Method for smelting high-manganese stainless steel through CO2 decarburization in AOD furnace

A stainless steel and high manganese technology, applied in the field of iron and steel metallurgy, can solve the problems of steelmaking production temperature control with great influence, large addition amount and easy oxidation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

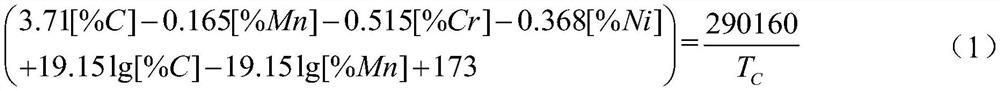

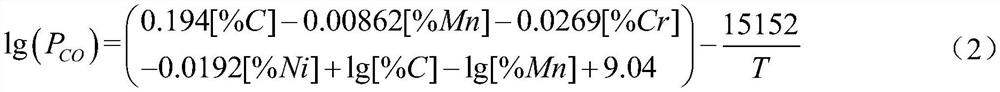

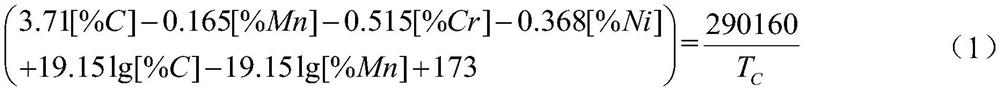

Method used

Image

Examples

example 1

[0036]The 80-ton AOD furnace was exchanged for 60 tons of iron water, the iron water temperature was 1345 ° C, the ferrous carbon content was 3.2%, the manganese content was 0.96%, and the chromium content was 3.8%.

[0037]The increase of lime is added 3 tons of lime, and the top gun is used to heat an oxygen-lifting silica deprophydric, top gun 4200nm3 / h, side gun 4500nm3 / h, blow oxygen 15 minutes;

[0038]Add 16.4 tons of high carbon chrome, using a top gun while blowing an oxygen-lifting die release, top gun 4200nm3 / h, side gun 4500nm3 / h, blow oxygen 5 minutes;

[0039]The top gun continues to blow an oxygen, the flow is 4200 nm3 / h, side gun change to CO2+ O2Blend, flow rate is 4500 nm3 / H, where carbon dioxide flow is 30% of the total air blowing amount of the side gun, blowing for 10 minutes;

[0040]Stop blowing, slag treatment, the slag rate is 80%, and the steel temperature is 1545 ° C, the carbon content is 2.2%, the manganese content is 0.46%, and the chromium content is 13.5%.

[...

example 2

[0047]The 80-ton AOD furnace was 56 tons of iron water, the iron water temperature was 1323 ° C, the ferrous carbon content was 3.2%, the manganese content was 1.0%, and the chromium content was 3.8%.

[0048]The increase in silica decarburization process is added to 2.0 tons, and the top gun is used to blow an oxygen-lifting and debride, and the top gun is 4200 nm.3 / h, side gun 4500nm3 / h, blow oxygen 15 minutes;

[0049]Add 25 tons of high-carbon chrome, using top guns, while blowing oxygen-lifting and removing silica, top gun 4200 nm3 / h, side gun 4500nm3 / h, blow oxygen 10 minutes;

[0050]The top gun continues to blow an oxygen, the flow is 4200 nm3 / h, side gun change to CO2+ O2Blend, flow rate is 4500 nm3 / H, where carbon dioxide flow is 20% of the total air blowing amount of the side gun, blown for 15 minutes;

[0051]Stop blowing, slag treatment, 渣 渣 rate of 80%, at this time, the water temperature is 1538 ° C, the carbon content is 3.8%, and the manganese content is 0.46%, and the ch...

example 3

[0058]The 80-ton AOD furnace was redded with 60 tons of iron water, the iron water temperature was 1340 ° C, the ferrous carbon content was 3.3%, the manganese content was 0.95%, and the chromium content was 3.8%.

[0059]The increase in the silica decarburization process is added to 3.0 tons, and the top gun is used to blow an oxygen and increased silica decarburization, top gun 4200nm3 / h, side gun 4500nm3 / h, blow oxygen 14 minutes;

[0060]Add 16.4 tons of high carbon chrome, using a top gun while blowing an oxygen-lifting die release, top gun 4200nm3 / h, side gun 4500nm3 / h, blow oxygen 5 minutes;

[0061]The top gun continues to blow an oxygen, the flow is 4200 nm3 / h, side gun change to CO2+ O2Blend, flow rate is 4500 nm3 / H, where carbon dioxide flow is 30% of the total air blowing amount of the side gun, blowing for 10 minutes;

[0062]Stopping, slag treatment, 渣 渣 rate of 80%, at this time, the water temperature is 1580 ° C, the carbon content is 2.3%, the manganese content is 0.38%, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com