Bar for large wind driven generator gear and manufacturing method of bar

A technology for wind turbines and gears, which is applied in the metallurgical field, can solve the problems of large environmental temperature changes, large shocks, and frequent load changes, and achieve the effects of high density, high purity, and good low-temperature impact performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

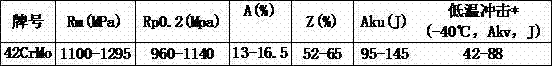

[0027] Examples 1-5 are the specific components of rods for large-scale wind turbine gears with specifications ranging from φ120mm to φ180mm as shown in Table 1 (weight percent):

[0028] Table 1

[0029] NumberingC Mn SiPSCr Mo AltHO Example 10.380.780.310.0080.0011.050.230.0350.000120.0008 Example 20.390.650.250.0100.0021.150.220.0220.000130.0009 Example 30.370.700.260.0060.0021.000.300.0270.000180.0014 Example 40.390.500.150.0100.0031.250.150.0310.000080.0005 Example 50.380.900.400.0100.0050.800.200.0330.000100.0007 Example 60.400.700.300.0060.0021.050.160.0270.000110.0006 Example 70.410.760.250.0100.0031.160.170.0310.000110.0007 Example 80.420.620.260.0110.0031.180.180.0330.000120.0009

[0030] The preparation method of the bars for large-scale wind turbine gears of Examples 1-5 includes the following steps: EAF smelting→LF refining→VD vacuum treatment→large-section continuous casting machine light reduction process continuous casting→cast slab slow cooling→casting B...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com