Integrated method for preparing xylose mother liquor from biomass through hydrolysis and of compression molding of residues

A technology of compression molding and xylose mother liquor, which is applied in the direction of xylose production, solid fuel, sugar production, etc., can solve the problems of directly obtaining compression molding blocks, complicated equipment and processes, and low ethanol yield, and achieves easy automatic control , saving drying cost, strong moisture absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The present invention will be further described below with reference to the drawings and embodiments, but it should be noted that these embodiments are only used to illustrate the system and method of the present invention, but not limit the scope of the present invention thereto.

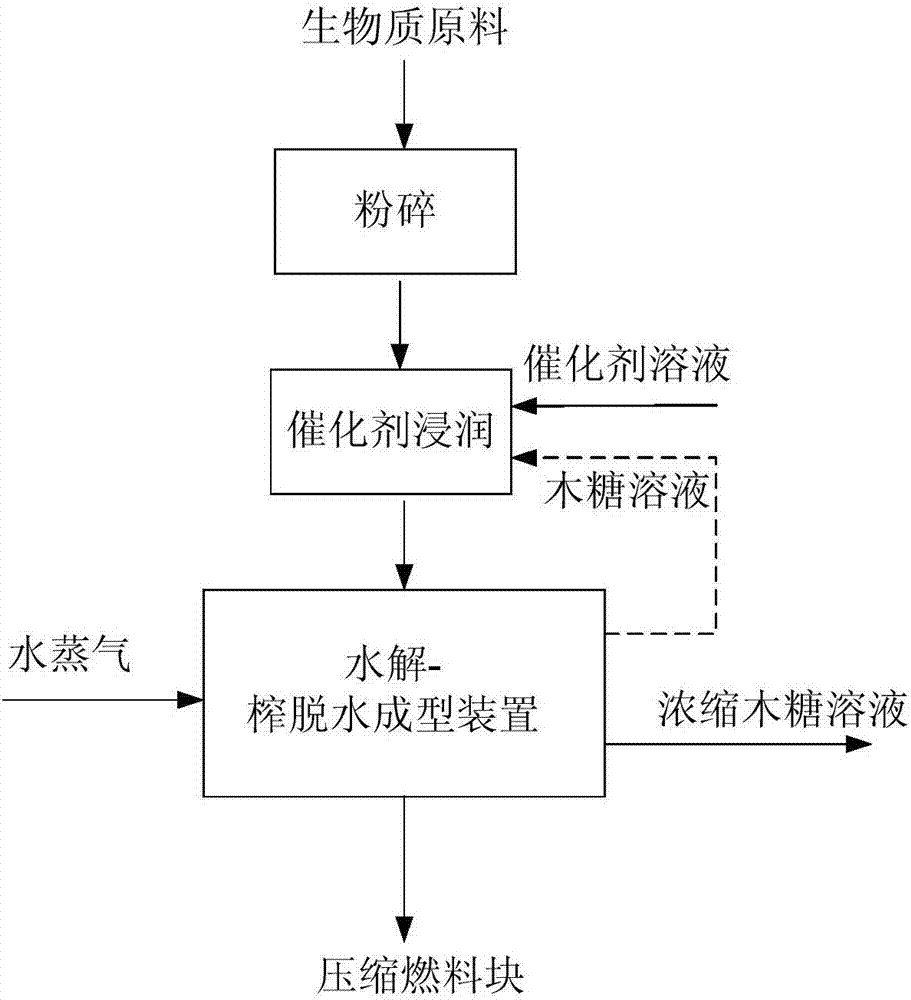

[0041] figure 1 It is a flow chart of the hydrolysis-compression molding integrated method for preparing xylose solution from biomass and simultaneously obtaining compression-molded fuel blocks in the present invention. When the xylose concentration in the hydrolyzed solution does not reach the target value, the solid-liquid separation The flow direction of the liquid is indicated by the dotted arrow pointing.

[0042] The core idea of the present invention is to complete hydrolysis-deep solid-liquid separation-compression molding simultaneously, and to increase the concentration of xylose in it through the recycling of hydrolyzed liquid, and to control the depth and depth of solid-liquid ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com