Patents

Literature

227 results about "Mangalloy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mangalloy, also called manganese steel or Hadfield steel, is an alloy steel containing an average of around 13% manganese. Mangalloy is known for its high impact strength and resistance to abrasion once in its work-hardened state.

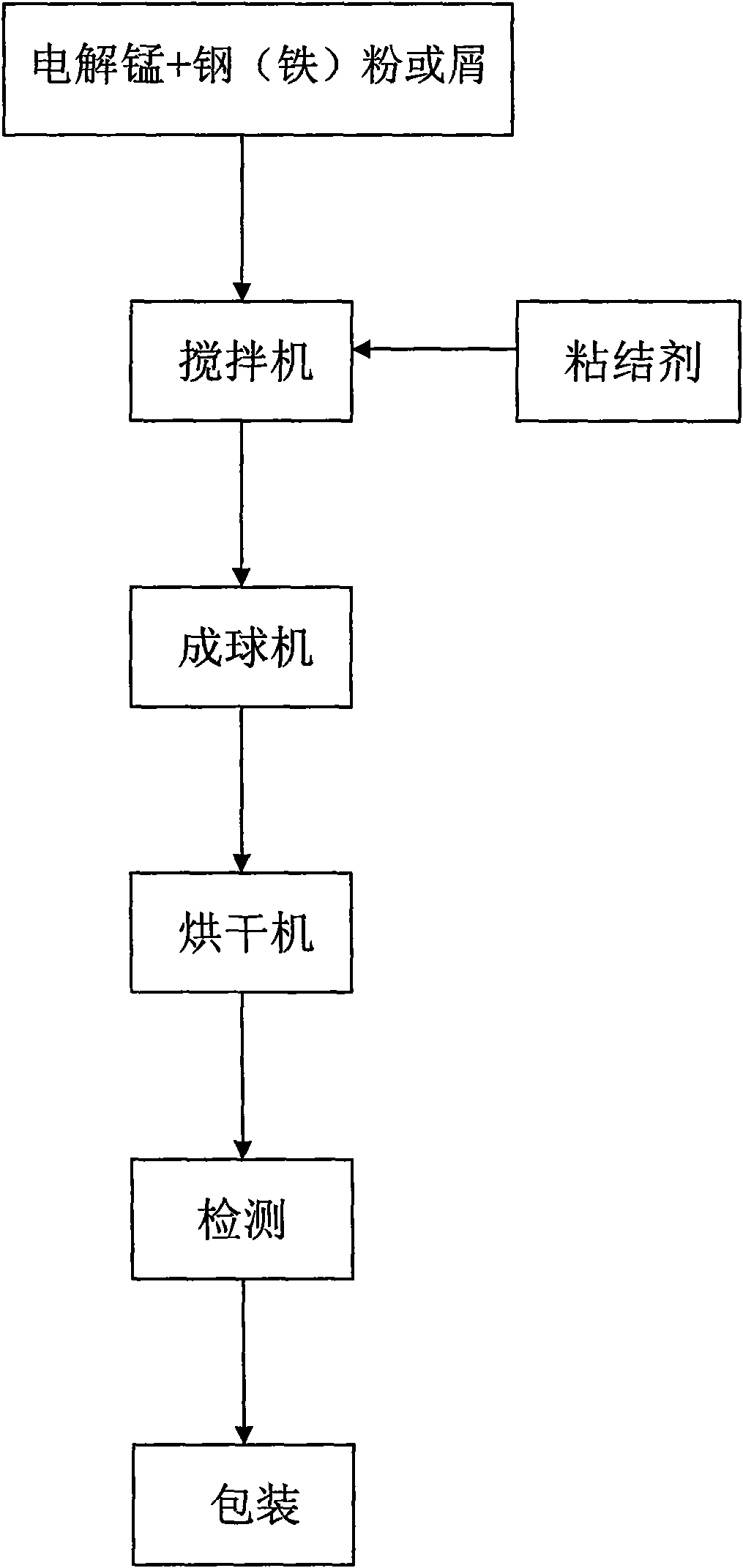

Method for producing manganese alloy

The invention relates to a method for producing a manganese alloy, which belongs to the technical field of ferroalloy production. The process comprises the following steps: adopting powdered or granular electrolytic manganese and pure iron powder or pure scrap iron as raw materials, wherein the electrolytic manganese accounts for 60 to 100 weight percent and the balance is Fe; adding a bonding agent of which the weight is 0.5 to 10 percent of that of the raw materials; sufficiently stirring the raw materials and the bonding agent evenly by a stirring machine; pressing the materials into balls by a ball press of which the pressure is not less than 20 T; drying the manganese alloy balls obtained by pressing for 15 to 25 minutes at a temperature of between 80 and 250 DEG C to obtain manganese alloy ball agglomerations of which the residual moisture is not more than 3 percent; and detecting the components and the strength of the ball agglomerations, and packaging the ball agglomerations for storage according to requirements. The method has the advantages of directly obtaining the manganese alloy with bright and clean surface, high strength and appropriate components.

Owner:CHINA IRON & STEEL RES INST GRP +2

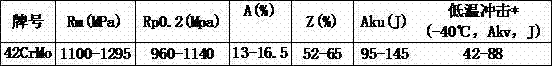

Bar for large wind driven generator gear and manufacturing method of bar

The invention relates to a preparation method of gear steel, in particular to a bar for a large wind driven generator gear and a manufacturing method of the bar. The bar comprises the following components of: 0.37-0.42 percent of C, 0.15-0.40 percent of Si, 0.80-1.25 percent of Cr, 0.50-0.90 percent of Mn, 0.15-0.30 percent of Mo, not more than 0.015 percent of S, 0.02-0.04 percent of Al, not more than 0.0015 percent of O, not more than 0.00020 percent of H, not more than 0.012 percent of P and the balance of Fe and unavoidable impurities. The manufacturing method comprises the steps of: adopting EAF (Electric Arc Furnace) and LF (Low Frequency) refining and VD (Vacuum Degassing) smelting, controlling aim carbon, aim phosphorus and tapping temperature of the electric arc furnace, adding synthetic slag, silicomangan and compound medium aluminum in a ladle in the tapping process for pre-deoxidizing; carrying out argon stirring in a refining process, fully deoxidizing, desulfurizing, removing impurities; treating for at least 10min under the vacuum degree of less than 0.5 torr of a VD furnace, feeding an Al wire after the vacuum is broken to control the content of the Al in the steelto be between 0.02 percent and 0.04 percent; and executing full-protection and low superheat degree pouring on continuous casting, adopting a medium-strength soft-pressing process on the solidified tail end, and adopting a heavy-pressing for carrying out rolling. The bar disclosed by the invention has high purity and compactness, and adapts to a complex and severe working environment of a wind power gear.

Owner:NANJING IRON & STEEL CO LTD

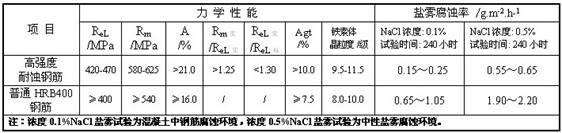

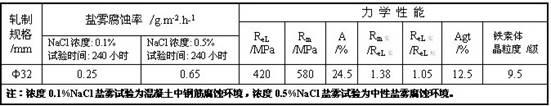

Corrosion resisting and shock resisting steel with high strength and preparation method thereof

ActiveCN102330026AImprove passivation corrosion resistanceEasy to weldTemperature control deviceManganeseFerrosilicon

The invention provides a corrosion resisting and shock resisting steel with high strength and a preparation method thereof. The method comprises the following steps of: after carrying out conventional composite top and bottom blowing, slagging and other smelting processes in a steel furnace, adding a compound deoxidizer, a silicon-manganese alloy, silicon iron, medium carbon ferrochromium, ferroniobium and a vanadium-nitrogen alloy to a steel ladle during tapping in sequence; carrying out deoxidation alloying treatment; after softly blowing argon to the molten steel for 4-5 minutes while the tapping is finished, casting the molten steel into a steel blank; after heating the steel blank at 1080-1120 DEG C, controlling open rolling temperature at 960-1010 DEG C to carry out rough rolling and medium rolling; controlling the cooling after the medium rolling is finished and before precision rolling is started; controlling the final rolling temperature at 870-960 DEG C to carry out final rolling; and then rapidly cooling the steel blank by water so that the steel is cooled to 640-680 DEG C; and naturally cooling the steel by air to room temperature so as to obtain the corrosion resisting and shock resisting steel with high strength. According to the invention, the corrosion resistance of the steel is obviously improved, the corrosion rate is only 1 / 5-1 / 4 of the corrosion rate of the400 MPa reinforcing steel bar produced by the traditional process, fine crystal particles, ferrite crystal particles at grade of 9.5-11.5 and excellent mechanical properties of the process are obtained; and the cost of the corrosion resisting and shock resisting steel with high strength is reduced by more than 20 yuan / t while being compared with the cost of the like products.

Owner:WUKUN STEEL

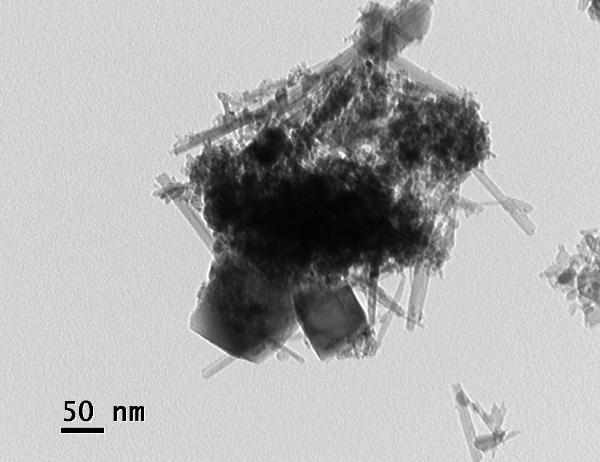

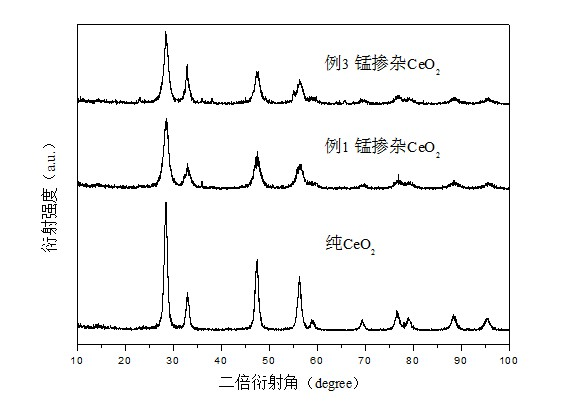

The preparation method of manganese-doped ceo2 nanopowder

InactiveCN102275972AEasy to operateLow reaction temperatureMaterial nanotechnologyRare earth metal compoundsCeriumCarbide

The invention relates to a method for preparing CeO2 nanopowder from cerium manganese carbide. A 25 kg vacuum induction furnace is used to melt 45.5-91% metal cerium, 3-45.5% electrolytic manganese and 6-9% graphite (mass percentage), and select graphite crucible , after melting and casting to obtain cerium-manganese carbide alloy, prepare cerium-manganese carbide alloy powder with a particle size of less than 0.15mm and deionized water at a mass ratio of 1:10 to 1:40, and stir at a constant temperature of 10 to 50°C for 18 to 36 hours reacting, washing and drying to obtain composite cerium-manganese nanopowder with a specific surface area of 118-142m2 / g. The composite cerium-manganese nanopowder is heat-treated at 600-800°C / 2h to obtain the nanopowder whose main phase is CeO2, and the manganese-doped CeO2nanopowder has good thermal stability. The method is simple to operate, environmentally friendly and easy to realize industrial production.

Owner:SHANGHAI UNIV

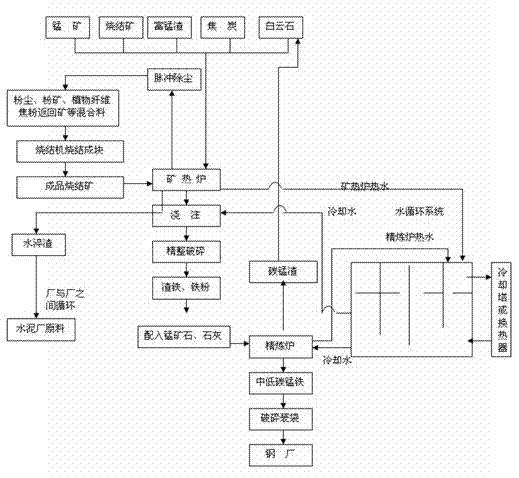

Recycling method for producing silicomanganese alloy and medium and low carbon ferromanganese

InactiveCN103695596AImprove protectionSave resourcesProcess efficiency improvementIron powderSmelting process

The invention discloses a method for mutually recycling solid wastes produced by production of a silicomanganese alloy and medium and low carbon ferromanganese. The method comprises the following steps: sintering dust produced by production of silicomanganese of a submerged arc furnace, manganese powder ores, plant fibers and coke powder to blocks, and re-melting down to smelt; refining scrap iron and iron powder of the silicomanganese alloy and preparing manganese ore and lime; and placing in a finery to smelt the medium and low carbon ferromanganese. Carbon manganese residues produced in the smelting process can further replace dolomite and rich-manganous slags as the production raw material of the silicomanganese alloy, so that the recycling production process which consumes the wastes as the raw materials and brings out the best in each other is realized among steps of a workshop.

Owner:广西敏诚矿业股份有限公司

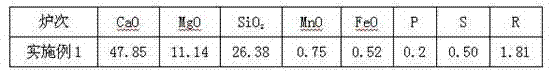

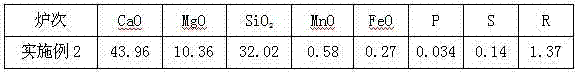

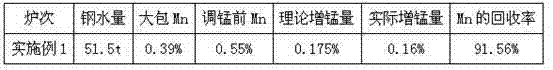

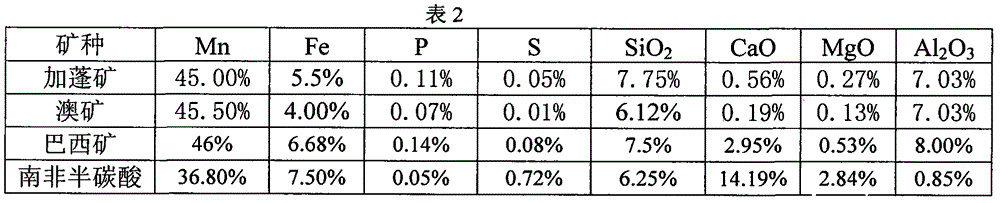

Technology for applying manganese ore to converter steelmaking in directly-alloying manner

InactiveCN105838843AHigh strengthImprove transportation effectManufacturing convertersSteelmakingManganese

The invention discloses a technology for applying manganese ore to converter steelmaking in a directly-alloying manner. A single carbon drawing method is adopted in the converter steelmaking technology; the content of FeO in final slag ranges from 13% to 15%; the average smelting cycle is 12.3 min; and manganese alloy ore is added into a converter in batches within 4 min to 10 min after converter steelmaking smelting begins, wherein the adding amount of the manganese alloy ore of each batch ranges from 10 kilograms per ton of steel to 14 kilograms per ton of steel, the end point carbon content is larger than or equal to 0.08%, the final point temperature ranges from 1650 DEG C-1680 DEG C, the content of end point residual manganese is increased by 0.16% to 0.20%, and the content of the manganese element in the manganese alloy ore is at least, by weight percentage, 44.2%.

Owner:XINJIANG BAYI IRON & STEEL

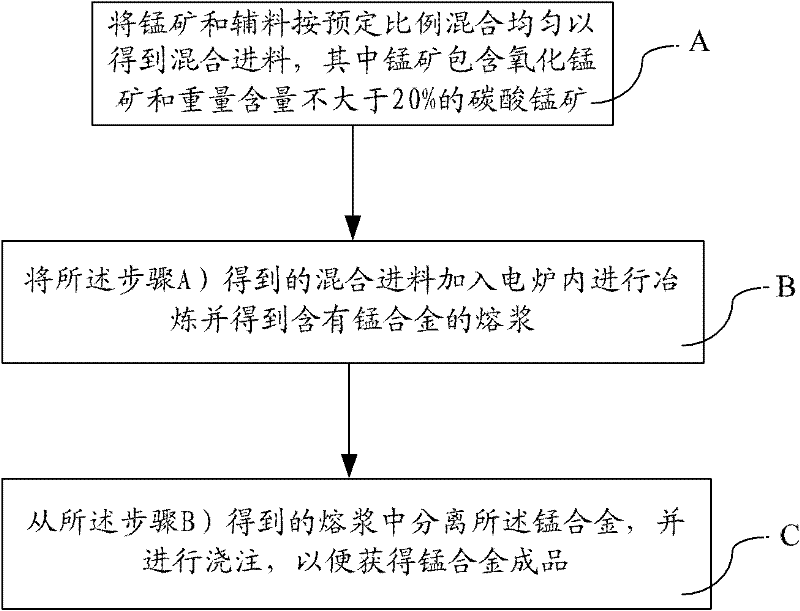

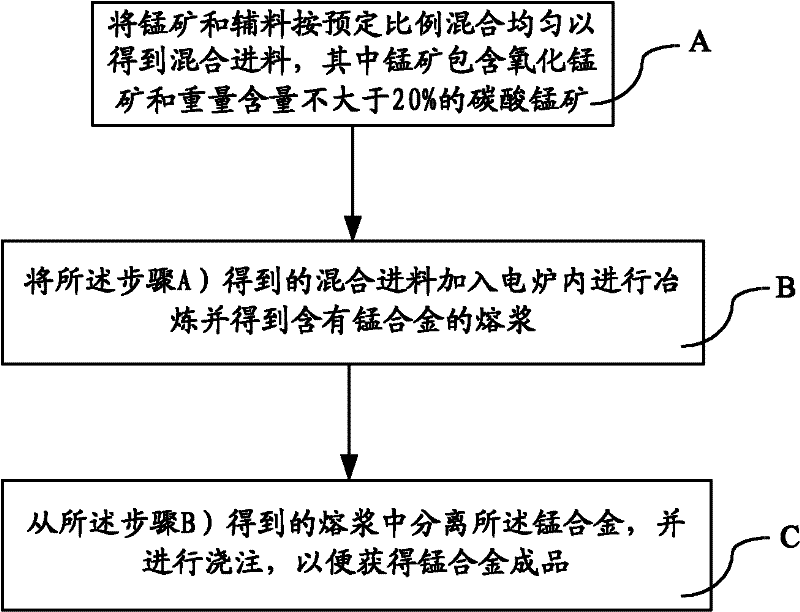

Smelting method of manganese alloy

The invention discloses a smelting method of a manganese alloy. The smelting method comprises the following steps of: A) mixing manganese ores and auxiliary materials evenly according to a preset ratio to obtain a mixed feeding material, wherein the manganese ores contain manganese oxide ores and manganese carbonate ores of which the weight content is no more than 20%; B) adding the mixed feedingmaterial obtained in the step A) in an electric furnace to smelt and obtain fused slurry containing the manganese alloy; and C) separating the fused slurry obtained in the step B) to obtain the manganese alloy, and pouring to obtain the manganese alloy finished product. According to the smelting method of the manganese alloy in the embodiment of the invention, the smelting cost of the manganese alloy can be greatly reduced and the pollution to the environment can be greatly lowered.

Owner:云南牧隆锰业有限公司

Excavator silicon-manganese alloy steel bucket tooth cast and processing process thereof

ActiveCN103014519AEasy to shapeImprove distributionFurnace typesHeat treatment furnacesRare-earth elementTempering

The invention discloses an excavator silicon-manganese alloy steel bucket tooth cast which comprises the following chemical components in percentage by weight: 0.28-0.32% of C, 0.8-1.2% of Si, 1.4-1.8% of Mn, 0.9-1.3% of Cr, 0.4-0.6% of Cu, 0.03-0.05% of Ca, 0.06-0.08% of Mg, 0.0015-0.003% of B, 0.08-0.14% of Ti, 0.02-0.04% of Nb, 0.02-0.03% of Y, 0.015-0.025% of Nd, P less than or equal to 0.03%, S less than or equal to 0.03% and the balance of iron and impurities. The excavator silicon-manganese alloy steel bucket tooth cast disclosed by the invention has the advantages of being added with Ca, Mg and rare earth elements, namely Y and Nd, purifying the molten steel, thinning the crystal grains, improving the form and distribution of impurities and realizing the comprehensive strengthening of an alloy steel, thereby enhancing the abrasion resistance of bucket teeth and prolonging the service life of the bucket teeth. According to the invention, a reasonable heat treatment process, appropriate annealing treatment, quenching and tempering are adopted, therefore the rigidity property and impact resistant property of the alloy steel can be outstandingly enhanced.

Owner:滁州恒昌机械装备制造有限公司

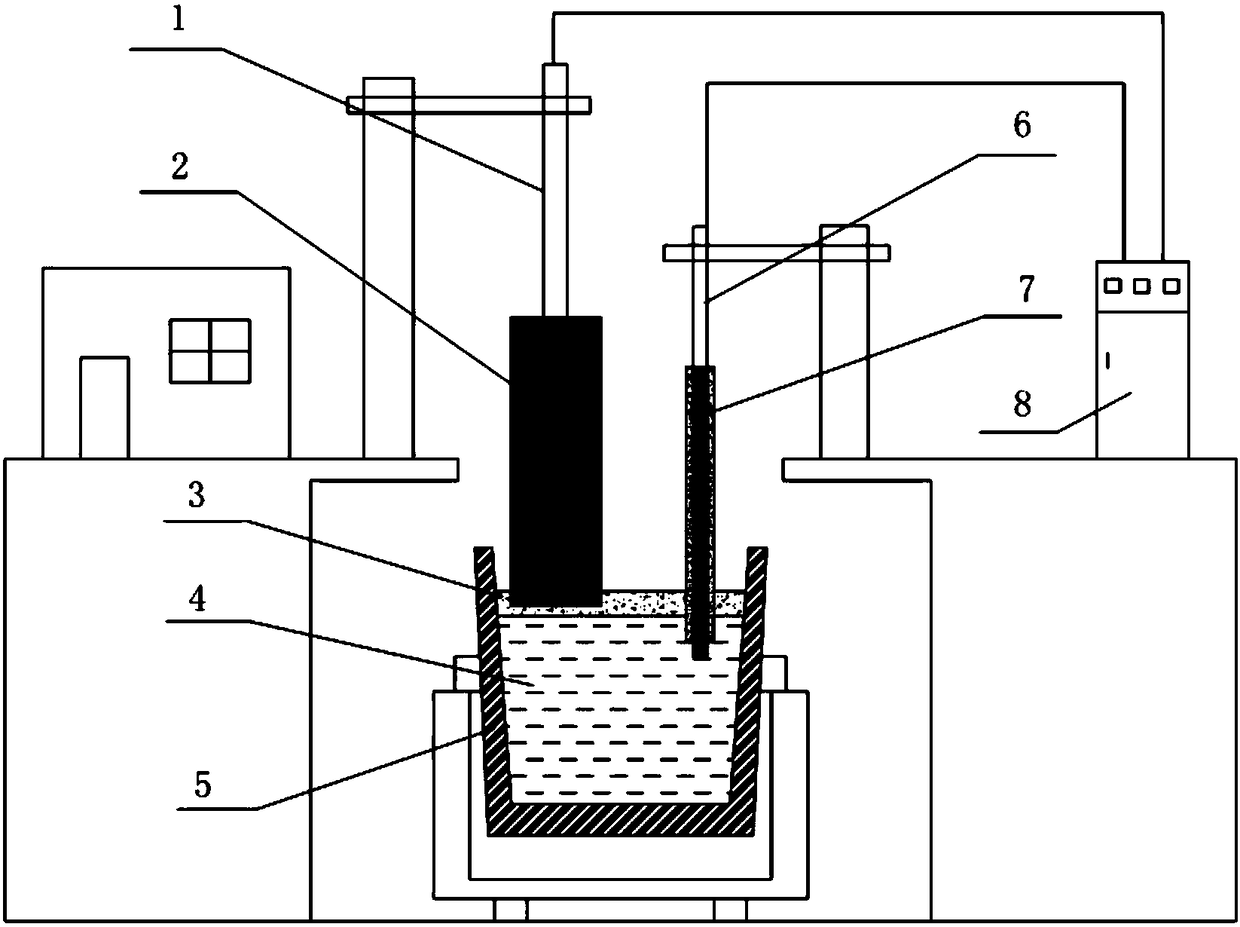

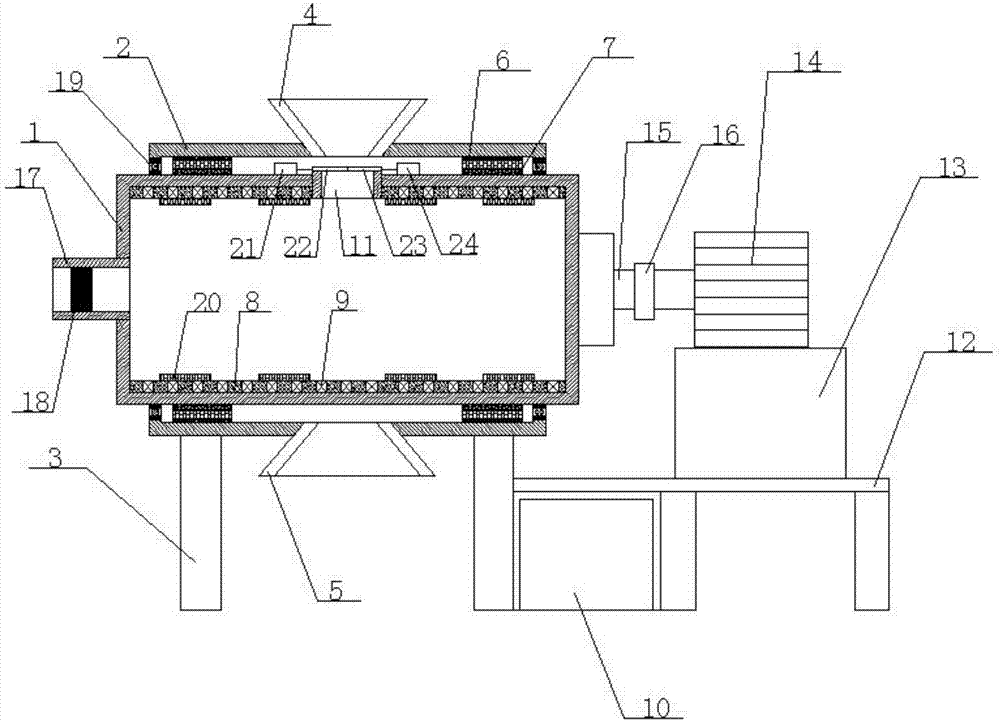

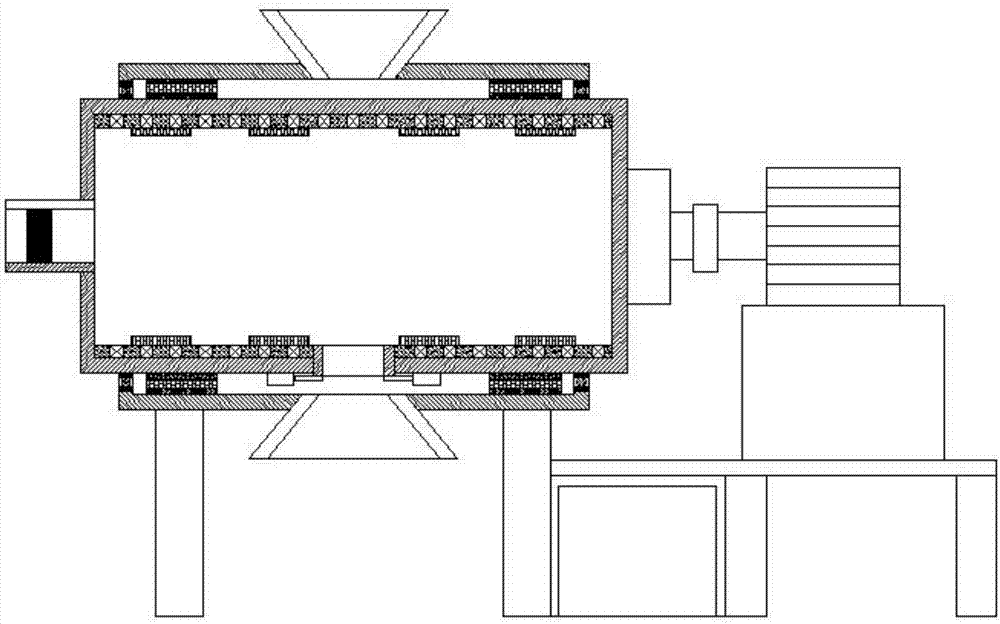

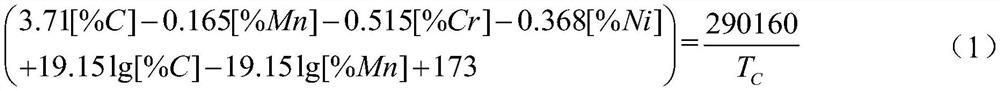

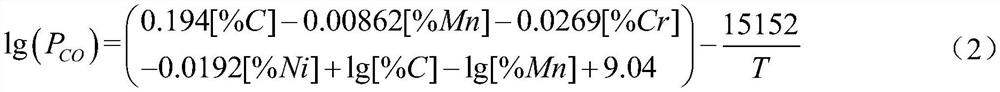

Method for manganese alloying by using manganese ore and device for manganese alloying by using manganese ore

InactiveCN108411065ASimple compositionEasy to operateManufacturing convertersGas emission reductionElectrochemical responseElectrolysis

The invention provides a method for manganese alloying by using manganese ore and a device for manganese alloying by using the manganese ore. According to the method, the manganese ore is molten, electrolyzed and reduced to finish manganese alloying; the objective of alloying is finished by applying a direct-current electric field between an inert anode placed in slag and a cathode placed in molten steel for an electrochemical reaction and then reducing manganese in manganese oxide to enter the molten steel and exhausting oxide in the manganese oxide into atmosphere in the form of oxygen by the anode reaction with the inert anode. By means of the technology, 3-10 kg per ton of steel of the manganese ore is added into the slag and the manganese content of the molten steel can be increased by 0.1%-0.2% (weight percentage). Compared with the other manganese alloying technology and equipment, the device is simple in structure, convenient to operate and capable of achieving the objective ofmanganese alloying which is low in cost and high in efficiency; the method is a bran-new low-cost green manganese alloying technology which is capable of realizing zero-emission of CO2 and achievingthe objective of low carbon environmental protection and is huge in social and economic benefits.

Owner:ANGANG STEEL CO LTD

Method for manufacturing high-carbon and high-chromium and high-manganese alloy cast ball

InactiveCN102864267AReduce labor intensitySignificant comprehensive benefitsFoundry mouldsFoundry coresHigh carbonEconomic benefits

The invention relates to a method for manufacturing a high-carbon and high-chromium and high-manganese alloy cast ball. According to the method, the high-carbon and high-chromium and high-manganese alloy cast ball comprises the following raw materials: scrap steel, high carbon ferro-chrome and high carbon ferromanganese, wherein the scrap steel is bearing leftovers and comprises 0.3 to 1.0 percent of C, less than or equal to 0.4 percent of Si, less than or equal to 0.3 percent of Mn and 0.5 to 1.5 percent of Cr; the high carbon ferro-chrome comprises 60 percent of Cr, less than or equal to 1.5 percent of Si and less than or equal to 38 percent of Fe; and high carbon ferromanganese comprises 58 percent of Mn, less than or equal to 2 percent of S and less than or equal to 40 percent of Fe. The method has the advantages that the machine halt number, warehouse clearing number and ball adding number are reduced, the labor intensity of workers is reduced, and the method has obvious comprehensive benefits of environment friendliness and social and economic benefits.

Owner:安徽省宁国诚信耐磨材料有限公司

Smelting method for producing high-manganese steel used in low-temperature environment by means of LF refining furnace

The invention discloses a smelting method for producing high-manganese steel used in a low-temperature environment by mean of an LF refining furnace. The smelting method comprises the steps of stationary ladle argon blowing, molten steel deoxygenation, molten steel desulfurization, refining and slagging, alloy adding and fine adjustment of composition temperature. According to the smelting method,the technical problems such as high steelmaking production difficulty due to high manganese alloy content and low oxygen and sulfur content of the high-manganese steel used in the low-temperature environment are solved, a practical solution is provided for the LF refining production in large-scale production of the high-manganese steel used in the low-temperature environment, and the smelting method can be widely used in steelmaking production of the high-manganese steel. According to the high-manganese steel molten steel produced through the smelting method, the content of Mn is larger thanor equal to 22.5%, the content of O is less than or equal to 0.0030%, the content of S is less than or equal to 0.003%, the manganese alloy yield is larger than or equal to 96%, and the smelting method meets the technical requirements of high manganese alloy content, high yield and low oxygen sulfur impurity content.

Owner:HEBEI IRON AND STEEL

Method for producing HRB 600 high-strength hot-rolled ribbed steel bars through vanadium-chromium microalloying

InactiveCN111575587AReduce manufacturing costAvoid high priceManufacturing convertersProcess efficiency improvementFerrosiliconRebar

The invention discloses a method for producing HRB 600 high-strength hot-rolled ribbed steel bars through vanadium-chromium microalloying. The method includes the following procedures of converter smelting; LF refining; continuous casting; heating; rolling; cooling bed air cooling; and shearing. In the converter smelting procedure, ferrosilicon, ferromanganese, a silicon-manganese alloy, ferrochromium and a silicon-nitrogen alloy are added when steel is tapped by 2 / 3 for silicon, manganese and chromium alloying; and in the LF refining procedure, the molten steel temperature of a refining furnace is higher than or equal to 1,570 DEG C, and ferrovanadium is added according to the component requirements for vanadium alloying. The method has the beneficial effects that (1), the blank in producing 600 MPa steel bars through V-Cr composite microalloying is filled in, V and Cr are used as microalloying strengthening elements, Nb and Ti with generally-high price are prevented from being used,and therefore the production cost is reduced; (2), 80% of V exists in a precipitation state after rolling, and the strength of the HRB 600 high-strength hot-rolled ribbed steel bars is remarkably improved; and (3), a certain amount of Cr is added into steel, the strength of the HRB 600 high-strength hot-rolled ribbed steel bars is obviously improved, and certain anti-corrosion capacity is achieved.

Owner:青海西钢特殊钢科技开发有限公司 +1

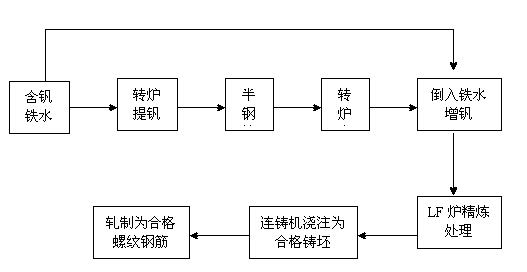

Smelting process for production of grade II hot-rolled reinforced bar

ActiveCN102978538AGuaranteed performanceReduce smelting costsManufacturing convertersSteelmakingSmelting process

The invention relates to a smelting process for production of a grade II hot-rolled reinforced bar, which belongs to the technical field of metallurgy. A technical scheme provided by the invention is as follows: through usage of a vanadium extraction-steelmaking duplex process, the grade II hot-rolled reinforced bar is produced by using molten iron containing vanadium and silicon-manganese alloy as main alloying raw materials; according to the process, production cost of the bar is reduced by increasing the content of V in the bar and properly reducing elements consisting of Mn and Si in the grade II hot-rolled reinforced bar on the base of ensuring performances of the grade II hot-rolled reinforced bar; the elements consisting of Mn and Si are mainly from the silicon-manganese alloy, the element C is mainly from C at a steelmaking terminal point and C brought by the molten iron containing vanadium, and the element V is mainly from residual vanadium at the steelmaking terminal point, V brought by the molten iron containing vanadium and V of V2O5 in final slag of a reduction converter. With the process provided by the invention, performances of the grade II hot-rolled reinforced bar are guaranteed, production cost of the grade II hot-rolled reinforced bar is reduced, a variety of performances of the grade II hot-rolled reinforced bar are guaranteed without passing through water, and quality of the bar is ensured.

Owner:HEBEI IRON AND STEEL

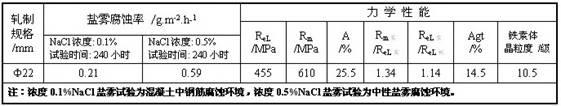

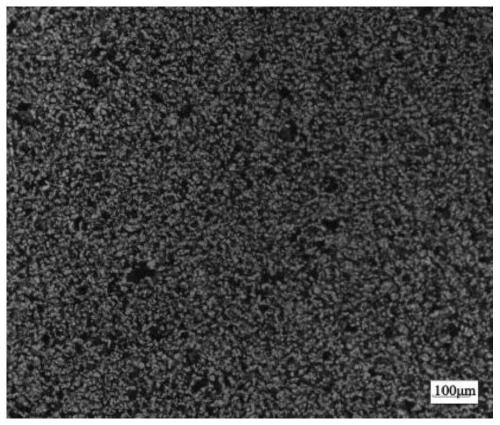

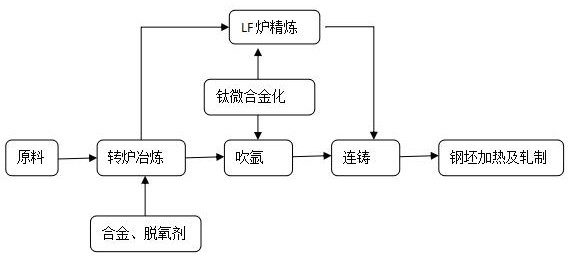

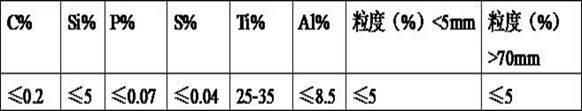

Deformed steel bar titanium microalloying production process

The invention relates to a production process of steel for HRB400E-grade deformed steel bars. The produced steel for the deformed steel bars is prepared from the following components in percentage byweight: 0.21%-0.25% of C, 0.65%-0.80% of Si, 1.40%-1.60% of Mn, 0.004%-0.030% of Ti, less than 0.045% of P, less than 0.045% of S and the balance Fe and inevitable impurities. The deformed steel bar titanium microalloying production process comprises the steps of converter smelting, external treatment, continuous casting, casting blank heating and rolling. Silicon-manganese alloy and the like areadded in the converter smelting step for deoxidation alloying treatment, and the external treatment step comprises argon blowing in an argon blowing station, unnecessary ladle furnace (LF) refining and ferrotitanium adding for titanium microalloying treatment. According to the method, the comprehensive production cost is low, the water gap blockage occurrence rate and the continuous casting billetcrack defect in the continuous casting process are obviously reduced, and low-cost stable sustainable production of the HRB400-grade deformed steel bars is achieved.

Owner:SHANDONG SHIHENG SPECIAL STEEL GROUP

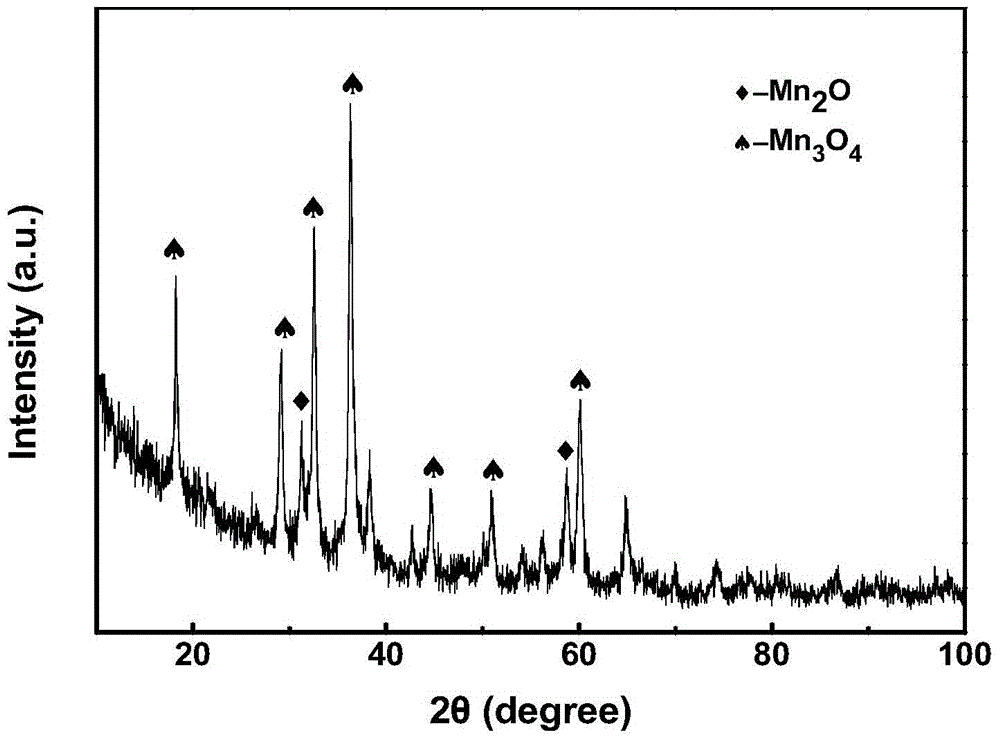

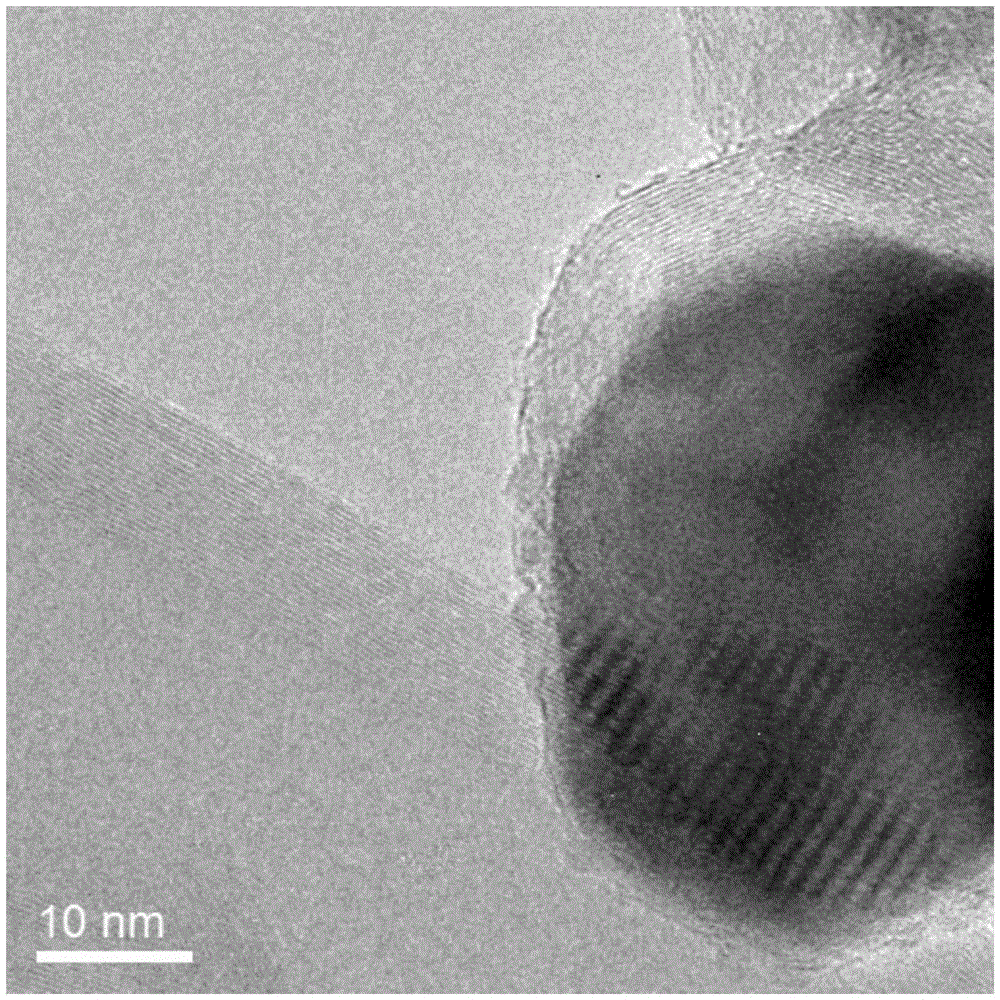

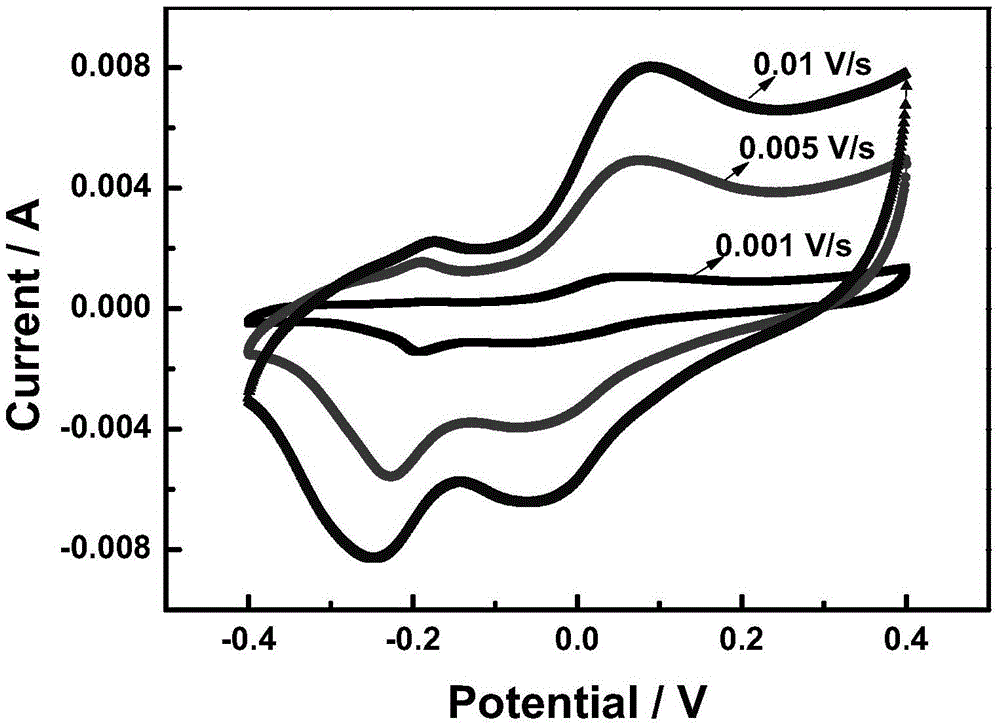

Preparation method of shell-core carbon coating manganese nanocomposite particles and hell-core carbon coating manganese alloy oxide nanocomposite particles, and application thereof

ActiveCN105590753AInhibition of volume expansionAvoid chalkingHybrid capacitor electrodesHybrid/EDL manufactureDouble-layer capacitanceCapacitance

The present invention provides a preparation method of shell-core carbon coating manganese nanocomposite particles and hell-core carbon coating manganese alloy oxide nanocomposite particles. The method comprises: an automatically controlling direct current arc metal nanometer powder production device is employed; the appropriate amount of metal manganese or manganese alloy raw materials is added; blocky metal manganese or manganese alloy materials are evaporated in the inert gas and mixing atmosphere containing carbon gas in a certain proportion; precursors of carbon coating manganese nanocomposite particles or carbon coating manganese alloy nanocomposite particles are obtained; the precursors are subjected to heating and oxidation treatment in the reaction atmosphere; and the carbon coating manganese nanocomposite particles or carbon coating manganese alloy nanocomposite particles are obtained. The nanocomposite particles prepared through the preparation method of shell-core carbon coating manganese nanocomposite particles and hell-core carbon coating manganese alloy oxide nanocomposite particles has a shell-core-type structure which takes graphitic carbon as a shell and takes manganese and manganese alloy oxide as a core, with electrical double-layer capacitances and the fake capacitance, so that the capacity of the electrodes of a supercapacitor is greatly improved.

Owner:DALIAN UNIV OF TECH

Copper, nickel and manganese alloy brazing filler metal powder and preparation method thereof

ActiveCN110732801AImprove yieldUniform qualityWelding/cutting media/materialsSoldering mediaSmelting processManganese

The invention discloses copper, nickel and manganese alloy brazing filler metal powder which is prepared from the following components in percent by mass: 28-30% of nickel, 27-30% of manganese, 4-6% of cobalt, 0.6-1.4% of silicon, 0.8-1.6% of ferrum, 0.1-0.3% of boron, 0.08-0.2% of phosphorus, less than 0.1% of oxygen, less than 0.05% of sulfur, less than 0.1% of carbon, less than 0.5% of total amount of other impurities and the balance copper. The invention also discloses a method of preparing the copper, nickel and manganese alloy brazing filler metal powder. The method comprises the following steps: uniformly mixing raw materials; putting the raw materials in vacuum induction melting gas atomization powder manufacturing equipment to be smelted to a mixed liquid alloy; and atomizing anddispersing the mixed liquid alloy to obtain the copper, nickel and manganese alloy brazing filler metal powder. The copper, nickel and manganese alloy brazing filler metal powder is small in difference of composition content and generation of an intermediate brittle phase is reduced. The heating and smelting processes and atomization are controlled, so that the copper, nickel and manganese alloy brazing filler metal powder which is uniform and stable in chemical component and low in impurity content is obtained.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Production of low carbon manganesium iron in medium frequency induction furnace by remelting process

A method for manufacturing low-carbon manganese iron alloy by medium-frequency furnace remelting includes: throwing manganese into medium-frequency furnace, electrofusing liquid, adding manganese solution into steel scrap and smelting with adding amount 5-30wt% of manganese, removing slag, cooling alloy solution in steel ladle, breaking alloy block, and forming require bulk. Its advantages include low cost, simple process and high output.

Owner:宁结算

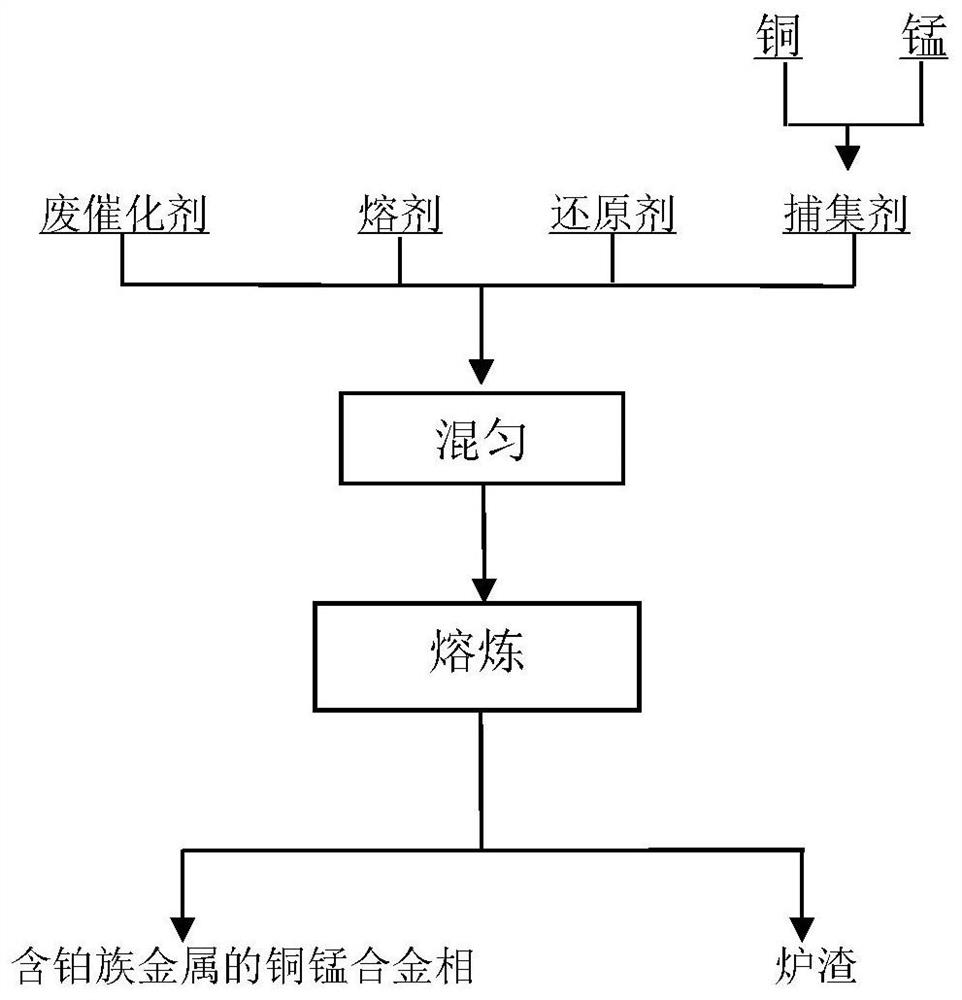

Method for collecting and recycling platinum group metal in waste catalyst by pyrogenic process

ActiveCN113802004ALower requirementHigh recovery rateProcess efficiency improvementPtru catalystSlag

The invention discloses a method for capturing and recycling platinum group metal in a waste catalyst by a pyrogenic process, which comprises the following steps: preparing a platinum group metal capturing agent from copper and manganese according to an element molar ratio of 1: (0.3-1.5), and uniformly mixing the waste catalyst, the capturing agent, a slagging flux and a reducing agent according to a set proportion; smelting the uniformly mixed materials at the temperature of 1100-1300 DEG C, reacting for a preset time, floating slag on the surface of an alloy phase, and carrying out solid-liquid separation to obtain a copper-manganese alloy phase containing the platinum group metal; and recovering the obtained copper-manganese alloy phase containing the platinum group metal to obtain the platinum group metal. According to the method of the invention, multi-metal synergistic trapping is utilized, the recovery rate of the platinum group metal is high, copper and manganese can form low-melting-point alloy with the melting temperature lower than 1000 DEG C, and the melting temperature is reduced. The method has the advantages of low energy consumption, low cost, high recovery rate and the like, and is beneficial to industrial application.

Owner:CENT SOUTH UNIV

Smelting method for producing manganese-rich slag by smelting and reduction of high-manganese liquid iron in electric furnace

The invention provides a smelting method for producing manganese-rich slag by smelting and reduction of high-manganese liquid iron in an electric furnace. According to the smelting method, the high-manganese liquid iron smelted and reduced by the electric furnace is placed in a converter and subjected to converting through constant pressure gun changing operation, without adding any slagging materials in the converting process; and oxygen supply converting is carried out for 6-9 minutes at the conditions of oxygen purity more than or equal to 99.5%, pressure of 0.65-0.65 MPa, oxygen supply intensity of 1.7-2.5 m<3> / min. t, so that Mn and Si in the liquid iron are oxidized quickly, the content of manganese in the slag is further increased and then the high-grade manganese-rich slag is formed. The efficient utilization of the manganese resource in the high-manganese liquid iron smelted and reduced by the electric furnace is realized and the manganese-rich slag can be used for producing silicon-manganese alloy, ferromanganese and manganese metal; the production technology is simple, the production cost is lowered greatly and the economic benefit is increased; and the semi-steel chemical components and the temperature after the production of the manganese-rich slag with the method are stable, thus the normal operation requirements of follow-up steel-making work procedures are completely met.

Owner:WUKUN STEEL

Method for alloying manganese ore in LF (ladle furnace)

InactiveCN102758066AReduce the amount addedIncrease electricity billProcess efficiency improvementSteelmakingAlloy

The invention relates to a method for alloying manganese ore in an LF (ladle furnace) furnace, and belongs to the field of steel-making production technologies. The technical scheme is as follows: the manganese ore is added to a ladle to be used as the top slag or added along with the slag in the LF furnace when a converter performs steel tapping; the LF furnace performs arcing and slagging, and carborundum-made reducing slag is synchronously added, and white slag is maintained; after the completion of manganese reduction, the refining is finished. Manganese ore is added with the proportioning of 3 to 6 kg / t; the manganese ore replaces wollastonite and fluorite, as well as replacing some silicomanganese, thus the quantity of added silicomanganese can be reduced; and the quantity of reduced replaced silicomanganese is 2.2 to 4.5 kg / t. According to the method, the manganese ore which is low in cost is applied to the LF furnace for alloying for the first time, and the silicomanganese or ferromanganese high in cost is replaced; the recovery rate of manganese is more than 90%, therefore, the cost of steelmaking is obviously reduced; and meanwhile, the manganese ore has high effect on slagging in the LF furnace, so the manganese ore can replace some fluorite for reducing the environmental pollution and erosion on wrapping liner.

Owner:HEBEI IRON AND STEEL

Method for smelting silicon manganese alloy through microwaves

The invention relates to a method for smelting silicon manganese alloy through microwaves. The method comprises the following steps that 10, a raw material containing manganese is placed into a microwave smelting furnace to be smelted to obtain a liquid manganese mixture; 20, a raw material containing silicon is placed into the microwave smelting furnace to be smelted to obtain a liquid silicon mixture; and 30, the liquid manganese mixture obtained after smelting is carried out in the step 10 and the liquid silicon mixture generated in the step 20 are mixed and remolten to obtain the silicon manganese alloy. The microwave smelting furnace is adopted for carrying out smelting, the smelting furnace can rotate automatically, the smelted raw materials in a furnace body are heated uniformly, the chemical reaction rate in the furnace is increased, the smelting speed is increased, the smelting cost is saved, and furnace interior heat transfer and mass transfer speed is increased. The reduction speed in the furnace is increased, the reactions are active, the three reactions can also generate silicon dioxide particles with the large specific area, and in the process of being affected with coke, the contact area is increased, which is beneficial for reducing silicon.

Owner:陕西盛华冶化有限公司

Method for smelting high-manganese stainless steel through CO2 decarburization in AOD furnace

The invention discloses a method for smelting high-manganese stainless steel through CO2 decarburization in an AOD furnace, and belongs to the field of ferrous metallurgy. The content of manganese in the high-manganese stainless steel is higher than 8%, the content of chromium in the high-manganese stainless steel is higher than 10%, an AOD smelting method is adopted, molten iron with the high content of manganese and chromium can be adopted as a raw material, a side gun adopts CO2 + O2 + (N2 or / and Ar) for mixed blowing, and the gas supply pressure is 0.2-1.5 Mpa; and in the decarburization process, the manganese content in molten iron can be controlled to be 2.0-8.0%, and the chromium content in the molten iron can be controlled to be 10.0-25.0%. And after decarburization is finished, a reducing agent is adopted for reduction, lime, fluorite and the like are added for slag adjustment, and the yield of metal manganese and chromium is increased. Good manganese and chromium protection effects can be achieved, a large amount of high-carbon ferromanganese and other low-price high-manganese alloys can be added in the decarburization process, the purpose of smelting high-manganese stainless steel through high-manganese high-chromium molten iron at low cost is achieved, the adding amount of electrolytic manganese and other manganese alloys and the using amount of the reducing agent in alloying are greatly reduced, and the alloying cost is reduced.

Owner:UNIV OF SCI & TECH BEIJING +1

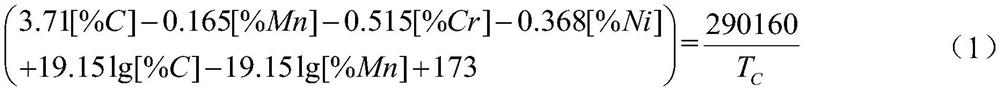

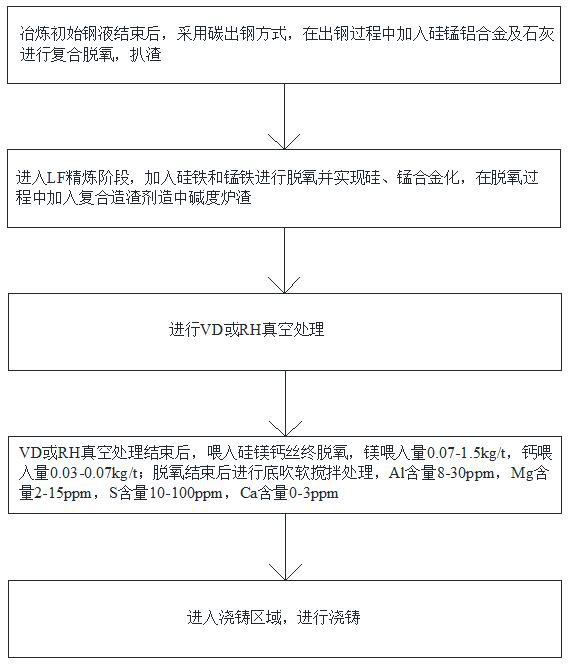

Deoxidation control method for high-end bearing steel inclusions

The invention discloses a deoxidation control method for high-end bearing steel inclusions, which comprises the following steps: step 1, after initial molten steel is smelted by an electric furnace ora converter, silicon-manganese-aluminum alloy and lime are added in the tapping process to carry out composite deoxidation, and slagging off is conducted; Step 2, an LF refining stage is entered, ferrosilicon and ferromanganese are added to deoxidize and realize alloying of silicon and manganese, and a composite slag former, lime and a slag surface deoxidizer are added in the deoxidizing processto prepare medium-alkalinity slag with alkalinity of 2-2.5; 3, vacuum treatment is conducted; 4, silicon-magnesium-calcium wires are fed for final deoxidation, wherein the magnesium feeding amount is0.07-1.5 kg / t, and the calcium feeding amount is 0.03-0.07 kg / t; and after bottom blowing soft stirring treatment, the content of deoxidation related elements in molten steel is as follows: the content of Al is 8-30 ppm, the content of Mg is 2-15 ppm, the content of S is 10-100 ppm, and the content of Ca is 0-3 ppm; and step 5, a casting area is entered for casting. By means of the method, microscopic Ds inclusions and macroscopic inclusions in the bearing steel can be well controlled, and the condition that C-type inclusions do not exceed the standard, and therefore the stability of the bearing steel in the using process is comprehensively improved.

Owner:BAOSHAN IRON & STEEL CO LTD

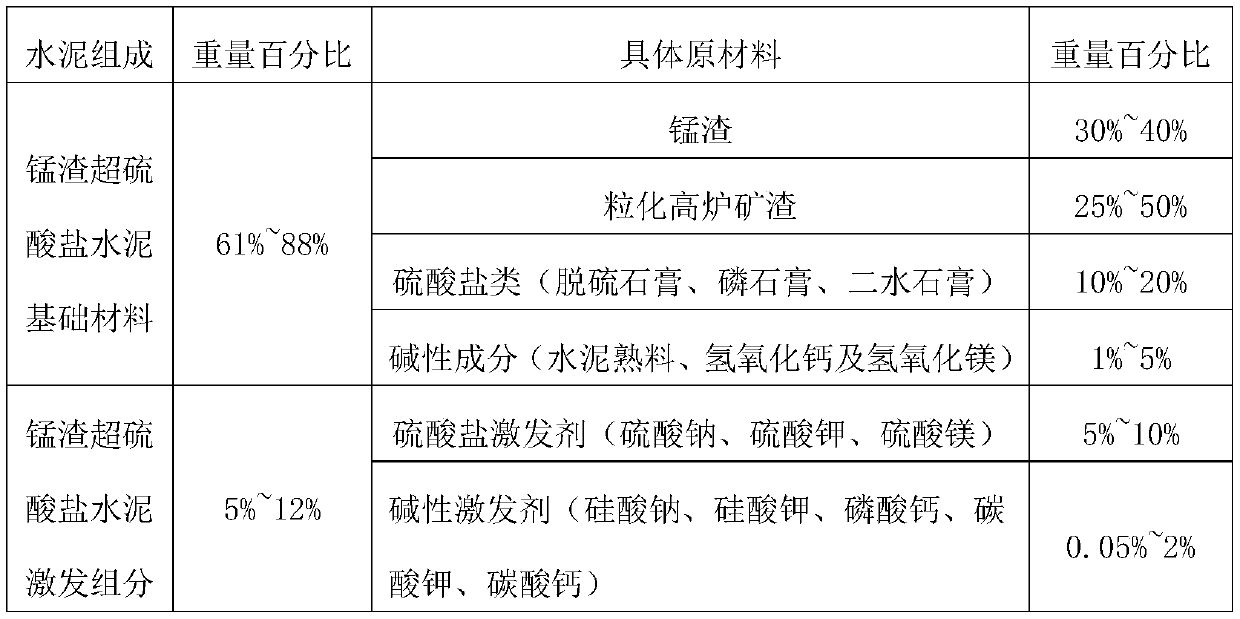

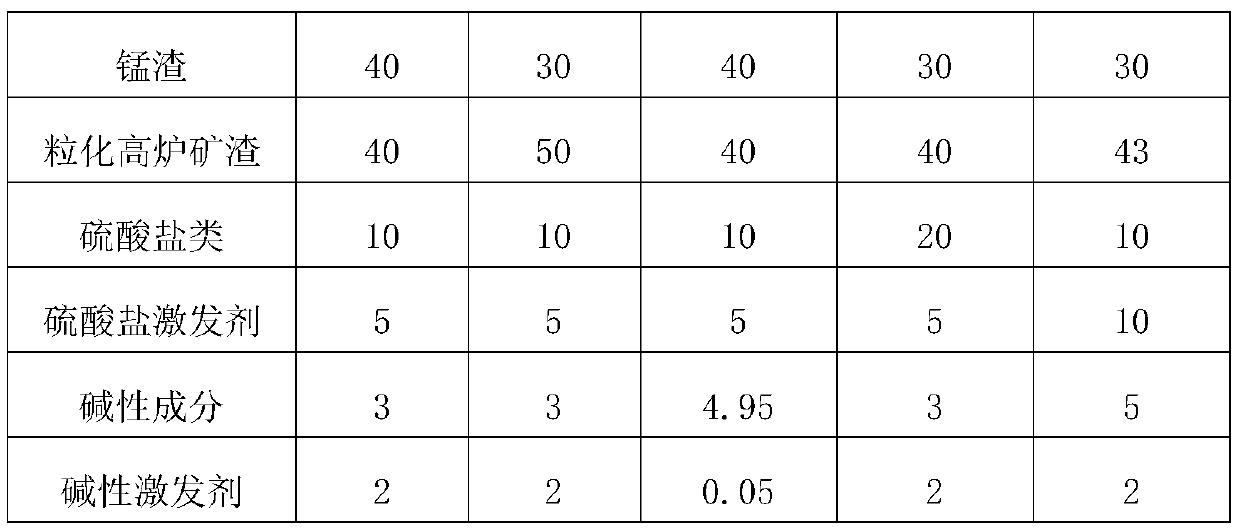

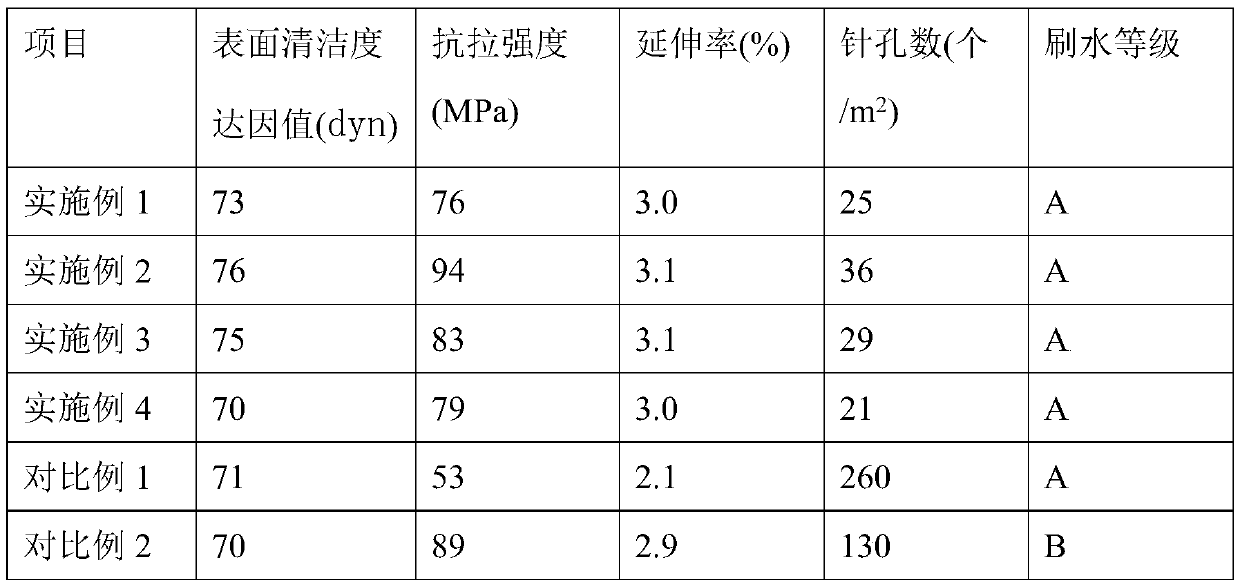

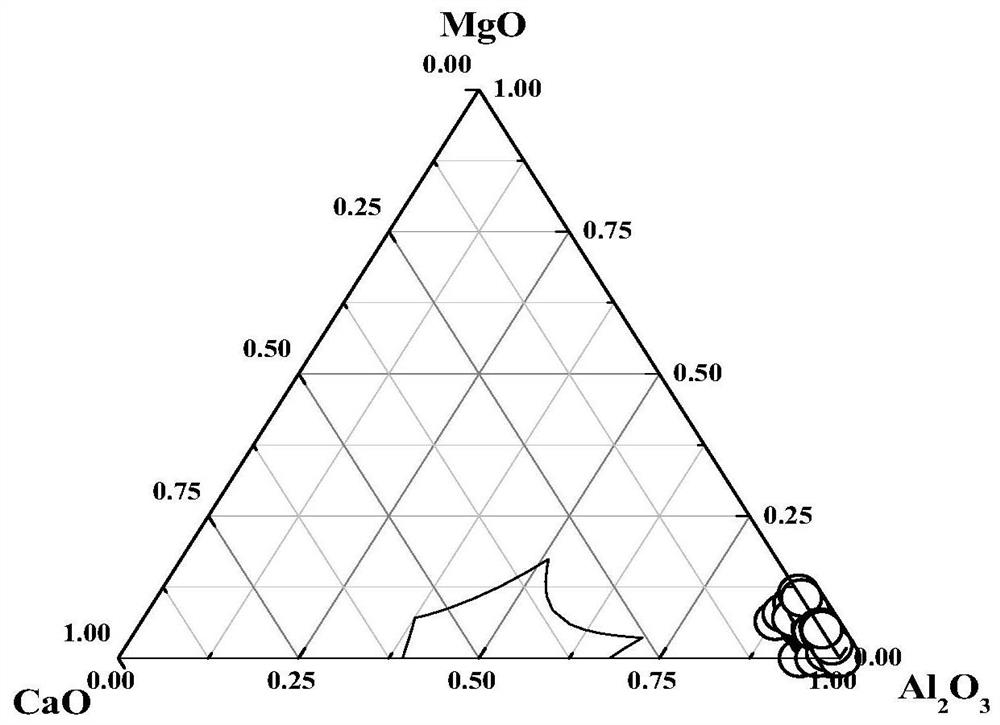

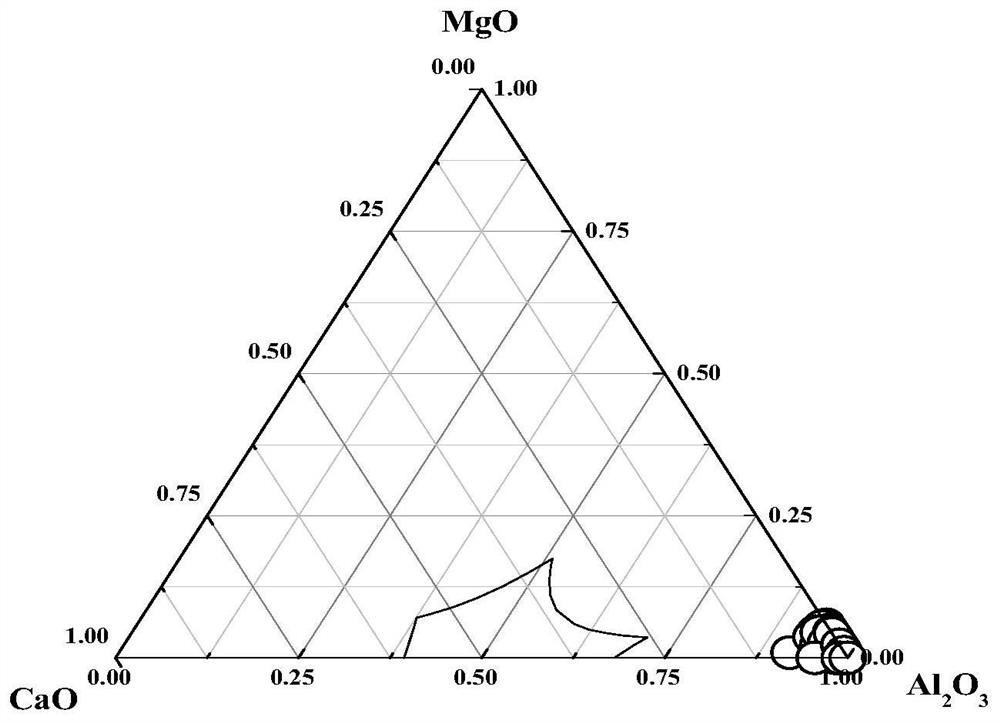

Manganese slag supersulfate cement and preparation method thereof

The invention belongs to the technical field of special cement, and particularly relates to a manganese slag supersulfate cement and a preparation method thereof. The manganese slag supersulfate cement is prepared from the components in percentage by weight: 30-40% of manganese slag, 25%-50% of granulated blast furnace slag powder, 10-20% of sulfates, 5%-10% of a sulfate activator, 1-5% of an alkaline component and 0.05-2% of an alkaline activator. The manganese slag which is a high-temperature slag waste discharged during the blast furnace smelting process of manganese iron or silicomaganeseis used as a main raw material, a material science principle is combined, the mineral characteristics of manganese slag and slag are taken as a basis, the potential hydration activity of the manganeseslag is activated by using sulfates and alkaline environment to form the initial strength, and novel manganese slag supersulfate cement with excellent properties is further designed.

Owner:中建西部建设新疆有限公司 +1

Rare earth aluminum-manganese alloy sterilization foil for fresh steaming brick of pet food package and production technology thereof

PendingCN111589861ANeat endsThickness deviation range is smallRollsMetal rolling arrangementsManganeseAlloy

The invention discloses rare earth aluminum-manganese alloy sterilization foil for a fresh steaming brick of a pet food package. The foil comprises the following raw materials of, by mass percentage,less than or equal to 0.3% of Si, less than or equal to 0.6% of Fe, 0.12-0.18% of Cu, 1.1-1.4% of Mn, 0.10-0.25% of La, less than or equal to 0.01% of Mg, less than or equal to 0.03% of Zn, less thanor equal to 0.05% of Ti, less than or equal to 0.01% of P, less than or equal to 0.03% of Li, and the balance Al. The foil is obtained through cast-rolled coil production, rolling in a cold rolling mill, a foil rolling process, a finished product cutting process, a finished product annealing process and an inspection and packaging process. The rare earth aluminum-manganese alloy sterilization foilfor the fresh steaming brick of the pet food package has the advantages of uniform structure, flatness, no wave, consistent foil surface color and high heat resistance, heat conduction, flexibility,corrosion resistance and air tightness of the aluminum foil completely meet the requirements of the sterilization aluminum foil for the fresh steaming brick of the pet food package.

Owner:JIANGSU ZHONGJI LAMINATION MATERIALS

Silicomanganese efficient absorption alloy ball and preparation method thereof

The invention discloses a silicomanganese efficient absorption alloy ball. Silicomanganese alloy, silicon iron, manganese ore, high alumina cement and a binder are mixed and made into the alloy ball with the particle size of 20 millimeters to 50 millimeters. The alloy ball replaces the traditionally used alloys such as silicon iron, high carbon ferromanganese, and the silicomanganese, and enables the cost of steel per ton to be obviously reduced. The alloy ball not only can improve the efficiency of silicon and manganese and the recovery rate of alloy can be increased, but also can completely replace the traditionally used alloys such as the silicon iron, the high carbon ferromanganese and the silicomanganese. The deoxygenation response is fast, the alloying speed is high, cost consumption of raw and auxiliary materials can be reduced, environmental pollution is reduced, working condition is improved, and steel-making cost is reduced. Therefore, the silicomanganese efficient absorption alloy ball and the preparation method of the silicomanganese efficient absorption alloy ball play a significant role in improvement of comprehensive economic benefits of steel enterprises.

Owner:河南鹏钰集团有限公司

Refining process for obtaining solid Al2O3 inclusions

The invention relates to a refining process for obtaining solid Al2O3 inclusions, which comprises the following steps of: controlling the addition of a deoxidizing agent in a converter tapping process, namely, not adopting aluminum deoxidization, and adopting silicon-manganese alloy and calcium carbide to carry out post-converter deoxidization, adjusting other chemical components except Al element in the components after tapping in place during tapping, and controlling the alkalinity of refining slag to be between 1.0 and 3.0; and in the refining heating process, the argon flow of ladle bottom blowing is controlled, the argon flow is smaller than 100 L / min, after the temperature of the molten steel meets the requirement, the Al content is adjusted in place at a time through an aluminum wire, so that solid Al2O3 inclusions are obtained, and the molten steel is transferred to an RH vacuum tank to be treated. According to the BOF-LF-RH-CC technological process production process adopted for the aluminum-containing steel, inclusions are controlled to be solid Al2O3 in the LF refining procedure, generation of low-melting-point calcium aluminate before the LF refining procedure is finished is effectively controlled, the Al2O3 inclusions are efficiently removed through RH vacuum, and it is guaranteed that the cleanliness of molten steel is high, and the inclusions are few.

Owner:ZENITH STEEL GROUP CORP +1

Copper-manganese alloy electroplating technique

The invention discloses a copper-manganese alloy electroplating technique which comprises the following steps: deoiling and derusting, ultrasonic cleaning, electroplating, dehydrogenation, water repelling treatment, alcohol washing, water washing and blow-drying. The technique integrates the deoiling and derusting steps, thereby saving the procedure, lowering the cost and enhancing the efficiency; and the weakly alkaline conditions can produce less pollution to the environment. The ultrasonic cleaning step is added, so that the overall pretreatment is efficient, environment-friendly and pollution-free. In the electroplating process, an acidic system is adopted, and thus, can produce less pollution to the environment. By adding ascorbic acid, hydroquinone and other additives, the electroplating is performed under the conditions of proper current density and electroplating temperature, so the copper / manganese codeposition effect is good, and the finally obtained copper-manganese alloy electroplating coating has the advantages of uniform color, fine crystals, high film thickness (up to 10 mu m) and favorable wear resistance. After being rubbed 100 times by W40 sand paper in a single direction, the coating can not peel. The alloy coating has favorable electric conductivity, and can effectively prevent chromium in the stainless steel from outward transfer and dispersion.

Owner:太仓市金鹿电镀有限公司

Formula for recycling silicon-manganese alloy slag during silicon-manganese alloy production

The invention relates to a formula for recycling silicon-manganese alloy slag during silicon-manganese alloy production, wherein the formula comprises manganese-rich ore and an auxiliary material, and the auxiliary material comprises dolomite and silica. The formula is characterized in that a silicon-manganese slag preparation material is adopted to replace dolomite and is added to manganese-rich ore. According to the present invention, the silicon-manganese slag preparation material can be adopted to replace dolomite, silica and other auxiliary materials or reduce addition amounts of dolomite, silica and other auxiliary materials so as to increase the manganese fed to the furnace in the whole ore, importantly the characteristic that the silicon-manganese slag has high Al2O3 content is adopted to increase Al2O3 of the material fed to the furnace, and the Al2O3 fed to the furnace is increased to 6-7% from the original about 3%, such that the Al2O3 content in the final slag is increased to about 18-20% from the original about 10% so as to substantially improve furnace material smelting performances.

Owner:内蒙古鄂尔多斯冶金有限责任公司

Steel cylinder sleeve and preparation method thereof

ActiveCN111979493AHigh strengthHigh hardnessFurnace typesHeat treatment furnacesAustemperingManganese

The invention provides a preparation method of a steel cylinder sleeve. The preparation method comprises the following steps that (A) smelting is carried out after burdening is completed, and molten steel with the following components is obtained; (B) the molten steel is subjected to centrifugal casting, and a steel cylinder sleeve blank is obtained; and (C) the steel cylinder sleeve blank is subjected to austenitizing heat treatment and then subjected to isothermal quenching, and the steel cylinder sleeve is obtained. The low-manganese alloy steel cylinder sleeve blank is prepared through a centrifugal casting method, a matrix is converted into bainite and part of martensite through austenitizing and isothermal salt bath quenching, and finally the obtained steel cylinder sleeve has high strength, abrasion resistance and anti-explosion performance and better cavitation erosion resistance.

Owner:ZYNP GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com