Production process of continuous casting gear steel bar for rail transit

A technology of rail transit and production technology, which is applied in the field of steel production, can solve the problems of high cost and low production efficiency, and achieve the effects of reducing hardness, ensuring uniform composition and good processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

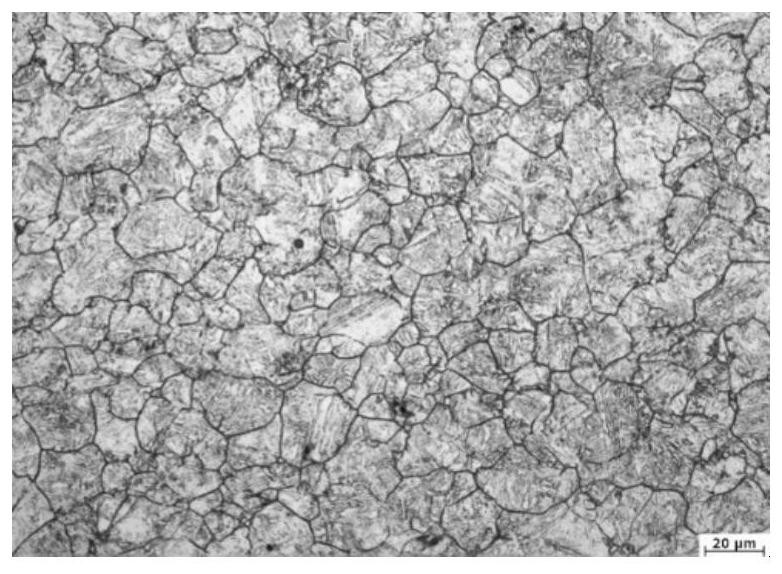

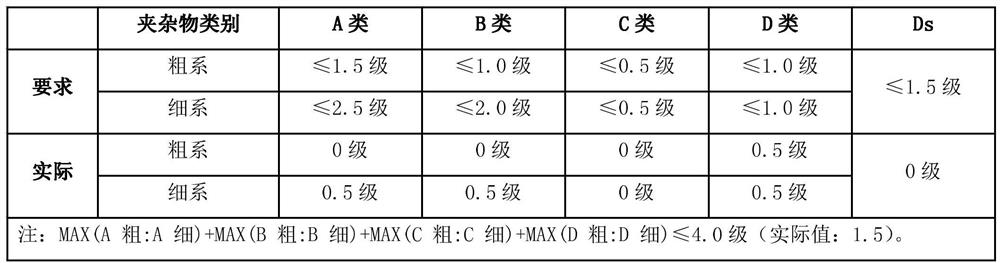

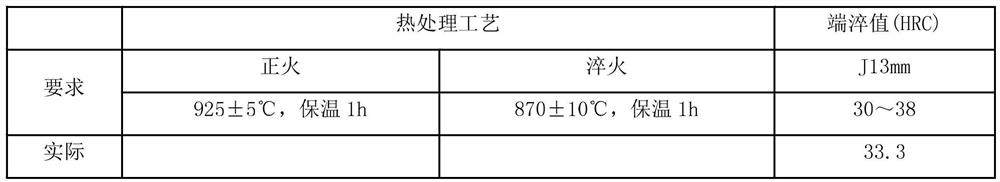

Image

Examples

Embodiment Construction

[0029] The production process of a continuous casting gear steel bar for rail transit provided in this embodiment adopts the production mode of continuous casting + continuous rolling instead of the production mode of die casting + forging, including EAF smelting→LF refining→VD refining→wire feeding , composition fine-tuning, static stirring→continuous casting→slab slow cooling→heating→rolling→pit slow cooling→high temperature tempering→straightening→peeling→ultrasonic flaw detection→finished product inspection→packaging→labeling→weighing→storage,

[0030] EAF smelting: control electric furnace endpoint C: 0.06%, P: 0.010%, tapping temperature: 1645°C, 15 tons of steel left in the electric furnace after tapping, adding synthetic slag, silicon-manganese alloy, and aluminum block for pre-deoxidation during tapping and alloying;

[0031] LF refining: by adding aluminum blocks, the aluminum content in the molten steel is guaranteed to be Al: 0.030%, and the white slag is kept for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com