Method for collecting and recycling platinum group metal in waste catalyst by pyrogenic process

A technology for platinum group metals and spent catalysts, which is applied in the field of pyrotechnic capture and recovery of platinum group metals in spent catalysts, can solve the problems of heavy metal pollution, large consumption of reagents, high energy consumption, etc., achieve high recovery rate, reduce energy consumption and production Cost, the effect of lowering the melting temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

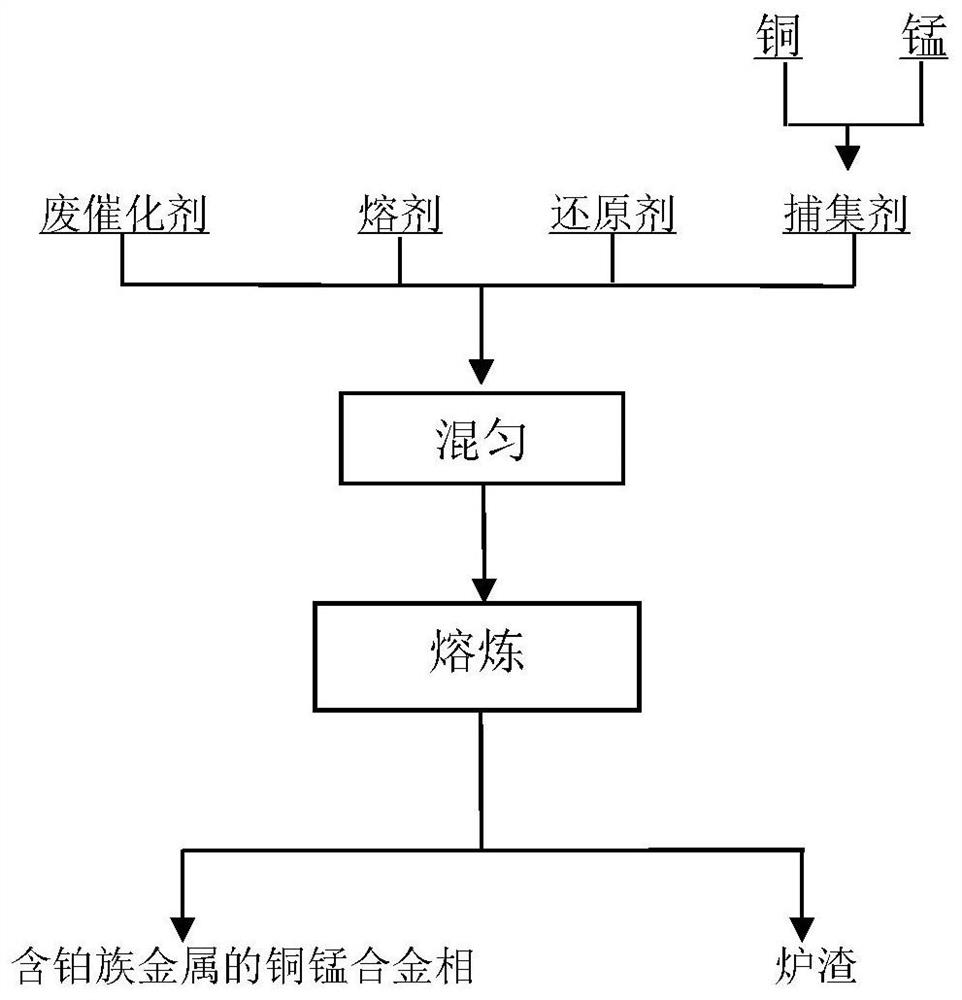

[0027] A method for capturing and recovering platinum group metals in spent catalysts by fire method, comprising the following steps:

[0028] (1) Copper powder and manganese powder are prepared as a collector according to 1:0.2, and 100 parts of waste catalysts containing platinum group metals are added to control the slag composition (alkalinity is 1.0, 10% B 2 o 3 , 10%CaF 2 ), 10 parts of collector, 10 parts of graphite powder are mixed in proportion;

[0029] (2) Melt the mixed material in a melting furnace at a melting temperature of 1300°C. After a full reaction, observe that the slag floats on the surface of the alloy phase, and separate the slag phase from the alloy to obtain a copper-based alloy containing platinum group metals;

[0030] (3) Acid hydrolysis, separation and purification are performed on the obtained copper-manganese alloy phase containing platinum group metals to obtain platinum group metals, and the recovery rate of platinum group metals is greater...

Embodiment 2

[0032] A method for capturing and recovering platinum group metals in spent catalysts by fire method, comprising the following steps:

[0033] (1) Copper powder and manganese carbonate are prepared as a collector according to 1:1, and 100 parts of waste catalysts containing platinum group metals are added to control slag composition (alkalinity is 1.0, 30% B 2 o 3 ), 30 parts of collector, 10 parts of graphite powder are mixed in proportion;

[0034] (2) Melting the mixed material in a smelting furnace at a melting temperature of 1100° C. After sufficient reaction, observe that the slag floats on the surface of the alloy phase, and separate the slag phase from the alloy to obtain a copper-based alloy containing platinum group metals;

[0035] (3) Acid hydrolysis, separation and purification are performed on the obtained copper-manganese alloy phase containing platinum group metals to obtain platinum group metals, and the recovery rate of platinum group metals is greater than ...

Embodiment 3

[0037] A method for capturing and recovering platinum group metals in spent catalysts by fire method, comprising the following steps:

[0038] (1) Copper powder and manganese powder are prepared as a collector according to 1:0.6, and 100 parts of waste catalysts containing platinum group metals are added to control the slag composition (alkalinity is 0.9, 10% B 2 o 3 , 20%CaF 2 ), 15 parts of collector, 10 parts of graphite powder are mixed in proportion;

[0039] (2) Melting the mixed material in a smelting furnace at a melting temperature of 1200° C. After sufficient reaction, observe that the slag floats on the surface of the alloy phase, and separate the slag phase from the alloy to obtain a copper-based alloy containing platinum group metals;

[0040] (3) Acid hydrolysis, separation and purification are performed on the obtained copper-manganese alloy phase containing platinum group metals to obtain platinum group metals, and the recovery rate of platinum group metals i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com