Method for producing manganese alloy

A production method and technology of manganese alloys, applied in the production of manganese alloys and high-purity manganese alloys, can solve the problems of environmental pollution and high energy consumption, and achieve the effects of protecting the environment, reducing energy consumption, and improving labor productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

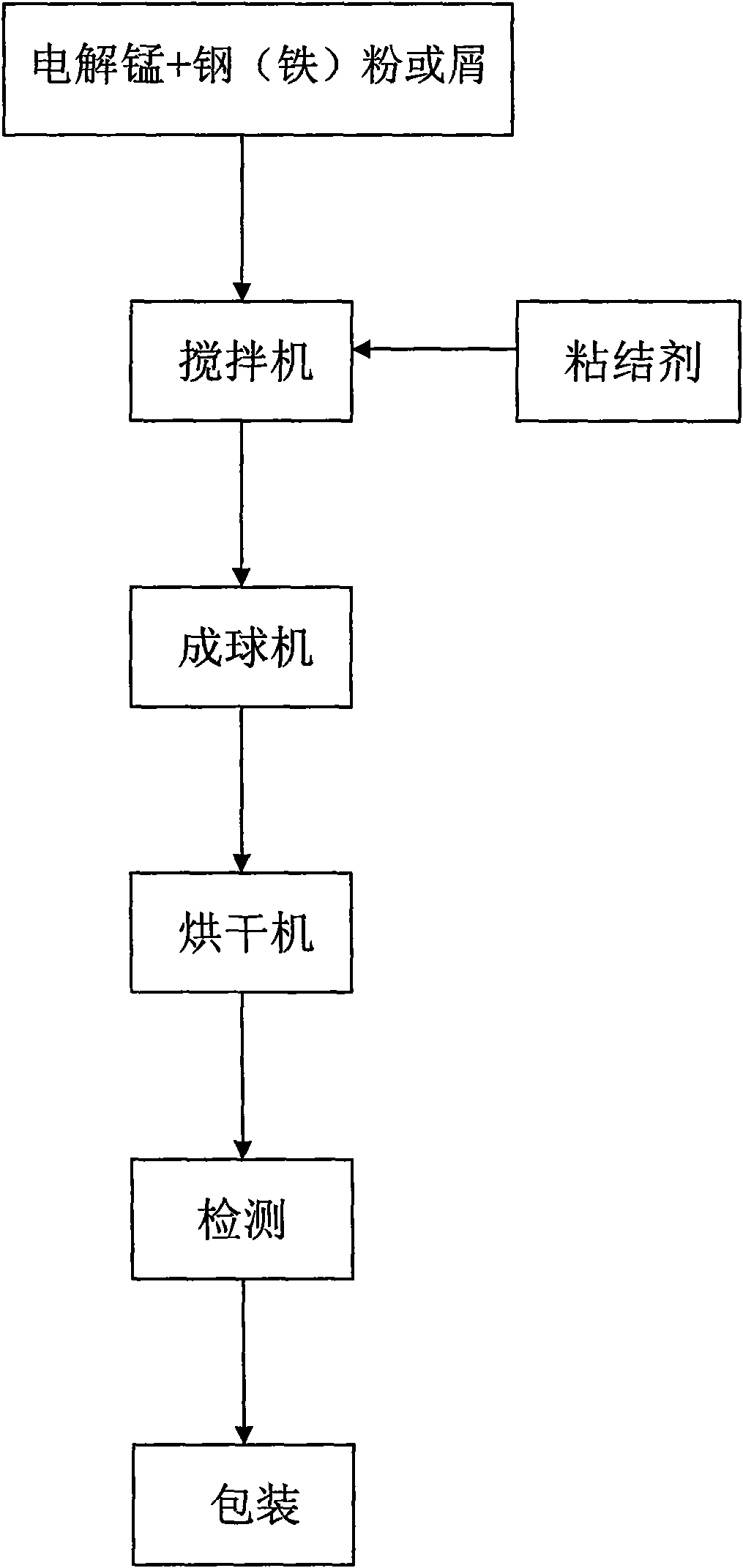

Method used

Image

Examples

Embodiment 1

[0023] Use electrolytic manganese 1000kg (Mn: 99.8%, C: 0.01%, S: 0.02%, P: 0.002%, Si: 0.008%), and 24kg alkaline sodium silicate solution (modulus 3.4, Baume degree 40) together Put into the JAC350A mixer and stir for 20 minutes. After the evenly stirred material goes through the belt conveyor to the hoist, it is evenly added to the GY520-150 high-pressure ball pressing machine (pre-pressing 15kw, main machine 55kw, main machine pressure and speed are adjusted according to the material into balls) , After pre-pressing, the pressed pellets are screened by the screen, and the qualified pellets are transported into the material box through the belt conveyor, and the underscreen material is re-entered into the briquette machine for pressing through the belt and the elevator. The material box containing the pellets is divided into two batches (each 500kg is a batch) into the hot air circulation oven, dried at 160°C for 20 minutes, and then taken out of the oven to obtain a residua...

Embodiment 2

[0026] Use electrolytic manganese 620kg (Mn: 99.8%, C: 0.01%, S: 0.02%, P: 0.002%, Si: 0.008%), scrap steel scrap 380kg (Mn: 0.58%, C: 0.03%, S: 0.004%, P : 0.01%, Si: 0.018%), mixed with 20kg alkaline sodium silicate solution (modulus 3.4, Baume degree 40), 10kg silica sol (SiO 2 Concentration 30%) put into JAC350A type mixer and stir for 20 minutes, put into the 20T ball forming machine designed by our company evenly through the conveying equipment, and dry once every 500kg batch of metal manganese pellets, drying temperature 105 ℃, time 3 After hours, the pellets were taken out to obtain pellets with a residual moisture content of 0.8% and a required strength. After the temperature dropped to room temperature, the composition of the manganese pellets was analyzed, and the qualified pellets were packaged and put into storage. The composition of this metal manganese ball is as follows:

[0027] Mn: 60.3%, C: 0.035%, S: 0.025%, P: 0.01%, Si: 0.015%, iron balance

Embodiment 3

[0029] Use electrolytic manganese 860kg (Mn: 99.8%, C: 0.01%, S: 0.02%, P: 0.002%, Si: 0.008%), scrap steel scrap 140kg (Mn: 0.37%, C: 0.05%, S: 0.008%, P: 0.01%, Si: 0.025%), add 25kg alkaline sodium silicate solution (modulus 3.4, Baume degree 40), 5kg aluminum hydroxide gel (aluminum hydroxide concentration 6%), polyvinyl alcohol 1kg Put them together into JAC350A mixer and stir for 20 minutes, then evenly put them into GY520-150 high-pressure briquette machine for pressing through the conveying equipment, and dry the pellets that pass the screening system every 500kg batch at 200°C for 15 minutes Finally, the pellets were taken out, the residual moisture was measured to be 0.5%, and the strength of the pellets reached the required strength. After the temperature dropped to room temperature, the composition of the manganese pellets was analyzed, and the qualified pellets were packed and put into storage. The composition of this metal manganese ball is as follows:

[0030] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com