Recycling method for producing silicomanganese alloy and medium and low carbon ferromanganese

A technology of silicon-manganese alloy and low-carbon ferromanganese, which is applied in the field of mutual recycling of solid waste and waste water, can solve the problems of comprehensive utilization of solid waste that have not been discussed, and achieve environmental protection, resource and energy saving, and improvement of enterprise economy benefit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

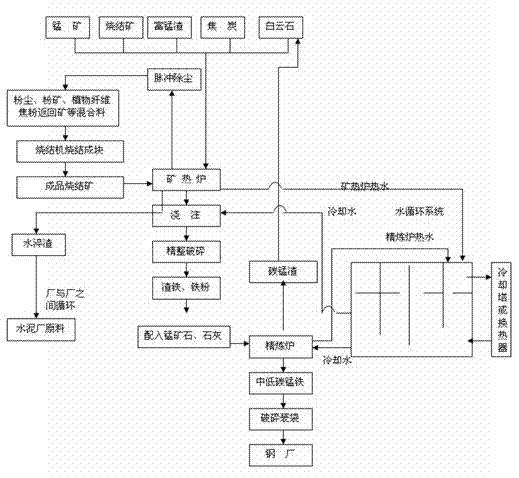

Image

Examples

Embodiment 1

[0025] One of the recycling methods for the production of silicon-manganese alloy and medium-low carbon ferromanganese of the present invention: sintering and utilization of silicon-manganese alloy dust, and its ingredients are:

[0026] Silicon-manganese alloy dust 15% to 20%;

[0027] Manganese powder ore 40%;

[0028] 20% of sintered ore powder;

[0029] Coke powder 8~10%;

[0031] Dolomite balance.

[0032] The above mixed sintering raw materials are placed in a box-type sintering machine and sintered at about 1250 ° C for 45 minutes, then condensed into blocks, crushed and screened, and returned to the furnace for smelting as finished raw materials.

[0033] The second recycling method of the present invention: part of the iron slag and iron powder produced by finishing and crushing of silicon-manganese alloy products has low use value, and being idle as an energy carrier is a large waste of energy. By analyzing the content of each element a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com