Formula for recycling silicon-manganese alloy slag during silicon-manganese alloy production

A technology for silicon-manganese alloy slag and silicon-manganese alloy, which is applied in the field of formula for the reuse of silicon-manganese alloy slag in the production of silicon-manganese alloy, can solve the problem of improving unfavorable indicators, increasing the amount of slag or slag ratio, and increasing unit power consumption, etc. problem, to achieve the effect of improving smelting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

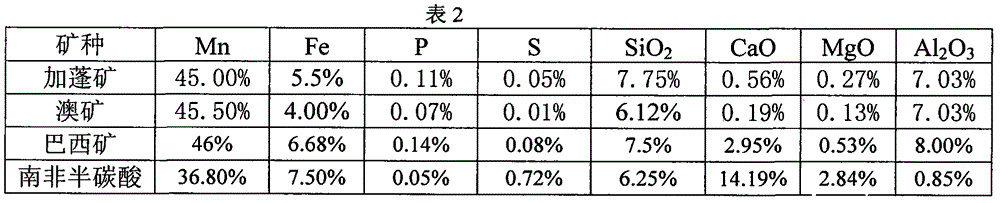

[0013] The invention is described in further detail below in conjunction with the accompanying drawings: as shown in Table 1, the present invention provides a formula for reusing silicon-manganese alloy slag in the production of silicon-manganese alloys, including manganese-rich ore and auxiliary materials, said auxiliary materials Dolomite and silica are included, and silicomanganese slag ingredients are used to replace the dolomite and added to the manganese-rich ore.

[0014] Please refer to Table 1:

[0015] mn SiO 2 P CaO MgO Al 2 o 3 R 9.0% 38.0% 0.04% 22.0% 6.0% 17.0% 0.68

[0016] Table 1 shows from the chemical composition of silicomanganese slag, the use of silicomanganese slag ingredients can replace or reduce the addition of dolomite, silica and other auxiliary materials, thereby increasing the manganese into the furnace of the whole ore, and more importantly, the use of silicomanganese slag containing Al 2 o 3 High character...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com