Preparation method of high-quality syrup and powdered sugar

A high-quality, syrup technology, applied in the production of sugar, sugar products, sucrose production, etc., can solve the problems of environmental burden, sugar loss, increase production cost, etc., achieve easy operation and adjustment, strong anti-moisture absorption ability, reduce The effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

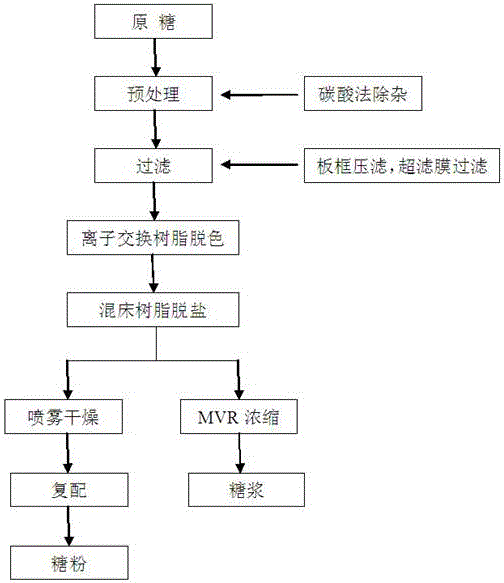

[0042] As shown in Figure 1, the preparation process of a high-quality syrup and powdered sugar of the present invention comprises the following steps:

[0043] (1) Pretreatment

[0044] a. Sugar melting Dissolve raw sugar in water to obtain raw sugar syrup; the temperature of sugar melting is 75°C, and the brix of raw sugar syrup is 55°Bx;

[0045] b. Purification Pass lime milk and raw sugar syrup into the purification system, slowly introduce carbon dioxide to fill, and form calcium carbonate precipitation to remove non-sugar substances; the Baume degree of lime milk is 18°Be, and the pH of the filling syrup is 8.0.

[0046] c. The filtered and filled syrup enters the filtration system, and first enters the clarifier (plate and frame filter press) to obtain clear and transparent syrup, and then performs precision filtration through the ultrafiltration membrane to remove non-sugar substances, macromolecular pigments, colloid, protein and other impurities to obtain clear jui...

Embodiment 2

[0070] As shown in Figure 1, the preparation process of a high-quality syrup and powdered sugar of the present invention comprises the following steps:

[0071] (1) Pretreatment

[0072] a. Sugar melting Dissolve raw sugar in water to obtain raw sugar syrup; the temperature of sugar melting is 75°C, and the brix of raw sugar syrup is 60°Bx;

[0073] b. Purification Pass lime milk and raw sugar syrup into the purification system, slowly pass in carbon dioxide for full filling, and generate calcium carbonate precipitation to remove non-sugar substances; lime milk Baume degree 18°Be, full filling syrup pH8.0 .

[0074] c. After the filtered and filled syrup enters the filtration system, it first enters the clarifier (plate and frame filter) to clear the transparent syrup, and then conducts precision filtration through the ultrafiltration membrane to remove non-sugar substances, macromolecular pigments, Colloid and protein and other impurities are removed to obtain clear juice; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com