A seamless submerged arc flux-cored welding wire for steel with a yield strength of 550mpa

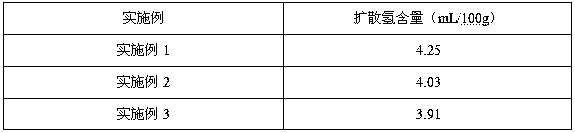

A technology of flux-cored welding wire and yield strength, applied in welding equipment, welding medium, welding/cutting medium/material, etc., can solve the problem of no seamless submerged arc flux-cored welding wire, etc., to reduce the content of inclusions and increase the quantity , reducing the effect of diffusing hydrogen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

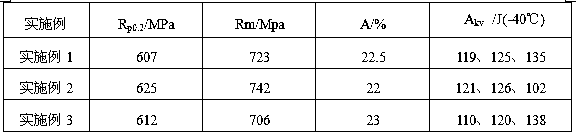

Examples

Embodiment Construction

[0014] In order to make the content of the present invention more obvious and understandable, the present invention will be described in detail below in conjunction with specific examples.

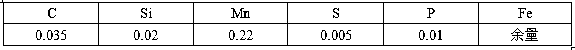

[0015] A seamless submerged arc flux-cored welding wire for steel with a yield strength of 550MPa, consisting of a sheath and a core powder, the sheath is a low-carbon steel strip, and the filling rate of the core powder is 10%-15%, and the core powder According to the weight percentage, it is composed of the following components: nickel powder 8%-10%, molybdenum iron 3%-6%, metal manganese 10%-14%, rare earth ferrosilicon 6%-8%, titanium iron 3%-5%, Zirconium iron 1%-2%, boron iron 1%-3%, potassium titanate 1%-2%, sodium fluoride 1%-3%, and the balance is iron powder.

[0016] In the present invention, the main function of the nickel powder is a transition alloy. Nickel is an important element to improve low-temperature toughness. It can refine grains, reduce segregation, and promote the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com