Refining process for obtaining solid Al2O3 inclusions

A kind of inclusion and solid-state technology, which is applied in the manufacture of converters, etc., can solve the problems of excessive Ds inclusions and Ca in easy-to-reduce slag, and achieve the effect of ensuring purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Converter blowing is completed, tapping temperature is 1635°C, tapping S: 0.012%, and 605kg of silicomanganese, 180kg of ferrosilicon, 562kg of ferromanganese, 320kg of recarburizer, 500kg of lime and 250kg of fluorspar are added sequentially from tapping 30s, and tapping The time is 5 minutes, and samples are taken after tapping.

[0025] Adjust the argon flow rate to 60L / min before refining and heating up, and measure the temperature at 1535°C. During the heating process, add 100kg of lime to make slag, and add 120kg of calcium carbide to deoxidize the slag surface. When the molten steel temperature is 1602°C, stop heating and feed it at one time 300m aluminum wire, after feeding the Al wire, the molten steel is transferred to RH for vacuum treatment, and the composition of the slag after refining is shown in Table 1 (unit / %).

[0026] Table 1

[0027]

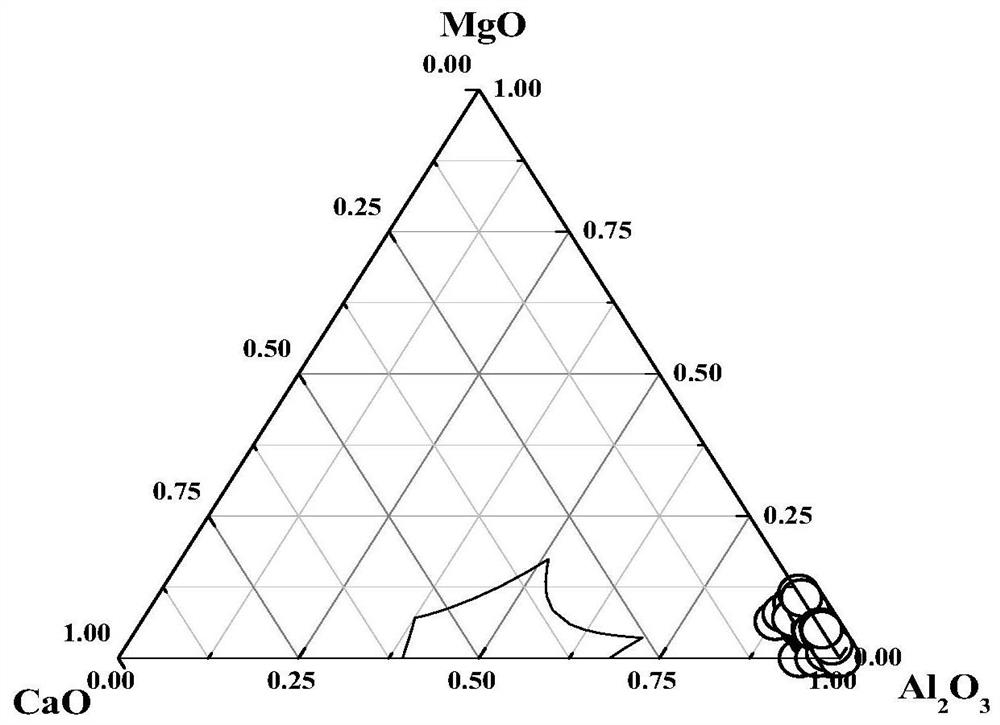

[0028] Al inclusions before RH treatment 2 o 3 ,Such as figure 1 shown.

[0029] RH boost gas flow 70m 3 / ...

Embodiment 2

[0035] Converter blowing is over, tapping temperature is 1628°C, tapping S: 0.015%, and 760kg silicomanganese, 270kg ferrosilicon, 100kg recarburizer, 500kg lime and 200kg fluorspar are added sequentially from tapping 30s, tapping time is 4.5min, Samples were taken after tapping.

[0036] Adjust the argon flow rate to 50L / min before refining and heating up, and measure the temperature at 1548°C. During the heating process, add 50kg of lime to make slag, and add 80kg of calcium carbide to deoxidize the slag surface. When the molten steel temperature is 1618°C, stop heating and feed it at one time 180m aluminum wire, after feeding the Al wire, the molten steel is transferred to RH for vacuum treatment, and the composition of the slag after refining is shown in Table 2 (unit / %).

[0037] Table 2

[0038]

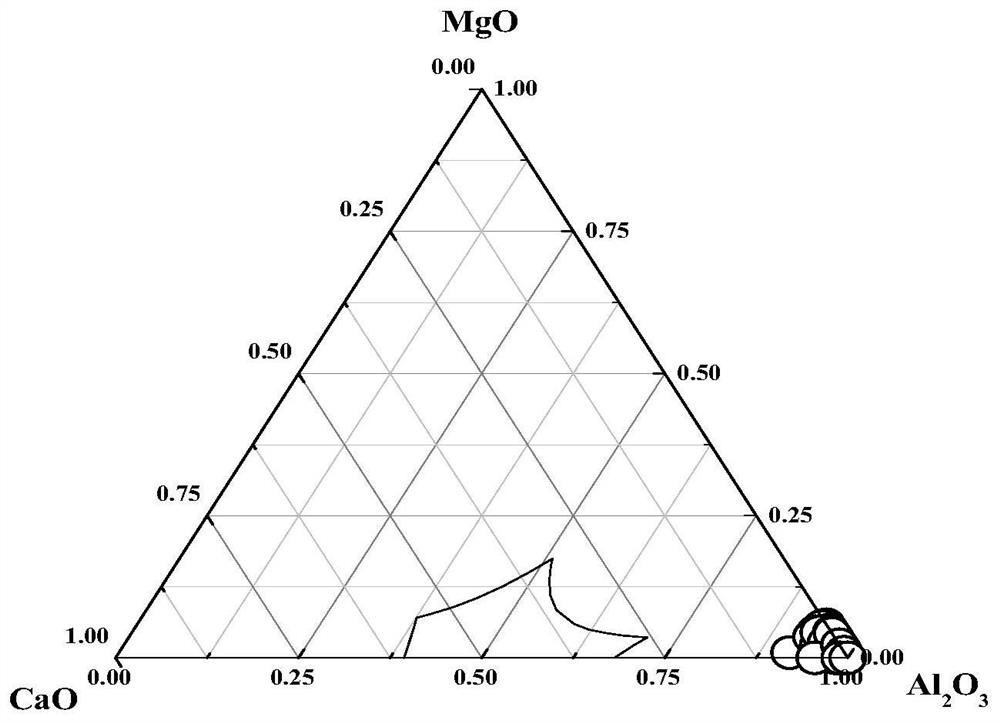

[0039] Al inclusions before RH treatment 2 o 3 ,Such as figure 2 shown.

[0040] RH lift gas flow 80m 3 / h, vacuum treatment for 20min, feeding 40m calcium wire for t...

Embodiment 3

[0046] Converter blowing is over, tapping temperature is 1645°C, tapping S: 0.009%, 1320kg silicomanganese, 1610kg ferromanganese, 80kg recarburizer, 500kg lime and 150kg fluorite are added sequentially from tapping 30s, tapping time is 4min, tapping Samples were taken after the steel was finished.

[0047] Adjust the argon flow rate to 55L / min before refining and heating up, and measure the temperature at 1525°C. During the heating process, add 100kg of lime to make slag, and add 120kg of calcium carbide to deoxidize the slag surface. When the molten steel temperature is 1606°C, stop heating and feed it at one time 300m aluminum wire, after feeding the Al wire, the molten steel is transferred to RH for vacuum treatment, and the composition of the slag after refining is shown in Table 3 (unit / %).

[0048] table 3

[0049]

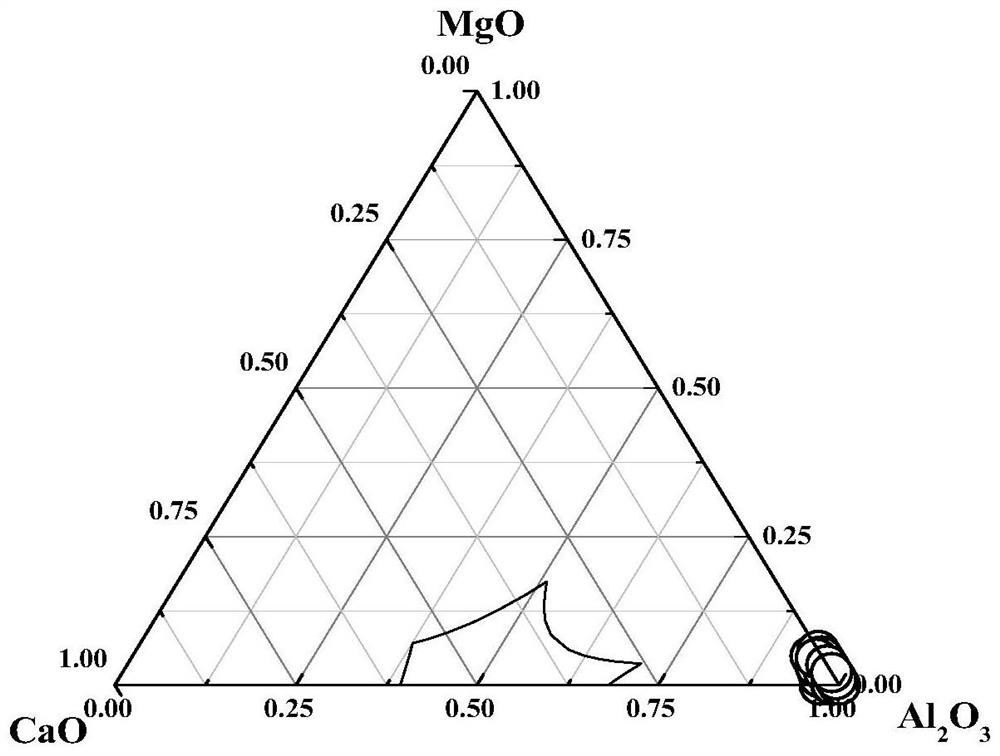

[0050] Al inclusions before RH treatment 2 o 3 ,Such as image 3 shown.

[0051] RH lift gas flow 90m 3 / h, vacuum treatment for 25min, feeding 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com