A kind of tc4 titanium alloy flux-cored welding wire and preparation method thereof

A technology of flux-cored welding wire and titanium alloy, which is applied in welding equipment, metal processing equipment, manufacturing tools, etc. It can solve the problems of high cost of formula adjustment, poor wetting and spreading, and low efficiency of welding wire deposition, achieving wetting and Good spreading performance, small welding spatter, improved welding process performance and joint mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

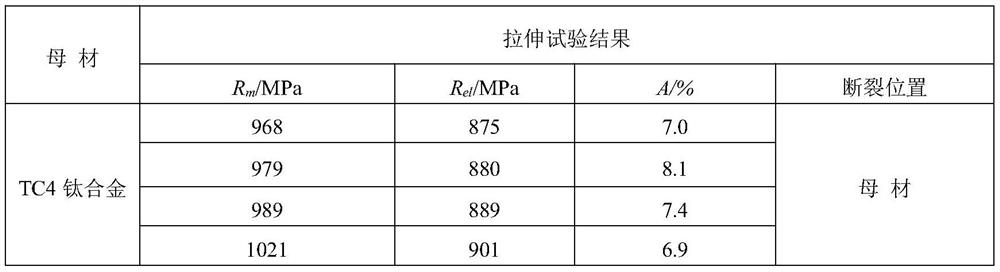

[0037]Embodiment 1: A TC4 titanium alloy flux-cored welding wire in this embodiment is prepared from a TA1 titanium alloy sheath and a flux core; the TA1 titanium alloy sheath is formed from a TA1 titanium strip through reeling, drawing, and annealing; The drug core is composed of vanadium powder, aluminum powder, molybdenum powder, cobalt powder, nickel powder, copper powder, silicon powder and titanium powder, wherein the mass percentage of each component is vanadium powder: 20%, aluminum Powder: 26%, molybdenum powder: 18%, cobalt powder: 0.1%, nickel powder: 2%, copper powder: 0.6%, silicon powder: 0.1%, the rest is titanium powder, the composition and content of the TA1 titanium alloy skin elements It is: Ti≥99%, H≤0.015%, N≤0.03%, the thickness of the TA1 titanium strip is 0.35mm, the width is 7mm, and the length is 35m, wherein the filling rate of the flux core in the TC4 titanium alloy flux cored wire is 20%, the particle size of the aluminum powder and titanium powder...

specific Embodiment approach 2

[0046] Specific embodiment two: a TC4 titanium alloy flux-cored welding wire in this embodiment is prepared from a TA1 titanium alloy sheath and a flux core; the TA1 titanium alloy sheath is formed from a TA1 titanium strip through reeling, drawing, and annealing; The drug core is made of vanadium powder, aluminum powder, molybdenum powder, cobalt powder, nickel powder, copper powder, silicon powder and titanium powder, wherein the mass percentage of each component is vanadium powder: 23%, aluminum powder: 25%, molybdenum powder: 15%, cobalt powder: 0.2%, nickel powder: 3%, copper powder: 0.8%, silicon powder: 0.2%, and the rest is titanium powder. The composition and content of the TA1 titanium alloy skin elements It is: Ti≥99%, H≤0.015%, N≤0.03%, the thickness of the TA1 titanium strip is 0.40mm, the width is 8mm, and the length is 35m, wherein the filling rate of the flux core in the TC4 titanium alloy flux cored wire is 22%, the particle size of aluminum powder and titaniu...

specific Embodiment approach 3

[0055] Specific embodiment three: a TC4 titanium alloy flux-cored welding wire in this embodiment is prepared from a TA1 titanium alloy sheath and a flux core; the TA1 titanium alloy sheath is formed from a TA1 titanium strip through reeling, drawing, and annealing; The drug core is mixed with vanadium powder, aluminum powder, molybdenum powder, cobalt powder, nickel powder, copper powder, silicon powder and titanium powder, wherein the mass percentage of each component is vanadium powder: 16%, aluminum powder: 25%, molybdenum powder: 15%, cobalt powder: 0.3%, nickel powder: 4%, copper powder: 1.0%, silicon powder: 0.3%, and the rest is titanium powder. The composition and content of the TA1 titanium alloy skin elements It is: Ti≥99%, H≤0.015%, N≤0.03%, the thickness of the TA1 titanium strip is 0.45mm, the width is 8mm, and the length is 35m, wherein the filling rate of the flux core in the TC4 titanium alloy flux cored wire is 25%, the particle size of aluminum powder and ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com