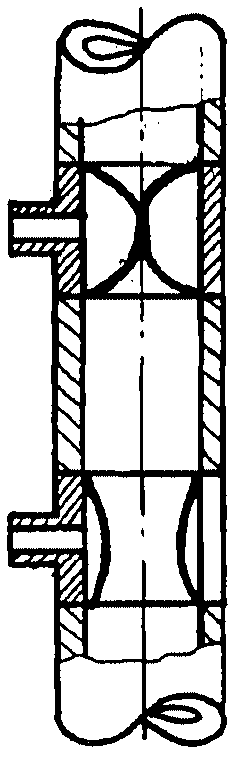

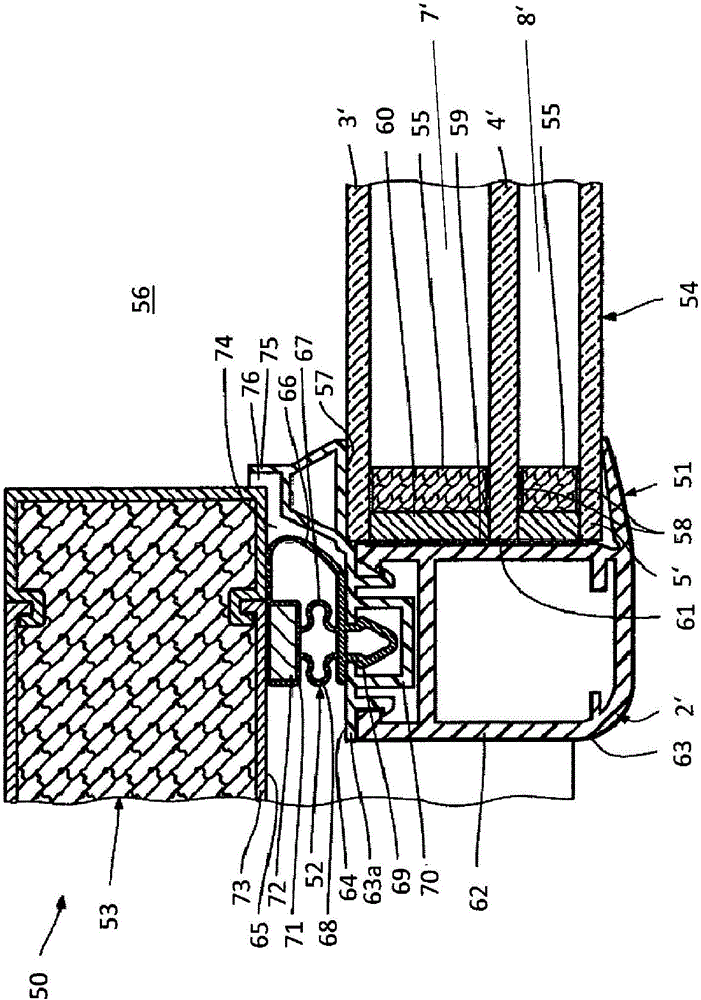

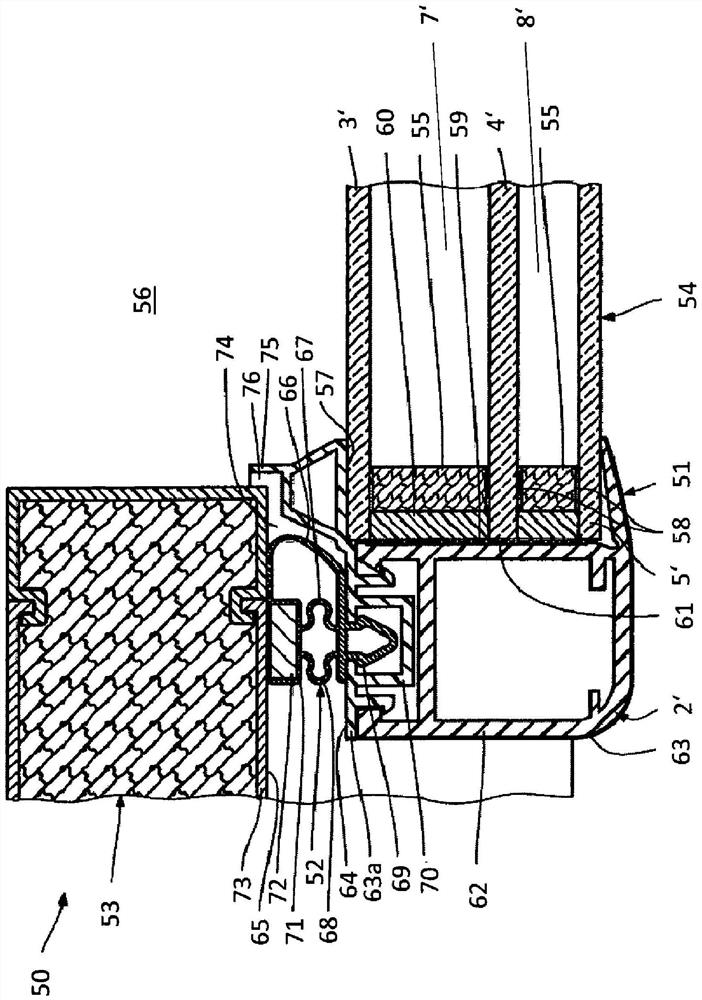

Method, controller, valve arrangement, and portioning device for portioning a flowable, optionally pressurized mass

InactiveCN102388297AIncrease volumeRelieve pressureDiaphragm valvesContracting/expanding measuring chambersPinch valveEngineering

The invention relates to a method for portioning a flowable, pressurized mass (m). In a first step, a first pinch valve (1, 1a..1c) is opened and a second pinch valve (2, 2a..2c) arranged thereafter in a main flow direction of the mass (m) is slightly closed. As soon as a desired amount of the mass (m) has passed the pinch valves (1, 1a..1c, 2, 2a..2c), the first pinch valve (1, 1a..1c) is closed. Afterwards, the second pinch valve (2, 2a..2c) is opened. The opening, the slight closing, and the closing of the first pinch valve (1, 1a..1c) and of the second pinch valve (2, 2a..2c) occur by means of a pressure medium. The invention further relates to a controller, to a valve arrangement (3), and to a portioning device for performing the method according to the invention.

Owner:莱奥·布勒尔

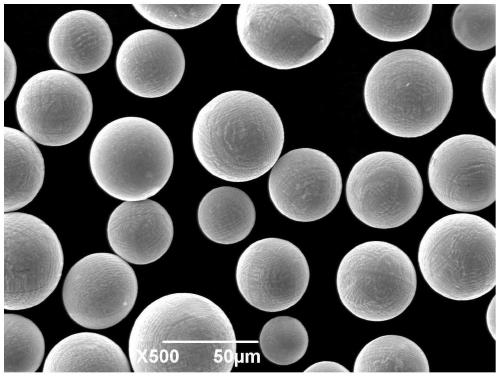

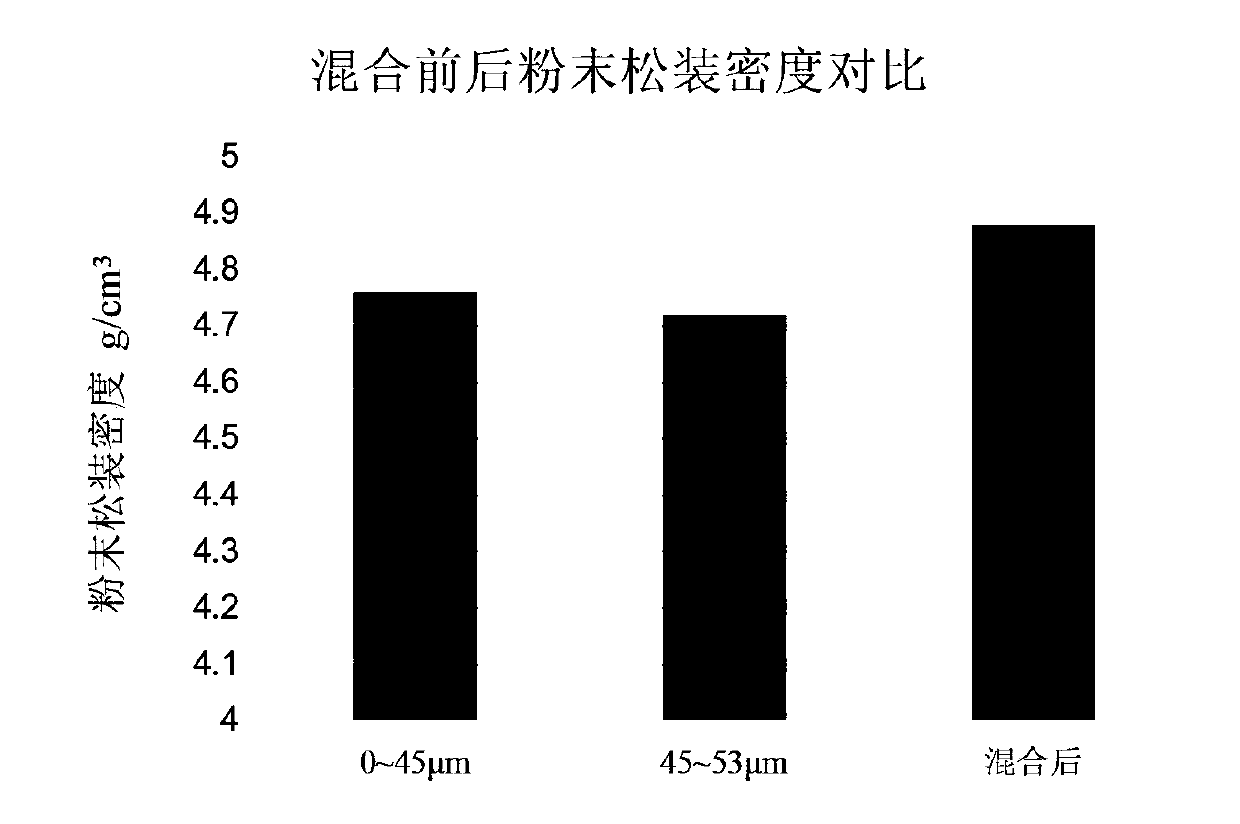

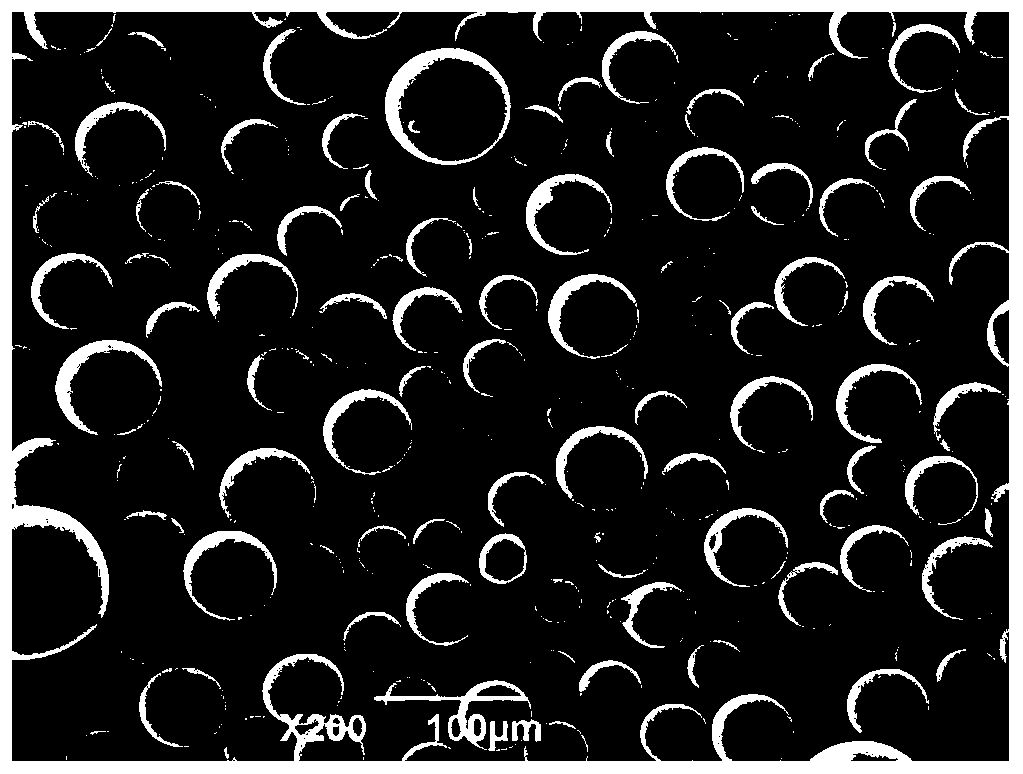

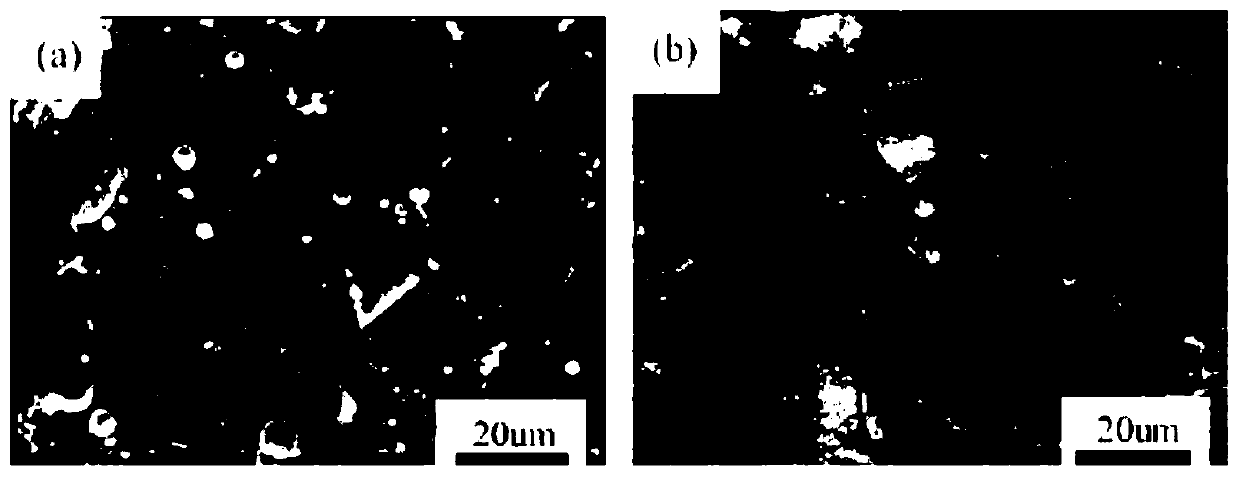

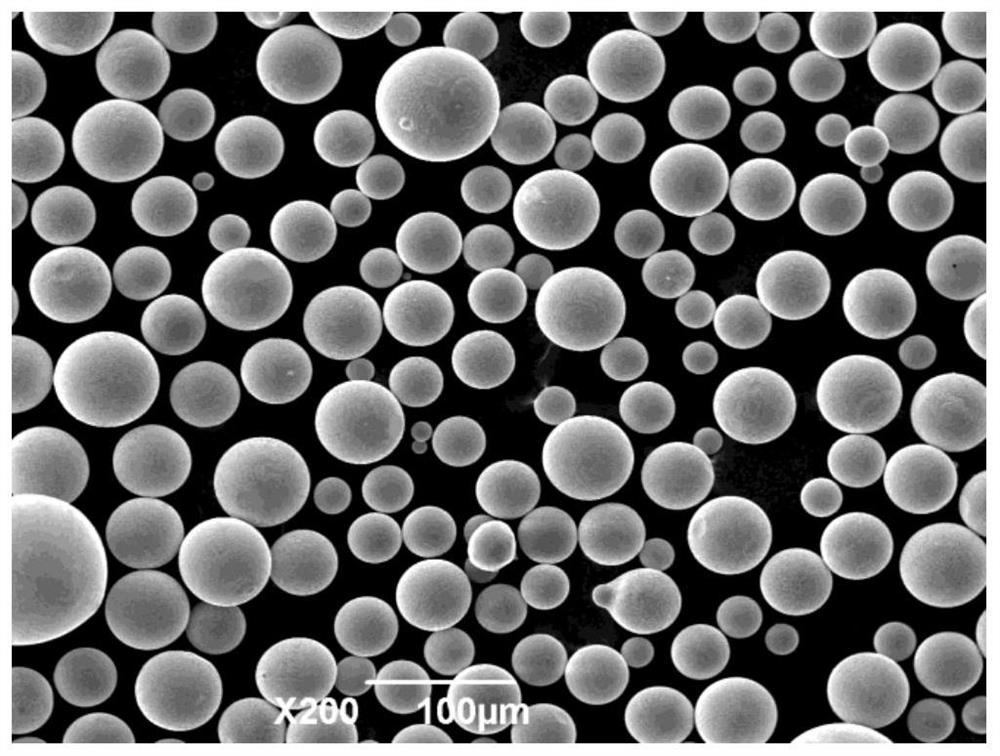

Preparation method of ferronickel-based alloy spherical powder for 3D printing

ActiveCN111570812AReduced propensity to formDrop high temperature stretchAdditive manufacturing apparatusTransportation and packagingChemical compositionMetal sphere

The invention discloses a preparation method of ferronickel-based alloy spherical powder for 3D printing. The preparation method comprises the following steps that 1) burdening is conducted by using the following chemical composition proportion of, in percentage by mass, 44.77%-51.5% of Ni, 18%-20% of Fe, 21.0%-22.5% of Cr, 1.0%-2.0% of Co, 8.0%-9.5% of Mo, 0.5%-1.0% of W, 0%-0.02% of C, 0%-0.01%of Mn and 0%-0.2% of Si; 2) the ingredients in the step 1) are prepared into an alloy ingot by adopting a vacuum induction melting horizontal continuous casting process, a shrinkage cavity defect at the head of the alloy ingot is removed, and then the alloy ingot is machined into an electrode bar; 3) the electrode bar in the step 2) is placed in a plasma rotating electrode powder making machine toform metal spherical powder; and 4) the prepared metal spherical powder is screened by adopting an ultrasonic vibrating screen under the protection of high-purity argon to obtain the ferronickel-based alloy spherical powder for the 3D printing.

Owner:SINO EURO MATERIALS TECH OF XIAN CO LTD

Antioxidant nickel-based high-temperature alloy powder and preparation method thereof

ActiveCN110629074AReduced propensity to formAvoid it happening againTransportation and packagingMetal-working apparatusElectrostatic separationIngot

The invention discloses antioxidant nickel-based high-temperature alloy powder and a preparation method thereof. Ni, Cr, W and other alloy elements are taken in proportion, the alloys are firstly putinto a vacuum induction furnace for melting and then put into in a vacuum self-consuming furnace for remelting to obtain a mother alloy ingot, and the mother alloy ingot is made into an electrode bar;the electrode bar is put into a plasma rotating electrode powder making machine, and the end of the electrode bar is melted by using a plasma gun to obtain spherical powder; screening is conducted onthe spherical powder through an ultrasonic vibrating sieve; and electrostatic separation is conducted on the spherical powder to remove non-metallic impurities from the spherical powder to obtain pure alloy powder. By means of the preparation method of the antioxidant nickel-based high-temperature alloy powder, by adopting Nb element to replace a part of W element, the content of W element is reduced, the forming tendency of carbon oxide of W is weakened, and the content of the carbon oxide of W in the alloy is significantly reduced.

Owner:SINO EURO MATERIALS TECH OF XIAN CO LTD

Method for solid-phase diffusion connection of hard alloy by utilizing nano-Co intermediate layer

ActiveCN105728928ARealize solid phase diffusion connectionSolid phase diffusion connection is reliableNon-electric welding apparatusAlloySand-paper

The invention relates to a method for solid-phase diffusion connection of hard alloy by utilizing a nano-Co intermediate layer. The method comprises the steps of polishing a to-be-welded surface of a hard alloy sample by using sand paper, and carrying out ultrasonic cleaning in an acetone solution; mixing nano-Co with absolute ethyl alcohol to form paste, coating the paste on the to-be-welded surface of the hard alloy, and assembling to form an assembly part of hard alloy / nano-Co / hard alloy; and placing the assembly part into a vacuum heating furnace, applying 10-20MPa pressure, starting to heat when the vacuum of the vacuum heating furnace reaches up to (1.5-2.0)*10<-3>Pa, controlling the in-furnace heating speed at 10-20 DEG C / min, heating to 1100-1300 DEG C, then, preserving the heat for 20-40 min, next, controlling the cooling speed at 5-10 DEG C / min, cooling to 400 DEG C, and then, carrying out furnace cooling. The method is simple in process, low in cost, simple in operation, high in efficiency and capable of realizing reliable connection of the hard alloy.

Owner:HARBIN INST OF TECH AT WEIHAI

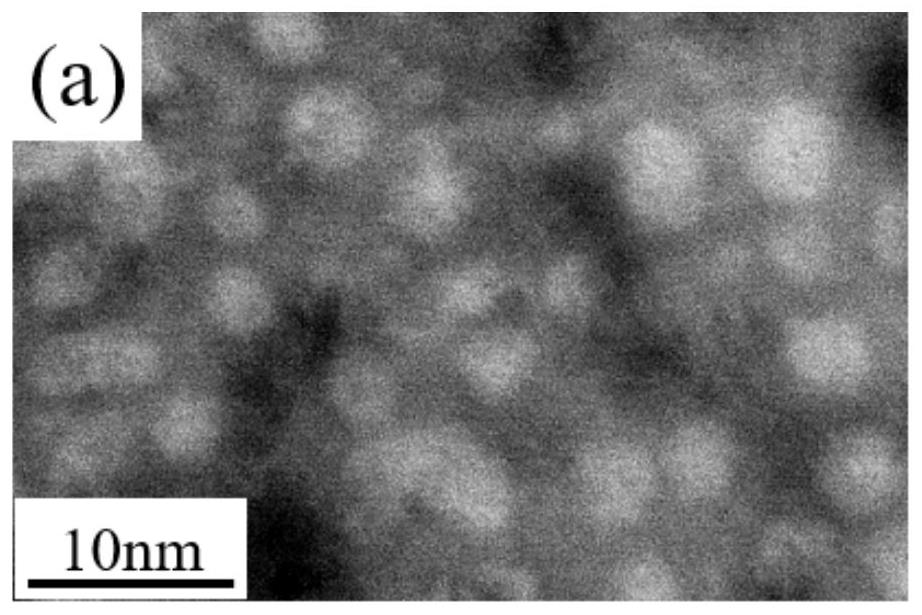

Coherent nanophase-reinforced medium-entropy alloy with excellent thermal stability and preparation method of coherent nanophase-reinforced medium-entropy alloy

The invention discloses a coherent nanophase reinforced medium-entropy alloy with excellent thermal stability and a preparation method, the coherent nanophase reinforced medium-entropy alloy comprises 30 at.%-33 at.% of Ni, 30 at.%-33 at.% of Co, 30 at.%-33 at.% of Cr, 5 at.%-7 at.% of Al and 1.0 at.%-3.0 at.% of Ta, gamma'phase is added into the NiCoCr medium-entropy alloy with excellent mechanical properties to form elements Al and Ta, and then a nanophase is introduced into a NiCoCr alloy matrix through an aging process, so that the thermal stability of the alloy is improved. A gamma + gamma'structure similar to a high-temperature alloy is constructed, and meanwhile, the strength of the NiCoCr alloy is also greatly improved through the nano precipitation strengthening effect; the alloy not only has the characteristic of high toughness, but also has excellent structure thermal stability, so that the alloy has great competitive advantages in alloys with similar structures, has great engineering application prospects in the high-temperature field, and is expected to become a next-generation high-temperature structural material.

Owner:XI AN JIAOTONG UNIV

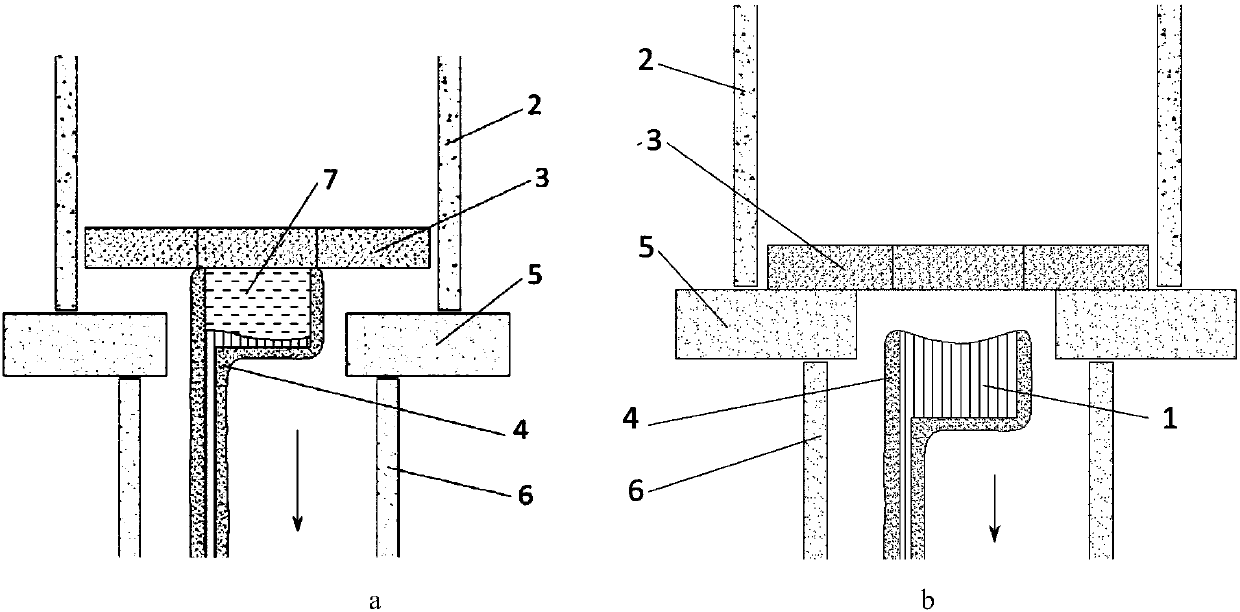

Directional solidification method capable of reducing number of freckles in variable-section casting

InactiveCN105880533AIncrease cooling rateReduced propensity to formPolycrystalline material growthFrom frozen solutionsRadiant heatDirectional solidification

The invention discloses a directional solidification method capable of reducing the number of freckles in a variable-section casting. By adding a radiation baffle on the top of a formwork of the variable-section casting, cooling rate or solidification rate is increased, so that freckles are removed. By means of the radiation baffle, radiant heat of a heating body on the upper portion is blocked, heat absorbed by liquid phase is reduced, so that casting cooling rate is increased, dendritic structure can be refined, thermosolutal convection flow resistance is increased, solidification rate is increased, and the possibility that dendritic growth rate is larger than interdendritic flow rate is increased. By the adoption of the method, cooling rate and solidification rate can be increased during casting solidification, and the possibility of freckle formation is reduced. Specific implementation is easy, material sources are wide, consumption is low, and the original formwork does not need to be changed.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

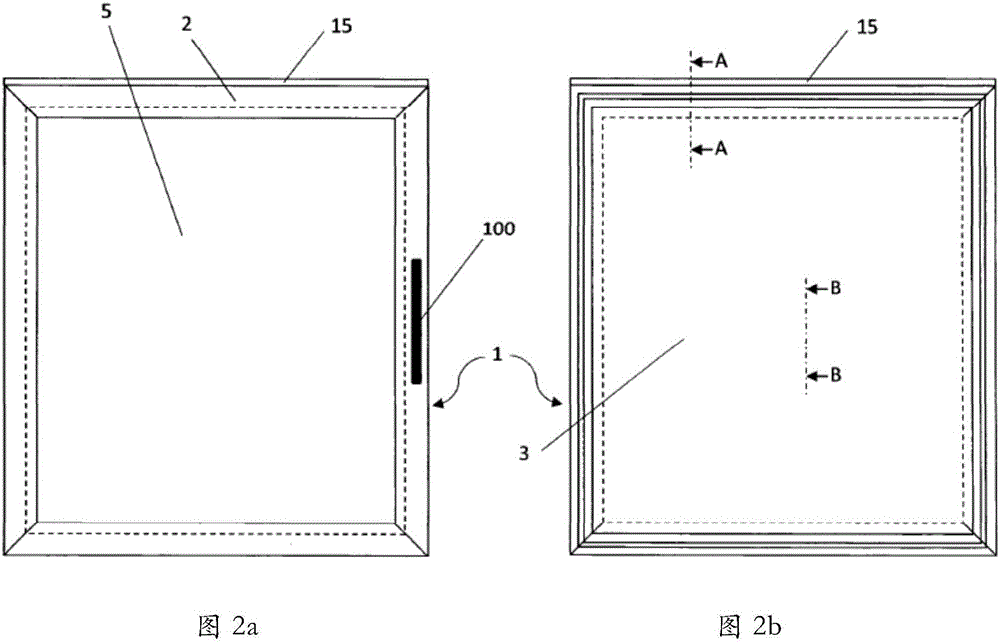

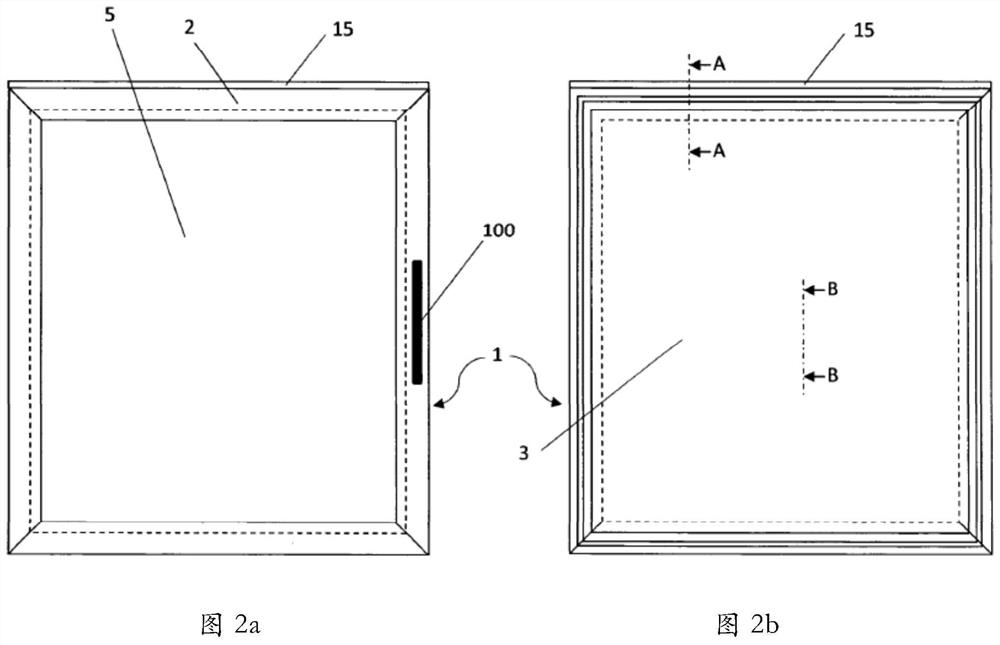

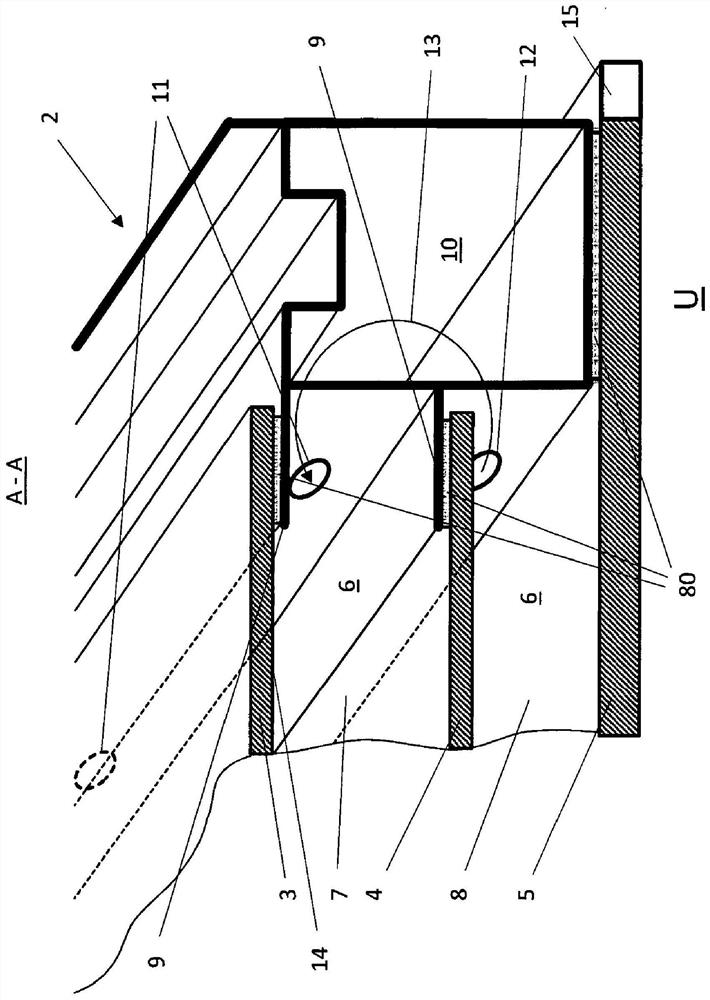

Door, in particular for a refrigerator and/or freezer

ActiveCN106793879AReduce weightAvoid formingShow cabinetsDomestic cooling apparatusEngineeringRefrigerated temperature

Owner:REHAU IND SE & CO KG

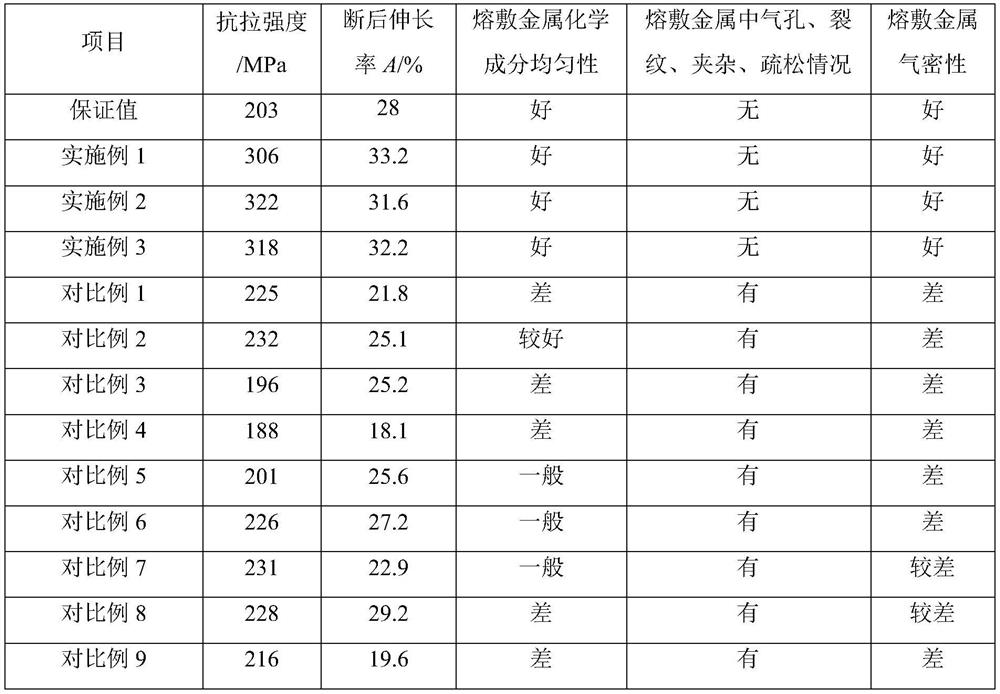

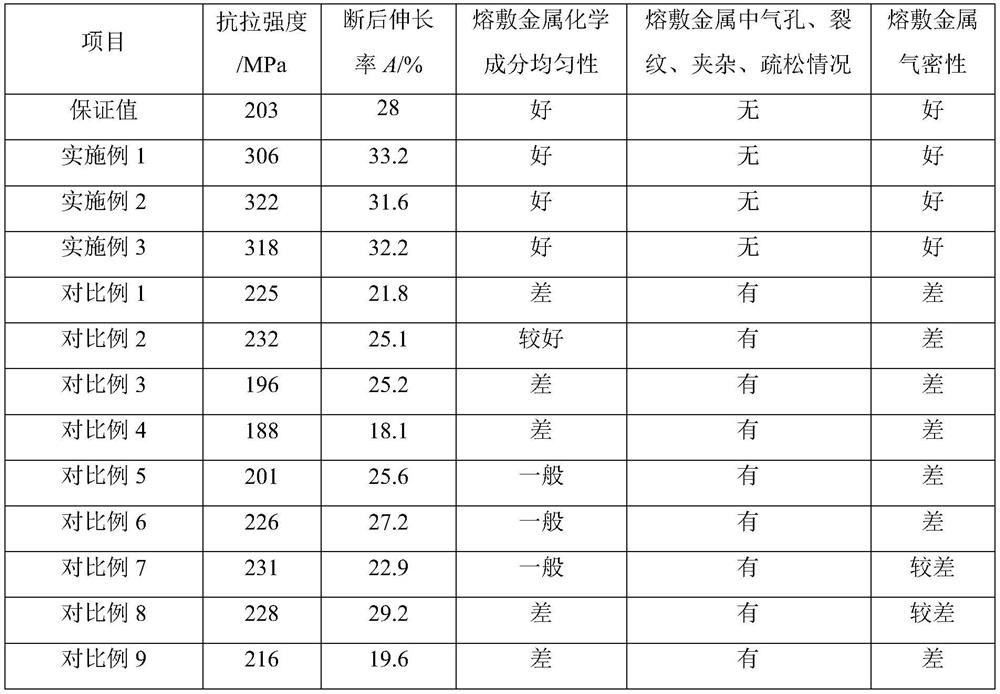

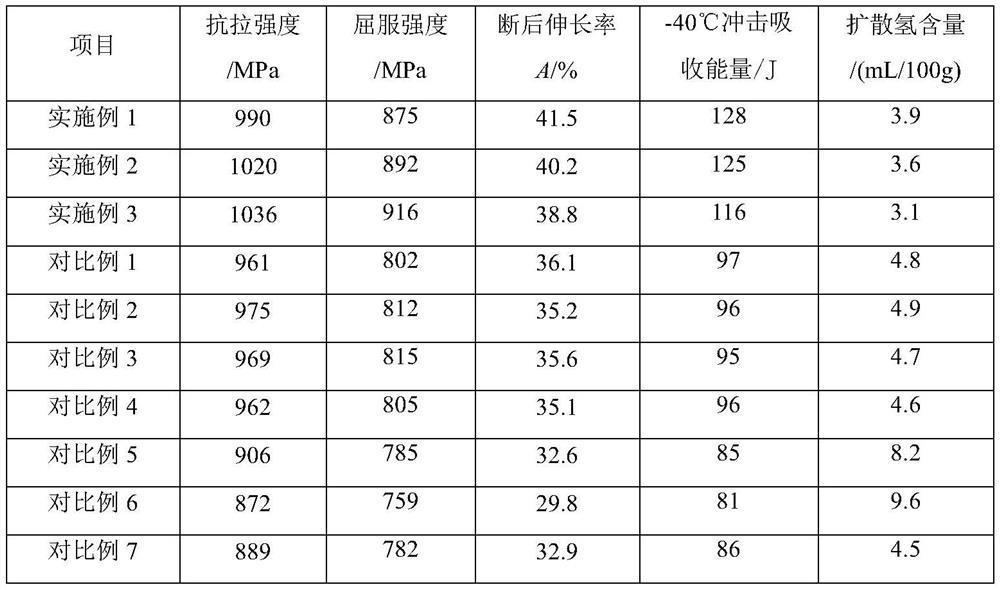

Matched flux-cored wire for medical gas and vacuum seamless copper pipe fusion welding

ActiveCN112077476AUniform chemical compositionHigh droplet temperatureWelding/cutting media/materialsSoldering mediaPipeFusion welding

The invention belongs to the field of welding materials, and particularly relates to a matched flux-cored wire for medical gas and vacuum seamless copper pipe fusion welding. The matched flux-cored wire comprises a TU1 semi-hard copper alloy sheath and a flux core; the flux core comprises 2.1%-3.2% of CuSi16 powder, 2.2%-3.0% of CuMn30 powder, 1.5%-2.2% of CuP12 powder, 3.0%-3.8% of AlSr40 powder,2.8%-3.6% of nanometer F3Ti powder, 3.2%-4.5% of nanometer NdF3 powder, and the balance FTD1 electrolytic copper powder; and the filling rate of the flux core is 32%-38%. Chemical components of deposited metal are uniform, inclusion, cracks and air hole defects are avoided, the air tightness is good, the minimum value of the tensile strength of the deposited metal is 306 MPa, the minimum value ofthe percentage elongation after fracture is 31.6%, and a component formed by fusion welding the seamless copper pipe completely meets the medical gas and vacuum requirements.

Owner:ZHENGZHOU UNIV

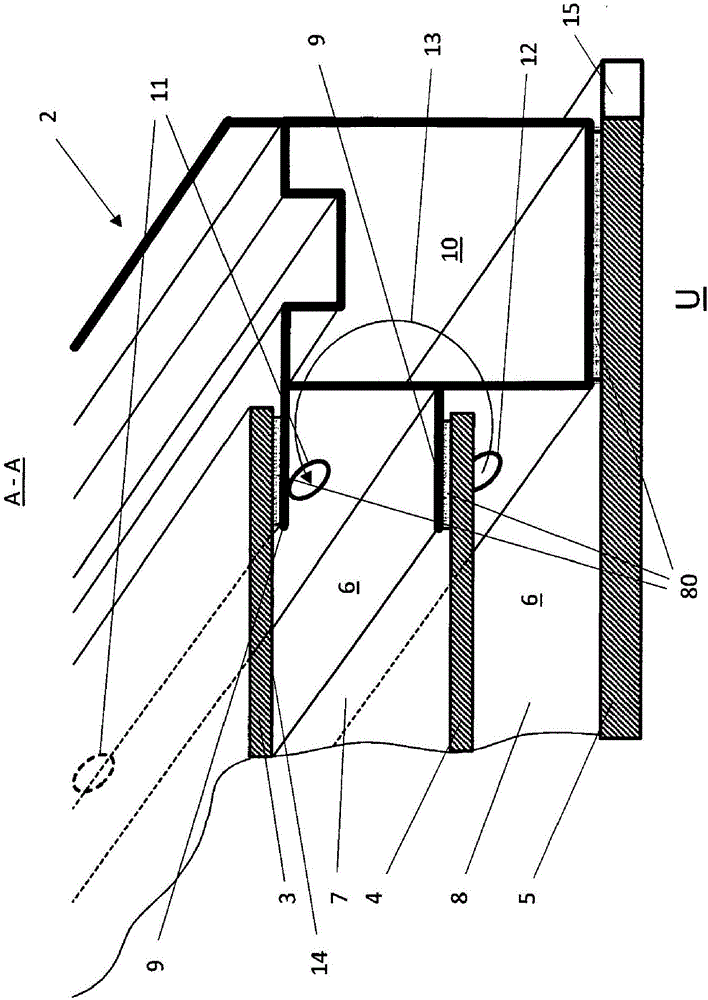

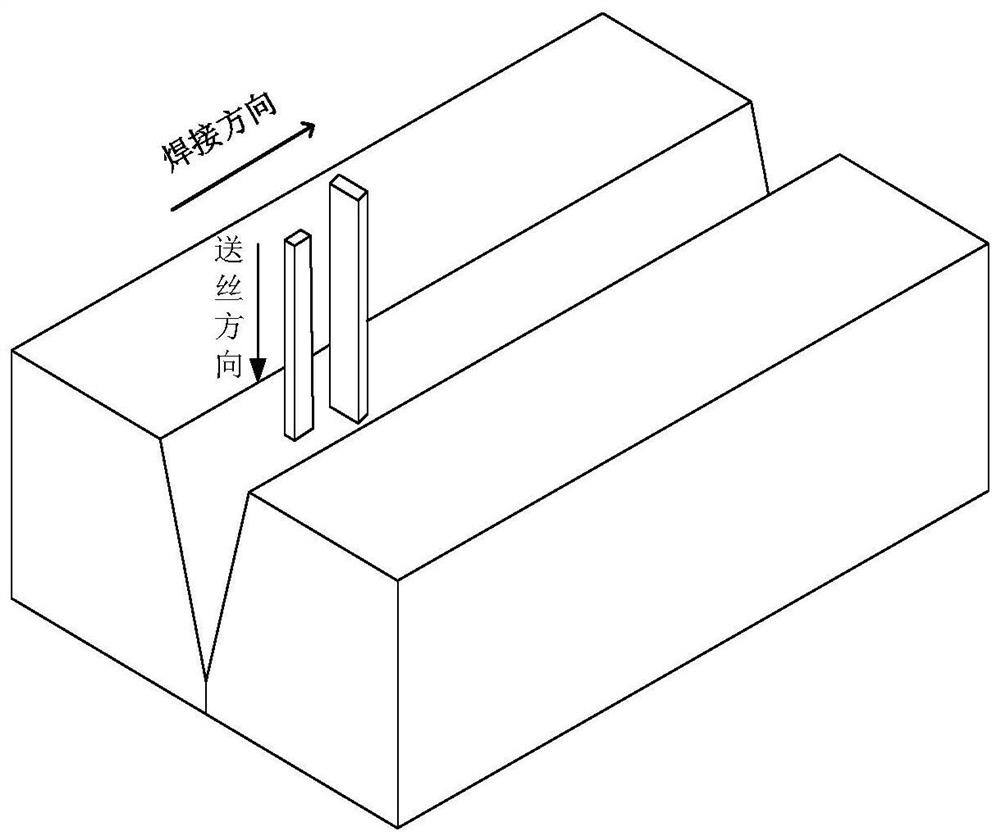

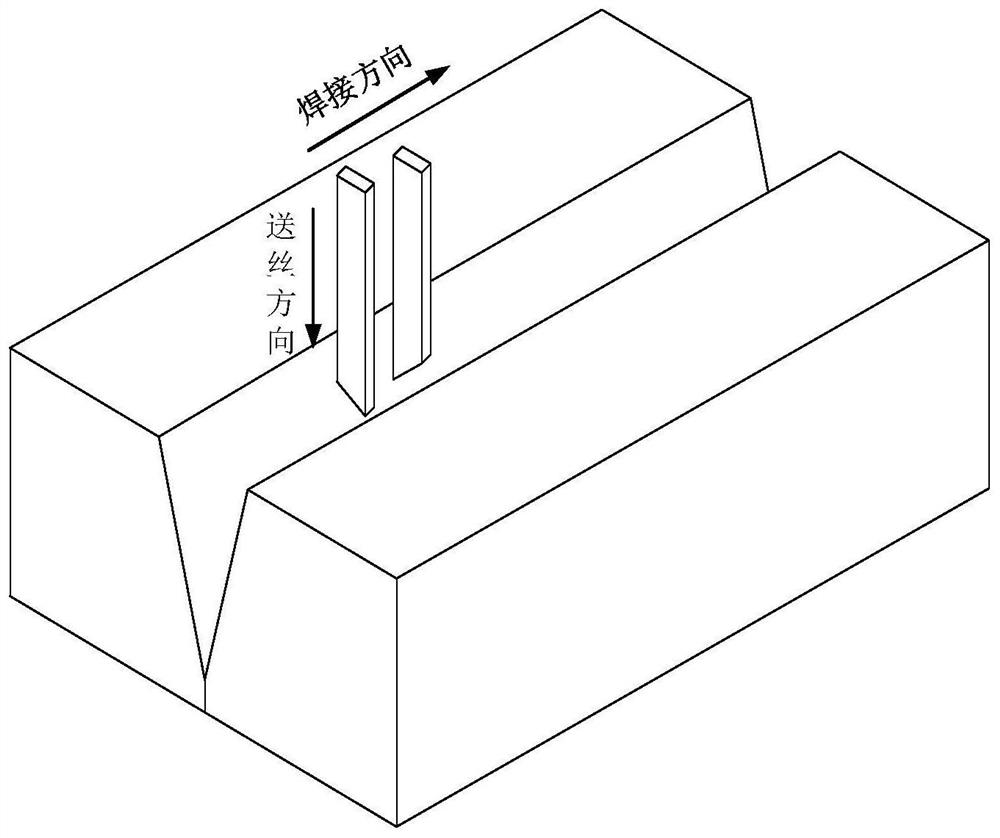

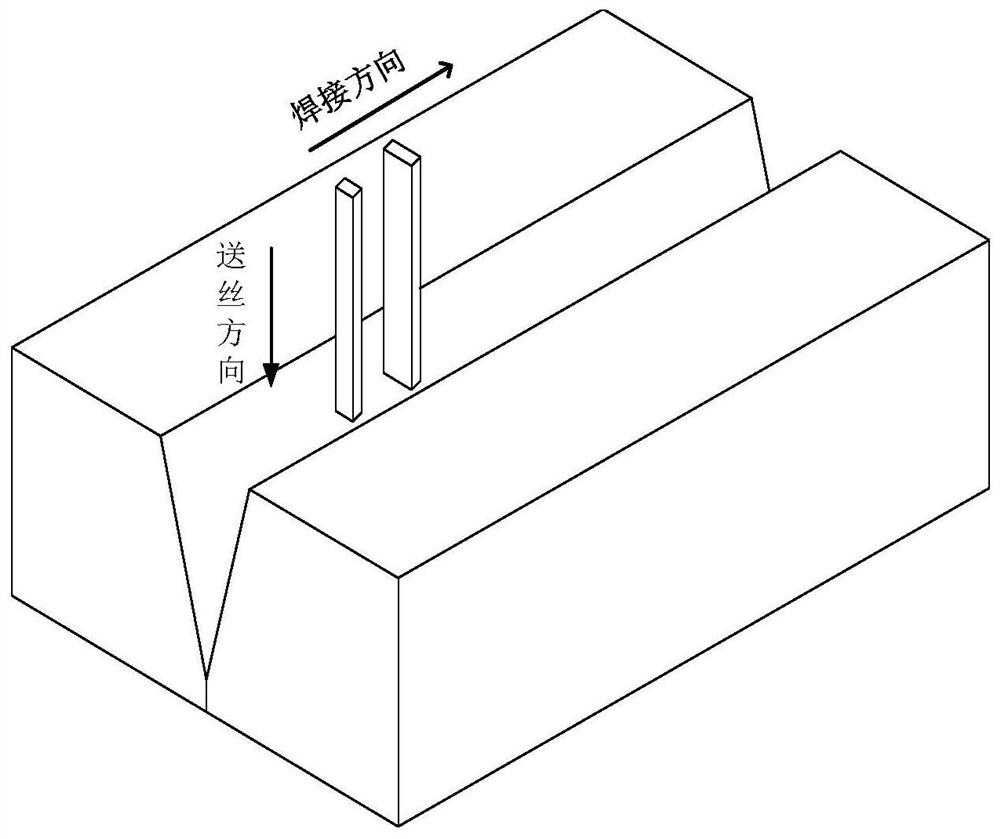

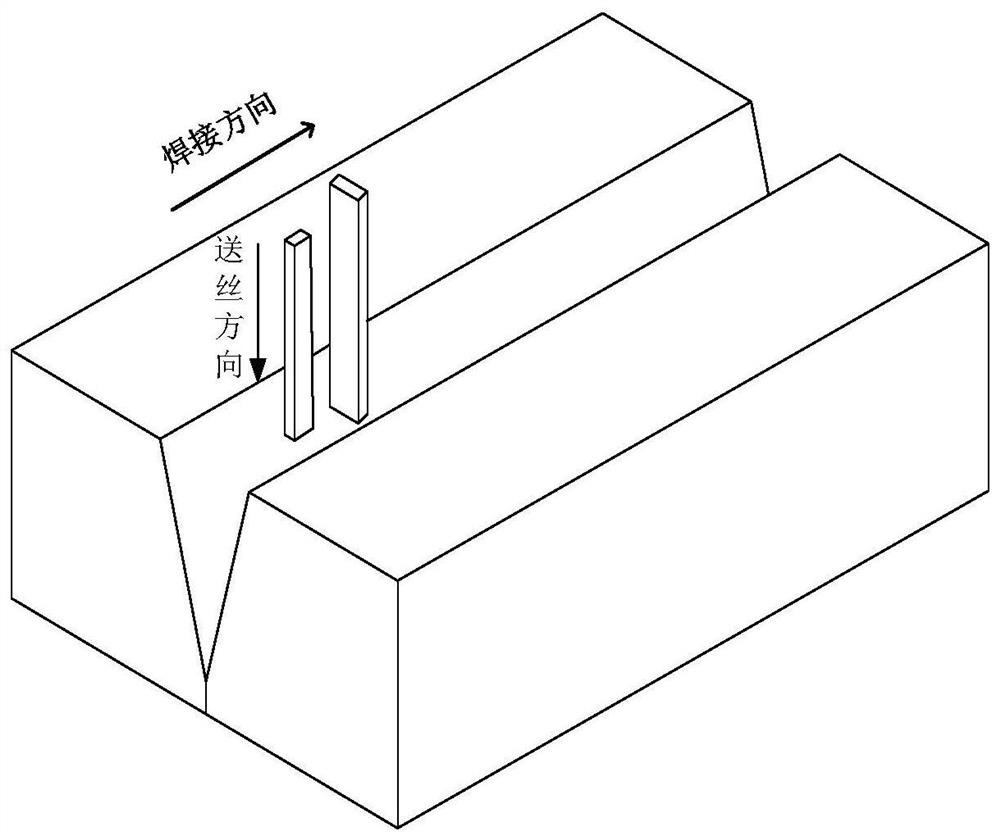

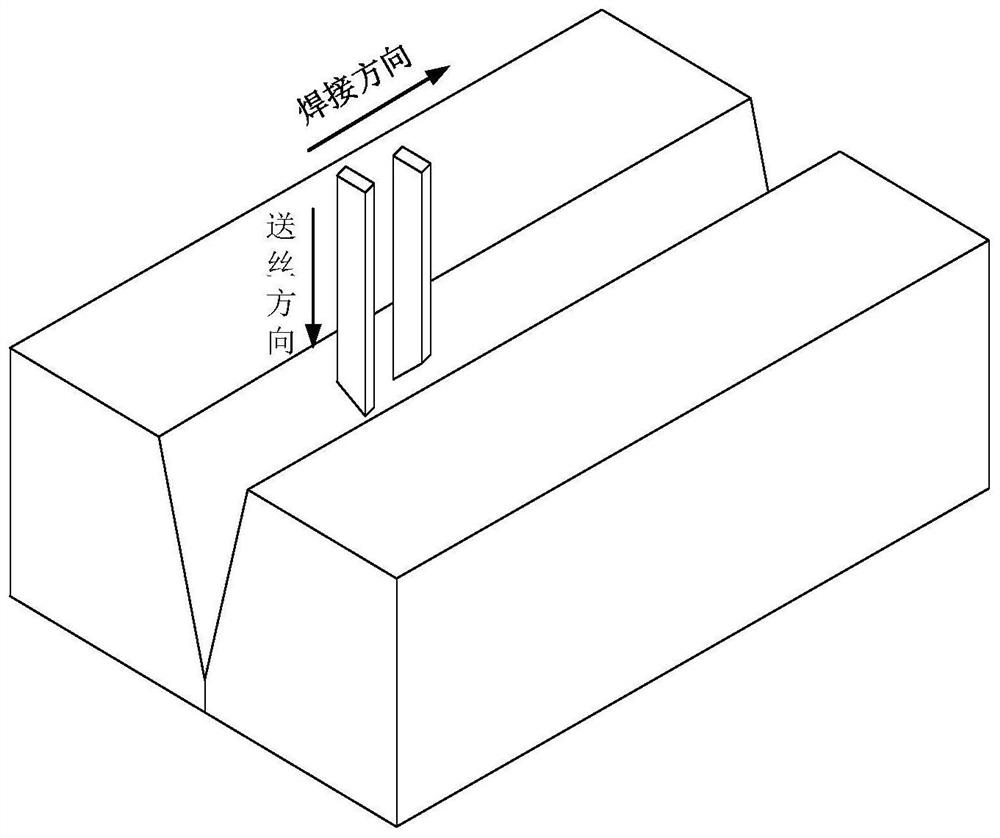

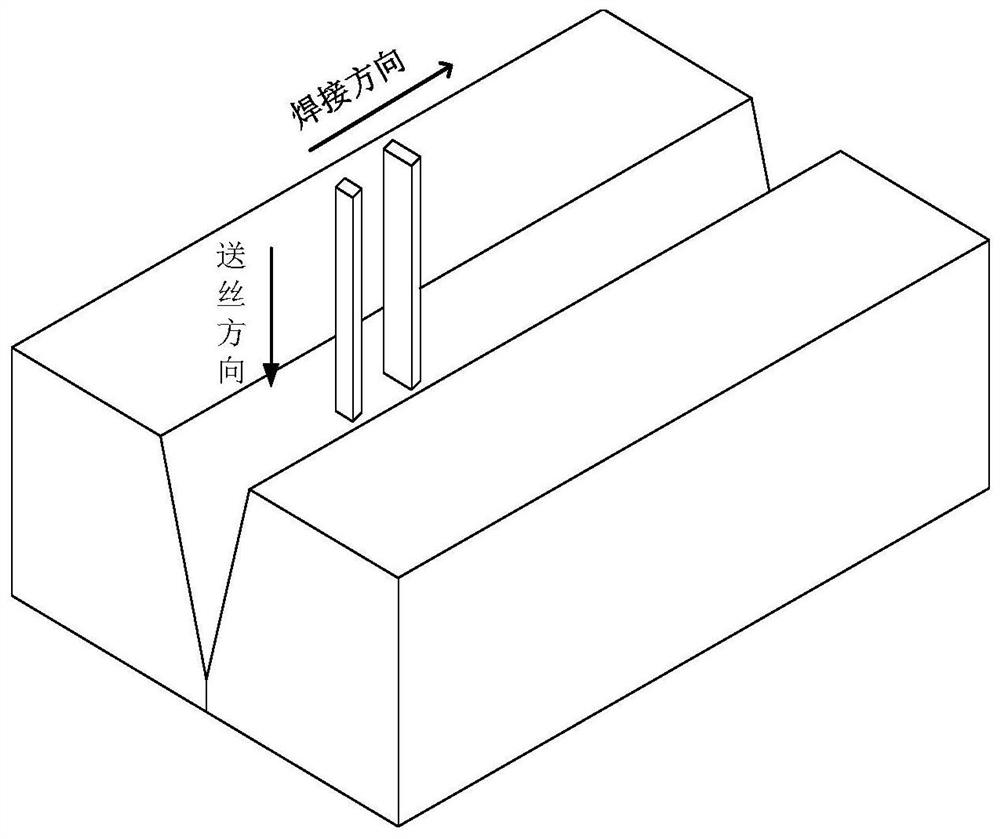

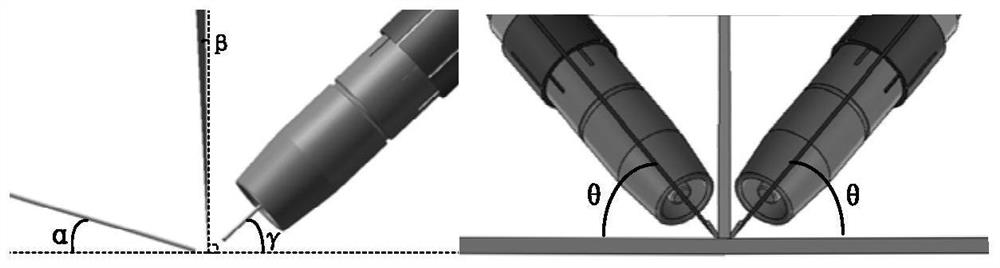

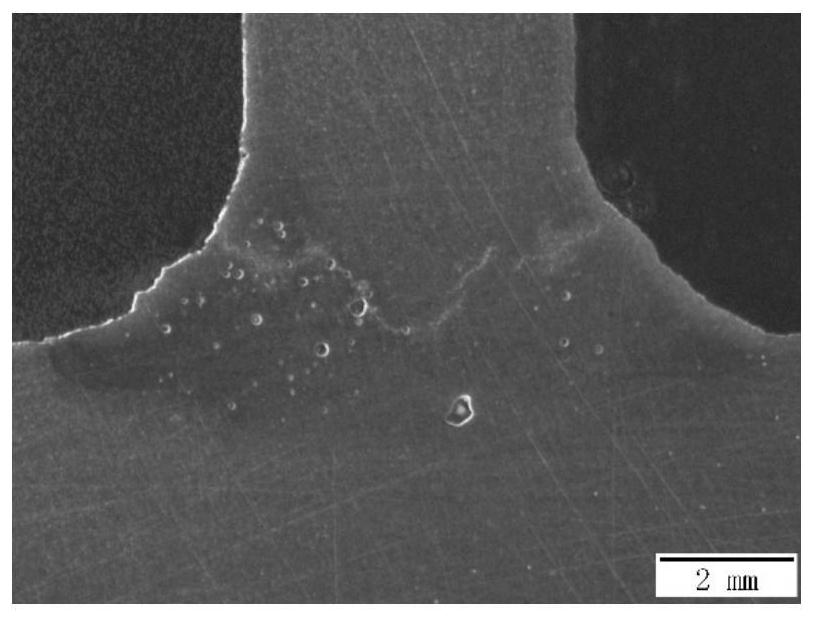

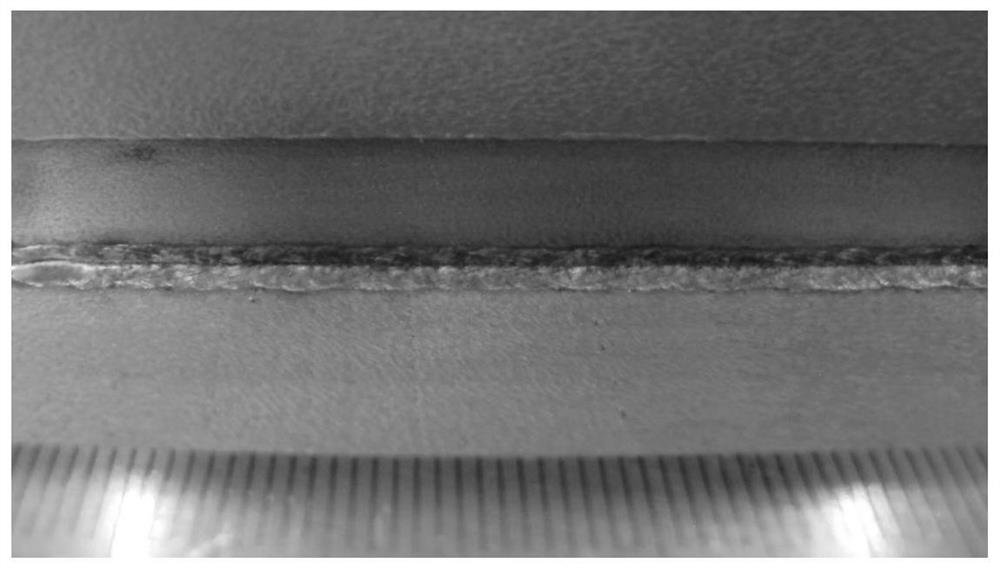

Large thick plate welding method and system based on double strip-shaped welding wires

ActiveCN112809138AEfficient and high-quality weldingStrong weld adaptabilityElectrode supporting devicesElectrode accessoriesThick plateWelding process

The invention provides a large thick plate welding method and system based on double strip-shaped welding wires. The method works on the basis of the double-welding-wire arc welding principle. In the welding process of a large thick plate, a welding bead layer is divided into backing welding, filling welding and cosmetic welding; and according to the characteristics of different welding bead layers, size selection and arrangement are carried out on the strip-shaped welding wires. The system comprises a double strip-shaped welding wire welding gun A, a double strip-shaped welding wire welding gun B and a welding control center. The double strip-shaped welding wire welding gun A is provided with two strip-shaped welding wires with the same width; the double strip-shaped welding wire welding gun B is provided with two strip-shaped welding wires with different widths; and the welding control center is used for presetting a welding program and controlling the double strip-shaped welding wire welding gun A and the double strip-shaped welding wire welding gun B to work according to the preset welding program. The preset welding program comprises selection of welding modes including a backing welding mode, a filling welding mode, a cosmetic welding mode I and a cosmetic welding mode II. By adopting the method and the system, high-efficiency and high-quality welding of large thick plates can be realized.

Owner:SOUTHWEST JIAOTONG UNIV

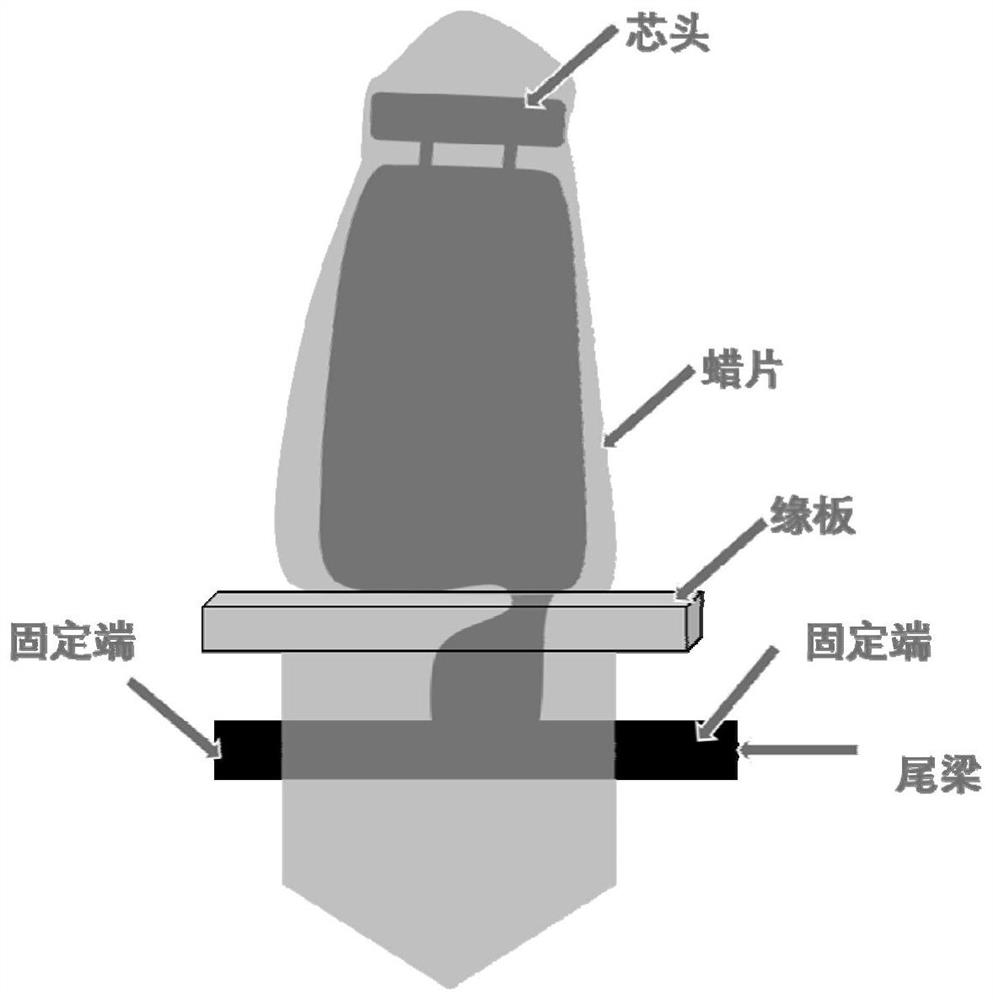

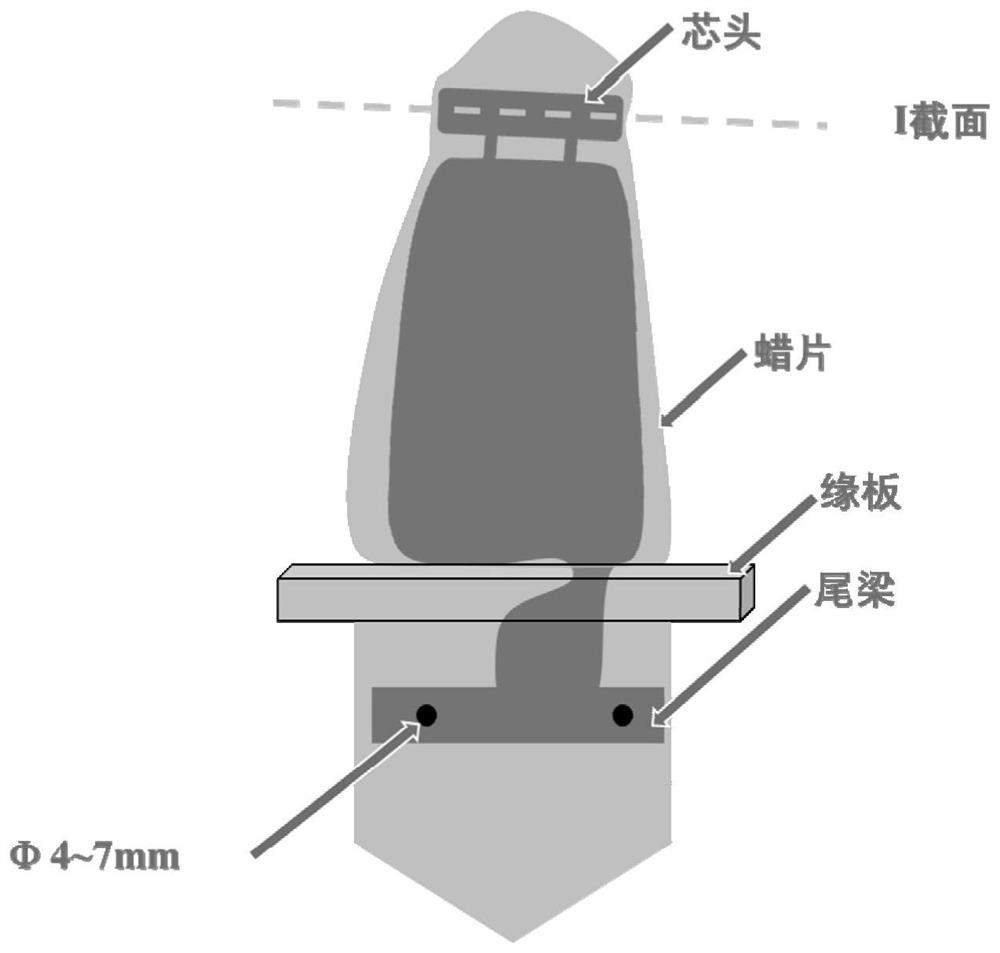

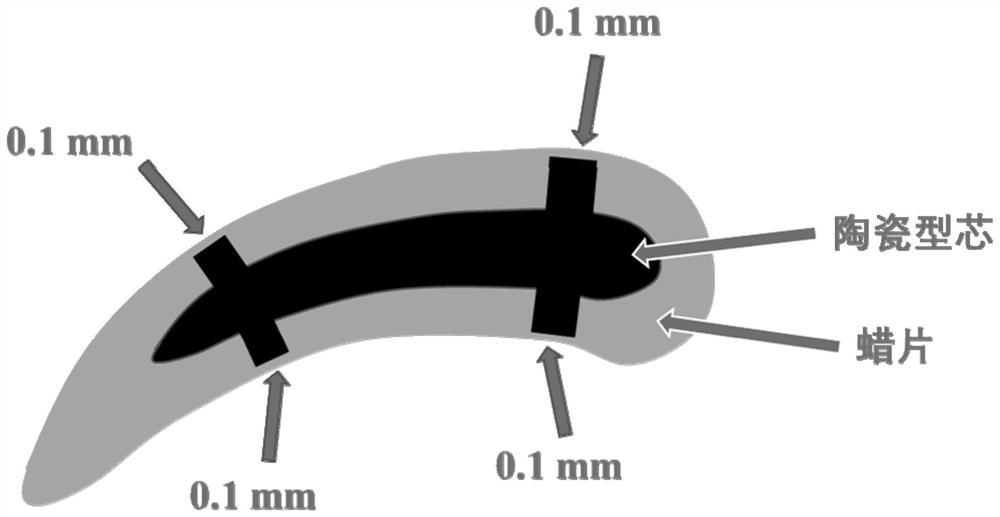

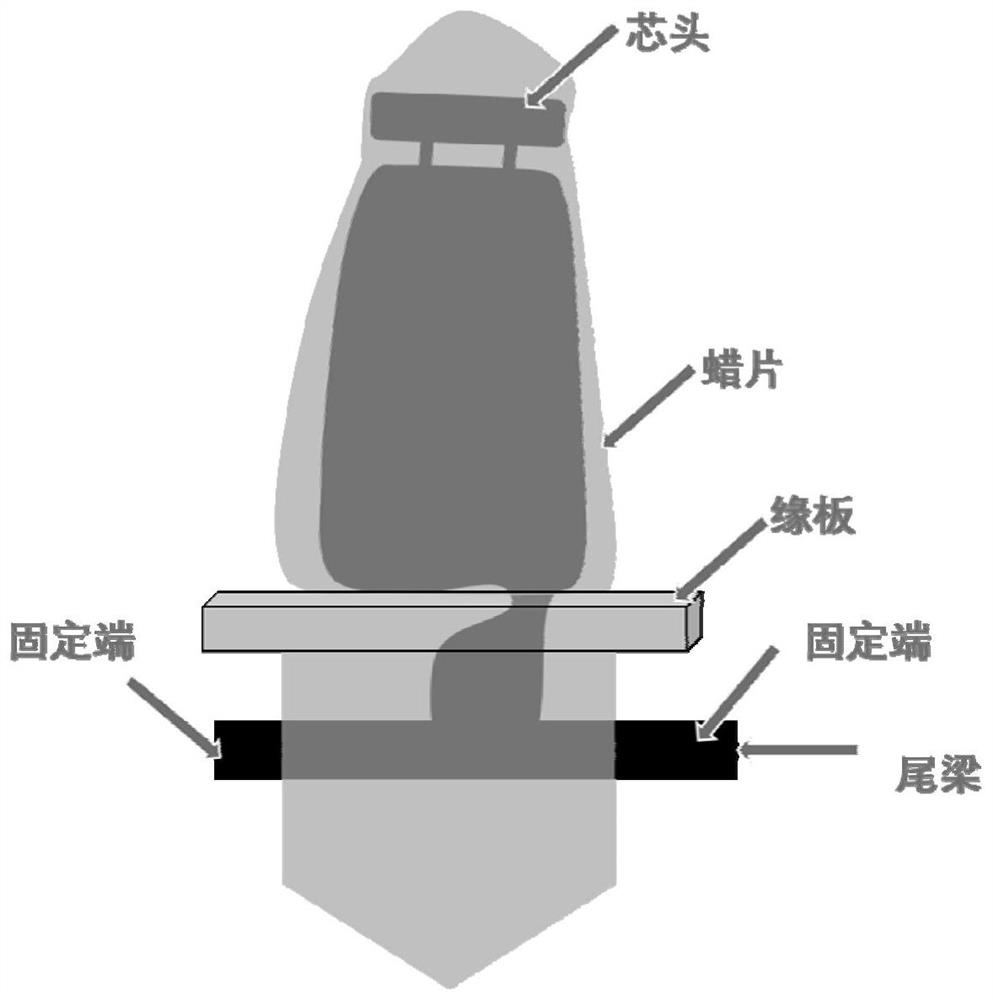

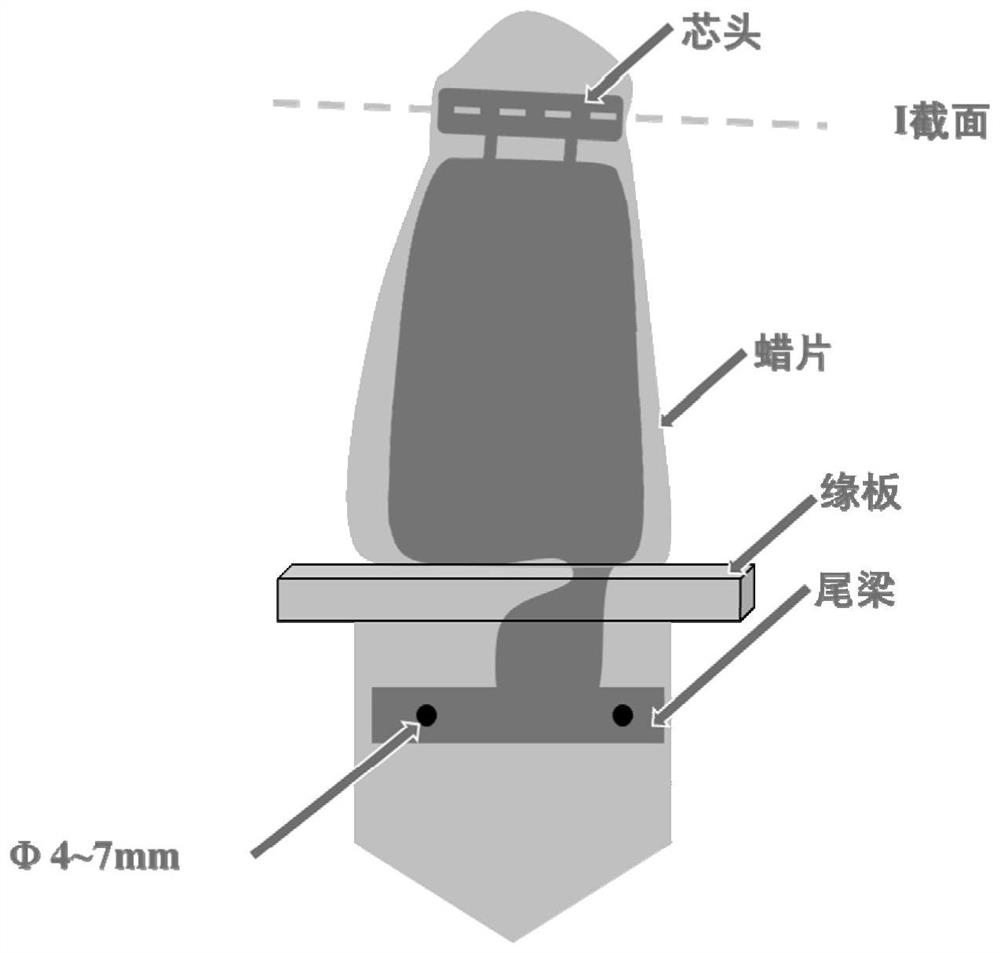

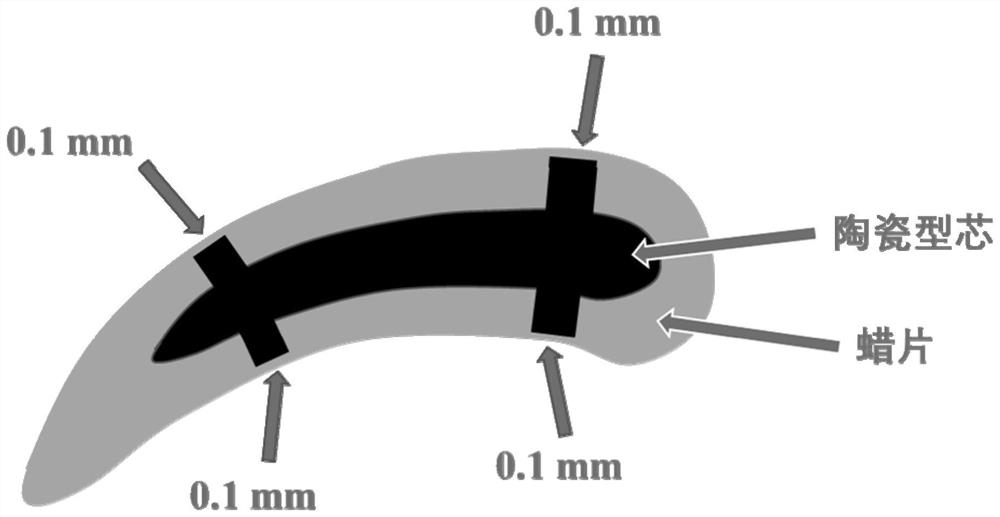

Wax mold assembly structure of cover plate integral casting and cantilever structure single crystal blade

ActiveCN112705671ASolve the problem of easy core deviation or exposed coreReduced propensity to formFoundry moulding apparatusDirectional solidificationEngineering

The invention belongs to the field of casting of complex hollow single crystal blades, and particularly relates to a wax mold assembly structure of a cover plate integral casting and cantilever structure single crystal blade. Due to the fact that the blade cover plate is integrally cast and the cast hole diameter on the cover plate is small, a blade ceramic core (forming a blade tip cast hole part) is extremely prone to breakage. In addition, the blade is of a cantilever structure and cannot be positioned, so that the defects of core shift, core exposure, mixed crystals, striped crystals and the like of the blade are extremely prone to occurrence in the directional solidification process. However, the combination mode of the wax molds is a main factor influencing the defects. According to the wax mold assembly structure, the ceramic core boss is reasonably designed at the allowance of the blade tip of the blade to solve the problem of core shift of the blade; the freedom degree and the fixed end of the mold core are reasonably designed based on the expansion difference value of the mold core and the mold shell, and mold core breakage is avoided; and the runner position is adjusted to reduce the blade defect forming tendency. The percent of pass of the single crystal blades formed through the mold assembling method is high.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

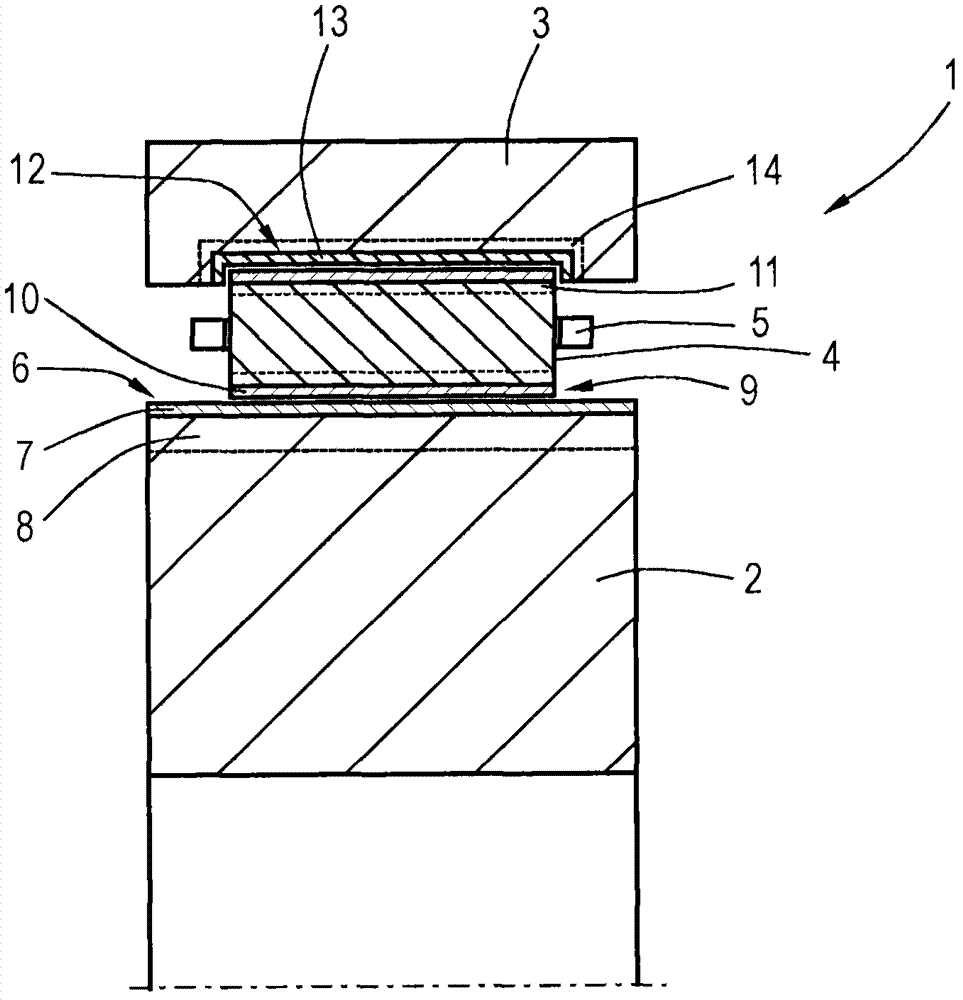

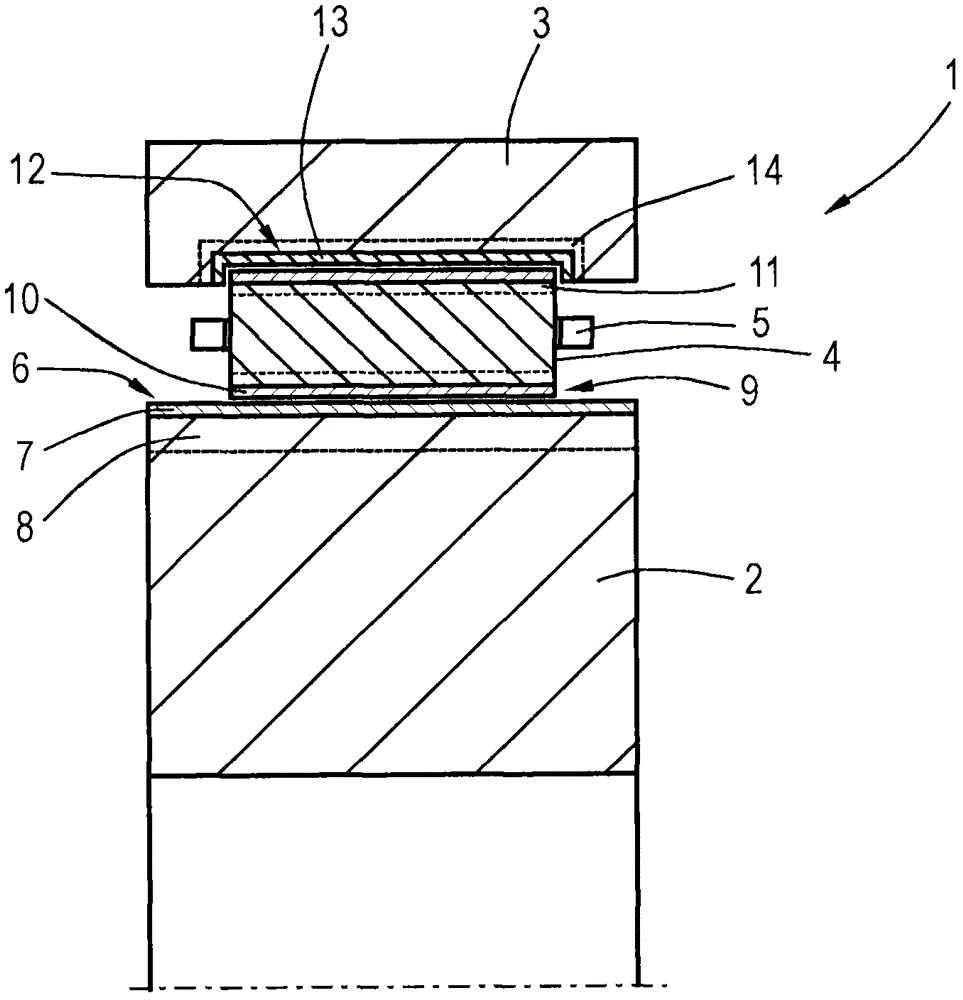

Rolling bearing

The present invention relates to a rolling bearing, comprising an outer ring, an inner ring and a rolling body rolling on a rolling way between the outer ring and the inner ring, wherein the rolling way of the inner ring and / or the outer ring and / or the surface of the rolling body are / is provided with a polishing layer, the inner ring and / or the outer ring and / or the rolling body are / is prepared by steel, the steel is provided with a hardness of 58 HRC at least below the polishing layer, and at least below the polishing layer there are provided 0.03-0.08% nitrogen at least in an edge layer, wherein the nitrogen is at least partially dissolved; 0.1-1.2% carbon; nickel not more than 0.4%; 0.2-1.0% silicon; chrome not smaller than 1.0%; sulphur not more than 0.008%; oxygen not more than 15 ppm; and titanium not more than 50 ppm.

Owner:SCHAEFFLER TECH AG & CO KG

rolling bearing

ActiveCN102734330BReduced propensity to formImprove mobilityShaftsBearing componentsRolling-element bearingTitanium

A rolling bearing includes: an outer ring, an inner ring, and rolling elements rolling on the raceways of the outer ring and the inner ring, wherein the surfaces of the inner ring and / or the raceways of the outer ring and / or the rolling elements have a polished layer, and the inner ring and / or the outer ring and / or the rolling elements are made of a steel that has a hardness of at least 58 HRC at least under the polishing layer and has: - at least 0.03 - 0.8% in the edge layer Nitrogen content, where the nitrogen is at least partially dissolved, - at least in the edge layer, a carbon content of 0.1-1.2%, a nickel content of ≤0.4%, a silicon content of 0.2-1.0%, a chromium content of ≥1.0% , ‑≤0.008% sulfur content, ‑≤15ppm oxygen content, ‑≤50ppm titanium content.

Owner:SCHAEFFLER TECH AG & CO KG

Directional solidification method capable of reducing freckles in castings with cross-sectional variations

InactiveCN105880533BIncrease cooling rateReduced propensity to formPolycrystalline material growthFrom frozen solutionsRadiant heatDirectional solidification

The invention discloses a directional solidification method capable of reducing the number of freckles in a variable-section casting. By adding a radiation baffle on the top of a formwork of the variable-section casting, cooling rate or solidification rate is increased, so that freckles are removed. By means of the radiation baffle, radiant heat of a heating body on the upper portion is blocked, heat absorbed by liquid phase is reduced, so that casting cooling rate is increased, dendritic structure can be refined, thermosolutal convection flow resistance is increased, solidification rate is increased, and the possibility that dendritic growth rate is larger than interdendritic flow rate is increased. By the adoption of the method, cooling rate and solidification rate can be increased during casting solidification, and the possibility of freckle formation is reduced. Specific implementation is easy, material sources are wide, consumption is low, and the original formwork does not need to be changed.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

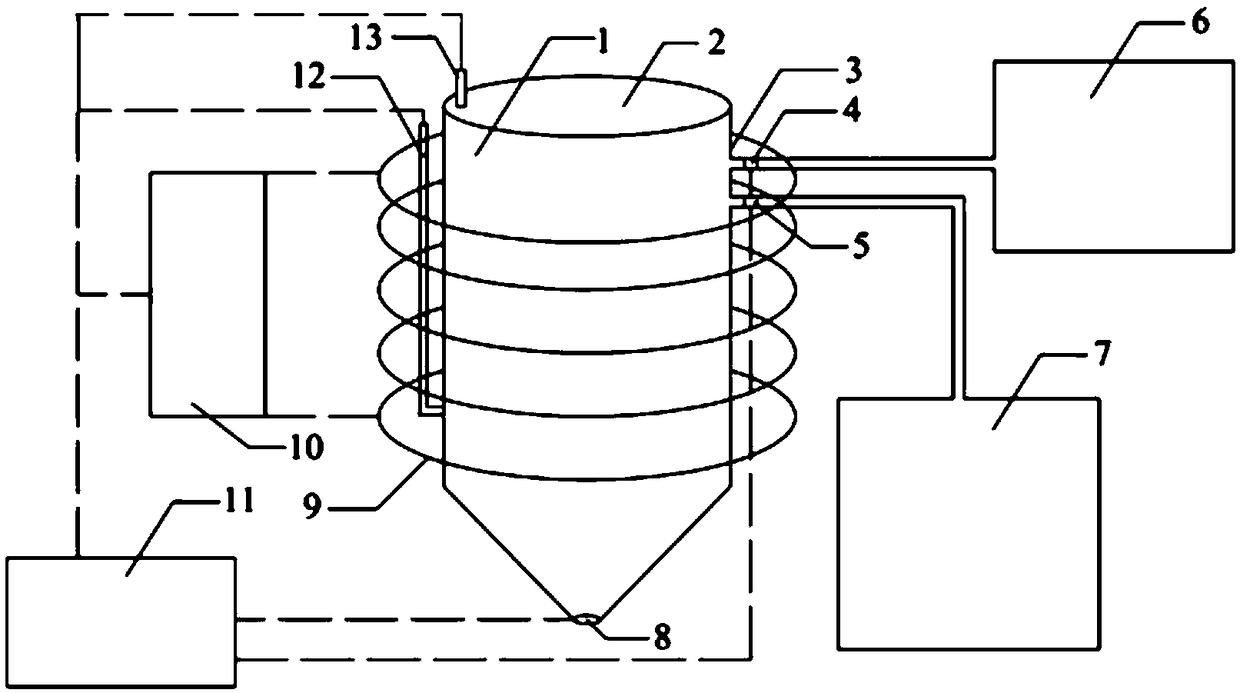

A powder preheating device for laser selective melting and powder feeding and its application

ActiveCN106799493BReduce usageEasy to operateAdditive manufacturing apparatusIncreasing energy efficiencyThermal breakSolenoid valve

The invention belongs to the field of advanced rapid manufacturing technology, and discloses a powder preheating device for laser selective melting and powder feeding, including a powder storage funnel, a vacuum pump, a protective gas storage tank, a power supply device and a central controller, the vacuum pump and the protective gas storage tank are respectively connected to the powder storage funnel through the first connecting pipe and the second connecting pipe; the bottom outlet of the powder storage funnel is provided with a third electromagnetic valve; the outer side of the powder storage funnel The wall is wrapped with a heat insulation layer; an induction coil is arranged around the outer wall of the powder storage funnel; a temperature sensor for detecting the temperature of the metal powder in the powder storage funnel and a temperature sensor for detecting the internal pressure of the powder storage funnel are arranged on the powder storage funnel. Pressure Sensor. The invention has simple structure and convenient operation, and can improve the utilization rate of the metal powder while realizing the preheating of the metal powder.

Owner:HUAZHONG UNIV OF SCI & TECH

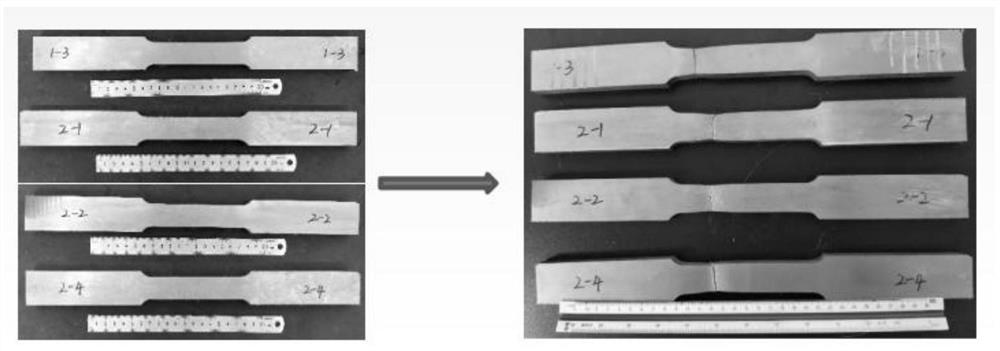

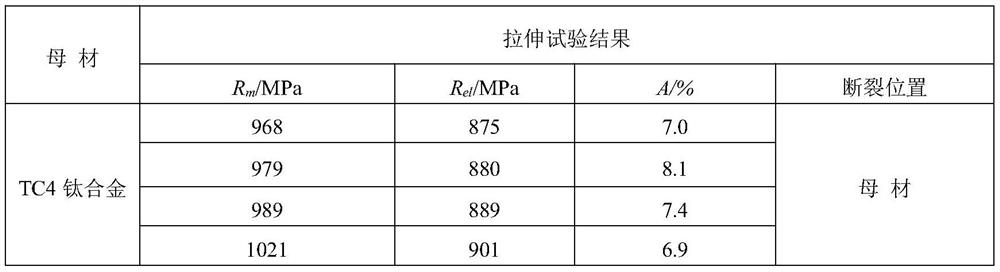

A kind of tc4 titanium alloy flux-cored welding wire and preparation method thereof

ActiveCN112404798BImprove performanceHigh strengthWelding/cutting media/materialsSoldering mediaSmelting processAluminium powder

Owner:HARBIN WELDING INST LTD +1

A kind of alloy powder for laser cladding repair of gray cast iron and preparation method thereof

ActiveCN104498774BImprove performanceOverall performance is moderateMetallic material coating processesCrack resistanceShock resistance

The invention provides alloy powder for gray pig iron laser cladding repair and a preparation method of the alloy powder. The alloy powder comprises the chemical components, by weight, 12% to 24% of Cu, 1.5% to 3.5% of C, 0.2% to 2.4% of Si, 0.01% to 0.05% of Al, 0.005% to 0.01% of Ba, 0.001% to 0.01% of Ca, 0.5% to 1.2% of Co, 0.0% to 0.04 % of Y2O3, 0.0% to 0.03% of La2O3, 0.0% to 0.04% of Ce and the balance Ni. According to the alloy powder, because alloy matrix strengthening elements, graphitizing-promoting elements and grain refinement grain boundary strengthening elements are added, and the percentages of the elements are adjusted, alloy acquires the excellent comprehensive performance, the alloy has both the appropriate hardness and the appropriate strength, the possibility of white cast tissue forming is reduced, shock resistance and fatigue resistance are improved, the crack resistance, the formability, the process stability and the component uniformity of the alloy powder in a laser cladding layer are improved, and an effective method convenient to use is provided for successive repair of gray pig iron parts.

Owner:ACADEMY OF ARMORED FORCES ENG PLA +1

Sand mould of precoated sand for casting single piston ring and manufacturing method of sand mould

ActiveCN102699280BQuality improvementImprove yieldFoundry mouldsFoundry coresPiston ringProcessing cost

The invention relates to a sand mould of precoated sand for casting single piston ring and a manufacturing method of the sand mould. The sand mould comprises a circular tray body, a pouring system arranged on the circular tray body, a retainer ring and air outlet holes, wherein the pouring system comprises a downsprue, a flow gate, a cross gate and a dead head, the downsprue penetrates through the middle part of the circular tray body, the flow gate arranged on the facade of the circular tray body is communicated with the downsprue through the cross gate, the flow gate is communicated with a ring body groove, the dead head is arranged to be opposite to the flow gate, and the dead head is communicated with the ring body groove through more than two inclined pouring gates; and the retainer ring higher than the surface of the sand mould is arranged on the periphery of the facade of the circular tray body, and more than four air outlet holes passing through the circular tray body are symmetrically arranged on the inner side of the ring body groove between the cross gate and the dead head along the axial line of the cross gate. The piston ring processed by the invention is stable in quality and high in yield, the piston ring casting has the advantages of clear outline, high dimension precision and good surface quality, and the piston ring casting is liable to clean, thereby reducing the processing allowance, reducing the successive processing cost and improving the production efficiency.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

A method and system for welding large and thick plates based on double-ribbon welding wire

ActiveCN112809138BEfficient and high-quality weldingStrong weld adaptabilityElectrode supporting devicesElectrode accessoriesThick plateWelding torch

The invention provides a large and thick plate welding method and system based on double strip welding wires. This method is based on the principle of double welding wire arc welding; in the welding process of large and thick plates, the weld bead layer is divided into bottom welding, filling welding and cover welding; according to the characteristics of different welding bead layers, the strip welding wire is Size selection and arrangement settings. The system includes double-ribbon welding torch A, double-ribbon welding torch B, welding control center; double-ribbon welding torch A is equipped with two ribbon welding wires of the same width; double-ribbon welding torch B is installed with two ribbon welding wire; the welding control center is used to preset the welding program, and control the double ribbon welding gun A and the double ribbon welding gun B to work according to the preset welding program; the preset welding program includes the selection of welding mode, Including root welding mode, filling welding mode, cover welding mode 1, and cover welding mode 2. The method and the system thereof can realize high-efficiency and high-quality welding of large and thick plates.

Owner:SOUTHWEST JIAOTONG UNIV

A kind of oxidation-resistant nickel-based superalloy powder and its preparation method

ActiveCN110629074BReduced propensity to formAvoid it happening againTransportation and packagingMetal-working apparatusElectrostatic separationOxidation resistant

The invention discloses an anti-oxidation nickel-based superalloy powder and a preparation method thereof. Alloy elements such as Ni, Cr, and W are taken according to the proportion, the alloy is put into a vacuum induction furnace for smelting, and then placed in a vacuum consumable furnace for reheating. The master alloy ingot is obtained by melting, and the master alloy ingot is made into an electrode rod; the electrode rod is put into a plasma rotary electrode pulverizer, and the end of the electrode rod is melted with a plasma gun to obtain a spherical powder; the spherical powder is passed through an ultrasonic vibrating sieve. Screening; and then electrostatically separate the spherical powder to remove non-metallic impurities in the spherical powder to obtain pure alloy powder. In the present invention, by replacing a part of W element with Nb element, the content of W element is reduced, the formation tendency of W carbon oxide is weakened, and the content of W carbon oxide in the alloy is obviously reduced.

Owner:SINO EURO MATERIALS TECH OF XIAN CO LTD

A matching flux-cored welding wire for fusion welding of seamless copper tubes for medical gas and vacuum

ActiveCN112077476BUniform chemical compositionHigh droplet temperatureWelding/cutting media/materialsSoldering mediaChemical compositionAir tightness

The invention belongs to the field of welding materials, in particular to a matching flux-cored welding wire for fusion welding of seamless copper pipes for medical gas and vacuum, including a TU1 semi-hard copper alloy sheath and a flux core, and the flux core content is: CuSi16 powder 2.1%- 3.2%, CuMn30 powder 2.2%‑3.0%, CuP12 powder 1.5%‑2.2%, AlSr40 powder 3.0%‑3.8%, nano F 3 Ti powder 2.8%‑3.6%, nanometer NdF 3 powder 3.2%‑4.5%, the balance is FTD1 electrolytic copper powder, and the filling rate of the drug core is 32%‑38%. The chemical composition of the deposited metal in the present invention is uniform, without inclusions, cracks, and pores, and has good air tightness. The minimum tensile strength of the deposited metal is 306MPa, and the minimum elongation after breaking is 31.6%. The seamless copper tube adopts The components formed after the fusion welding process fully meet the medical gas and vacuum requirements.

Owner:ZHENGZHOU UNIV

Doors, especially for refrigeration and/or freezing appliances

ActiveCN106793879BReduce weightAvoid formingShow cabinetsDomestic cooling apparatusCool storageEngineering

Owner:REHAU IND SE & CO KG

A kind of method of nano cobalt interlayer solid phase diffusion bonding cemented carbide

ActiveCN105728928BRealize solid phase diffusion connectionSolid phase diffusion connection is reliableNon-electric welding apparatusAlcoholSand-paper

The invention relates to a method for bonding hard alloy by solid-phase diffusion of a nano-Co intermediate layer. The surface of the hard alloy sample to be welded is polished and polished with sandpaper, and ultrasonically cleaned in acetone solution; the nano-Co is mixed with absolute ethanol to form a paste. Shape, coated on the surface of cemented carbide to be welded, assembled into cemented carbide / nano-Co / hard alloy assembly; place the assembly in a vacuum heating furnace, apply a pressure of 10MPa~20MPa, when vacuum heating When the vacuum degree of the furnace reaches (1.5~2.0)×10-3Pa, start heating, control the heating rate in the furnace to 10℃ / min~20℃ / min, raise the temperature to 1100℃~1300℃, then keep it warm for 20min~40min, and then Control the cooling rate at 5°C / min~10°C / min, cool to 400°C, and then cool with the furnace. The invention has the advantages of simple process, low cost, simple operation and high efficiency, and can realize reliable connection of cemented carbide.

Owner:HARBIN INST OF TECH AT WEIHAI

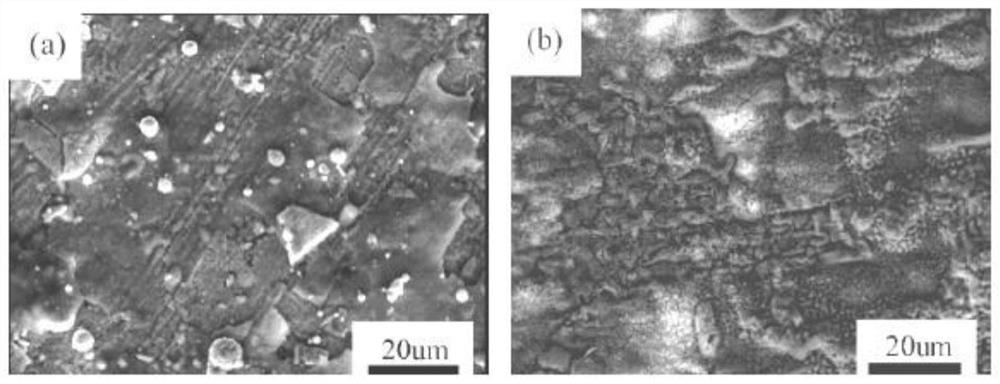

A welding method for suppressing cracks in aluminum alloy t-joints

ActiveCN112475540BGrain refinementCrack suppressionElectrode holder supportersWelding accessoriesWeld seamUltimate tensile strength

A welding method for suppressing cracks in an aluminum alloy T-shaped joint relates to the field of welding. The invention aims to solve the problem of thermal cracks existing in the double-sided laser welding of the aluminum alloy T-joint. The present invention mainly utilizes the composition of the welding wire 1 to enhance the internal consistency of the welding seam and improve the strength of the welding seam, and uses the composition of the welding wire 2 to suppress cracks at the front of the solidification of the rear molten pool. On the premise of ensuring the overall flow trend of the molten pool, the invention can further improve the elimination of pores and the reduction of heat input by using heat sources such as swing laser and pulse / AC CMT. The invention is applied to the field of manufacturing welding.

Owner:HARBIN INST OF TECH

Low-hydrogen easy-to-weld alkaline flux-cored wire prepared from steel slag and used for structural steel

ActiveCN112247398AReduced propensity to formImprove mechanical propertiesWelding/cutting media/materialsSoldering mediaSlag (welding)Electric arc

The invention belongs to the technical field of welding materials, and particularly relates to a low-hydrogen easy-to-weld alkaline flux-cored wire prepared from steel slag and used for structural steel. The flux-cored wire is formed in a manner that a low-carbon cold-rolled steel strip is wrapped with flux core powder, and the flux core powder comprises 22%-28% of steel slag, 7.5%-9.0% of Mo40V40Al20 powder, 5.6%-8.2% of FeMn60Si34C 0.02 powder, 4.1%-5.0% of FeTi80-A powder, 7.8%-9.6% of CaF2 powder plated with Ni on the surface, 4.2%-6.0% of nano TiO2, 3.1%-3.8% of 200-mesh nitrocellulose powder, 2.1%-3.0% of feldspar and the balance FHT100.25 iron powder reduced. During welding, the flux-cored wire is stable in electric arc, small in splashing, good in post-welding forming, easy to deslag, suitable for all-position welding, low in residual hydrogen content in deposited metal, uniform in chemical component and high in mechanical property, and is an innovation in the aspect of alkaline flux-cored wires.

Owner:ZHENGZHOU UNIV

A kind of diffusion welding connection method using cu foil and ti foil as composite intermediate layer

ActiveCN109014549BForm to avoidFully consider compatibilityWelding/soldering/cutting articlesNon-electric welding apparatusCopper foilSuperalloy

The invention relates to a method for connecting a nickel-based superalloy with a Ti2AlNb alloy or a Ti3Al-based alloy, in particular to a diffusion welding connecting method adopting Cu foil and Ti foil as a composite interlayer. The diffusion welding connecting method comprises the steps that the nickel-based superalloy and the Ti2AlNb alloy or the Ti3Al-based alloy are processed into the neededsizes, ground and polished; the Cu foil and the Ti foil are subjected to oxidation film removing, and are placed into acetone with a welded base material to be subjected to ultrasonic cleaning; and the Cu foil makes contact with the nickel-based superalloy, the Ti foil makes contact with the Ti2AlNb alloy or the Ti3Al-based alloy, and thus a welded test piece with the structure of the Ti2AlNb alloy or the Ti3Al-based alloy / the Ti foil / the Cu foil / the nickel-based superalloy is obtained, a welded workpiece is placed into a vacuum heating furnace, the pressure is applied, and welding is completed after heating, heat preservation and cooling heat circulating. The welding temperature can be lowered, forming of a brittle phase of a joint is controlled, and the property of the joint is improved; and the obtained shearing strength of the joint at the room temperature reaches 240-310 MPa.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

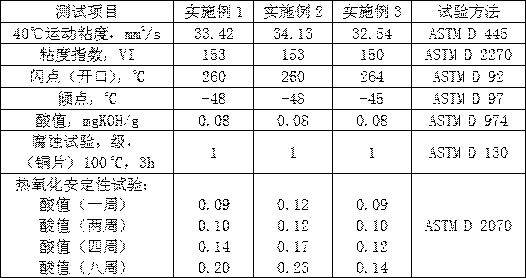

Polyether type fully synthetic compressor oil composition and preparation method thereof

ActiveCN106753719BImprove Oxidation StabilityGood thermal stabilityLubricant compositionOil sludgeOxidation stability

Owner:上海森帝润滑技术有限公司

Wax mold assembly structure of a single-crystal blade with integral casting of cover plate and cantilever structure

ActiveCN112705671BAvoid breakingReduced propensity to formFoundry moulding apparatusEngineeringSingle crystal

The invention belongs to the field of complex hollow single-crystal blade casting, and in particular relates to a wax mold assembly structure of a single-crystal blade with integral casting of a cover plate and a cantilever structure. Since the blade cover plate is integrally cast and the casting hole diameter on the cover plate is small, the ceramic core of the blade (the part where the casting hole of the blade tip is formed) is easily broken. In addition, the blade is a cantilever structure, which cannot be positioned, which leads to defects such as eccentricity, exposed core, and miscellaneous crystals and stripe crystals in the blade during the directional solidification process. However, the combination of wax patterns is the main factor affecting the above defects. The invention solves the problem of blade eccentricity by rationally designing the ceramic core boss at the tip margin of the blade; rationally designing the degree of freedom of the core and the fixed end based on the expansion difference between the core and the shell to avoid fracture of the core; and adjusting the position of the sprue Reduces propensity for blade defect formation. The pass rate of single crystal blades formed by the molding method of the invention is relatively high.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com