Smelting method for improving sulfur dispersion of medium-carbon sulfur-containing steel

A smelting method and sulfur-containing steel technology, which is applied in the field of iron and steel smelting, can solve the problems of deterioration of the comprehensive mechanical properties of steel and the easy deformation of sulfide, and achieve the effects of improving the form of sulfide, improving the purity of molten steel, and simplifying the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

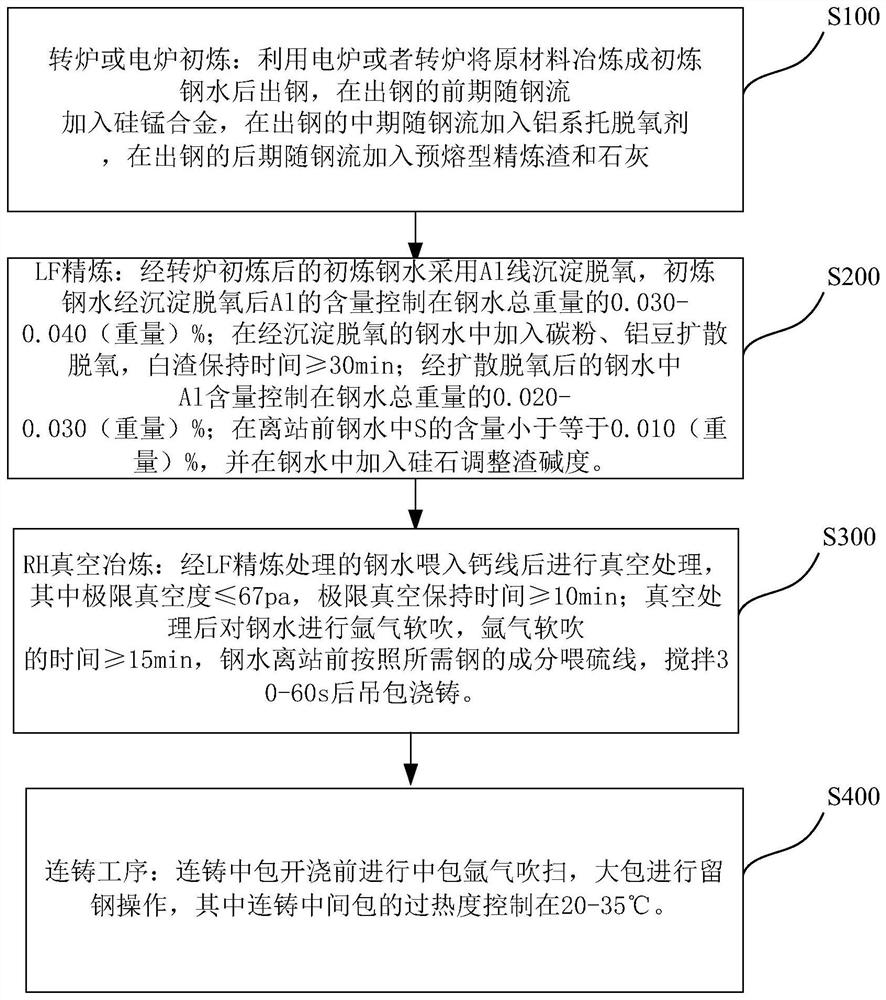

Method used

Image

Examples

Embodiment 1

[0044] In this embodiment, medium-carbon sulfur-containing steel is produced by using the converter primary refining-LF refining-RH vacuum smelting-continuous casting process, and the composition requirements of the steel are C: 0.40-0.44%, Si: 0.20-0.30%, and Mn: 0.50-0.60 %, S: 0.012-0.030%, P≤0.020%, Cr: 0.90-1.10%, Mo: 0.10-0.20%, H≤2.0ppm%, O≤20ppm.

[0045] Converter or electric furnace primary refining:

[0046] Use electric furnace or converter to smelt raw materials into primary molten steel. The total amount of molten steel for tapping is controlled at 110t, and the tapping temperature of molten steel is 1630°C; when the tapping amount is about 25t, 950kg of silicon-manganese alloy is added. After increasing to 55t, add 110kg of aluminum-based deoxidizer. When the tapping amount reaches 100t, add 700kg of pre-melted refining slag and 350kg of lime with the steel flow. The steel retention operation is carried out in the later stage of tapping in the electric furnace ...

Embodiment 2

[0058] In this embodiment, medium-carbon sulfur-containing steel is produced by using the converter primary refining-LF refining-RH vacuum smelting-continuous casting process. The composition requirements of the steel are C: 0.38-0.42%, Si: 0.30-0.45%, and Mn: 0.60-0.80 %, S: 0.035-0.055%, P≤0.015%, Cr: 1.00-1.25%, Mo: 0.15-0.30%, H≤2.0ppm%, O≤20ppm.

[0059] Converter or electric furnace primary refining:

[0060]Use electric furnace or converter to smelt raw materials into primary molten steel. The total amount of molten steel for tapping is controlled at 100t, and the tapping temperature of molten steel is 1640°C; when the tapping amount is about 20t, add 820kg of silicon-manganese alloy. After increasing to 50t, add 105kg of aluminum-based deoxidizer. When the tapping amount reaches 95t, add 650kg of pre-melted refining slag and 350kg of lime with the steel flow. The steel retention operation is carried out in the later stage of tapping in the electric furnace or converte...

Embodiment 3

[0072] In this embodiment, medium-carbon sulfur-containing steel is produced by using the process route of primary smelting in converter-LF refining-RH vacuum smelting-continuous casting, and the composition requirements of the steel are C: 0.50-0.60%, Si: 0.20-0.35%, and Mn: 0.40-0.60 %, S: 0.055-0.075%, P≤0.025%, Cr: 1.10-1.30%, Mo: 0.20-0.45%, H≤2.0ppm%, O≤20ppm.

[0073] Converter or electric furnace primary refining:

[0074] Use electric furnace or converter to smelt raw materials into primary molten steel. The total amount of molten steel for tapping is controlled at 115t, and the tapping temperature of molten steel is 1620°C; when the tapping amount is about 30t, 900kg of silicon-manganese alloy is added. After increasing to 60t, add 120kg of aluminum-based deoxidizer. When the tapping amount reaches 105t, add 600kg of pre-melted refining slag and 350kg of lime along with the steel flow. The steel retention operation is carried out in the later stage of tapping of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com