Directional solidification method capable of reducing freckles in castings with cross-sectional variations

A technology of directional solidification and cross-section change, which is applied in the direction of self-solidification, chemical instruments and methods, crystal growth, etc., can solve the problems of low cooling rate and solidification rate, such as freckles, and achieve improved cooling rate and solidification rate, less consumption, and materials The effect of a wide range of sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] This embodiment is a directional solidification method capable of reducing freckles in castings with varying cross-sections.

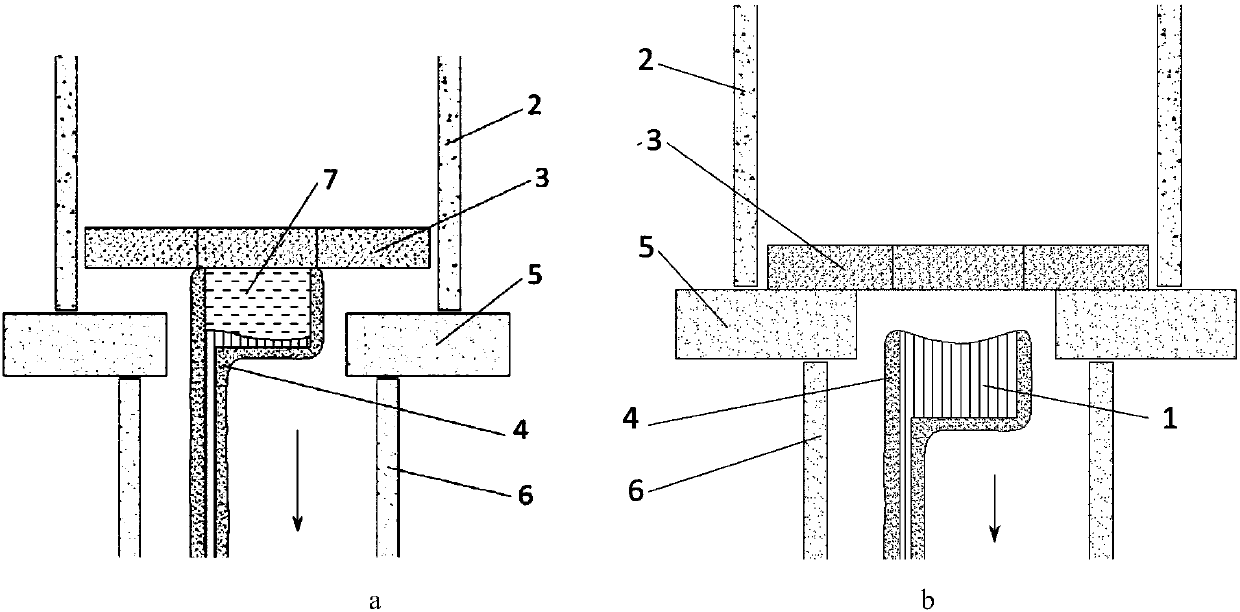

[0036] Apply this embodiment to the directional solidification of a casting 1 simulating the section change of the hollow blade, such as figure 1 As shown; the size of the small section of the casting with the section change is 4mm×20mm×100mm, the size of the large section of the casting is 40mm×20mm×25mm, and the material is nickel-based superalloy. Specific steps are as follows:

[0037] Step 1, start to determine the cooling rate and solidification rate distribution of the casting with cross-section change during the directional solidification process.

[0038] The cooling rate and solidification rate distribution of the cross-sectional casting in the process of directional solidification are obtained by simulation calculation. Use ProCAST software to numerically simulate the directional solidification process of casting 1 according to conve...

Embodiment 2

[0053] Apply the present invention to the directional solidification of a casting 1 simulating the section change of the hollow blade, such as figure 1 As shown; the size of the small section of the casting with the section change is 4mm×20mm×100mm, the size of the large section of the casting is 40mm×20mm×50mm, and the material is a nickel-based superalloy; the specific steps are as follows:

[0054] Step 1, start to determine the cooling rate and solidification rate distribution of the casting with cross-section change during the directional solidification process.

[0055] The cooling rate and solidification rate distribution of the cross-sectional casting in the process of directional solidification are obtained by simulation calculation. Use ProCAST software to numerically simulate the directional solidification process of casting 1 according to conventional methods, and perform post-processing to obtain the cooling rate and solidification rate distribution on the castin...

Embodiment 3

[0070] Apply the present invention to the directional solidification of a casting 1 simulating the section change of the hollow blade, such as figure 1 As shown; the size of the small section of the casting with the section change is 4mm × 20mm × 100mm, the size of the large section of the casting is 40mm × 20mm × 50mm, and the material is a nickel-based superalloy; the specific steps are as follows:

[0071] Step 1, start to determine the cooling rate and solidification rate distribution of the casting with cross-section change during the directional solidification process.

[0072] The cooling rate and solidification rate distribution of the cross-sectional casting in the process of directional solidification are obtained by simulation calculation. Use ProCAST software to numerically simulate the directional solidification process of casting 1 according to conventional methods, and perform post-processing to obtain the cooling rate and solidification rate distribution on th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com