High-strength casting of mobile crushing station for mines and buildings and production process of high-strength casting

A mobile crushing and production process technology, applied in the direction of process efficiency improvement, casting mold, casting mold composition, etc., can solve the problems of difficult production, poor casting performance, etc., to reduce maintenance costs, improve mechanical properties, and increase service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

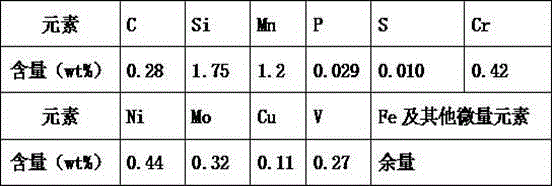

Embodiment 1

[0026] A production process for high-strength castings of mobile crushing stations for mines and buildings, the steps of which are as follows:

[0027] (1) Melting in an intermediate frequency furnace with a neutral sand lining, mixing steel shavings, low-carbon punched briquettes without rust and micro-carbon ferrochrome, then heating and melting in an electric furnace to form molten steel in a molten state.

[0028] (2) Put the molten steel into the AOD refining furnace for refining.

[0029] (3) Ferrosilicon and electrolytic manganese are added to the refined molten steel for smelting.

[0030] (4) Add the returned material of the same grade after derusting for smelting, and after the molten steel is melted, take a sample and analyze its chemical composition with a spectrometer.

[0031] (5) According to the results of chemical composition analysis, the alloy composition of molten steel is fine-tuned; the added alloy material is baked to 200°C before adding.

[0032] (6) ...

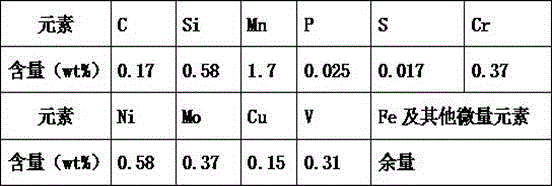

Embodiment 2

[0047] A production process for high-strength castings of mobile crushing stations for mines and buildings, the steps of which are as follows:

[0048] (1) Melting in an intermediate frequency furnace with a neutral sand lining, mixing steel shavings, low-carbon punched briquettes without rust and micro-carbon ferrochrome, then heating and melting in an electric furnace to form molten steel in a molten state.

[0049] (2) Put the molten steel into the AOD refining furnace for refining.

[0050] (3) Ferrosilicon and electrolytic manganese are added to the refined molten steel for smelting.

[0051] (4) Add the returned material of the same grade after derusting for smelting, and after the molten steel is melted, take a sample and analyze its chemical composition with a spectrometer.

[0052] (5) According to the results of chemical composition analysis, the alloy composition of molten steel is fine-tuned; the added alloy material is baked to 200°C before adding.

[0053] (6) ...

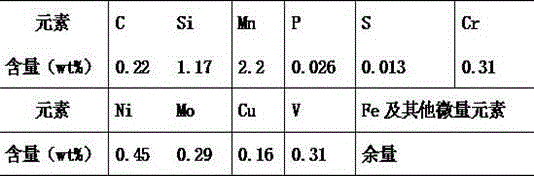

Embodiment 3

[0068] A production process for high-strength castings of mobile crushing stations for mines and buildings, the steps of which are as follows:

[0069] (1) Melting in an intermediate frequency furnace with a neutral sand lining, mixing steel shavings, low-carbon punched briquettes without rust and micro-carbon ferrochrome, then heating and melting in an electric furnace to form molten steel in a molten state.

[0070] (2) Put the molten steel into the AOD refining furnace for refining.

[0071] (3) Ferrosilicon and electrolytic manganese are added to the refined molten steel for smelting.

[0072] (4) Add the returned material of the same grade after derusting for smelting, and after the molten steel is melted, take a sample and analyze its chemical composition with a spectrometer.

[0073] (5) According to the results of chemical composition analysis, the alloy composition of molten steel is fine-tuned; the added alloy material is baked to 200°C before adding.

[0074] (6) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com