A welding method for suppressing cracks in aluminum alloy t-joints

A welding method, aluminum alloy technology, applied in welding equipment, welding accessories, manufacturing tools, etc., to release internal stress, avoid repeated softening, and suppress cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

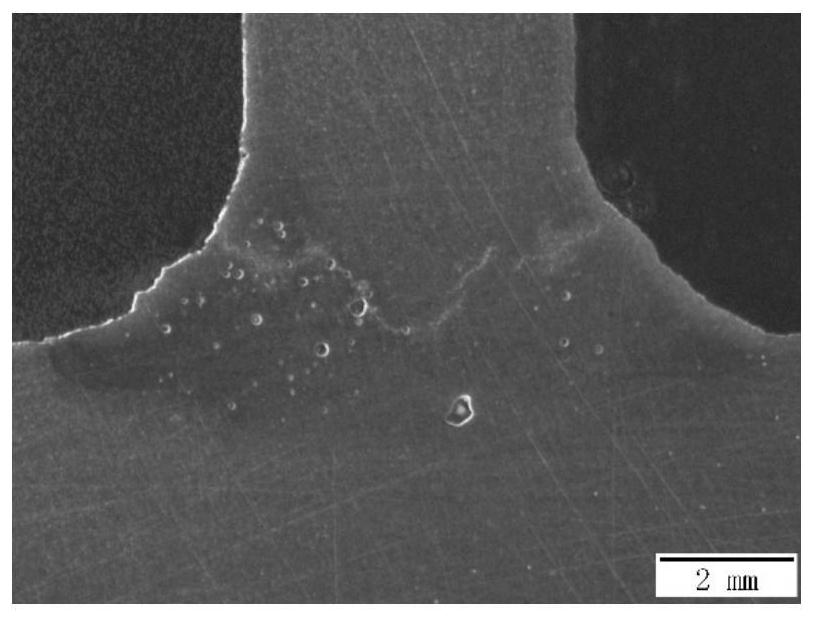

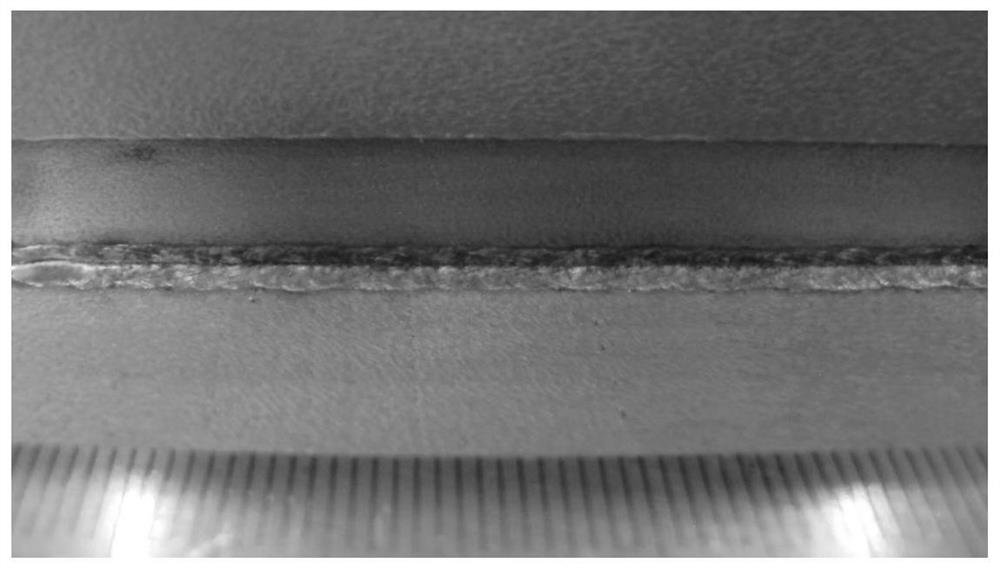

Examples

Embodiment 1

[0039] The method of welding 2195 aluminum-lithium alloy 4mm stringer and 6mm skin T-joint in this embodiment is as follows:

[0040] Step 1: the parts to be welded of the workpiece are processed to the required precision as required, and the two side surfaces after the workpiece are processed are polished or cleaned;

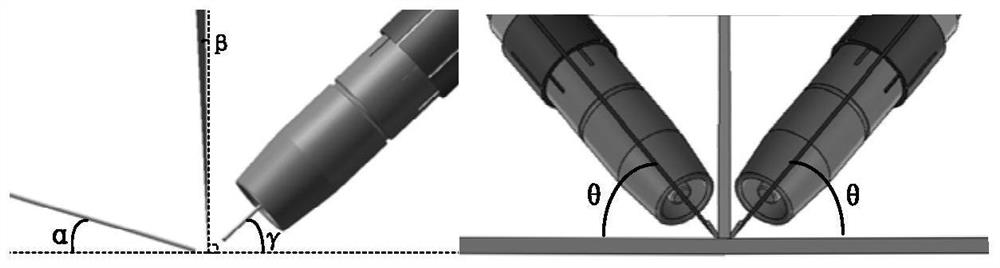

[0041] Step 2: fix the workpiece to be welded after grinding or cleaning on the welding fixture, the stringer is perpendicular to the surface of the skin, the upper preload is not less than 50N, the inclination angle α of the welding wire 1 is 20°, and the inclination angle β of the laser is 52°, The inclination angle γ of the welding torch is 35°, and the inclination angle θ of the composite welding head is 32°.

[0042] Step 3: The same parameters are used on both sides, the laser defocus amount is ﹢3mm, the laser power is 5000W, the welding speed is 5m / min, the wire feeding speed is 180mm / min, the filament spacing is 5mm, the arc current is 85A, and the arc ...

Embodiment 2

[0046] The method of welding 2195 aluminum-lithium alloy 4mm stringer and 6mm skin T-joint in this embodiment is as follows:

[0047] Step 1: the parts to be welded of the workpiece are processed to the required precision as required, and the two side surfaces after the workpiece are processed are polished or cleaned;

[0048] Step 2: fix the workpiece to be welded after grinding or cleaning on the welding fixture, the row bar is perpendicular to the surface of the skin, the upper preload is not less than 50N, the inclination angle α of the welding wire 1 is 20°, and the inclination angle β of the laser is 52°, The inclination angle γ of the welding torch is 35°, and the inclination angle θ of the composite welding head is 32°.

[0049] Step 3: use the same parameters on both sides, the laser defocus amount is ﹢3mm, the laser power is 5000W, the welding speed is 5m / min, the wire feeding speed is 180mm / min, the distance between the filaments is 2mm, the arc current is 85A, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com