Preparation method of shell-core carbon coating manganese nanocomposite particles and hell-core carbon coating manganese alloy oxide nanocomposite particles, and application thereof

A nano-composite particle, manganese oxide technology, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., can solve the problems of complex preparation methods, many by-products, and difficult to repeat, and achieve high cycle stability, prevent The effect of agglomeration, high power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

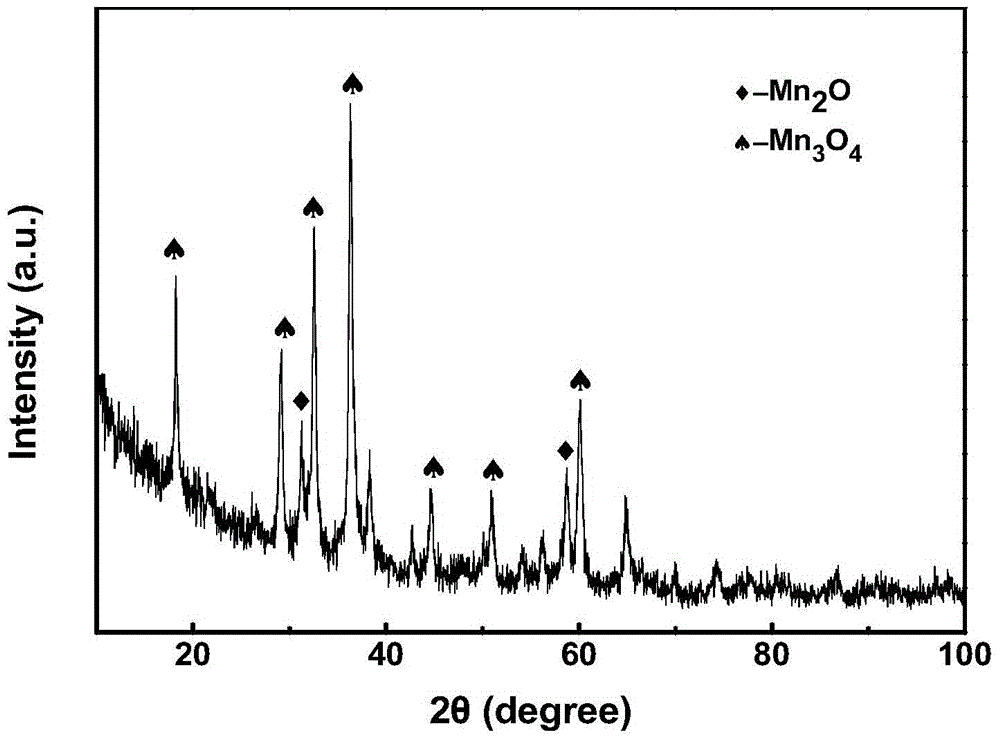

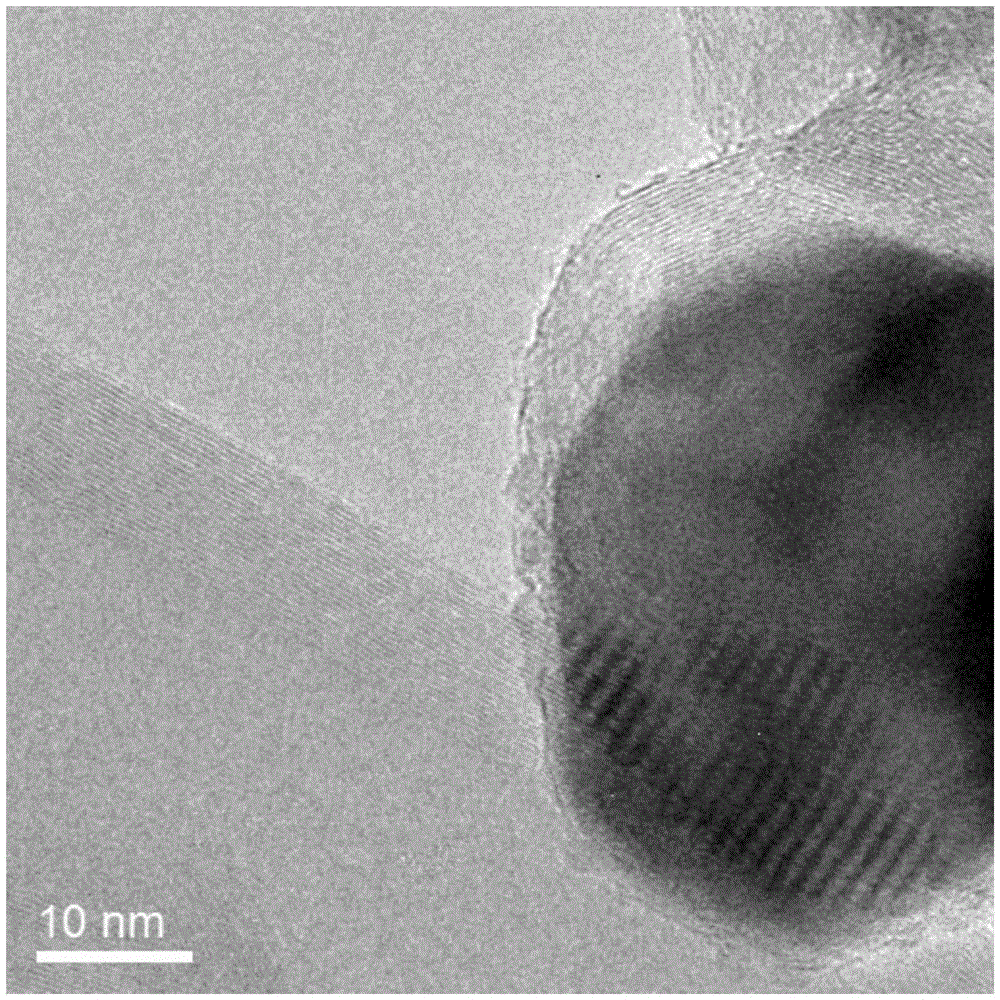

[0041] Take 50g of metal manganese powder and press it into a block, put it in the automatic control DC arc metal nano powder production equipment to evaporate, and at the same time feed methane and argon with a ratio of 1:2, and the total pressure is 3×10 4 Pa, to obtain a carbon-coated manganese nanocomposite particle precursor whose outer shell is carbon and manganese core; put the carbon-coated manganese nanocomposite particle precursor into a vacuum tube furnace to dry, then evacuate and feed oxygen, at 300 ° C Heat treatment for 4 hours, and cool to room temperature to obtain carbon-coated manganese oxide nanocomposite particles.

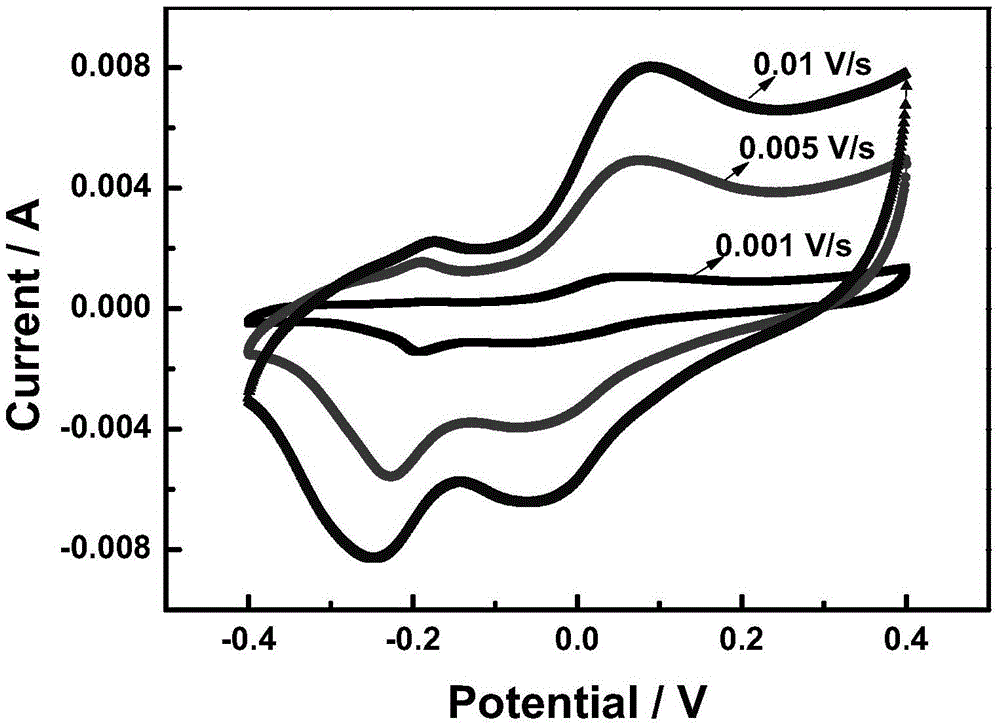

[0042] The above-mentioned carbon-coated manganese oxide nanocomposite particles are made into electrodes of a supercapacitor, dispersed in ethanol at a mass ratio of 95:5 as active material: polyvinylidene fluoride, baked into a semi-dry state in a drying box, coated with On the nickel foam, it is pressed under a pressure of 10MPa to make a s...

Embodiment 2

[0048] Take 100g of metal manganese powder and press it into a block, place it in the automatic control direct current arc metal nano powder production equipment to evaporate, and at the same time feed butene and argon with a ratio of 1:1, the total pressure is 9×10 4 Pa, to obtain a carbon-coated manganese nanocomposite particle precursor whose outer shell is carbon and manganese core; put the carbon-coated manganese nanocomposite particle precursor into a vacuum tube furnace to dry, then vacuumize and feed oxygen, at 400 ° C Heat treatment for 4 hours, and cool to room temperature to obtain carbon-coated manganese oxide nanocomposite particles.

[0049] The above-mentioned carbon-coated manganese oxide nanocomposite particles are made into electrodes of supercapacitors, dispersed in methyl acetate according to the mass ratio of active material: polyvinylidene fluoride of 90:10, and baked into a semi-dry state in an oven , coated on foam nickel, pressed under a pressure of 15...

Embodiment 3

[0051] Take 150g of metal manganese powder and press it into a block, place it in an automatic control direct current arc metal nano powder production equipment to evaporate, and at the same time feed propylene and argon with a ratio of 4:3, and the total pressure is 7×10 4 Pa, to obtain a carbon-coated manganese nanocomposite particle precursor whose outer shell is carbon and manganese core; put the carbon-coated manganese nanocomposite particle precursor into a vacuum tube furnace to dry, then vacuumize and feed oxygen, at 350 ° C Heat treatment for 4 hours, and cool to room temperature to obtain carbon-coated manganese oxide nanocomposite particles.

[0052] The above-mentioned carbon-coated manganese oxide nanocomposite particles are made into electrodes of supercapacitors, dispersed in ethyl acetate at a mass ratio of 88:12 by active material: polytetrafluoroethylene, and baked into a semi-dry state in an oven. , coated on nickel foam, pressed under a pressure of 5MPa to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com