Deformed steel bar titanium microalloying production process

A technology of microalloying and production technology, applied in the field of steel materials, can solve problems such as fluctuations in mechanical properties of steel materials, achieve the effects of reducing crack defects and reducing overall costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] A HRB400E grade rebar steel production process, the rebar is made of steel weight percentage: C: 0.21%, Si: 0.65%, Mn: 1.40%, Ti: 0.004%, P: 0.045%, S : 0.045%, the rest is Fe and unavoidable impurities.

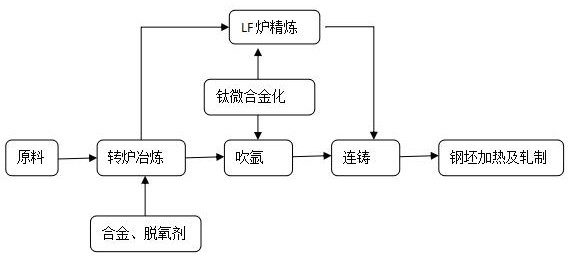

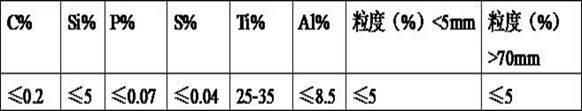

[0015] This production process includes the following steps: converter smelting, out-of-furnace treatment, continuous casting, slab heating and rolling. The converter smelting step includes adding silicon-manganese alloy for deoxidation alloying treatment. The out-of-furnace treatment steps include argon blowing station, argon blowing, Optional LF furnace refining, adding ferro-titanium for titanium micro-alloying treatment.

[0016] Converter smelting steps include: raw materials are smelted in a 60-ton converter, the temperature range of the end point is 1630°C, the C content of the end point is 0.06%, and the P content is ≤0.03%; after 1 / 3 of the steel is tapped, silicon-manganese alloy and aluminum-calcium-carbon are added to the ladle Composite deoxidizer etc. a...

Embodiment 2

[0021] A titanium micro-alloying production process for threaded steel, the threaded steel contains the following components by weight percentage: C: 0.25%, Si: 0.80%, Mn: 1.60%, Ti: 0.030%, P: 0.04%, S: 0.04 %, the rest is Fe and unavoidable impurities.

[0022] A titanium micro-alloying production process for threaded steel, comprising the following steps: converter smelting, treatment outside the furnace, continuous casting, slab heating and rolling; the step of converter smelting includes adding silicon-manganese alloy etc. for deoxidation alloying treatment; The processing steps include argon blowing at the argon blowing station, optional LF furnace refining, adding ferro-titanium for titanium micro-alloying treatment.

[0023] Converter smelting steps include: raw materials are smelted in a 60-ton converter, the temperature range of the end point is 1660°C, the C content of the end point is 0.08%, and the P content is ≤0.03%; after 1 / 3 of the steel is tapped, silicon-man...

Embodiment 3

[0028] A titanium microalloying production process for threaded steel, the threaded steel contains the following components in weight percentage: C: 0.23%, Si: 0.7%, Mn: 1.50%, Ti: 0.010%, P: 0.03%, S: 0.035 %, the rest is Fe and unavoidable impurities.

[0029] A titanium micro-alloying production process for threaded steel, comprising the following steps: converter smelting, treatment outside the furnace, continuous casting, slab heating and rolling; the step of converter smelting includes adding silicon-manganese alloy etc. for deoxidation alloying treatment; The processing steps include argon blowing at the argon blowing station, optional LF furnace refining, adding ferro-titanium for titanium micro-alloying treatment.

[0030] Converter smelting steps include: raw materials are smelted in a 60-ton converter, the temperature range at the end point is 1640°C, the C content at the end point is 0.07%, and the P content is ≤0.03%; after 1 / 3 of the steel is tapped, silicon-mang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com