Vertical continuous preparing device for carbon nano tube fibers and preparing method

A carbon nanotube fiber, a technology for preparing a device, applied in nanotechnology and other directions, can solve the problems of increasing the complexity of the device, the production cost, and the unfavorable process continuity, and achieve the effects of simple structure, low cost, uniform injection and gasification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

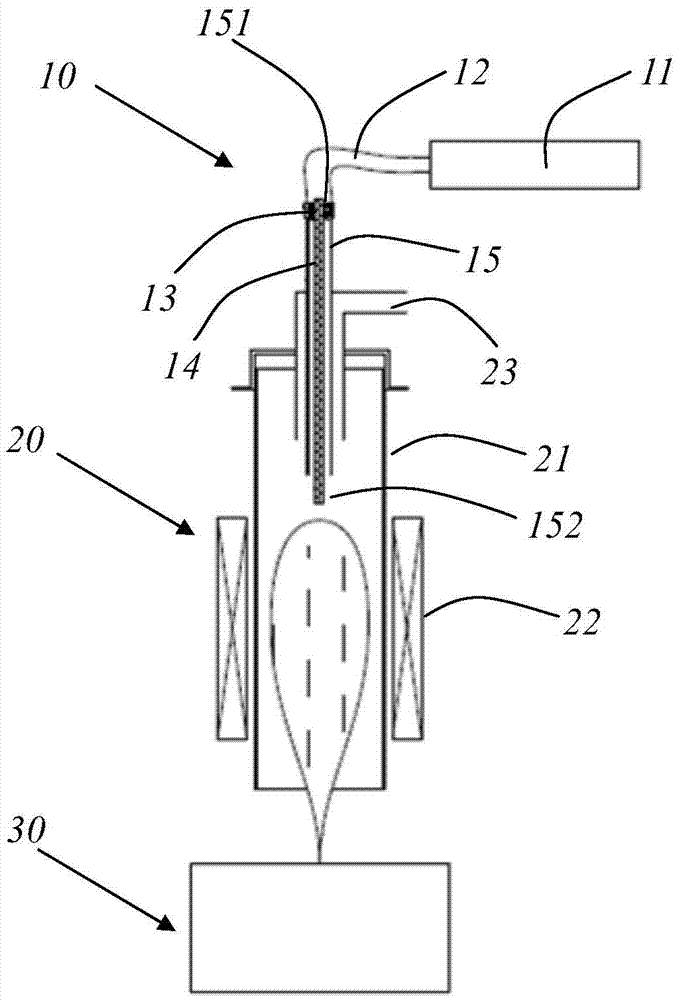

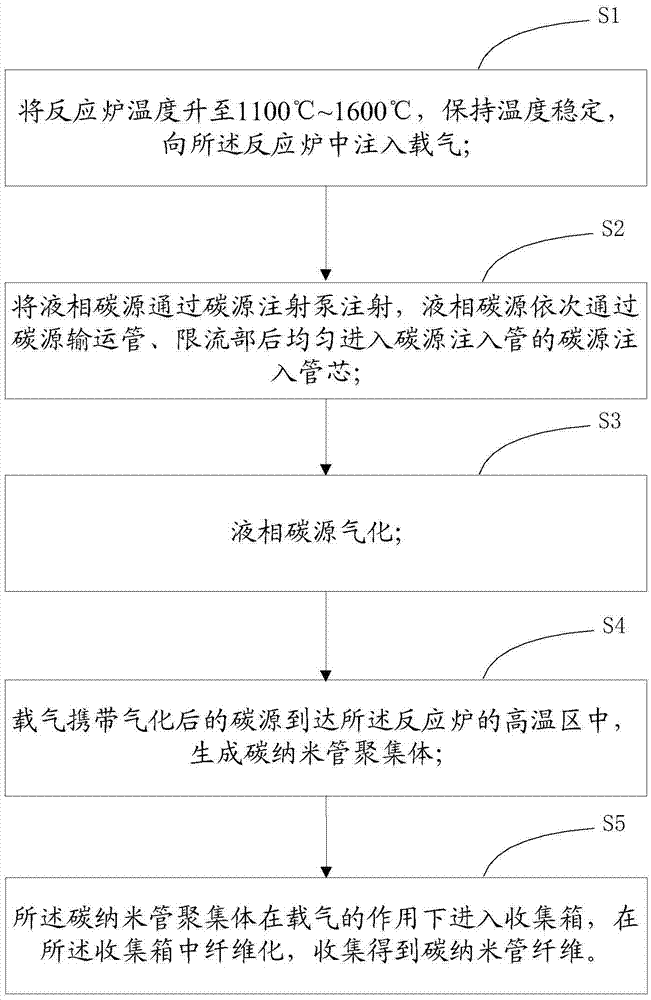

[0037] to combine figure 1 and figure 2 , to introduce a specific embodiment of the method for preparing carbon nanotube fibers of the present invention. In this embodiment, the method specifically includes:

[0038] S1. Raise the temperature of the reaction furnace to 1100° C. to 1600° C., keep the temperature stable, and inject carrier gas into the reaction furnace. In this embodiment, the preparation of carbon nanotube aggregates is carried out in a tubular furnace 20 by using the floating catalytic chemical vapor deposition method, the carrier gas is a mixed gas of hydrogen and nitrogen or hydrogen and an inert gas, and the volume percentage of hydrogen is 10~ 100%, the inert gas is argon or helium, and the flow rate of the carrier gas is 2~10L / min.

[0039] S2. Inject the liquid-phase carbon source through the carbon source injection pump, and the liquid-phase carbon source passes through the carbon source transport pipe, the flow limiting part, and then evenly enters...

Embodiment 1

[0046] Use the mixture of ethanol, ferrocene and thiophene as the liquid-phase carbon source, heat the reaction furnace to 1100°C, and inject it through the carbon source injection pump. The carbon source that enters the carbon source injection tube is injected into the tube core, the mixed gas of hydrogen and argon is used as the carrier gas, the flow rate of the carrier gas is 2L / min, and the continuous collection time is 1 hour. The carbon nanotube fibers are continuously collected by the roller shaft, and finally Continuous 100m carbon nanotube fiber material can be obtained.

Embodiment 2

[0048] Use ethanol, ferrocene, and thiophene mixture as the liquid-phase carbon source, heat the reaction furnace to 1300°C, and inject it through the carbon source injection pump. The carbon source that enters the carbon source injection tube is injected into the tube core, the mixed gas of hydrogen and argon is used as the carrier gas, the flow rate of the carrier gas is 6L / min, and the continuous collection time is 5 hours. The carbon nanotube fibers are continuously collected by the roller shaft, and finally Continuous 800m carbon nanotube fiber material can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com