Smelting method of manganese alloy

A smelting method and manganese alloy technology, applied in the field of metallurgy, can solve problems such as increasing environmental pollution, consuming large fuel, reducing manganese grade, etc., achieving huge economic benefits, reducing pollution, and reducing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

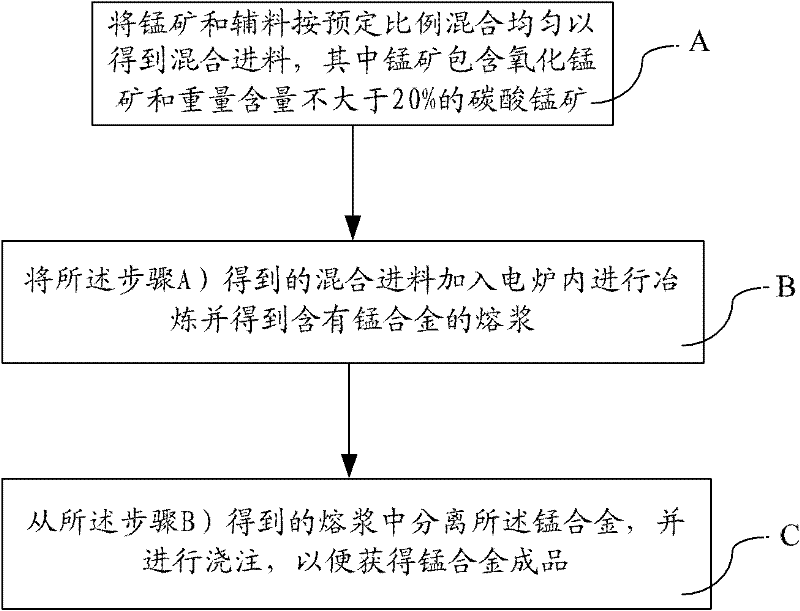

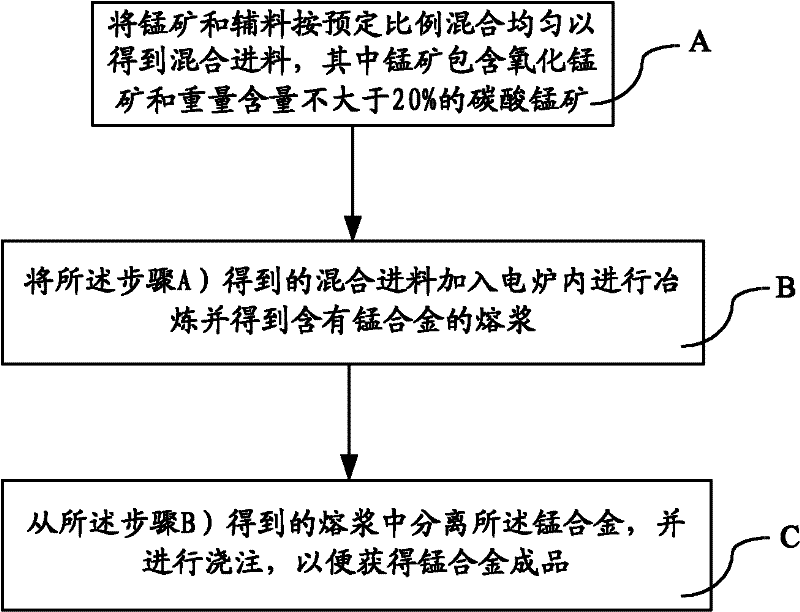

Method used

Image

Examples

Embodiment 1

[0040] Manganese ore with a particle size of 5 cm and coke with a particle size of 3 cm are uniformly mixed according to a weight ratio of 1:0.16 to obtain a mixed feed for smelting high-carbon ferromanganese. Wherein, the weight content of manganese carbonate in the manganese ore is 10%. The above-mentioned mixed feed is added to a three-phase resistance furnace for smelting. The primary current of the three-phase resistance furnace is 220A and the secondary voltage is 140V. Turn on the three-phase resistance furnace every four hours and pour the magma containing high-carbon ferromanganese in the three-phase resistance furnace into the ladle. Subsequently, the slag-iron separation (that is, the separation of high-carbon ferromanganese from the molten slurry) and pouring are carried out on the ladle containing high-carbon ferromanganese, and high-carbon ferromanganese finished products with qualified quality are obtained. In this embodiment, the grade of the manganese ore is ...

Embodiment 2

[0042] Manganese ore with a particle size of 15 cm and coke with a particle size of 5 cm are uniformly mixed according to a weight ratio of 1:0.22 to obtain a mixed feed for smelting high-carbon ferromanganese. Wherein, the weight content of manganese carbonate in the manganese ore is 15%. The above-mentioned mixed feed is added to a three-phase resistance furnace for smelting. The primary current of the three-phase resistance furnace is 300A and the secondary voltage is 160V. Turn on the three-phase resistance furnace every four hours and pour the magma containing high-carbon ferromanganese in the three-phase resistance furnace into the ladle. Then, the slag and iron are separated and poured into the ladle containing high-carbon ferromanganese, and high-carbon ferromanganese finished products with qualified quality are obtained. In this embodiment, the grade of the manganese ore is 31.40%, the recovery rate is 77.28%, and the production cost of high-carbon ferromanganese is ...

Embodiment 3

[0044] Manganese ore with a particle size of 10 cm and coke with a particle size of 4 cm are uniformly mixed according to a weight ratio of 1:0.19 to obtain a mixed feed for smelting high-carbon ferromanganese. Wherein, the weight content of manganese carbonate in the manganese ore is 20%. The above-mentioned mixed feed is added to a three-phase resistance furnace for smelting, the primary current of the three-phase resistance furnace is 260A, and the secondary voltage is 150V. Turn on the three-phase resistance furnace every four hours and pour the magma containing high-carbon ferromanganese in the three-phase resistance furnace into the ladle. Then, the slag and iron are separated and poured into the ladle containing high-carbon ferromanganese, and high-carbon ferromanganese finished products with qualified quality are obtained. In this embodiment, the grade of the manganese ore is 31.31%, the recovery rate is 77.31%, and the production cost of high-carbon ferromanganese is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com