Steel cylinder sleeve and preparation method thereof

A cylinder liner, steel technology, applied in the field of cylinder liner manufacturing, can solve the problems of poor anti-cavitation performance, scrapped engine, low strength, etc., and achieve the effect of good anti-cavitation performance, good anti-knock performance and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

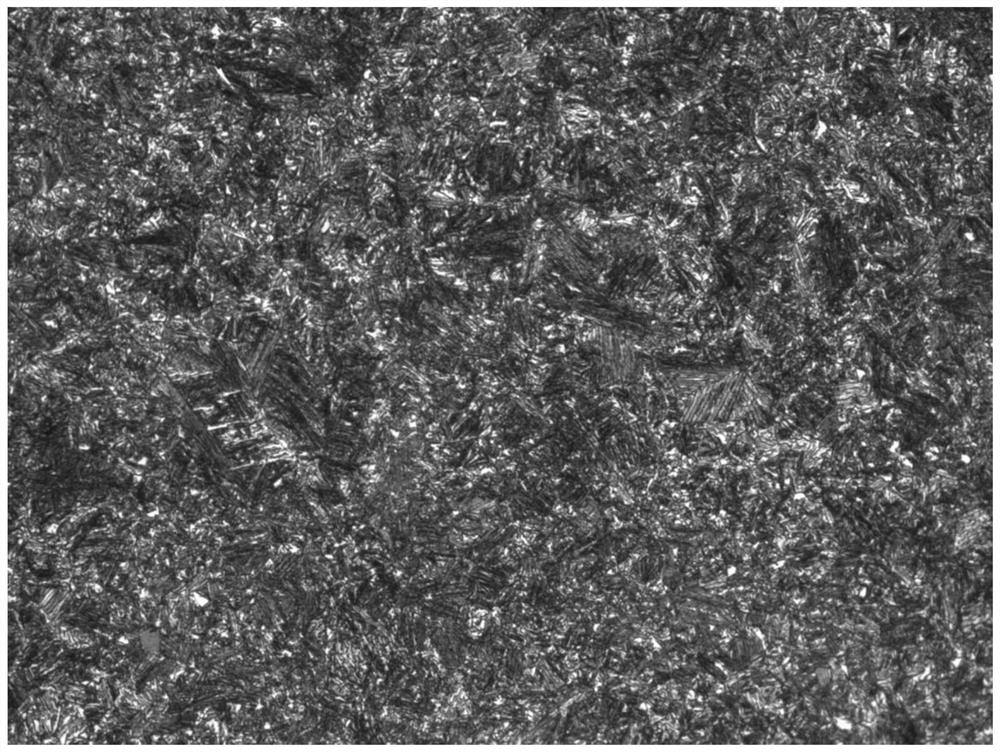

Image

Examples

preparation example Construction

[0020] In view of the problems of low strength of the cylinder liner, inability to withstand high explosion pressure and high power in the prior art, the present application designs a low-manganese alloy steel cylinder liner, and provides a preparation method thereof, so that the hardness of the steel cylinder liner, The elastic modulus and strength are high, which realizes the improvement of high explosion pressure and high power of the engine, and at the same time solves the anti-cavitation performance of the cylinder liner and improves the utilization rate of materials; due to the better toughness of the steel cylinder liner, it reduces the The occurrence of failures such as the collapse of the cylinder and the fall of the platform, and the cast steel cylinder liner is thinner than the cast iron material, which achieves the purpose of energy saving and environmental protection. Specifically, the embodiment of the present invention discloses a method for preparing a steel cyl...

Embodiment 1

[0035] Embodiment 1 A kind of high-strength, anti-cavitation cast steel cylinder liner is realized in the following manner:

[0036] 1) Smelting: use carbon steel scrap (scrap steel) to smelt at a temperature of 1600 ° C. After the melting is complete, add an appropriate amount of ferrosilicon and ferromanganese to make the content of each component as C: 0.15%, Si: 0.30%, Mn: 0.95%, P: 0.035%, S: 0.032%;

[0037]2) Deoxidation and slag removal: add deoxidizer and slag remover for deoxidation and slag removal, the temperature continues to rise to 1680°C, and the slag is removed and left to stand for 10 minutes;

[0038] 3) Casting: use a multi-station centrifugal casting machine for casting;

[0039] 4) Rough machining: rough machining of the cylinder liner blank, the unilateral allowance is about .5mm;

[0040] 5) Heat treatment: put the cylinder liner into the pit furnace, quickly heat up to 920 ° C for austenitization, and keep it for 1 hour, then open the furnace cover, ...

Embodiment 2

[0043] Embodiment 2 A high-strength, cavitation-resistant cast steel cylinder liner is obtained in the following manner:

[0044] 1) Smelting: use carbon steel scrap (scrap steel (carbon content less than 0.45%), smelt completely at 1600 ° C, then add ferrosilicon and ferromanganese to continue smelting, and finally obtain the mass percentage of each component: C: 0.18%, Si: 0.34%, Mn: 1.32%, P: 0.038%, S: 0.028;

[0045] 2) Deoxidation and slag removal: Add deoxidizer and slag remover to deoxidize and remove slag from molten iron, and continue to heat up to 1680°C and let stand for 15min;

[0046] 3) Casting: use a multi-station casting machine to cast and form;

[0047] 4) Rough machining: Rough machining the cylinder liner blank inside and outside, with a unilateral allowance of about 0.5mm;

[0048] 5) Heat treatment: put the cylinder liner into the pit furnace, quickly heat up to 920 ° C for austenitization, and keep it for 1 hour, then open the furnace cover and put it...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com