Sand mould of precoated sand for casting single piston ring and manufacturing method of sand mould

A production method and technology of piston rings, which are applied in the direction of casting molding equipment, casting molds, casting mold components, etc., can solve the problems of difficult technical index requirements for casting performance, low first-time yield of piston ring castings, and difficulty in controlling the amount of gas generated by molding sand, etc. , to achieve the effect of improving the working environment in the workshop, good internal quality, and preventing shrinkage and porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

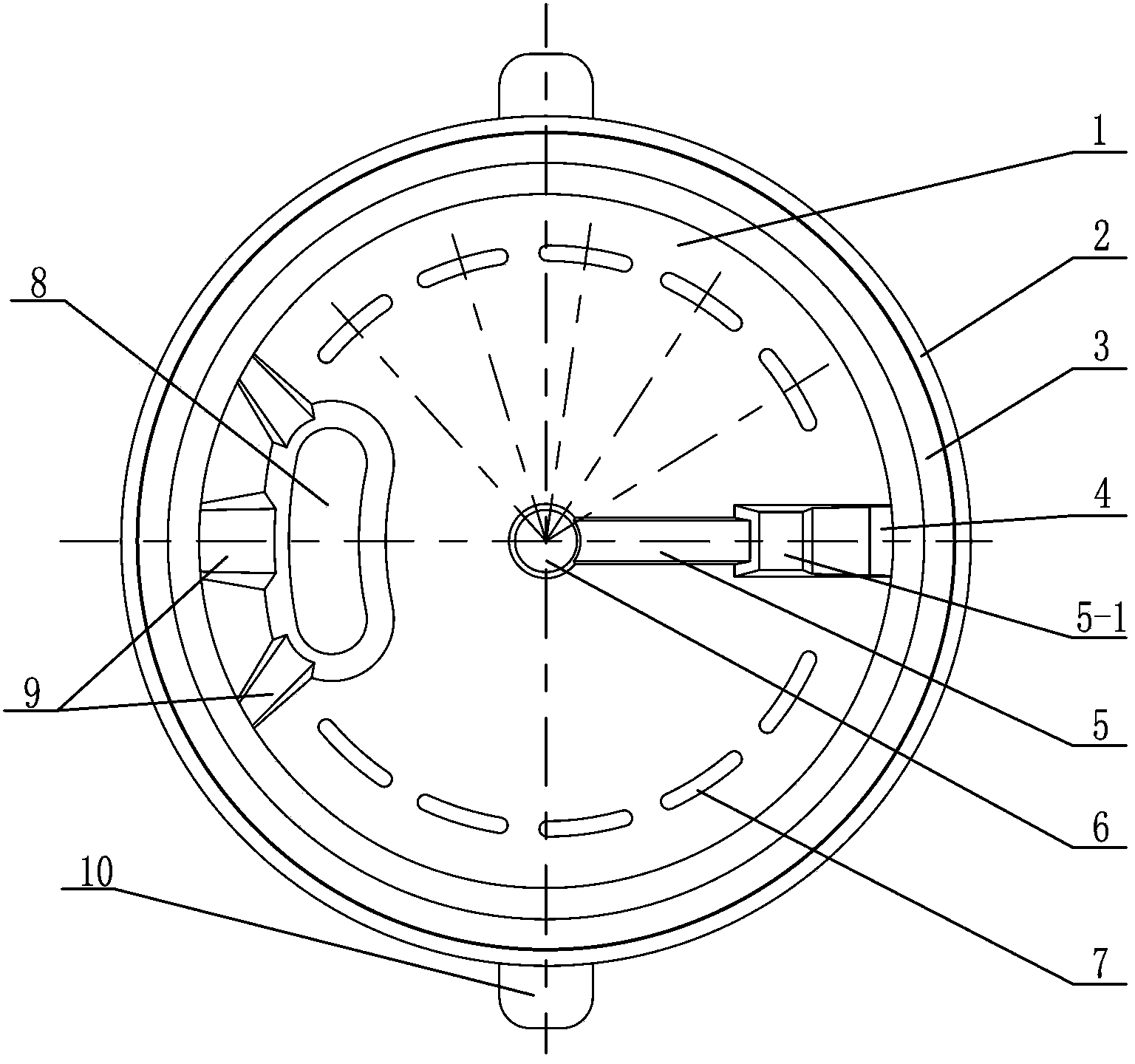

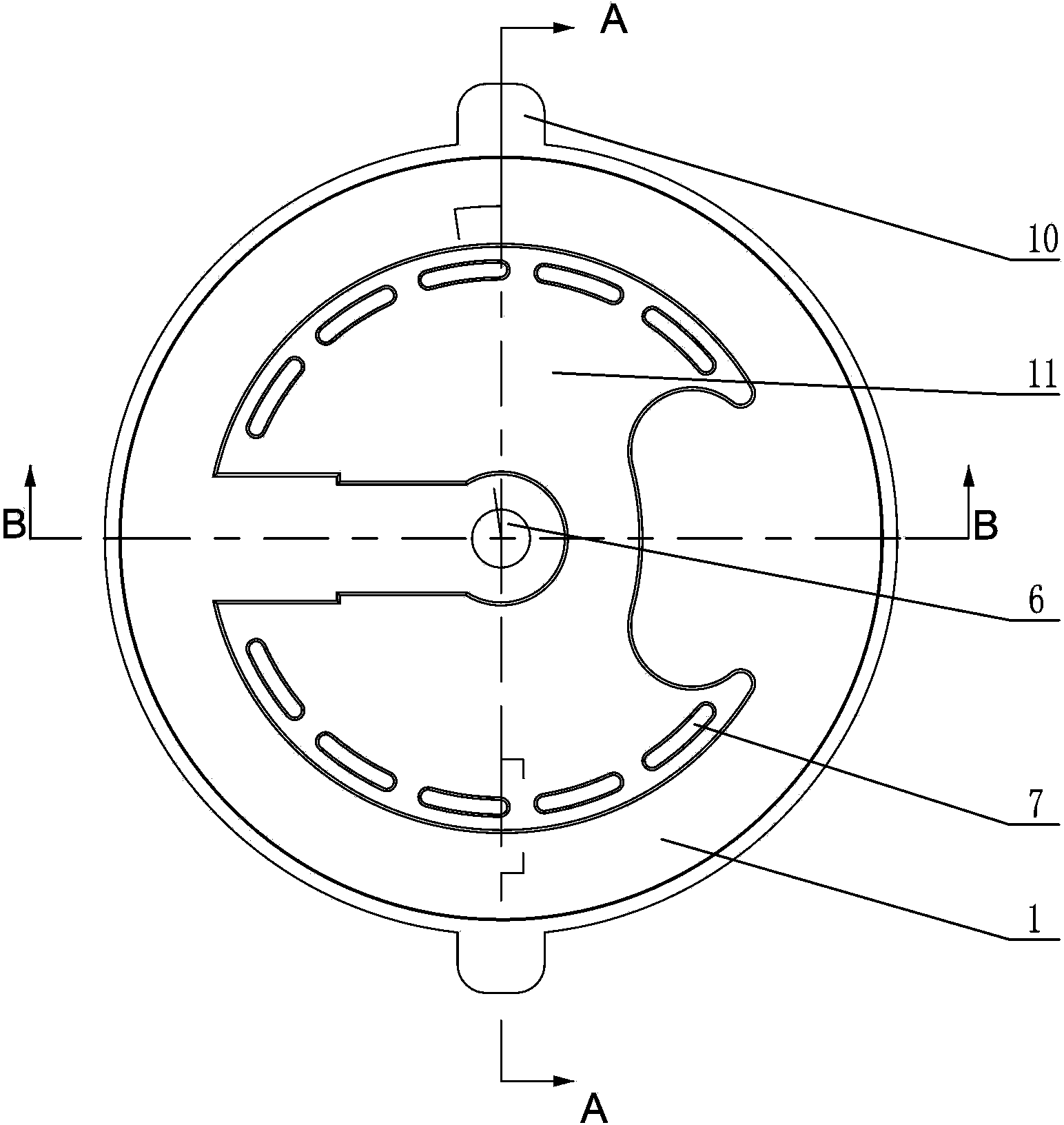

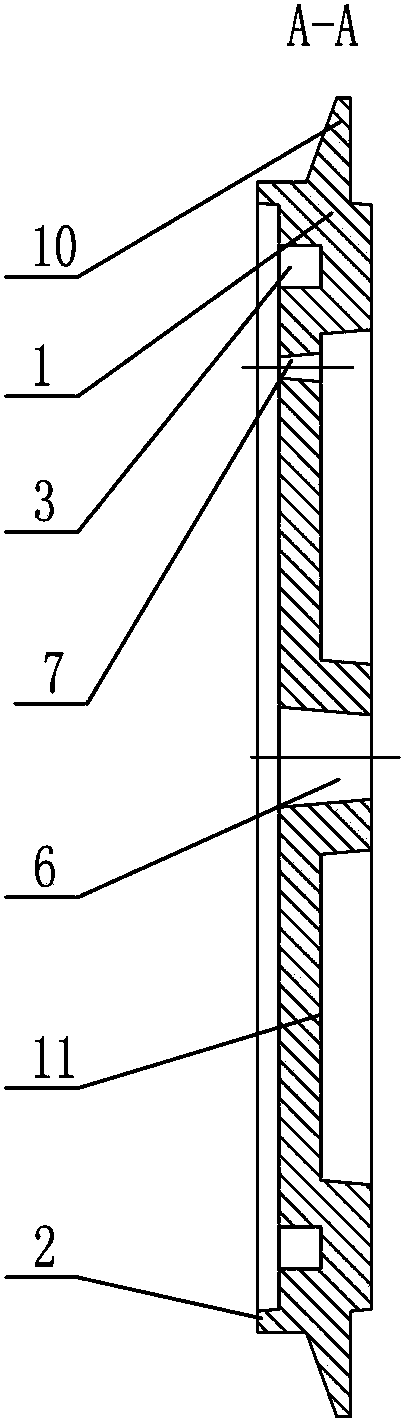

[0021] See Figure 1~4 As shown, a coated sand mold for single piston ring casting of the present invention includes a circular disc body 1, a pouring system arranged on the circular disc body 1, a retaining ring and an air outlet, and the pouring system of the present invention includes The sprue 6, the ingate 4, the runner 5 and the riser 9, the sprue 6 runs through the middle of the circular disc body 1, and the ingate 4 arranged on the front of the circular disc body 1 passes through the runner 5 communicates with the straight gate 6, the inner gate 4 communicates with the ring body groove 3, the riser 9 is arranged opposite to the inner gate 4, and the riser 9 communicates with the ring body groove 3 through more than two inclined gates 8, so that The molten iron flows into the groove 3 of the ring body and finally flows into the riser 9, through which the cold molten iron can be collected. In particular, the molten iron is injected into the riser 9 through a plurality of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com