Steam turbine condenser water-supplementing and deoxidizing system

A technology of condenser and steam turbine is applied in the field of steam turbine to achieve the effects of reliable operation, simple operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

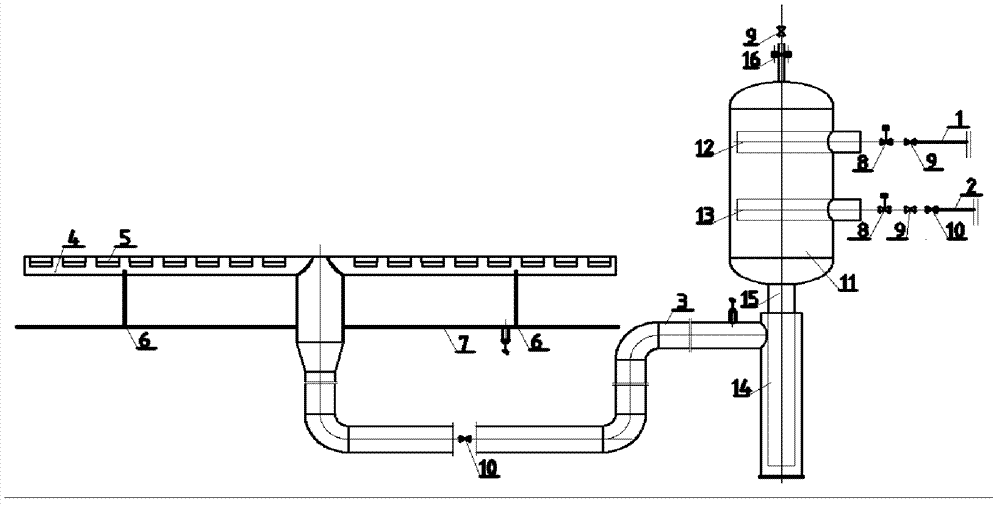

[0042]It is used for replenishing water and deoxidizing the condenser of a 300MW steam turbine. The design pressure of the condenser is 4.9kpa, and the design pressure inside the deaeration device 11 is 15kpa. 12. There are 240 small holes of φ10 on the water spray header 12. The heating steam is extracted from the 6-section steam extraction pipe of the steam turbine body. The steam enters the steam header 13 through the steam pipe 2. There are 120 φ10 holes on the steam header 13. The extraction pressure of this section is 0.173MPa, which can prevent the 0.1MPa make-up water from being sucked into the turbine and causing accidents. The replenishing water at 20 degrees is sprayed into the water replenishing and deoxygenating device 11 with a design pressure of 15kpa and an outer diameter of φ924x12 through the small hole of φ10, and it is fully diffused, and the heat released by the heating steam is fully absorbed in the space with a jet length of about 500mm , is heated to 36...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com