Method for producing HRB 600 high-strength hot-rolled ribbed steel bars through vanadium-chromium microalloying

A hot-rolled ribbed steel bar and micro-alloying technology, applied in the field of metallurgy, can solve the problems of high price and large proportion of production cost, and achieve the effects of low cost, low inclusion level and high purity of molten steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following describes the present invention in detail with reference to the drawings and specific embodiments.

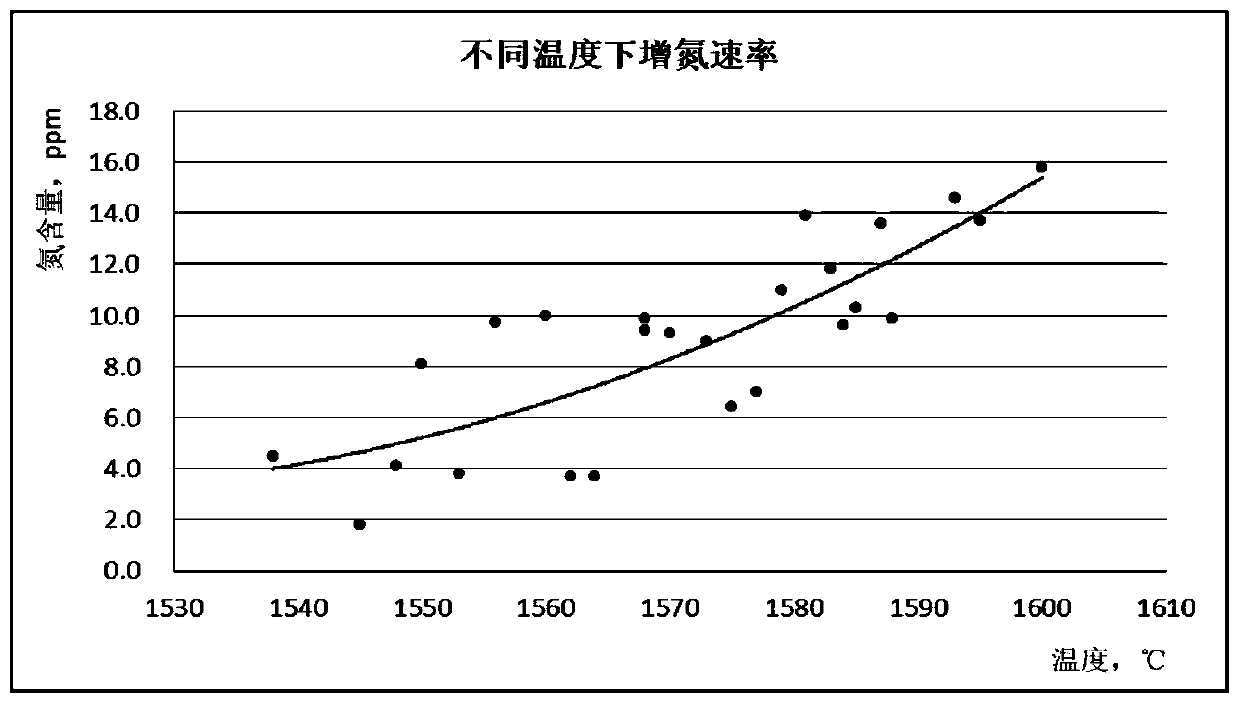

[0037] 1. Composition requirements

[0038] In order to make the yield strength of the produced HRB600 hot-rolled ribbed steel bars reach 630~680MPa, the tensile strength reach 760~890MPa, the elongation after fracture A reaches ≥15%, and the maximum elongation Agt reaches ≥10%. The indicators can all meet the requirements of GB / T1499.2-2018. The main measures we take are precipitation strengthening and fine-grain strengthening of Cr and V microalloying elements. In order to ensure the precipitation of precipitates, the content of V microalloys is adjusted to 0.140 % Or so, the nitrogen content in the steel must be within the range of 120ppm to 180ppm. The chemical composition of HRB600 hot-rolled ribbed steel bars and the specific requirements of the weight percentage of each component are shown in Table 1.

[0039] Table 1 The chemical composition of HRB600 hot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com