Smelting process for production of grade II hot-rolled reinforced bar

A threaded steel bar and process technology, applied in the direction of manufacturing converters, etc., can solve the problems of enterprise cost impact, steel bar surface corrosion, high cost price, etc., to achieve the effect of reducing production costs, reducing smelting costs, and reducing waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

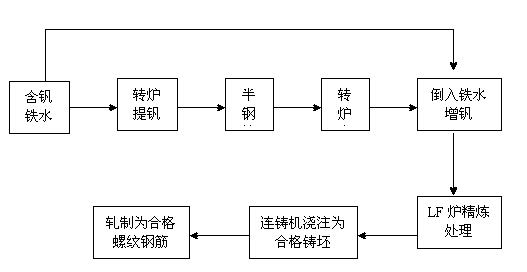

Method used

Image

Examples

Embodiment 1

[0024] This furnace smelts ∮6mm HR335 steel bar, mixes semi-steel and steel scrap into the converter, supplies oxygen and makes slag, the converter end point C: 0.04%, P: 0.025%, S: 0.030%, end point residual V: 0.002%, and then Tapping is carried out. During the tapping process, the silicon-manganese alloy is evenly added, and the amount of addition is controlled to make the steel grade manganese [Mn] = 0.9%, silicon [Si] = 0.2%, no recarburizer is added, and the deoxidizer is added normally. At the same time, argon is blown to the molten steel during the tapping process, and the gas supply intensity is 4L / min·t steel; after tapping, vanadium-containing molten iron is added according to the end point of the converter (the components of the vanadium-containing molten iron used are: C: 4.00%, V: 0.260% , P≤0.120%, S≤0.080%, the rest is Fe and other elements, the temperature is 1250℃), the amount of molten iron added is calculated according to the vanadium-increased amount of 0....

Embodiment 2

[0026] This furnace smelts ∮16mm HR335 steel bar, puts semi-steel and steel scrap into the converter, supplies oxygen and makes slag, the converter end point C: 0.08%, P: 0.020%, S: 0.033%, end point residual V: 0.005%, and then Tapping is carried out. During the tapping process, the silicon-manganese alloy is evenly added, and the amount of addition is controlled to make the steel grade manganese [Mn] = 1.05%, silicon [Si] = 0.3%, no recarburizer is added, and the deoxidizer is added normally. At the same time, argon is blown to the molten steel during the tapping process, and the gas supply intensity is 2L / min·t steel; after tapping, vanadium-containing molten iron is added according to the end point of the converter (the components of the vanadium-containing molten iron used are: C: 4.10%, V: 0.350% , P≤0.120%, S≤0.080%, the rest is Fe and other elements, the temperature is 1260℃), the amount of molten iron added is calculated according to the vanadium-increased amount of 0...

Embodiment 3

[0028]This furnace smelts ∮28mm HR335 steel bars, mixes semi-steel and scrap steel into the converter, supplies oxygen and makes slag, the converter end point C: 0.10%, P: 0.021%, S: 0.040%, end point residual V: 0.010%, and then Tapping is carried out. During the tapping process, the silicon-manganese alloy is evenly added, and the amount of addition is controlled to make the steel grade manganese [Mn] = 1.20%, silicon [Si] = 0.4%, no carburant is added, and the deoxidizer is added normally. At the same time, argon is blown to the molten steel during the tapping process, and the gas supply intensity is 6L / min·t steel; after tapping, vanadium-containing molten iron is added according to the end point of the converter (the components of the vanadium-containing molten iron used are: C: 4.20%, V: 0.440% , P≤0.120%, S≤0.080%, the rest is Fe and other elements, the temperature is 1270℃), the amount of molten iron added is calculated according to the amount of vanadium added by 0.01...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com