Patents

Literature

45results about How to "Fully deoxygenated" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

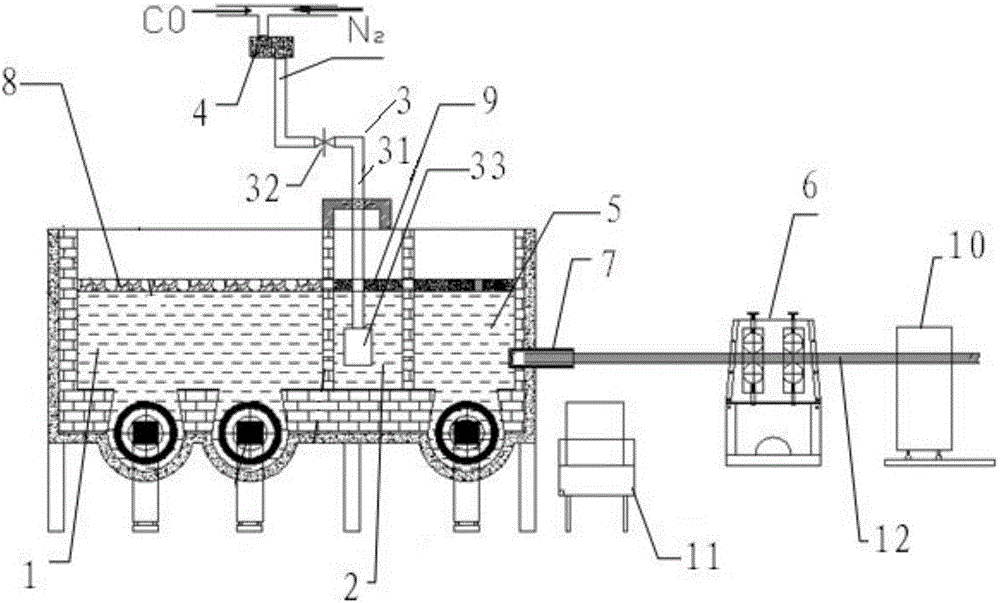

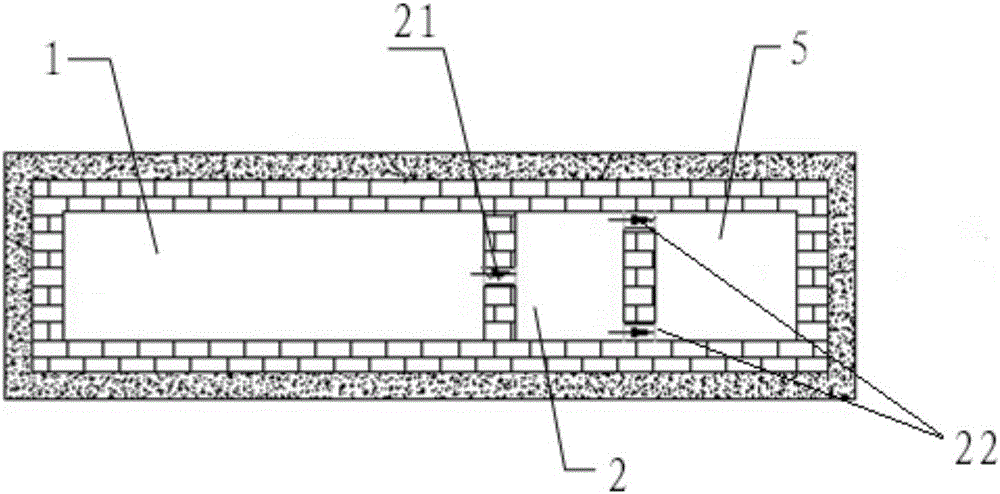

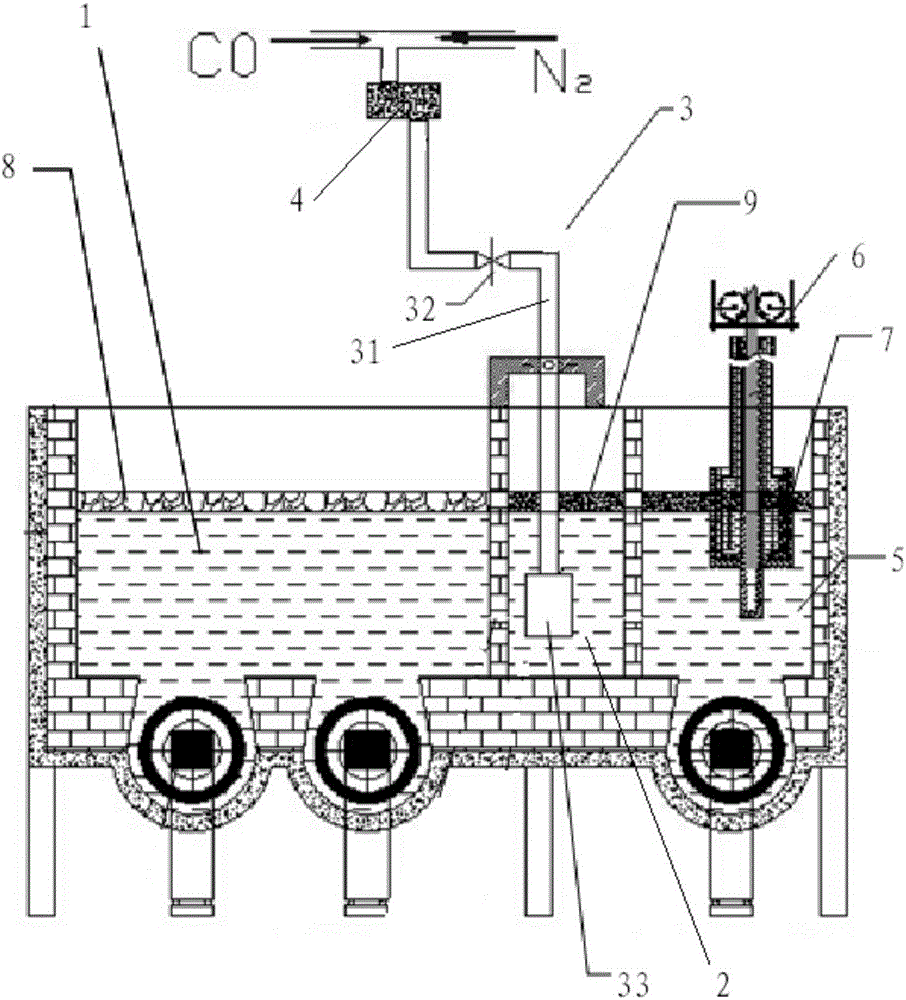

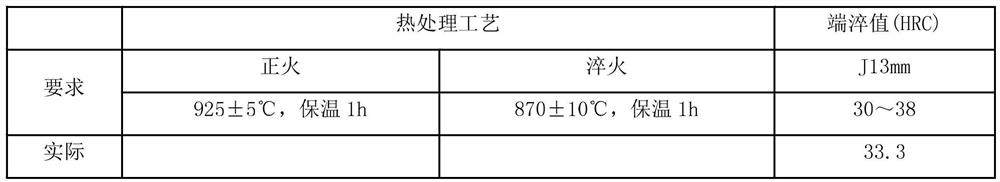

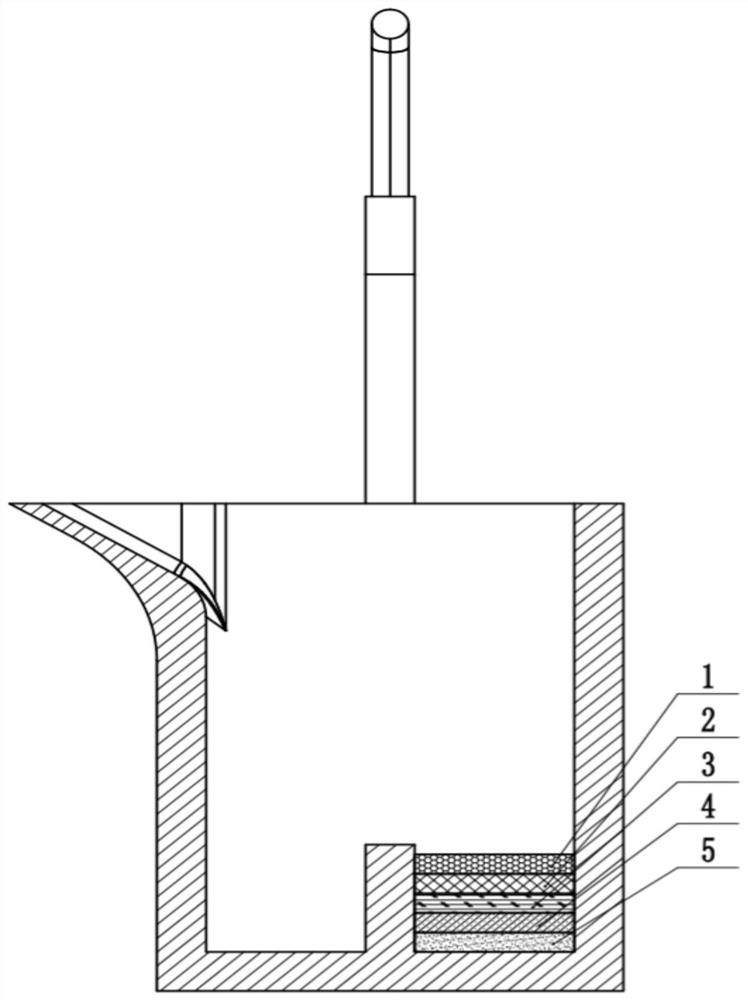

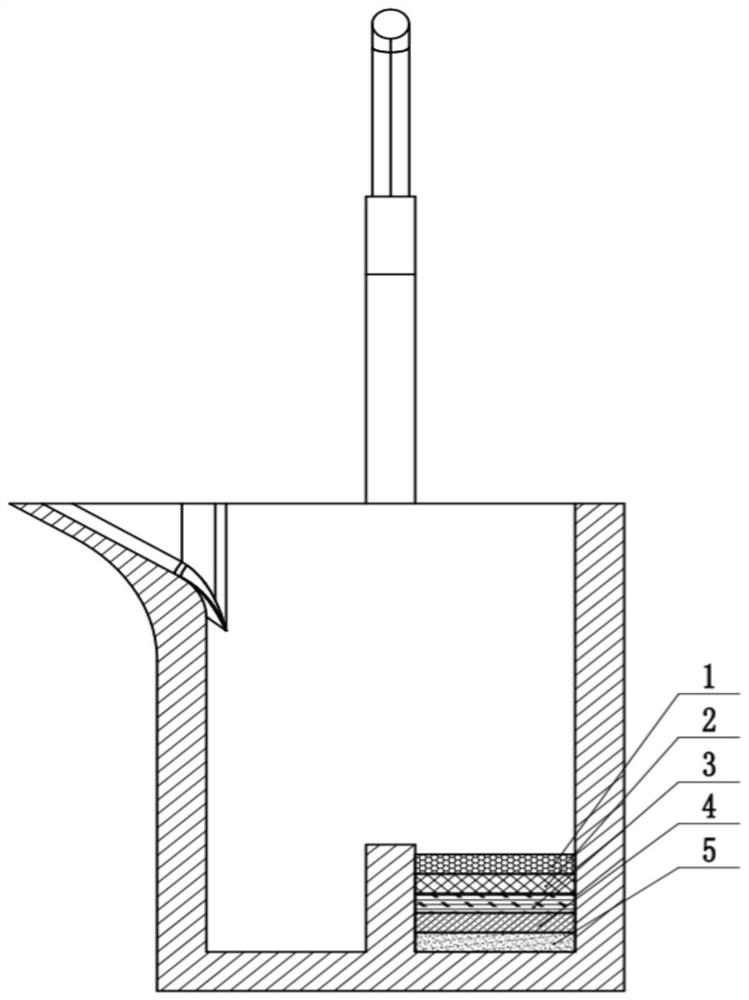

Production device and method of high-purity oxygen-free copper ingot billet

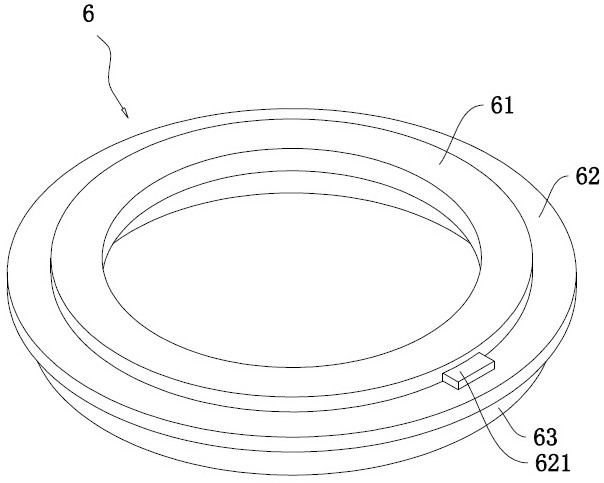

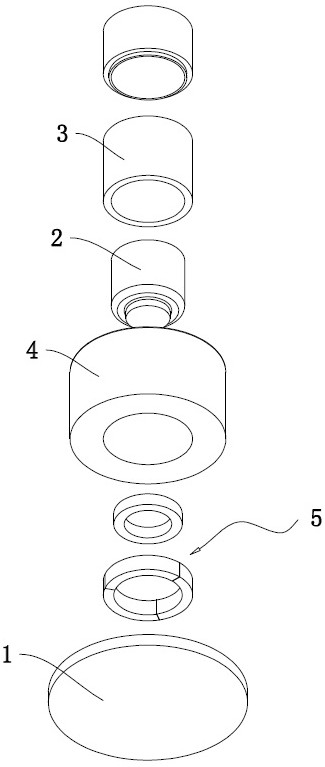

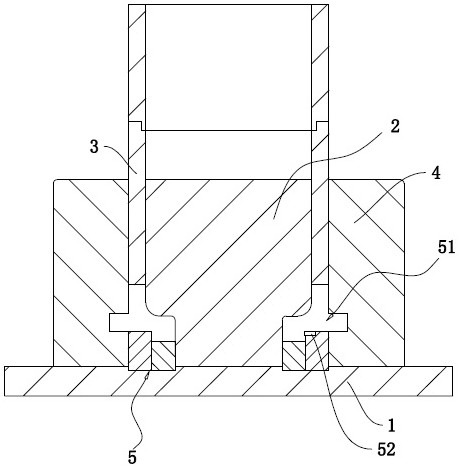

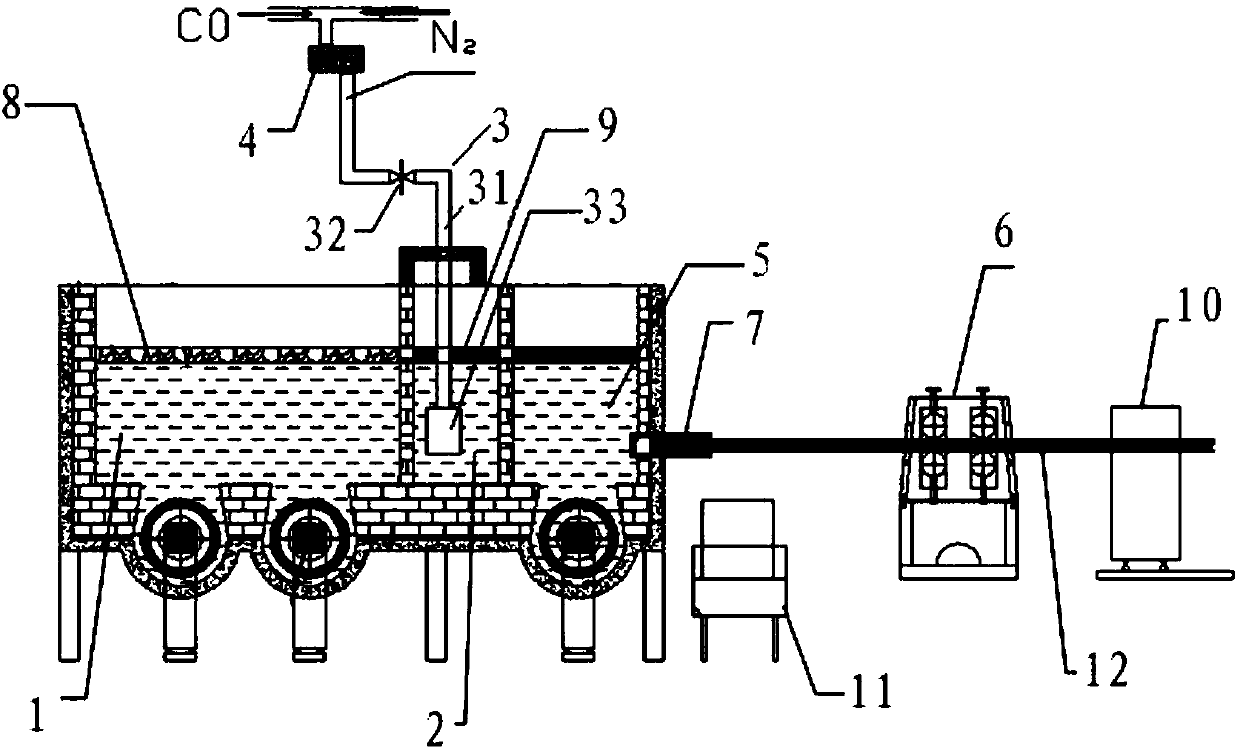

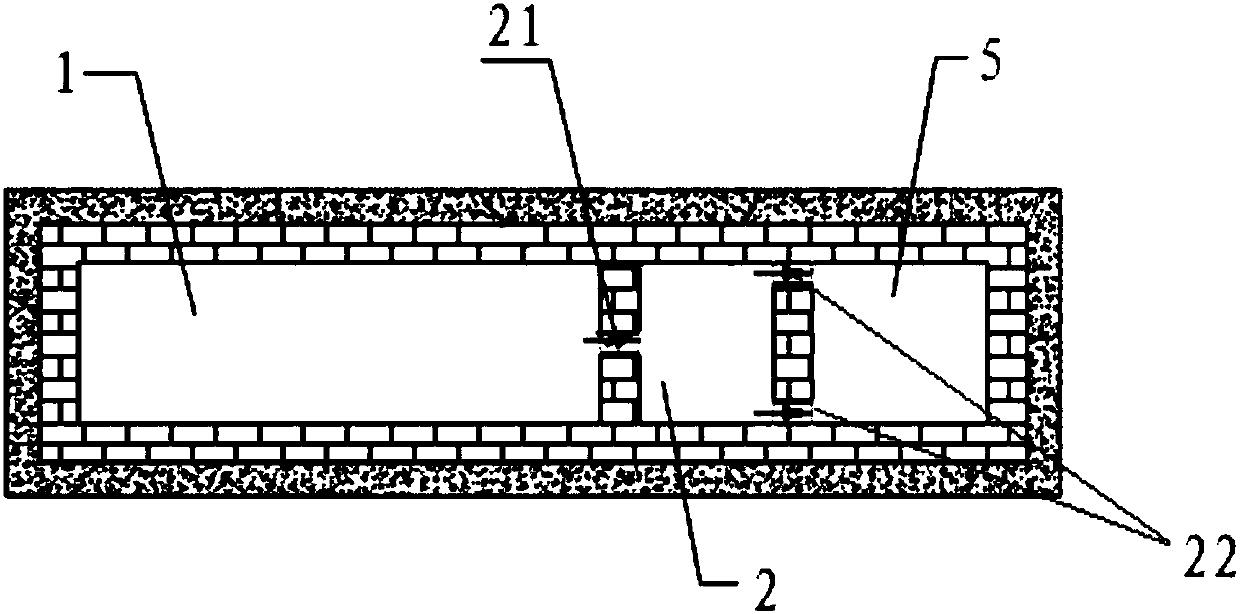

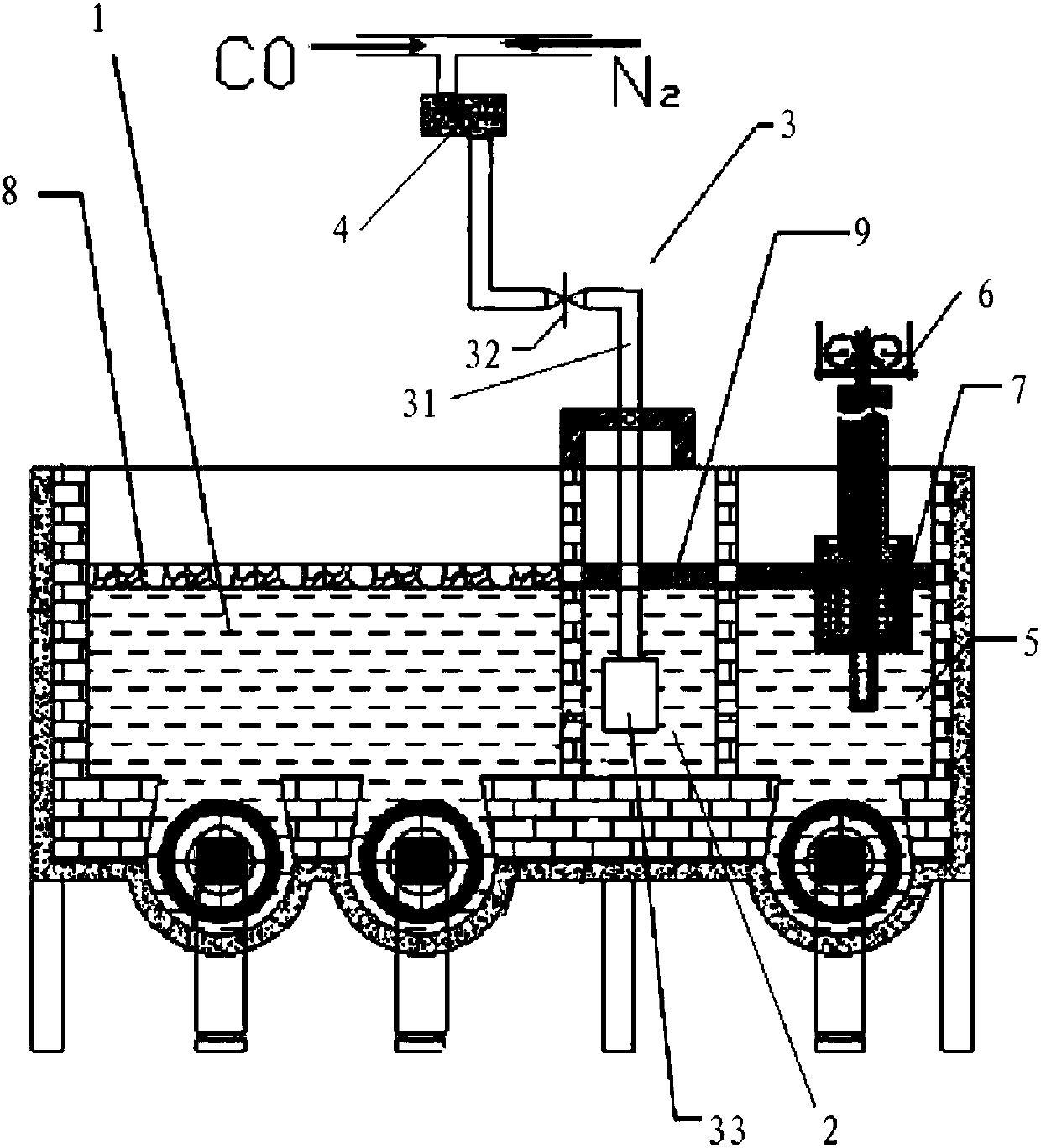

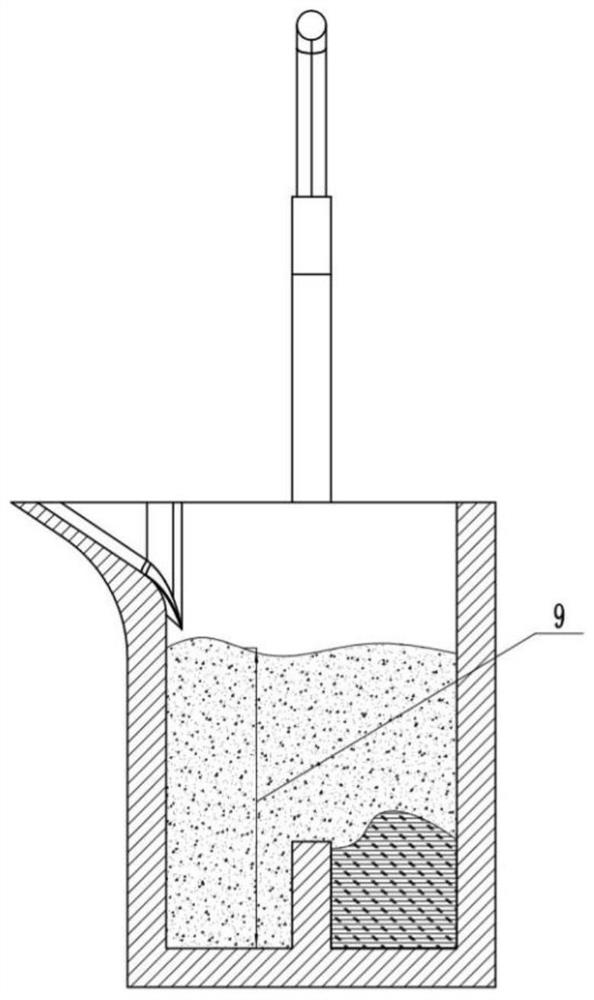

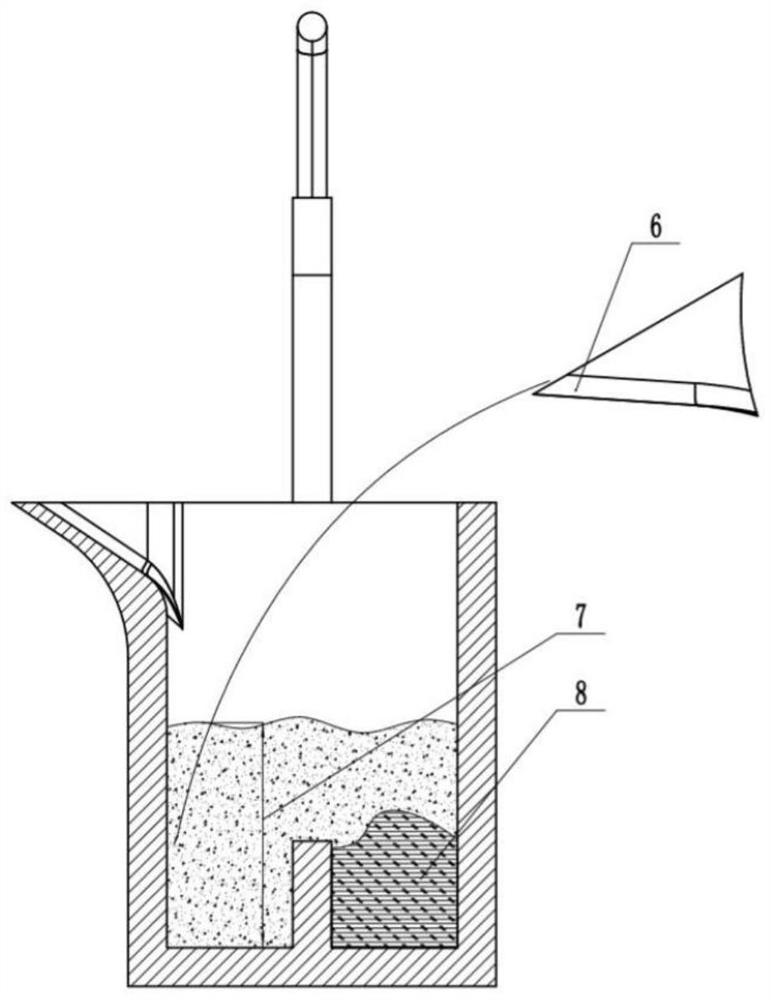

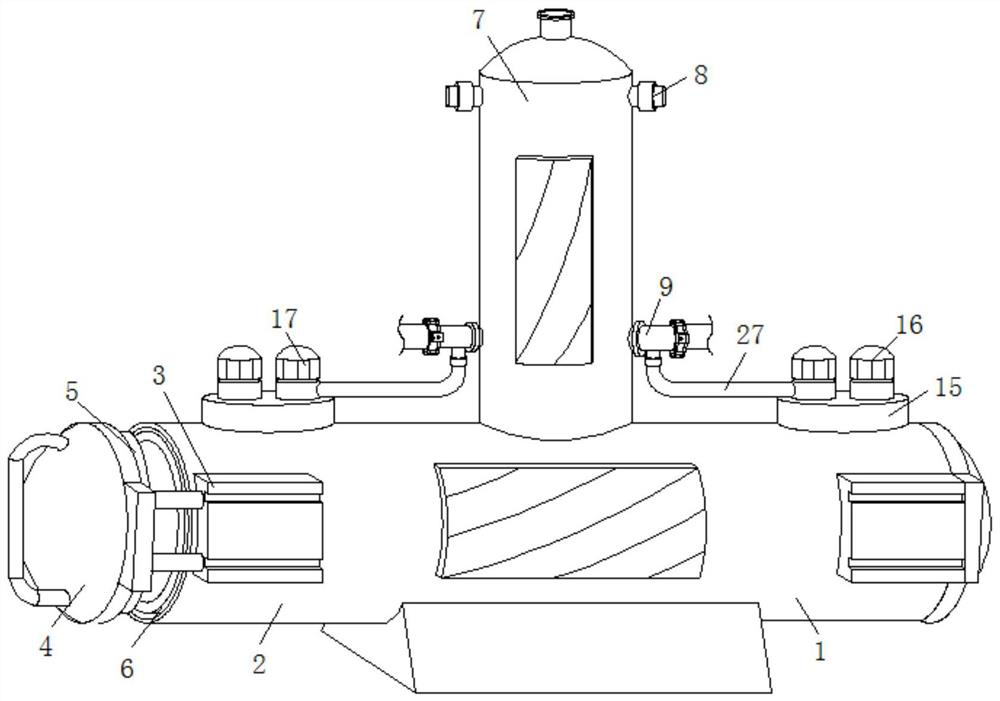

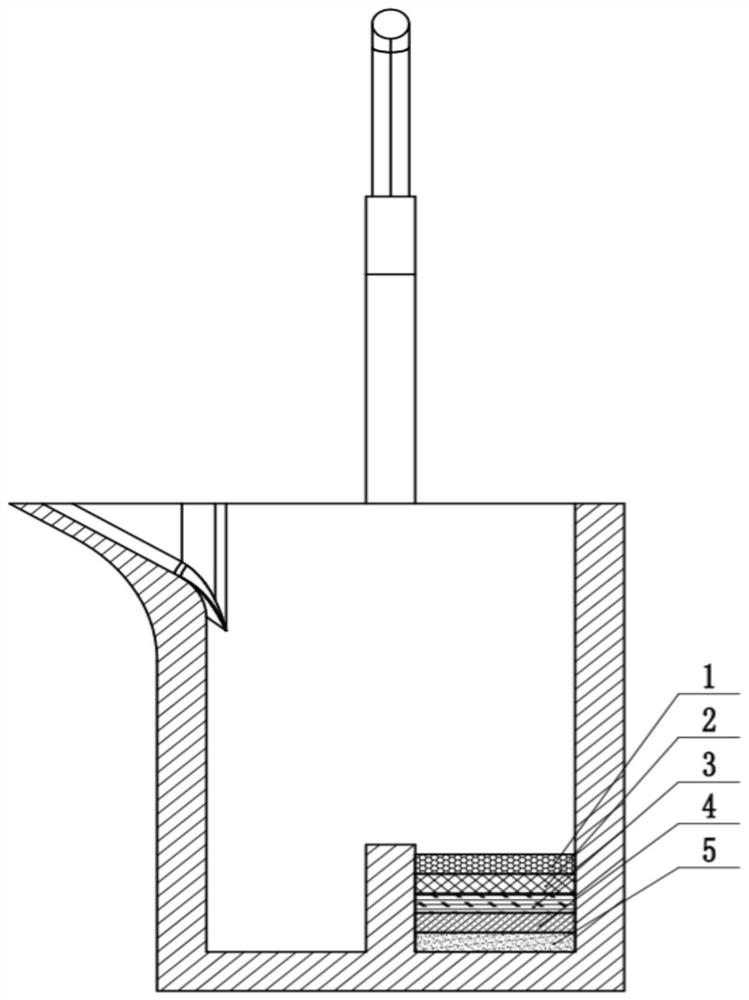

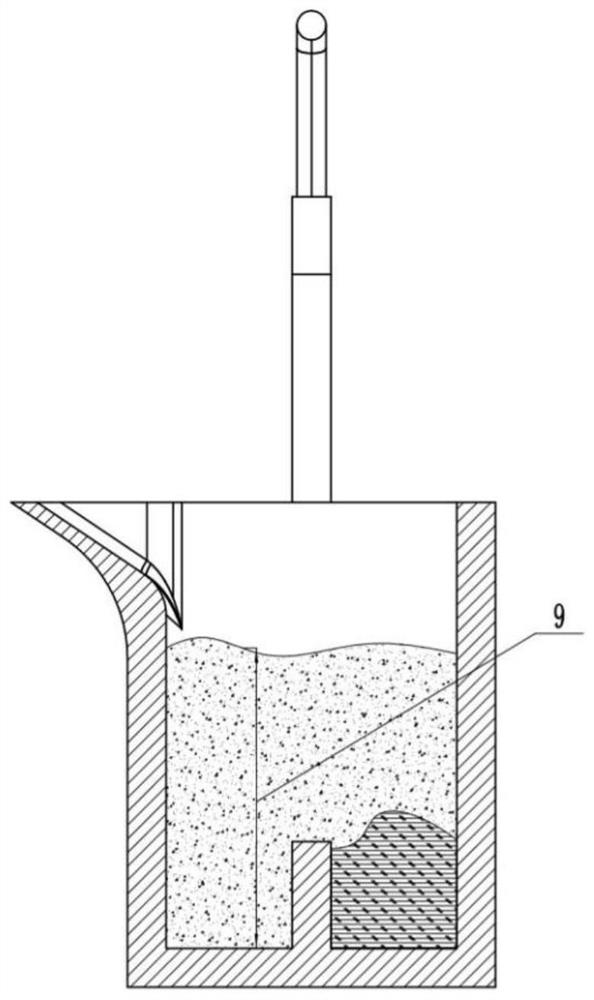

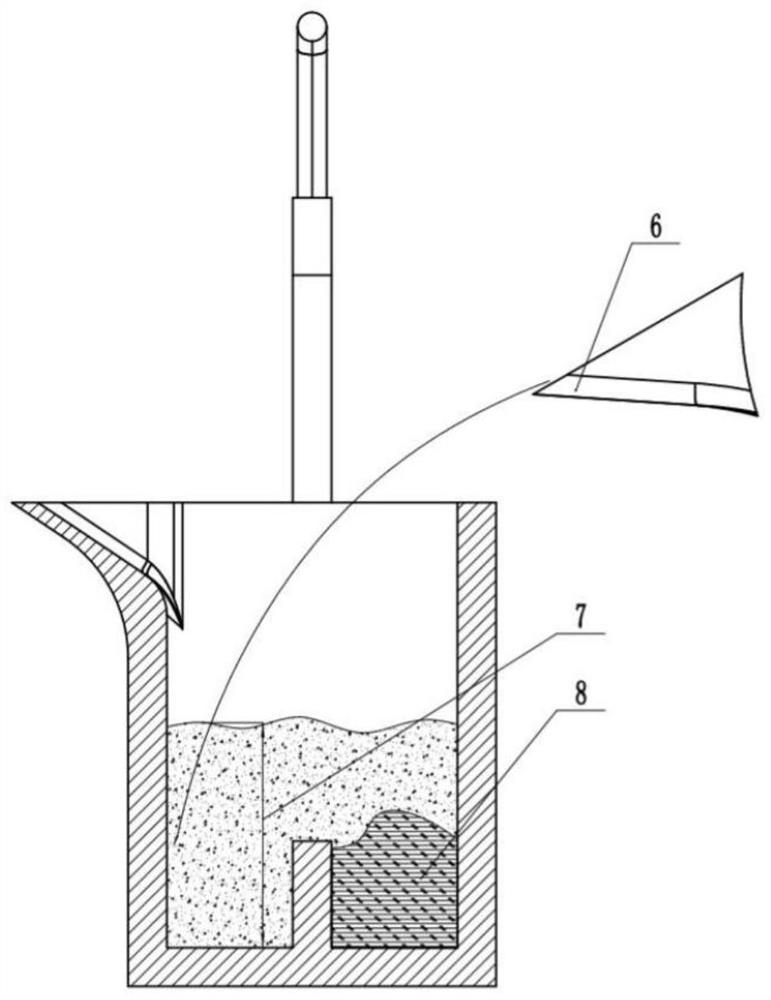

The invention provides a production device of a high-purity oxygen-free copper ingot billet. The device comprises a melting furnace, a partition bin and a heat preservation furnace which are sequentially communicated, the partition bin is further provided with a deoxygenator, the deoxygenator comprises a gas conveying pipe used for conveying deoxygenation gas and an air exhaust cover which is located in the partition bin and connected with the outlet end of the gas conveying pipe, and a plurality of air exhaust holes with the diameter of 0.5 mm to 1 mm are formed in the air exhaust cover; the melting furnace and the partition bin are connected through a liquid inlet hole, the air exhaust cover right faces the liquid inlet hole, and the distance between the air exhaust cover and the liquid inlet hole ranges from 10 mm to 40 mm; in the flowing direction of molten copper, the projection of the air exhaust cover is larger than the projection of the liquid inlet hole; the invention further provides a method capable of adopting the device for producing the oxygen-free copper ingot billet. By the adoption of the method, the oxygen-free copper ingot billet which is good in production compactness and low in oxygen content can be produced.

Owner:JIANGXI GUANGXIN COPPER IND

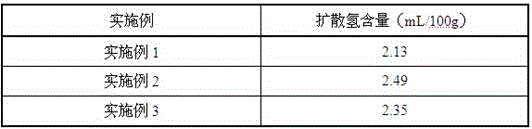

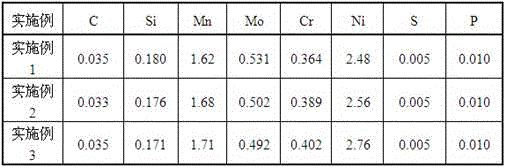

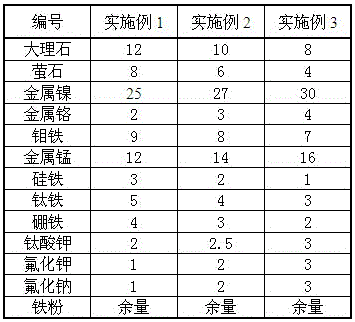

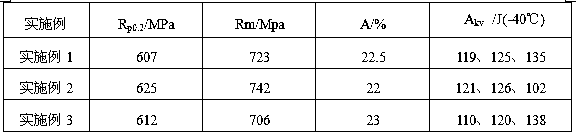

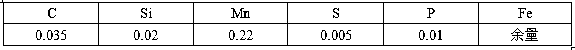

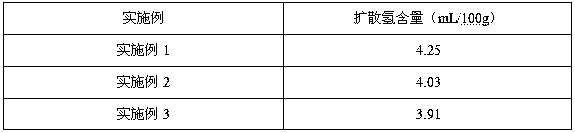

Ultralow hydrogen seamless submerged arc flux-cored wire for steel with yield strength being 690 MPa level

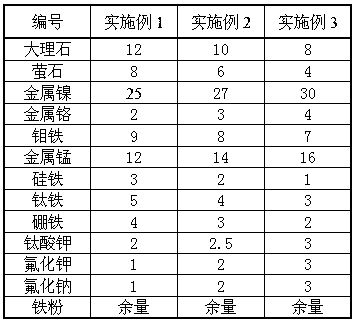

ActiveCN106141500AStrong resistance to moisture absorptionGood workmanshipWelding/cutting media/materialsSoldering mediaPotassium fluorideManganese

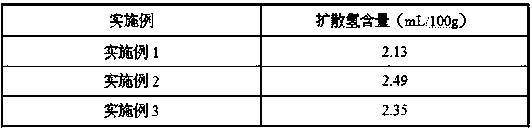

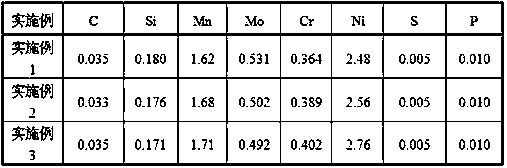

The invention discloses an ultralow hydrogen seamless submerged arc flux-cored wire for steel with yield strength being the 690 MPa level. The submerged arc flux-cored wire is composed of a sheath and flux core powder. The sheath is made of a low-carbon steel strip. The flux core powder is prepared from, by mass percent, 8%-12% of marble, 4%-8% of fluorite, 25%-30% of metal nickel, 2%-4% of metal chromium, 7%-9% of ferromolybdenum, 12%-16% of electrolytic manganese, 1%-3% of ferrosilicon, 3%-5% of ferrotitanium, 2%-4% of ferro-boron, 2%-3% of potassium titanate, 1%-3% of potassium fluoride, 1%-3% of sodium fluoride and the balance ferrous powder. The ultralow hydrogen seamless submerged arc flux-cored wire for the steel with the yield strength being the 690 MPa level is high in moisture absorption resisting property, and excellent in processing property of being matched with fluorine and alkali sintered flux SR-SJ613, diffusible hydrogen is extremely low (smaller than or equal to 4 mL / 100 g), minus 40 DEG C charpy impact energy reaches over 100 J, and the wire can be applied to welding of a steel plate with the yield strength being the 690 MPa level in the ocean engineering field.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Steel for composite microalloying welding wire and preparation method thereof

ActiveCN103255354AGrain refinementRefined deoxidationWelding/cutting media/materialsSoldering mediaWeld strengthUltimate tensile strength

The invention provides steel for a composite microalloying welding wire and a preparation method thereof. The steel is characterized by comprising the following chemical components in percentage by weight: no less than 0.06% and no more than 0.15% of C, no less than 0.81% and no more than 1.15% of Si, no less than 1.40% and no more than 1.85% of Mn, no less than 0.08% and no more than 0.15% of Ni, no less than 0.05% and no more than 0.15% of Cr, no less than 0.05% and no more than 0.15% of Mo, no less than 0.008% and no more than 0.012% of Ti, no less than 0.006% and no more than 0.030% of V, no less than 0.015% and no more than 0.025% of Nb, no less than 0.0005% and no more than 0.0030% of B, no more than 0.025% of S, no more than 0.025% of P, no more than 0.005% of O and the balance of Fe. The preparation method comprises the following steps of converting, ladle bottom argon blowing, LF refinement, fully-protected continuous casting, hot rolling and STELMOR cooling. The composite alloying provided by the invention is beneficial to refine molten drops, stabilize current and enhance the weld quality, and is beneficial to enhance the weld strength.

Owner:江阴智产汇知识产权运营有限公司

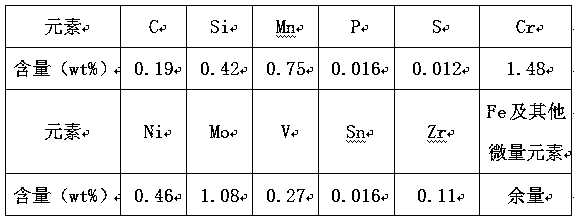

Composite material for engine exhaust valve

The invention discloses a composite material for an engine exhaust valve. The composite material for the engine exhaust valve is prepared from the following raw materials in parts by weight: 95 to 98 parts of aluminum, 2.3 to 3 parts of manganese, 0.4 to 0.5 part of silicon, 0.2 to 0.3 part of molybdenum, 0.1 to 0.2 part of titanium, 0.06 to 0.07 part of beryllium, 0.1 to 0.2 part of nickel, 0.07 to 0.1 part of tin, 0.06 to 0.1 part of hexadecyl trimethyl ammonium bromide, 3 to 5 parts of graphene oxide, 5 to 8 parts of zirconium hydride, 1.2 to 1.6 parts of hexachloroethane, 0.23 to 0.26 part of polyvinyl alcohol, 0.6 to 0.8 part of diamond micro-powder, 0.7 to 0.9 part of activated carbon, 0.2 to 0.4 part of manganese oxide, 0.9 to 1.3 parts of nano zirconium diboride, not more than 0.01 part of impurity and a proper volume of deionized water. The engine exhaust valve obtained by casting an aluminum alloy material provided by the invention has the advantages of a light weight, high strength, oxidation corrosion resistance, high temperature resistance and the like, and extremely has application value.

Owner:HEFEI HAIYUAN MACHINERY

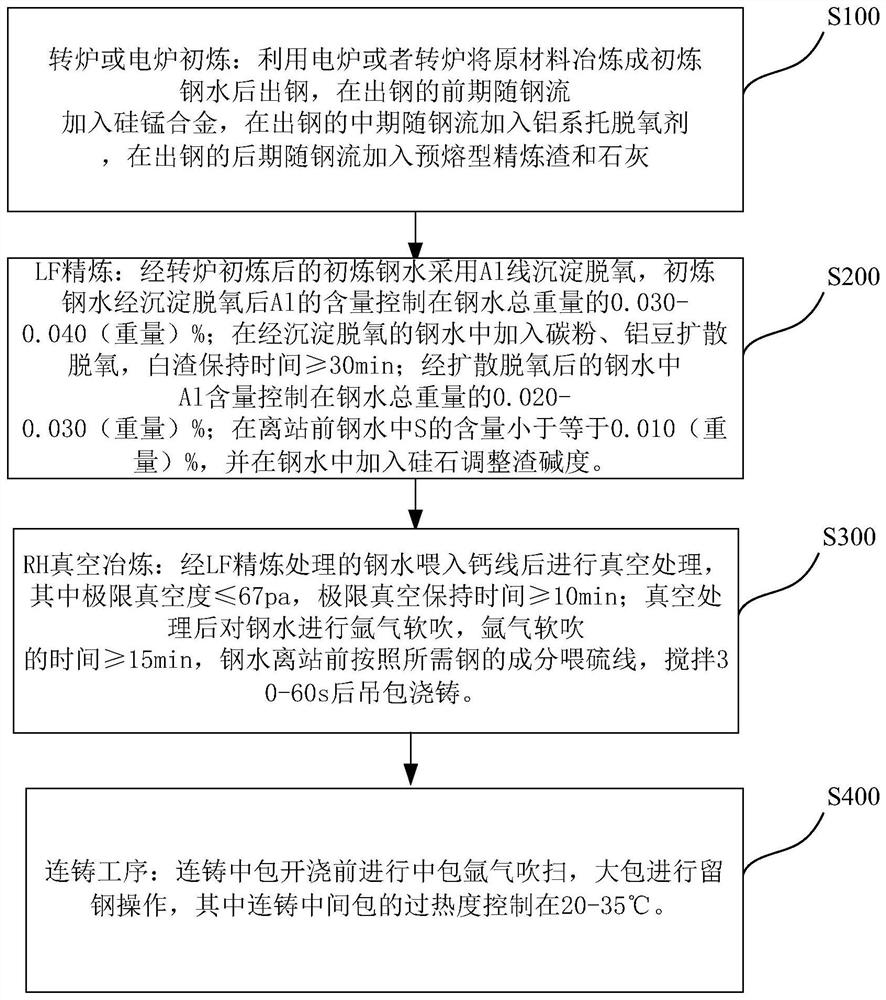

Smelting method for improving sulfur dispersion of medium-carbon sulfur-containing steel

ActiveCN113278764AImprove the purity of molten steelIncrease the yield of sulfur elementManufacturing convertersProcess efficiency improvementSmelting processAluminium

The invention relates to a smelting method for improving sulfur dispersion of medium-carbon sulfur-containing steel. The smelting method comprises the following steps that in the primary smelting process of a converter, composite deoxidation is carried out by adopting silicon-manganese alloy and aluminum, in the refining process, high-alkalinity slag is formed in molten steel by utilizing pre-melting type refining slag and lime, and then precipitation deoxidation is carried out by adopting an aluminum wire and diffusion deoxidation is carried out by adopting carbon powder and aluminum shots; the content of Al is controlled in the LF refining process, silica is added into molten steel at an LF off-station for slag changing operation, and high-alkalinity slag is adjusted into low-alkalinity slag, so that the yield of a sulfur element is increased; and before RH vacuum smelting, a calcium line is adopted for calcium treatment, so that fine dispersed Al2O3 is denatured into calcium aluminate (Al2O3-CaO), and the calcium aluminate serves as a nucleation center for sulfide precipitation. According to the method, the yield of the sulfur element can be increased, the purity of molten steel is obviously improved, the form of sulfide is improved, the sulfide is well dispersed, and the method has the advantages of being simple in technological process, easy to operate on site, low in production cost and the like.

Owner:DONGBEI SPECIAL STEEL GROUP

Aluminium-matrix composite material for automobile transmission gear, and preparation method thereof

The invention discloses an aluminium-matrix composite material for an automobile transmission gear, and a preparation method thereof. The aluminium-matrix composite material is prepared from the following raw materials in parts by weight: 95-98% of aluminium, 0.1-0.14% of germanium, 1-1.2% of manganese, 0.13-0.16% of titanium, 0.3-0.35% of copper, 0.04-0.06% of lithium, 0.2-0.3% of zinc, 0.06-0.1% of cetyl trimethyl ammonium bromide, 3-5% of graphene oxide, 5-8% of zirconium hydride, 0.85-1% of hexachloroethane, 0.4-0.6% of calcareous shale, 0.24-0.3% of sodium alginate, 0.2-0.4% of calcium silicide, 2.3-2.4% of silicon dioxide, not greater than 0.01% of impurities, and an appropriate amount of deionized water. According to the aluminium-matrix composite material disclosed by the invention, improvement for the comprehensive performance of an industrial aluminium alloy is effectively realized through improvement for a casting process, and the requirements of a high load, a light weight and good toughness of the automobile transmission gear can be met; and the aluminium-matrix composite material is low in preparation cost and worthy of popularization.

Owner:安徽瑞林精科股份有限公司

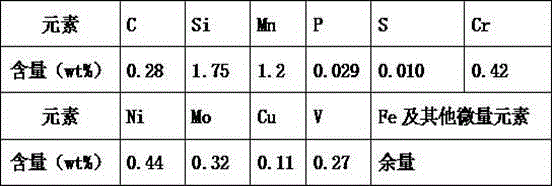

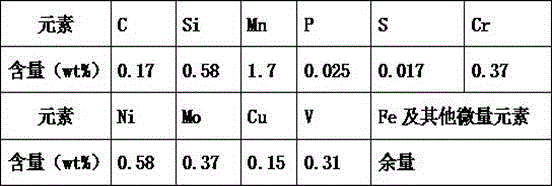

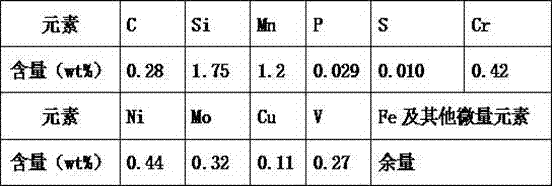

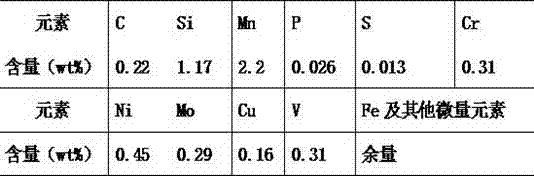

High-strength casting of mobile crushing station for mines and buildings and production process of high-strength casting

ActiveCN104878320AHigh mechanical strengthGood mechanical strength Mechanical strengthFoundry mouldsFoundry coresWear resistanceToughness

The invention discloses a high-strength casting of a mobile crushing station for mines and buildings. The high-strength casting comprises the following chemical components by weight percent: 0.15-0.35% of C, 0.50-2.50% of Si, Mn not larger than 2.5%, P not larger than 0.04%, S not larger than 0.02%, 0.3-0.5% of Cr, 0.4-0.6% of Ni, Mo not larger than 0.5%, Cu not larger than 0.2%, 0.25-0.35% of V, and the balance of Fe and unavoidable trace impurities. The invention further discloses a production process of the high-strength casting; the casting has good mechanical properties and wear and corrosion resistance, still has good toughness in low temperature conditions, and is suitable for the production of the mobile crushing station for mines and buildings.

Owner:SANMING CITY YIJUN MACHINERY FOUNDRY

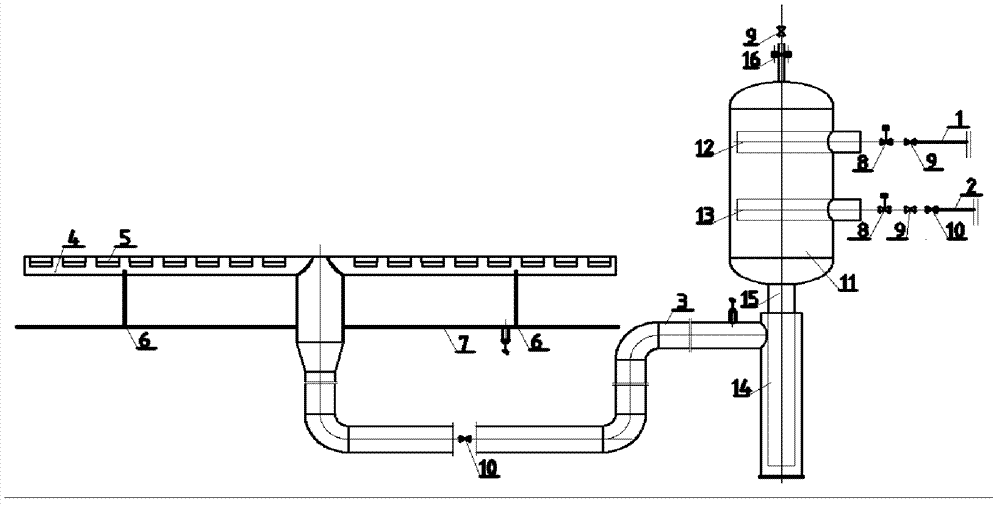

Steam turbine condenser water-supplementing and deoxidizing system

ActiveCN102901370ASolve the problem of large flow water replenishmentEasy to operateSteam/vapor condensersDistributed control systemEngineering

The invention discloses a steam turbine condenser water-supplementing and deoxidizing system and relates to a steam turbine technology. The steam turbine condenser water-supplementing and deoxidizing system comprises a water-supplementing pipeline, a steam pipeline, a water outlet pipeline, a water-supplementing and deoxidizing device, a water sealing device, a restriction orifice and the like; water supplemented to the system is heated by steam from steam extraction of a steam turbine body; the temperature of the heated supplemented water is 3-3.5 degrees higher than the saturation temperature of a condenser under an operating pressure, thereby providing a flash evaporation effect; and after the hot water enters a hot well of the condenser, part of steam is extracted out through flash evaporation, and oxygen dissolved in the water can escape together with the steam, thereby achieving the purpose of deoxidizing. Both the water supplementing quantity and the steam extraction quantity of the system are regulated through a flow regulating valve, and the flow regulating valve is controlled by a distributed control system (DCS). According to the system disclosed by the invention, the condenser itself does not need to be reconstructed, the structure is simple, and the operation is reliable.

Owner:FULL DIMENSION POWER TECH

Seamless steel pipe for high-pressure oil pipe of automobile engine and manufacturing method of seamless steel pipe

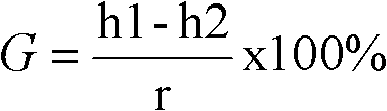

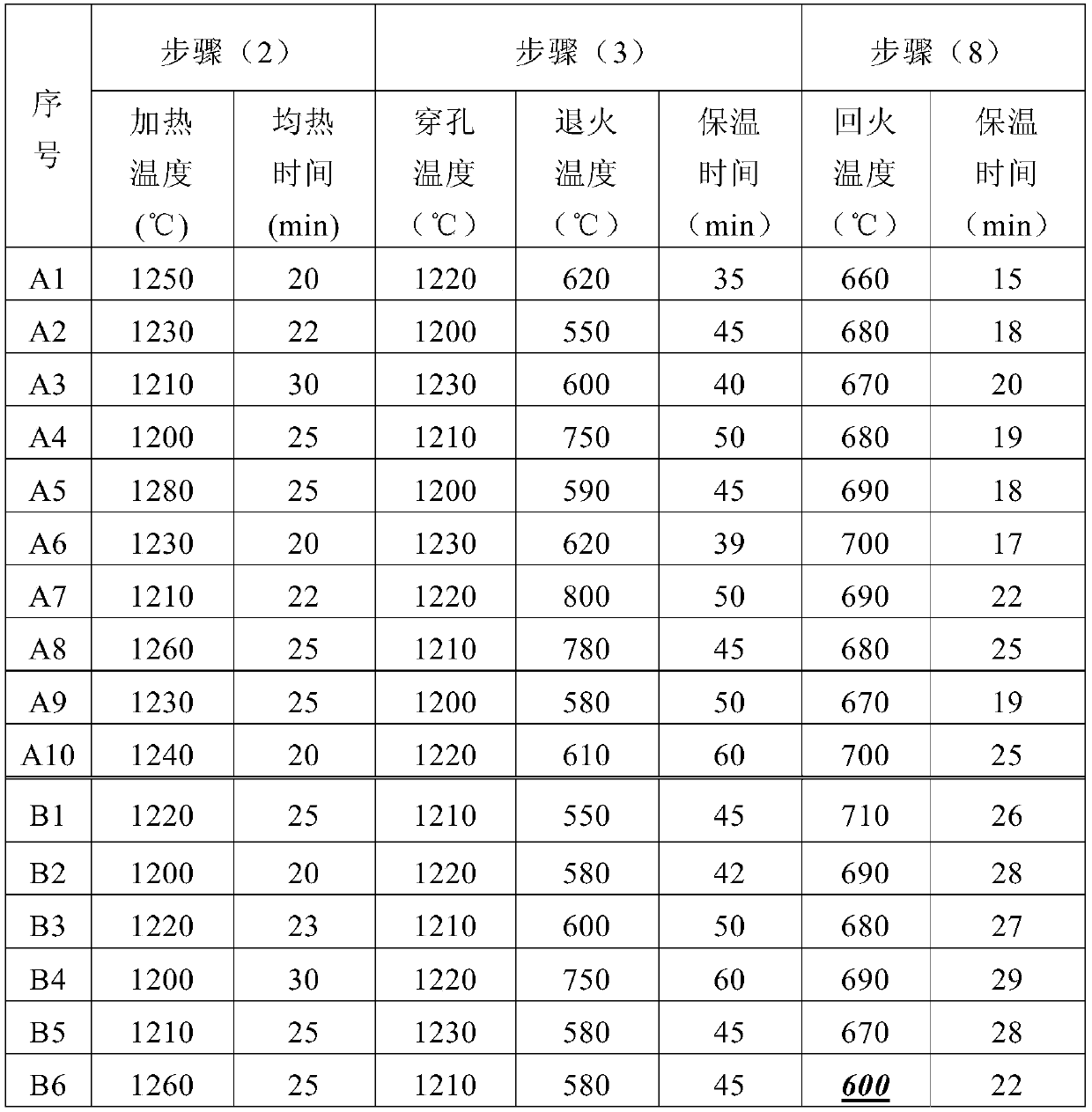

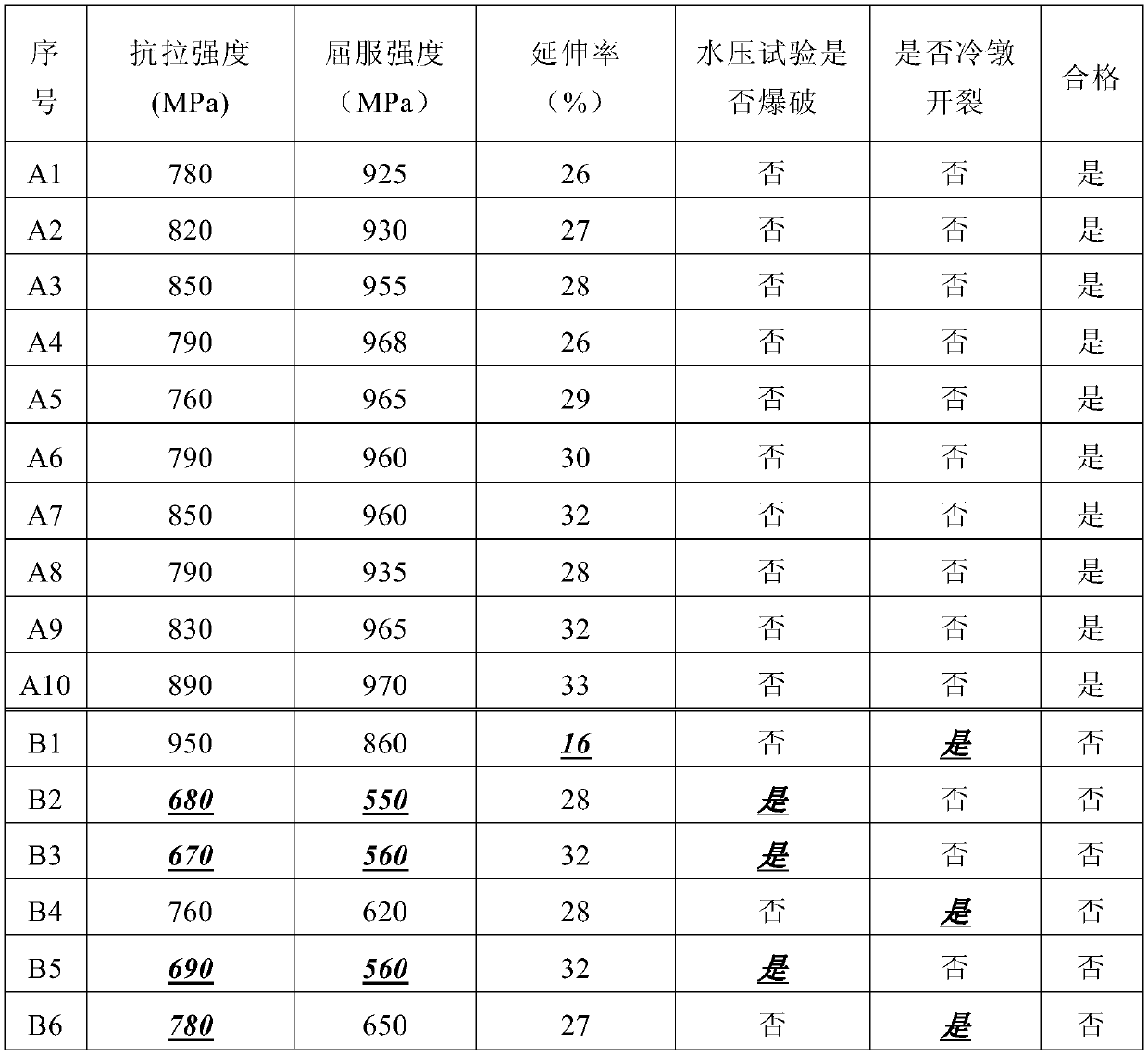

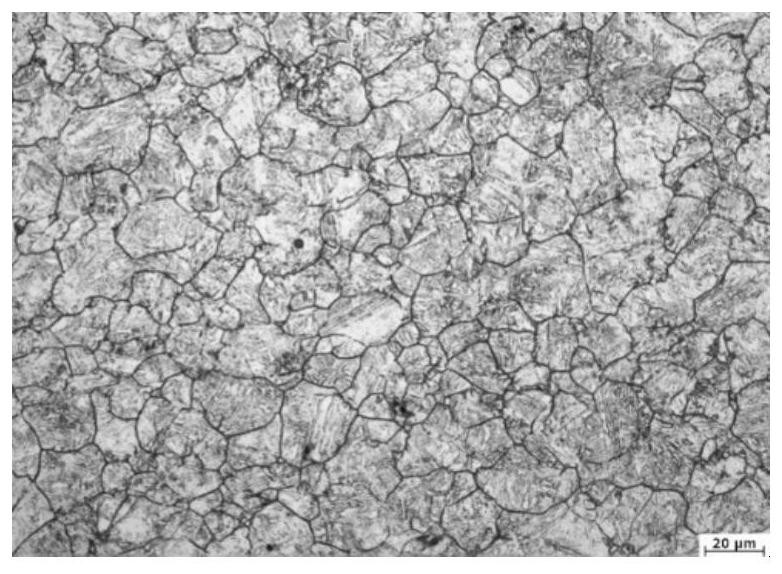

The invention discloses a seamless steel pipe for a high-pressure oil pipe of an automobile engine and a manufacturing method of the seamless steel pipe. The seamless steel pipe is prepared from the components in percentage by mass: 0.09-0.17% of C, 0.08-0.5% of Si, 1.2-1.8% of Mn, 0.02-0.06% of Al, 0.02-0.10% of Nb, 0.02-0.08% of V, 0.05-0.4% of Ni, 0.03-0.15% of Cu, less than or equal to 0.015%of S, less than or equal to 0.025% of P, less than 0.002% of O, less than 0.008% of N, larger than or equal to 2 of Al / N, larger than 0.08 and less than 0.15 of V+Nb and the balance of Fe and other inevitable impurities. The seamless steel pipe for the high-pressure oil pipe of the automobile engine has high strength, good plasticity and toughness, and high resistance to cold heading cracking; thetensile strength is larger than 700MPa, the yield strength is larger than 580MPa, elongation is larger than 20%, no blasting occurs under a 500MPa water pressure test; and cracking cannot occur underthe deformation condition that cold heading deformation is larger than 50%.

Owner:BAOSHAN IRON & STEEL CO LTD

High-heat-resistant and corrosion-resistant aluminum matrix composite for automobile exhaust valve

The invention discloses a high-heat-resistant and corrosion-resistant aluminum matrix composite for an automobile exhaust valve. The high-heat-resistant and corrosion-resistant aluminum matrix composite is prepared from the following raw materials in parts by weight: 95-98 parts of aluminum, 0.1-0.2 part of stannum, 0.04-0.06 part of selenium, 0.06-0.08 part of germanium, 0.1-0.2 part of nickel, 1-1.3 parts of copper, 1.8-2.4 parts of zinc, 0.11-0.13 part of titanium, 0.06-0.1 part of cetyltrimethylammonium bromide, 0.2-0.25 part of bismuth, 3-5 parts of graphene oxide, 5-8 parts of zirconium hydride, 0.9-1.2 parts of hexachloroethane, 0.25-0.3 part of xanthan gum, 1.2-1.6 parts of black manganese ores, 2-3 parts of barium carbonate, 0.6-0.8 part of sodium sulfide, less than or equal to 0.01 part of impurities and a proper amount of deionized water. An aluminum alloy material disclosed by the invention has the advantages of good heat resistance, corrosion resistance and wear resistance, has the advantages of durability and long service life when being used for the automobile exhaust valve and is capable of reducing the cost so as to be worthy of popularization.

Owner:安徽瑞林精科股份有限公司

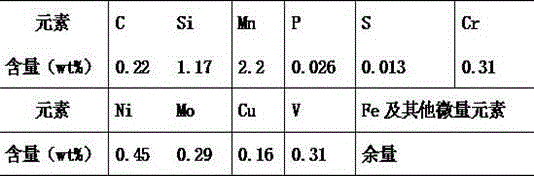

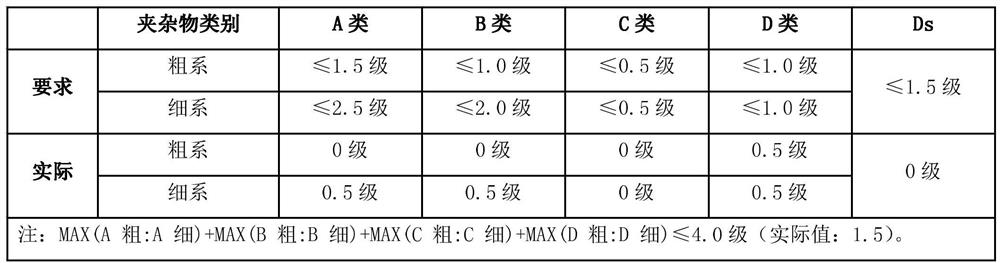

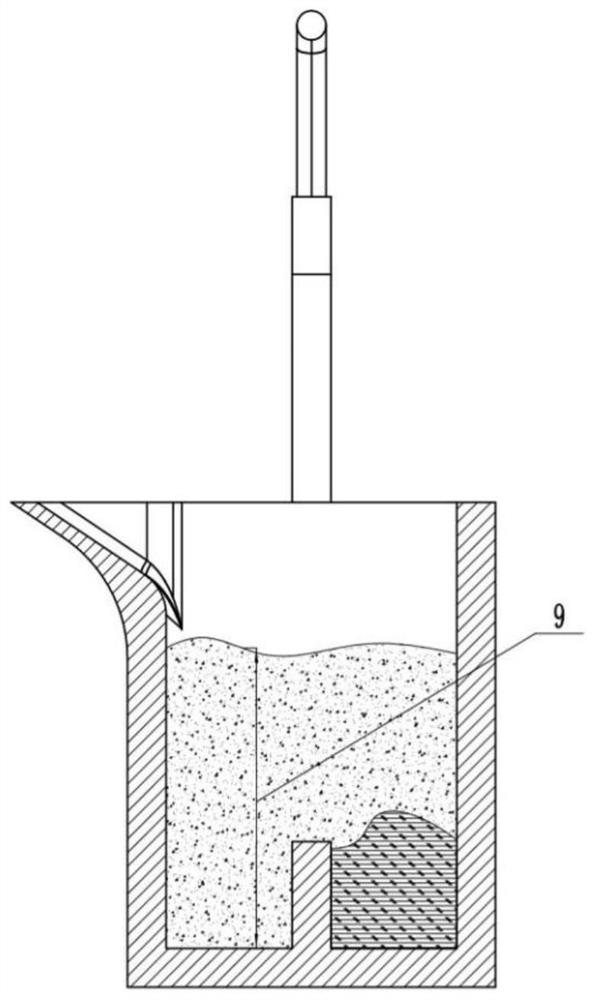

Production process of continuous casting gear steel bar for rail transit

InactiveCN113817951AFully deoxygenatedFull desulfurization removalElectric furnaceProcess efficiency improvementTemperingSlow cooling

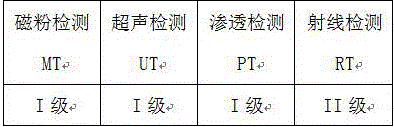

The invention discloses a production process of a continuous casting gear steel bar for rail transit, and relates to the technical field of steel production. The production process adopts a production mode of continuous casting and continuous rolling to replace a production mode of die casting and forging. The production process comprises the steps of EAF smelting, LF refining, VD refining, wire feeding, fine component adjustment, static stirring, continuous casting, casting blank slow cooling, heating, rolling, pit entering slow cooling, high-temperature tempering, straightening, peeling, ultrasonic flaw detection, finished product inspection, packaging, marking, weighing and warehousing. The production process aims at the purity control problem, the segregation control problem and the hardness control problem in the production process, the preparation method is provided, and the gear steel with the purity, the structure, the hardenability, the grain size and the surface quality meeting the rail transit requirements can be prepared.

Owner:NANJING IRON & STEEL CO LTD

Abrasion-resistant composite material for automobile brake pads

The invention discloses an abrasion-resistant composite material for automobile brake pads. The abrasion-resistant composite material for automobile brake pads is prepared from, by weight, 95-98 parts of aluminum, 0.03-0.05 part of cobalt, 3-3.5 parts of iron, 0.3-0.4 part of zinc, 1.2-2 parts of copper sulphide, 0.3-0.4 part of molybdenum, 0.1-0.2 part of nickel, 0.24-0.3 part of magnesium, 0.06-0.1 part of hexadecyl trimethyl ammonium bromide, 3-5 parts of graphene oxide, 5-8 parts of zirconium hydride, 0.88-1 part of hexachloroethane, 0.2-0.3 part of titanium dioxide, 0.24-0.3 part of sodium carboxymethylcellulose, 0.55-0.8 part of tungsten disulfide, 0.6-0.8 part of carbide slag, 0.01 or less of impurities and a proper amount of deionized water. The prepared alloy material has good strength, corrosion resistance, abrasion resistance, high-temperature stability and thermal stability, and is durable and high in safety when applied to automobile brake pads.

Owner:HEFEI HAIYUAN MACHINERY

Production method of ultra-high strength toughness ductile iron crankshaft with pearlite matrix

ActiveCN111687380BProduction Method AdvantagesImprove roundnessFoundry mouldsFurnace typesFerrosiliconDuctile iron

The production method of the pearlite matrix ultra-high strength ductile ductile iron crankshaft provided by the present invention selects low-sulfur and low-titanium pig iron, ordinary carbon steel and self-produced recycled iron as the main charge, and adds specific proportions of 75% ferrosilicon and 65% high-carbon manganese Iron, electrolytic copper and graphite-type recarburizers; smelted at a specific frequency in an intermediate frequency furnace, adding nodulizers, inoculants, silicon-calcium-manganese deoxidizers, and then tapped for nodularization. The nodularization process requires a specific tapping position, speed, and tapping The first step is to select a specific inoculant flow rate and total amount during the pouring process, and adopt a specific normalizing process for the crankshaft casting to prepare an ultra-high-strength ductile ductile iron material with a strength exceeding 1000 MPa, an elongation ≥ 5%, and a matrix material of pearlite type. Its comprehensive performance far exceeds that of ordinary ductile iron and ADI materials with the same tensile strength. The preparation method is applied to J4200 crankshaft, JX400 crankshaft and other parts to realize the preparation of ultra-high strength and toughness material with pearlite matrix, reduce the cost and obtain remarkable benefits.

Owner:GUANGXI YUCHAI MACHINE PARTS MFG CO LTD

Method for reinforcing anti-fatigue performance of wheel steel

InactiveCN110484692AImprove fatigue resistanceReduce secondary oxidation pollutionProcess efficiency improvementSteelmakingRare earth

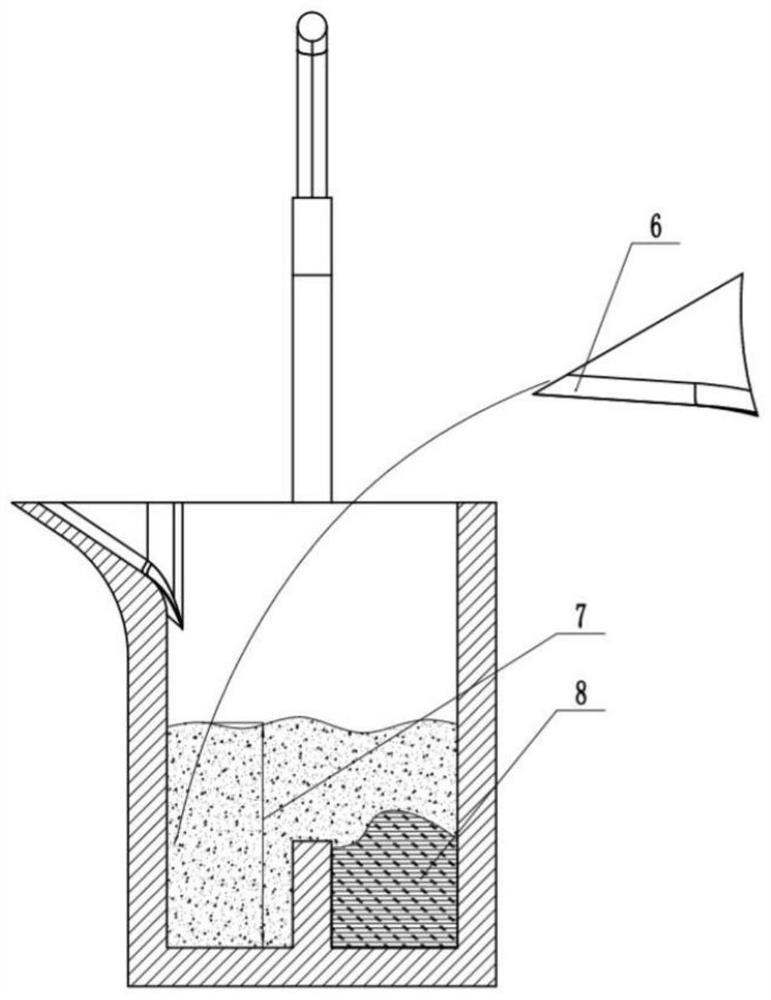

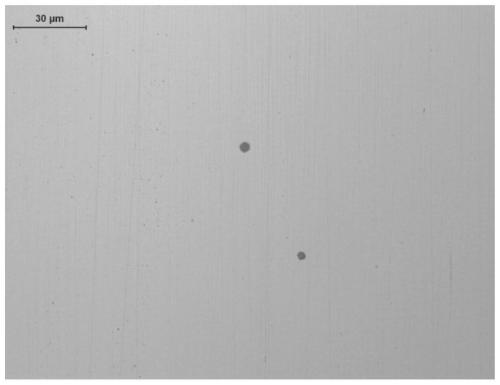

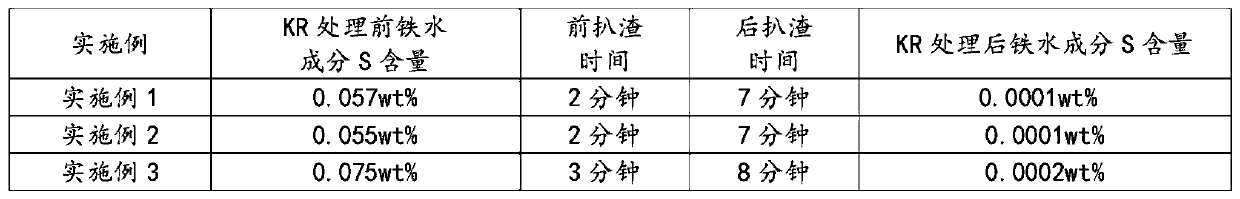

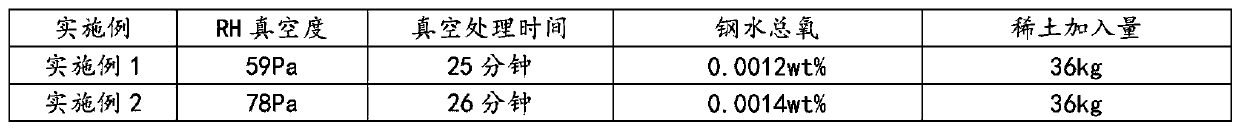

The invention provides a method for reinforcing anti-fatigue performance of wheel steel, and belongs to the technical field of steelmaking refining. The method comprises the steps of KR molten iron pre-treatment, converter smelting, LF refining, RH vacuum refining and continuous casting. In the RH vacuum refining procedure, the RH vacuum degree is controlled smaller than or equal to 100 Pa, and the vacuum treatment time is larger than or equal to 20 min. When the vacuum treatment time is larger than or equal to 15 minutes, rare earth alloy is added into the vacuum treatment molten steel; the mass percent of total oxygen in the vacuum treatment molten steel is smaller than or equal to 0.0015%, and the rare earth alloy is added in the vacuum state; through rare earth treatment, nonmetal inclusion in steel is subjected to denaturation into spherical rare earth sulfur oxide inclusion, the kind of inclusion is not gathered or grow in the smelting and casting processes, the non-metallic inclusion is controlled to small-size inclusion, in the rolling process, following with matrix deforming is avoided, inclusions in the final product are still small-size spherical non-metal inclusions, and the wheel steel fatigue life can be prolonged.

Owner:SHOUGANG CORPORATION

Silicon-calcium-carbon based deoxidizer

A disclosed silicon-calcium-carbon based deoxidizer comprises the chemical compositions in percent by weight: 32-38% of Ca, 7-11% of Si, 6-15% of C, 3-5% of Al, 0.5-1.5% of Re, and the balance Fe and unavoidable impurities. The deoxidizer is good in deoxygenation effect, and helps to reduce steelmaking cost and improve steelmaking efficiency.

Owner:CHANGXING SANZHONG KILN TECH

Hard alloy stop block and compression molding process

ActiveCN112024890AGuarantee molding qualitySmall shrinkagePositive displacement pump componentsTransportation and packagingCompression moldingAlloy

The invention discloses a hard alloy stop block and a compression molding process. According to the technical scheme, the compression molding process is characterized by comprising the following stepsof S1, mixing cobalt powder, metal nickel powder and tungsten carbide powder; S2, carrying out wet grinding on the mixture to obtain thick liquid; S3, drying the thick liquid, and then adding a forming agent to obtain particles; S4, performing compression molding to obtain a blank; and S5, sintering, in the first stage, raising the temperature from room temperature to 345-355 DEG C and then keeping the temperature; in the second stage, raising the temperature to 370-375 DEG C and then keeping the temperature, in the third stage, raising the temperature to 490-510 DEG C and then keeping the temperature, in the fourth stage, raising the temperature to 780-810 DEG C and then keeping the temperature, in the fifth stage, raising the temperature to 1180-1200 DEG C and then keeping the temperature, in the sixth stage, raising the temperature to 1440-1450 DEG C and then keeping the temperature, in the seven stage, cooling. The compression molding process has the effects that the molding quality of the blank is improved, so that the uniform shrinkage during sintering is ensured, and the cracking is prevented.

Owner:宁波新宇硬质合金密封有限公司

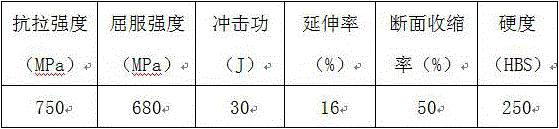

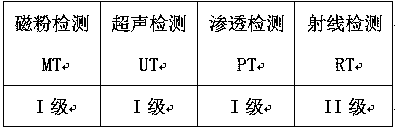

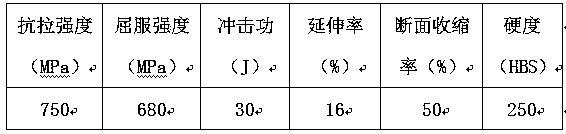

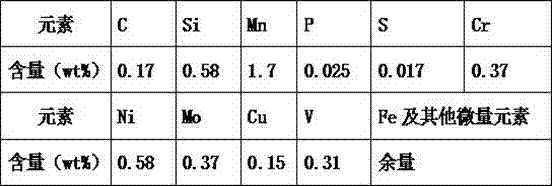

Cast steel part for nuclear power unit and production technology thereof

The invention discloses a zero-defect high-quality cast steel part for nuclear power. The cast steel part is characterized in that the cast steel part is chemically composed of, by weight, 0.18% to 0.20% of C, less than or equal to 0.60% of Si, 0.60% to 0.80% of Mn, less than or equal to 0.02% of P, less than or equal to 0.015% of S, 1.35% to 1.50% of Cr, less than or equal to 0.50% of Ni, 0.90% to 1.10% of Mo, 0.20% to 0.30% of V, less than or equal to 0.025% of Sn, 0.08% to 0.12% of Zr, the balance Fe and unavoidable trace impurities. The invention further discloses a technology used for producing the cast steel part, and according to the technology, the cast steel part has no defects, is high in quality, and is good in abrasion resistance and corrosion resistance, and high in toughness when in the high-temperature environment, and therefore, the cast steel part is suitable for a nuclear power unit.

Owner:SANMING CITY YIJUN MACHINERY FOUNDRY

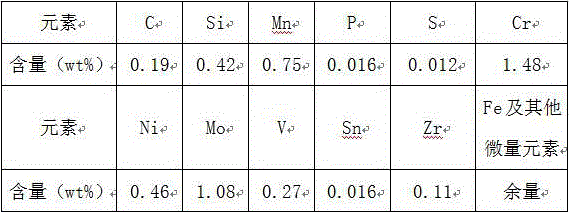

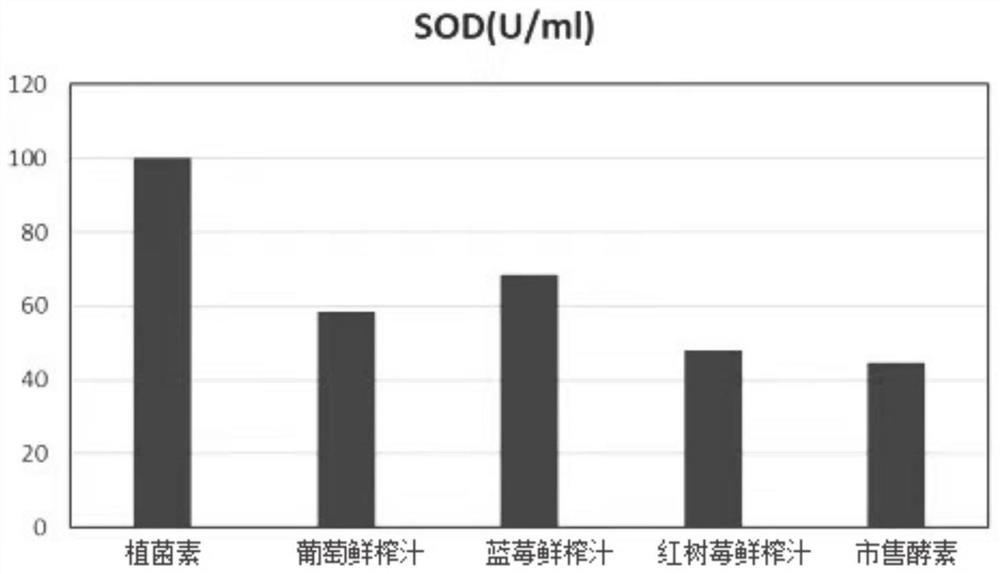

Composite fruit and vegetable fermented composition and preparation method thereof

PendingCN113854549AFree from alcoholAlter microbial metabolismYeast food ingredientsDigestive systemBiotechnologyBrassicaceae

The invention provides a composite fruit and vegetable fermented composition (namely plant rhzomorph) and a preparation method thereof. The composition is prepared from raw materials selected from various different small berries, celery, cruciferous vegetables, algae and the like through a fermentation mode of adding lactic acid bacteria, acetic acid bacteria and saccharomycetes for submerged fermentation and introducing nitrogen for multiple times. The composite fruit and vegetable fermented composition can achieve the effects of dispelling the effects of alcohol and protecting the liver.

Owner:SHENZHEN QUANJIAOYUAN BIOTECHNOLOGY CO LTD

Steel for composite microalloyed welding wire and preparation method thereof

ActiveCN103255354BGrain refinementThin Weld DropletWelding/cutting media/materialsSoldering mediaWeld strengthUltimate tensile strength

Owner:江阴智产汇知识产权运营有限公司

A production device and method for a high-purity oxygen-free copper ingot

The invention provides a production device of a high-purity oxygen-free copper ingot billet. The device comprises a melting furnace, a partition bin and a heat preservation furnace which are sequentially communicated, the partition bin is further provided with a deoxygenator, the deoxygenator comprises a gas conveying pipe used for conveying deoxygenation gas and an air exhaust cover which is located in the partition bin and connected with the outlet end of the gas conveying pipe, and a plurality of air exhaust holes with the diameter of 0.5 mm to 1 mm are formed in the air exhaust cover; the melting furnace and the partition bin are connected through a liquid inlet hole, the air exhaust cover right faces the liquid inlet hole, and the distance between the air exhaust cover and the liquid inlet hole ranges from 10 mm to 40 mm; in the flowing direction of molten copper, the projection of the air exhaust cover is larger than the projection of the liquid inlet hole; the invention further provides a method capable of adopting the device for producing the oxygen-free copper ingot billet. By the adoption of the method, the oxygen-free copper ingot billet which is good in production compactness and low in oxygen content can be produced.

Owner:JIANGXI GUANGXIN COPPER IND

A seamless submerged arc flux-cored welding wire for steel with a yield strength of 550mpa

ActiveCN106181122BStrong resistance to moisture absorptionGood workmanshipWelding/cutting media/materialsSoldering mediaRare earthManganese

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Production method for improving graphite form of spheroidal graphite cast iron

ActiveCN111607678AImprove roundnessReduce the amount of free oxygenFoundry mouldsFoundry coresFerrosiliconDuctile iron

The invention provides a production method for improving graphite form of spheroidal graphite cast iron. The method is characterized in that low-sulfur low-titanium pig iron, carbon steel and foundryreturns are selected as main furnace materials, and 75 ferrosilicon, 65 high-carbon ferromanganese, electrolytic copper and a graphite type carburant are added; and smelting is carried out in an intermediate frequency furnace at a specific frequency, and after a spheroidizing agent, an inoculant and a SiCaMn deoxidizer are added, tapping spheroidizing is carried out, wherein in the spheroidizing process, the tapping position, speed and tapping steps are specially set, and in the pouring process, specific inoculant flow velocity and total amount are selected. According to the method, round graphite, which is 2 grade or above in graphite spheroidizing grade, 93 %-99 % in spheroidizing rate and 7 grade in graphite sphere diameter, of a pearlite matrix and mixed-matrix spheroidal graphite castiron casting can be achieved; and the treatment process of the production method is simple and convenient, high in reliability and low in production cost.

Owner:GUANGXI YUCHAI MACHINE PARTS MFG CO LTD

A cast steel part for nuclear power unit and its production process

The invention discloses a zero-defect high-quality cast steel part for nuclear power. The cast steel part is characterized in that the cast steel part is chemically composed of, by weight, 0.18% to 0.20% of C, less than or equal to 0.60% of Si, 0.60% to 0.80% of Mn, less than or equal to 0.02% of P, less than or equal to 0.015% of S, 1.35% to 1.50% of Cr, less than or equal to 0.50% of Ni, 0.90% to 1.10% of Mo, 0.20% to 0.30% of V, less than or equal to 0.025% of Sn, 0.08% to 0.12% of Zr, the balance Fe and unavoidable trace impurities. The invention further discloses a technology used for producing the cast steel part, and according to the technology, the cast steel part has no defects, is high in quality, and is good in abrasion resistance and corrosion resistance, and high in toughness when in the high-temperature environment, and therefore, the cast steel part is suitable for a nuclear power unit.

Owner:SANMING CITY YIJUN MACHINERY FOUNDRY

A kind of high-strength casting for mine and construction mobile crushing station and its production process

ActiveCN104878320BImprove purityImprove mechanical propertiesFoundry mouldsFoundry coresArchitectural engineeringWear resistance

The invention discloses a high-strength casting of a mobile crushing station for mines and buildings. The high-strength casting comprises the following chemical components by weight percent: 0.15-0.35% of C, 0.50-2.50% of Si, Mn not larger than 2.5%, P not larger than 0.04%, S not larger than 0.02%, 0.3-0.5% of Cr, 0.4-0.6% of Ni, Mo not larger than 0.5%, Cu not larger than 0.2%, 0.25-0.35% of V, and the balance of Fe and unavoidable trace impurities. The invention further discloses a production process of the high-strength casting; the casting has good mechanical properties and wear and corrosion resistance, still has good toughness in low temperature conditions, and is suitable for the production of the mobile crushing station for mines and buildings.

Owner:SANMING CITY YIJUN MACHINERY FOUNDRY

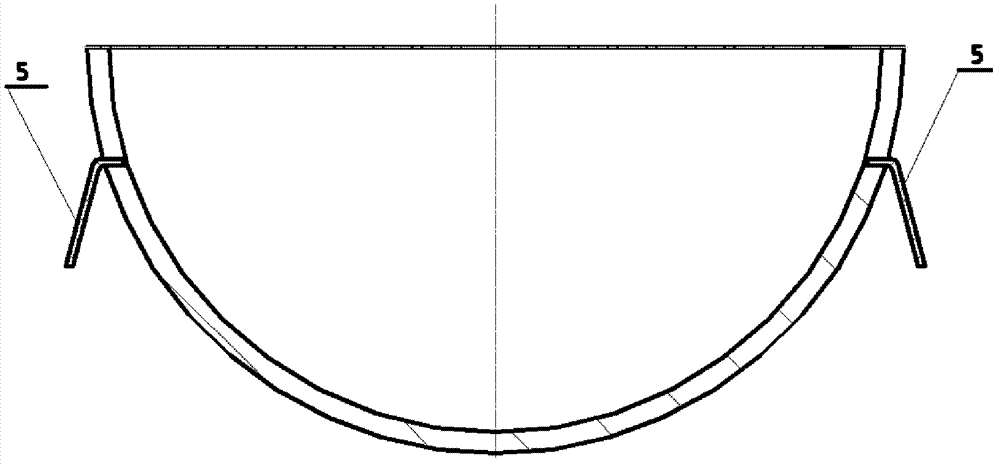

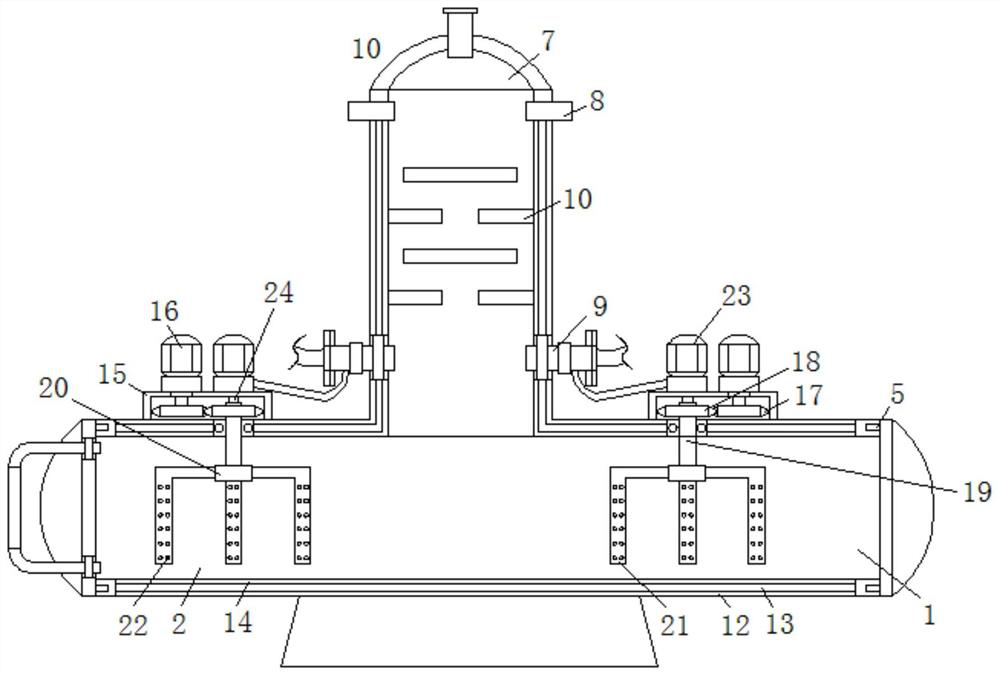

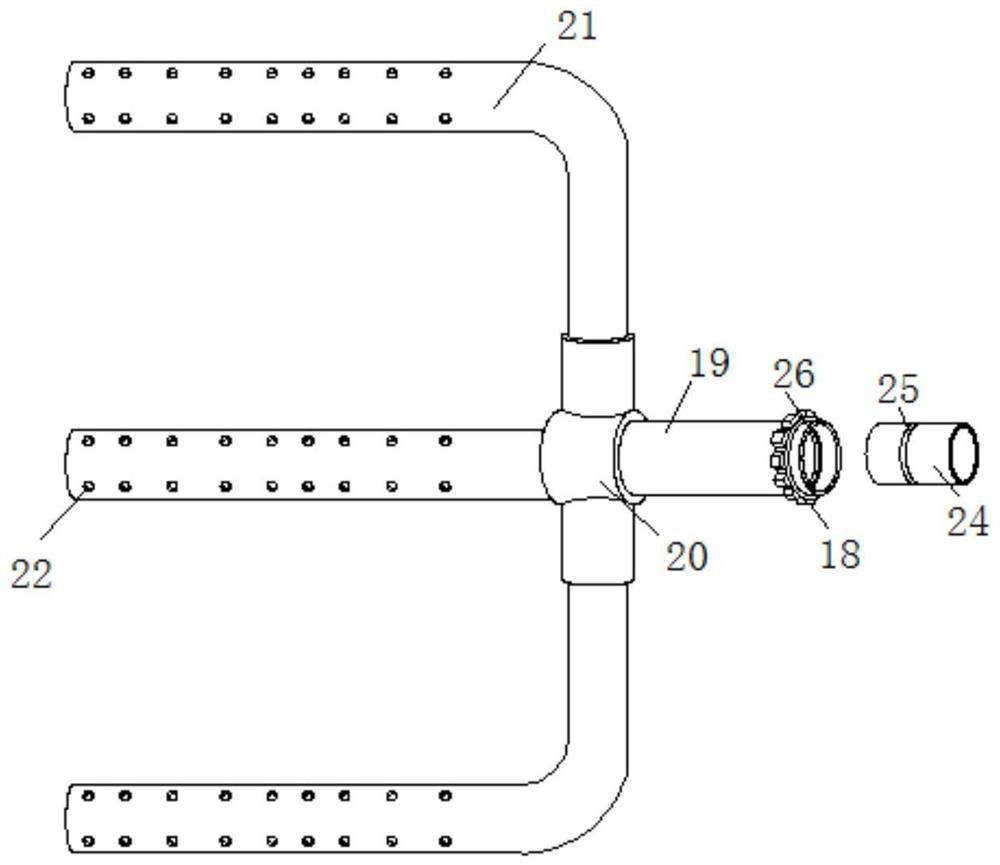

Low-heat-loss type deaerator for power plant boiler

PendingCN112062197AEasy maintenanceIncrease flexibilityWater/sewage treatment by degassingHeat conservationWater storage tank

The invention discloses a low-heat-loss type deaerator for a power plant boiler. The low-heat-loss type deaerator comprises a deaerator body, the deaerator body internally comprises a water storage tank body, the outer side of the water storage tank body is fixedly connected with an air cylinder, the movable end of the air cylinder is fixedly connected with a tank door, and the inner side of the tank door is fixedly connected with a sealing clamping block; the upper end of the gear box is fixedly connected with an air pump, an air outlet of the air pump is fixedly connected with a deflation pipe, a guide groove is formed in the outer wall of the deflation pipe, a guide block is fixedly connected in the sleeving pipe, a spring is fixedly connected in the mounting groove, a positioning clamping button is fixedly connected to the outer side of the spring, and a sealing groove is formed in the connecting pipe fitting. According to the low-heat-loss type deaerator for the power plant boiler, the overall heat preservation effect is improved, rapid heat dissipation of the whole deaerator in the using process is facilitated, the overall heating speed is increased, violent shaking caused bythe excessively large overall temperature difference is reduced, and the overall practicability is improved.

Owner:SUZHOU RONGBAOCHANG MACHINERY TECH CO LTD

Production method for improving the morphology of ductile iron graphite

ActiveCN111607678BImprove roundnessReduce the amount of free oxygenFoundry mouldsFoundry coresIntermediate frequencyFerrosilicon

The production method for improving the morphology of ductile iron graphite provided by the present invention, selects low-sulfur and low-titanium pig iron, carbon steel and returned iron as the main charge, and adds 75% ferrosilicon, 65% high-carbon ferromanganese, electrolytic copper and graphite recarburizer; After smelting at a specific frequency in an intermediate frequency furnace, adding nodulizers, inoculants, and SiCaMn deoxidizers, the iron is spheroidized. The nodularization process requires specific iron tapping positions, speeds, and iron tapping steps. The specific inoculant flow rate and total amount are selected during the pouring process. , can achieve pearlite matrix, mixed matrix nodular cast iron casting graphite to achieve spheroidization level 2 and above, the spheroidization rate reaches 93-99%, and the graphite spherical diameter is 7-level rounded graphite. The production method has simple processing technology, high reliability and low production cost.

Owner:GUANGXI YUCHAI MACHINE PARTS MFG CO LTD

An ultra-low hydrogen seamless submerged arc flux-cored welding wire for steel with a yield strength of 690mpa

ActiveCN106141500BStrong resistance to moisture absorptionGood workmanshipWelding/cutting media/materialsSoldering mediaPotassium fluorideManganese

The invention discloses an ultralow hydrogen seamless submerged arc flux-cored wire for steel with yield strength being the 690 MPa level. The submerged arc flux-cored wire is composed of a sheath and flux core powder. The sheath is made of a low-carbon steel strip. The flux core powder is prepared from, by mass percent, 8%-12% of marble, 4%-8% of fluorite, 25%-30% of metal nickel, 2%-4% of metal chromium, 7%-9% of ferromolybdenum, 12%-16% of electrolytic manganese, 1%-3% of ferrosilicon, 3%-5% of ferrotitanium, 2%-4% of ferro-boron, 2%-3% of potassium titanate, 1%-3% of potassium fluoride, 1%-3% of sodium fluoride and the balance ferrous powder. The ultralow hydrogen seamless submerged arc flux-cored wire for the steel with the yield strength being the 690 MPa level is high in moisture absorption resisting property, and excellent in processing property of being matched with fluorine and alkali sintered flux SR-SJ613, diffusible hydrogen is extremely low (smaller than or equal to 4 mL / 100 g), minus 40 DEG C charpy impact energy reaches over 100 J, and the wire can be applied to welding of a steel plate with the yield strength being the 690 MPa level in the ocean engineering field.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Method for reclaiming and cyclic utilizing residue molten steel slag in steel making

InactiveCN100424189CWell mixedReduce oxidationBlast furnace componentsBlast furnace detailsSulfurSludge

The method to pour residual hot steel sludge for recovery in steel production comprises: a. after casting, pouring the residual steel sludge into empty ladle; b. conveying the sludge to converter and tapping; c. refining; d. casting; repeating. This invention makes full use of the sulfur capacity and strong reducibility to absorb inclusion and improve liquid steel cleanness rapidly, overcomes the consumption for low-melting, and reduces pollution and cost.

Owner:HEBEI IRON AND STEEL

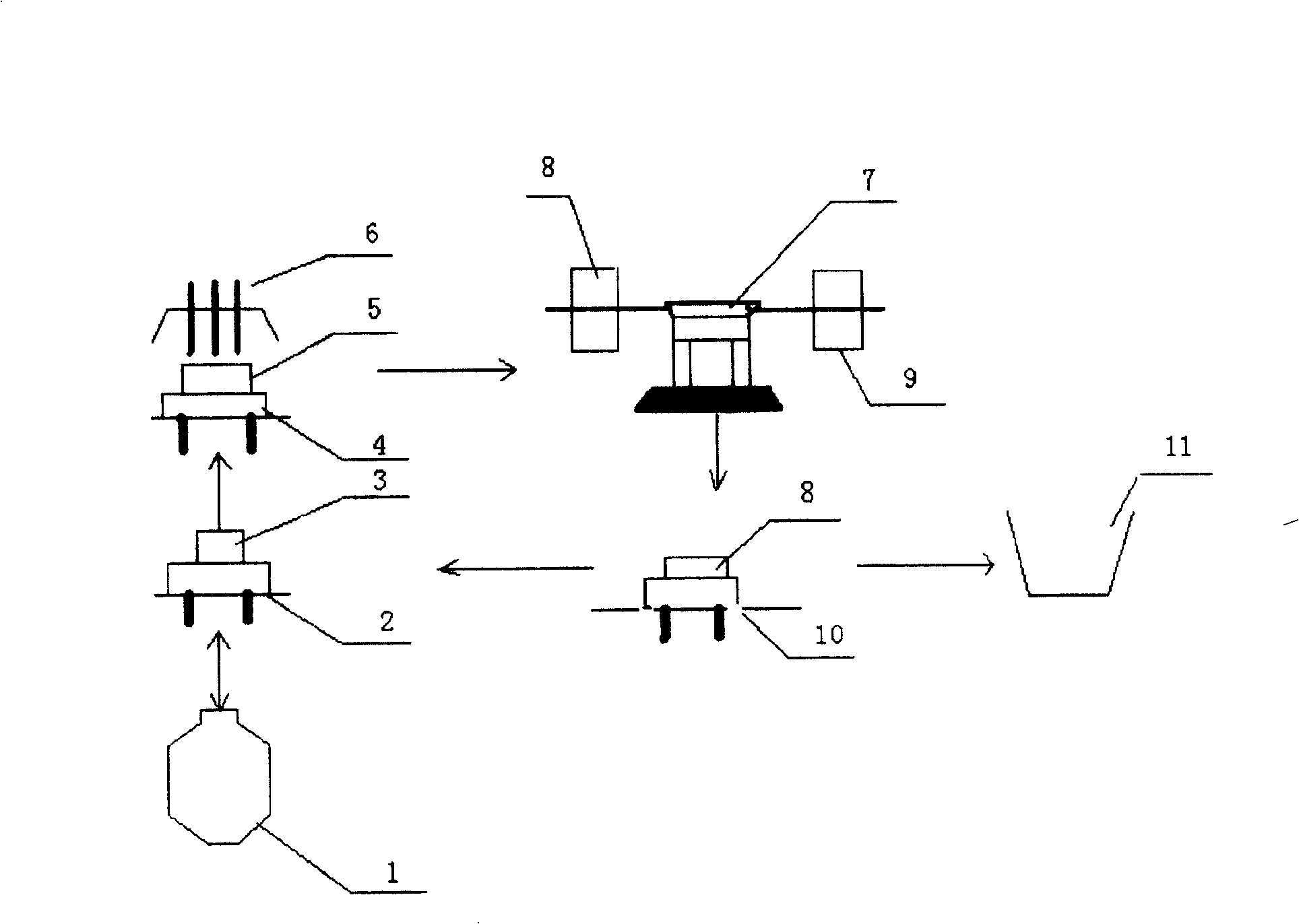

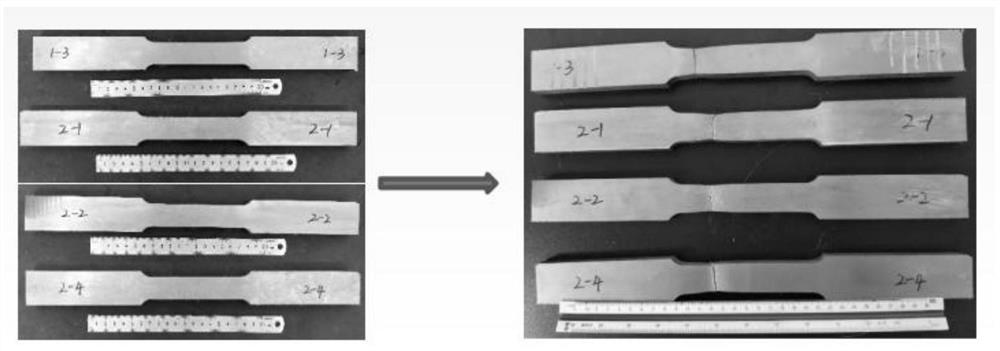

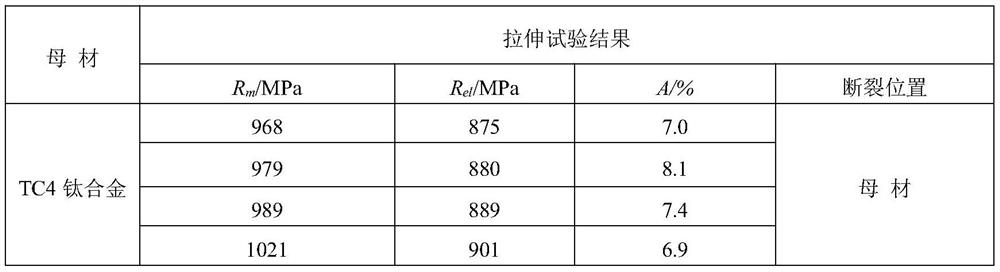

A kind of tc4 titanium alloy flux-cored welding wire and preparation method thereof

ActiveCN112404798BImprove performanceHigh strengthWelding/cutting media/materialsSoldering mediaSmelting processAluminium powder

Owner:HARBIN WELDING INST LTD +1

A kind of medium manganese low carbon martensitic steel, ultra-deep drilling rig lifting ring and preparation method thereof

The invention belongs to the field of petroleum equipment manufacturing, and specifically discloses a medium-manganese low-carbon martensitic steel, which comprises the following components in terms of mass percentage: C: 0.18-0.21%, Si: 0.65-0.85%, Mn: 1.65- 1.85%, Cr: 0.9~1.1%, Mo: 0.5‑0.6%, Ni: 1.8~2.1%, V: 0.21~0.25%, S≤0.005% and P≤0.01%, the rest are iron and unavoidable impurities, Has high strength and toughness. The invention also discloses an ultra-deep well drilling rig suspension ring prepared by using the medium-manganese low-carbon martensitic steel, the diameter of which can reach 150 mm, and meets the use requirements of the ultra-deep well drilling rig suspension ring. The invention also discloses a preparation method of the suspension ring of the ultra-deep well drilling rig, which has low cost and short manufacturing period.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com