The preparation method of manganese-doped ceo2 nanopowder

A nano-powder, manganese-doped technology, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve problems such as nanoparticle agglomeration, and achieve the effect of low reaction temperature and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

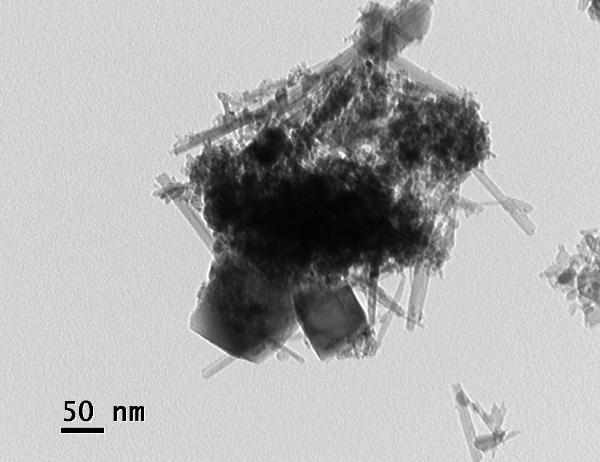

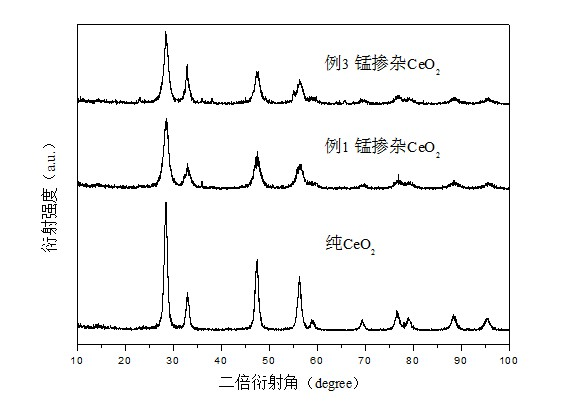

[0021] Use a 25 kg vacuum induction furnace to melt 64.4% metal cerium, 27.6% electrolytic manganese and 8% graphite (mass percentage), choose a graphite crucible, fully melt and cast to obtain a cerium-manganese carbide alloy. Break the cerium-manganese carbide alloy into powder with a particle size of less than 0.15mm, put 100ml of deionized water in a 200ml beaker, place it on a magnetic stirrer, adjust the temperature to stabilize it at 30°C, and take the cerium-manganese carbide alloy powder 5 g, it was slowly poured into deionized water, stirred and reacted for 18 hours to obtain a brown suspension. Pour off the upper layer, then add deionized water to stir and wash, repeat this several times, and dry in an oven at 80°C in the air to obtain brown composite cerium-manganese nanopowder. The specific surface area of the nanopowder is 142m 2 / g. Composite cerium-manganese nanopowder is heat-treated at 600℃ / 2h, and the main phase is CeO 2 nanopowder.

Embodiment 2

[0023] Use a 25 kg vacuum induction furnace to melt 78.2% of metal cerium, 13.8% of electrolytic manganese and 8% of graphite (mass percentage), choose graphite crucible, fully melt and cast to obtain cerium-manganese carbide alloy. Break the cerium-manganese carbide alloy into a powder with a particle size of less than 0.15mm, put 150ml of deionized water in a 200ml beaker, place it on a magnetic stirrer, adjust the temperature to stabilize it at 20°C, and take the cerium-manganese carbide alloy powder 5 g, it was slowly poured into deionized water, and stirred for 24 hours to obtain a brown suspension. Pour off the upper layer, then add deionized water to stir and wash, repeat this several times, and dry in an oven at 50°C in the air to obtain brown composite cerium-manganese nanopowder. The specific surface area of the nanopowder is 121m 2 / g. The composite cerium-manganese nanopowder is heat-treated at 800°C / 2h to obtain the main phase as CeO 2 nanopowder.

Embodiment 3

[0025] Use a 25 kg vacuum induction furnace to melt 45.5% metal cerium, 45.5% electrolytic manganese and 9% graphite, choose graphite crucible, fully melt and cast to obtain cerium manganese carbide alloy. Break the cerium-manganese carbide alloy into a powder with a particle size of less than 0.3mm, take 100ml of deionized water in a 200ml beaker, place it on a magnetic stirrer for stirring, adjust the temperature to stabilize it at 40°C, and take the cerium-manganese carbide alloy 5 g of powder was slowly poured into deionized water, and stirred for 30 hours to obtain a brown suspension. Pour off the upper layer, then add deionized water to stir and wash, repeat this several times, and dry in an oven at 60°C in the air to obtain brown composite cerium-manganese nanopowder. The specific surface area of the nanopowder is 118m 2 / g. The composite cerium-manganese nanopowder is heat-treated at 600°C / 2h to obtain the main phase as CeO 2 nanopowder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com