Refined sugar clarifying method

A technology for refining sugar and syrup, which is applied in the direction of purification using physical methods, sucrose production, sugar production, etc. It can solve the problems of poor clarification effect of re-dissolved syrup and low service life of ion exchange resins, so as to prolong membrane cleaning cycle and clarification effect Good, slow decay effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

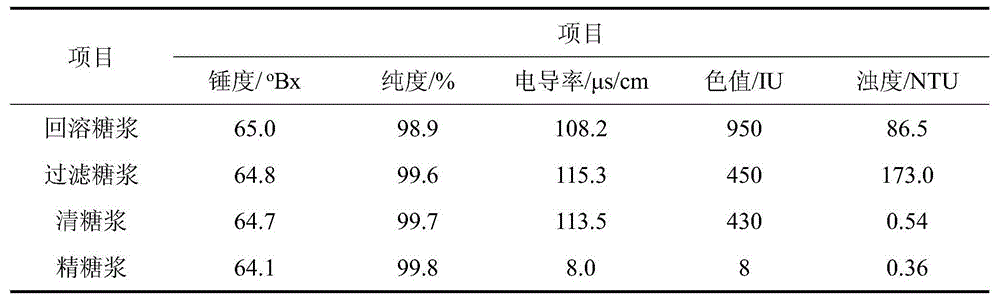

Embodiment 1

[0027] A refined sugar clarification method, its operation steps are:

[0028] (1) Honey washing: Put the raw sugar into the top-suspension centrifugal honey separator, use R 4 Molasses cleans the pigment on the surface of raw sugar to obtain honey-washed raw sugar;

[0029] (2) Dissolving sugar: dissolving the honey-washed raw sugar with 85°C washing filter cloth water in a sugar-dissolving box to obtain 65.0°Bx back-dissolving syrup for subsequent use;

[0030] (3) Carbon filling: first pump the remelted syrup to the No. 1 carbon filling tank, and add lime milk and carbon dioxide to the No. The carbon-filled syrup is pumped to the No. 2 carbon-filled tank, and carbon dioxide is continued to be filled into the No. 2 carbon-filled tank to obtain the 2-carbon-filled syrup for use. The alkalinity of the 1-carbon-filled syrup is 0.05 and the pH value is 11.0 , the pH value of the carbon dioxide filling is 8.5, and the carbon dioxide comes from the boiler flue gas;

[0031] (4)...

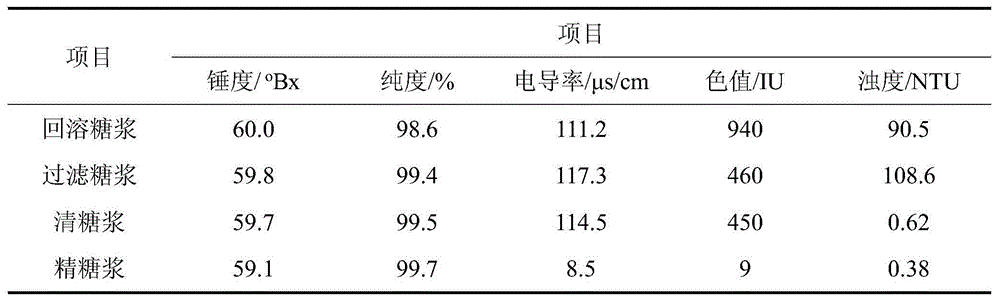

Embodiment 2

[0037] A refined sugar clarification method, its operation steps are:

[0038] (1) Honey washing: Put the raw sugar into the top-suspension centrifugal honey separator, use R 4 Molasses cleans the pigment on the surface of raw sugar to obtain honey-washed raw sugar;

[0039] (2) Dissolving sugar: dissolving the honey-washed raw sugar with 80°C washing filter cloth water in a sugar-dissolving box to obtain 60.0°Bx back-dissolving syrup for subsequent use;

[0040] (3) Carbon filling: first pump the remelted syrup to the No. 1 carbon filling tank, and add lime milk and carbon dioxide to the No. The carbon-filled syrup is pumped to the No. 2 carbon-filled tank, and carbon dioxide is continued to be filled into the No. 2 carbon-filled tank to obtain the 2-carbon-filled syrup for use. The alkalinity of the 1-carbon-filled syrup is 0.03 and the pH value is 10.5. , the pH value of carbon dioxide filling is 8.2, and the carbon dioxide comes from the boiler flue gas;

[0041] (4) Pl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com