Deoxidation control method for high-end bearing steel inclusions

A control method and technology of bearing steel, applied in the field of iron and steel smelting, to achieve the effects of not being easy to collide and grow, improving the stability of use, and stabilizing casting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

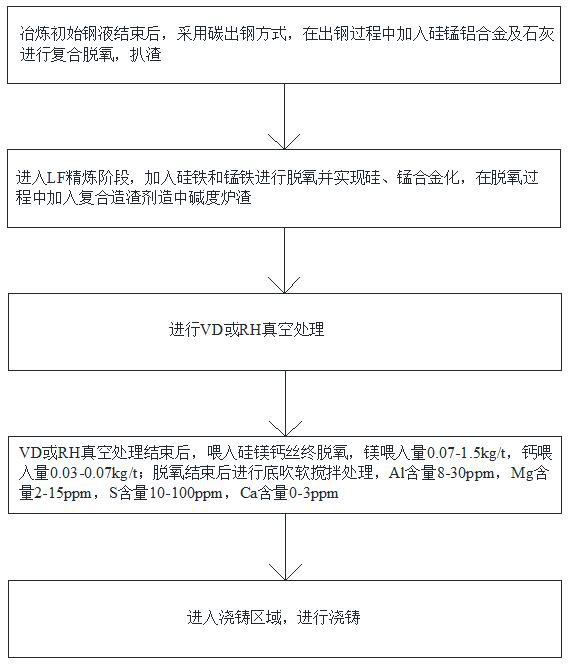

Method used

Image

Examples

Embodiment 1

[0049] Example 1: This method is implemented in a 150-ton electric furnace equipped with LF and VD processes, and the smelted steel is high-carbon bearing steel with a carbon content of about 1%. The specific implementation process is as follows:

[0050] Step 1: After 150 tons of electric furnace smelting, the carbon content of the steel is controlled at 0.5%, and 150 tons of steel is started to be tapped. After the steel is tapped, ferrochrome or carburizer can be added. When the steel is tapped to one-third to half Silicon-manganese-aluminum composite deoxidation is carried out at all times, specifically adding 400kg of aluminum-iron with an aluminum content of 60%, 450kg of silicon-containing 75% of silicon, 380kg of manganese-containing ferromanganese, and adding 750kg of lime at the same time. After the steel tapping is completed, the ladle is transported to the slag removal station for automatic slag removal.

[0051] Step 2: When the ladle arrives at the LF refining s...

Embodiment 2

[0056] Example 2: This method is implemented in a 120-ton electric furnace equipped with LF and RH processes, and the smelted steel is high-carbon bearing steel with a carbon content of about 1%. The specific implementation process is as follows:

[0057] Step 1: After the 120-ton electric furnace is smelted, the carbon content of the steel is controlled at 0.15%, and 119 tons of steel are started to be tapped. After the steel is tapped, ferrochrome or recarburizer can be added. When the steel is tapped to one-third to half Silicon-manganese-aluminum compound deoxidation is carried out at all times, specifically adding 330kg of aluminum-iron with an aluminum content of 60%, 360kg of silicon-containing 75% of silicon, 325kg of manganese-containing ferromanganese, and adding 600kg of lime at the same time. After the steel tapping is completed, the ladle is transported to the slag removal station for automatic slag removal.

[0058] Step 2: When the ladle arrives at the LF refin...

Embodiment 3

[0063] Example 3: This method is implemented in a 150-ton electric furnace equipped with LF and VD processes, and the smelted steel is medium-carbon bearing steel with a carbon content of about 0.55%. The specific implementation process is as follows:

[0064] Step 1: After the 150-ton electric furnace is smelted, the carbon content of the steel is controlled at 0.2%, and 148 tons of steel are started to be tapped. After the steel is tapped, ferrochrome or recarburizer can be added. When the steel is tapped to one-third to half Silicon-manganese-aluminum compound deoxidation is carried out at all times, specifically adding 410kg of aluminum-iron with an aluminum content of 60%, 400kg of silicon-containing 75% of silicon, 400kg of manganese-containing 80% of ferromanganese, and adding 800kg of lime at the same time. After the steel tapping is completed, the ladle is transported to the slag removal station for automatic slag removal.

[0065] Step 2: When the ladle arrives at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com