Copper, nickel and manganese alloy brazing filler metal powder and preparation method thereof

A technology for alloy brazing filler metal and alloy powder, which is applied in the field of copper-nickel-manganese alloy brazing filler metal powder and its preparation, can solve the problem that it is difficult to produce alloy brazing filler metal whose composition meets the requirements, the key process technologies and methods are very different, and the composition of alloy elements is very different. Control the deviation from the required value and other problems to achieve the effect of overcoming the instability of chemical composition, reducing the formation of intermediate brittle phases, and improving plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

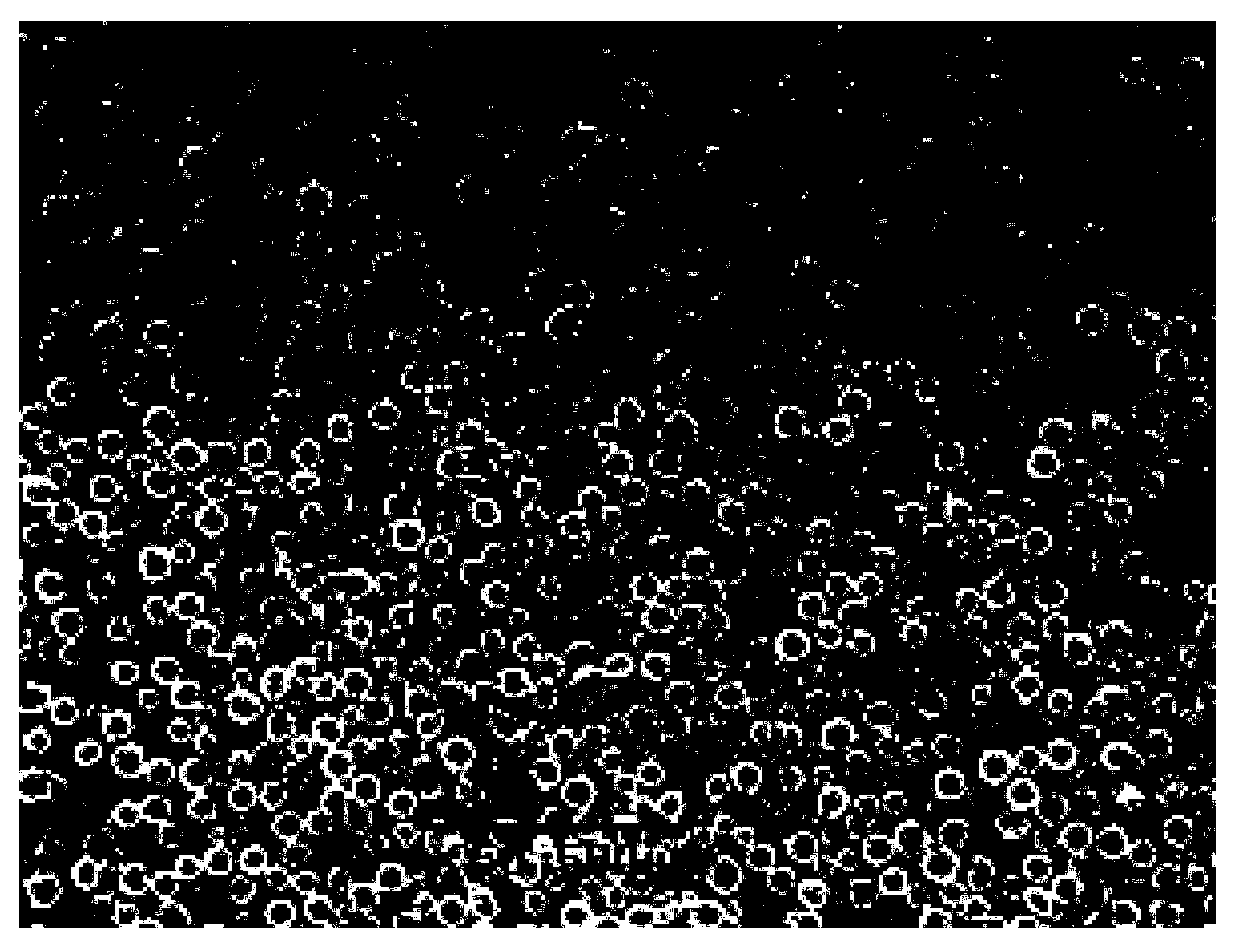

Image

Examples

Embodiment 1

[0026] The chemical composition of the copper-nickel-manganese alloy solder powder of the present embodiment is Cu-28Ni-27Mn-0.6Si-0.8Fe-0.1B-4.0Co-0.08P, which is composed of the following components in mass percentage: nickel 28%, Manganese 27%, cobalt 4.0%, silicon 0.6%, iron 0.8%, boron 0.1%, phosphorus 0.08%, and the balance is copper.

[0027] The preparation method of the copper-nickel-manganese alloy solder powder of the present embodiment may further comprise the steps:

[0028] Step 1. Tamping the magnesia crucible in the vacuum air atomization powder making equipment, and then heating and dehumidifying; the temperature of the heating and dehumidifying is 800° C., and the time is 12 hours;

[0029] Step 2, raw materials 33.79kg of Cu-CATH-2 electrolytic copper plate, 27.1kg of Ni9996 electrolytic nickel plate, 27kg of DJMnD electrolytic manganese, 4.0kg of Co998 electrolytic cobalt plate, 0.8kg of YT3 industrial pure iron, 0.6kg of Si-2 pure silicon and 1kg nickel-b...

Embodiment 2

[0035] The chemical composition of the copper-nickel-manganese alloy solder powder of the present embodiment is Cu-29Ni-28.5Mn-1.0Si-1.2Fe-0.2B-5.0Co-0.14P, and is made up of the composition of following mass percent: nickel 29% , manganese 28.5%, cobalt 5.0%, silicon 1.0%, iron 1.2%, boron 0.2%, phosphorus 0.14%, and the balance is copper.

[0036] The preparation method of the copper-nickel-manganese alloy solder powder of the present embodiment may further comprise the steps:

[0037] Step 1. Tamping the magnesia crucible in the vacuum air atomization powder making equipment, and then heating and dehumidifying; the temperature of the heating and dehumidifying is 850° C., and the time is 11 hours;

[0038] Step 2. The raw materials are 34.23kg of Cu-CATH-2 electrolytic copper plate, 27.6kg of Ni9996 electrolytic nickel plate, 28.5kg of DJMnD electrolytic manganese, 5.0kg of Co998 electrolytic cobalt plate, 1.2kg of YT3 industrial pure iron, 1.0kg Si-2 pure silicon and 1.66k...

Embodiment 3

[0043] The chemical composition of the copper-nickel-manganese alloy solder powder of the present embodiment is Cu-30Ni-30Mn-1.4Si-1.6Fe-0.3B-6.0Co-0.2P, which consists of the following components in mass percentage: 30% nickel, Manganese 30%, cobalt 6.0%, silicon 1.4%, iron 1.6%, boron 0.3%, phosphorus 0.2%, and the balance is copper.

[0044] The preparation method of the copper-nickel-manganese alloy solder powder of the present embodiment may further comprise the steps:

[0045] Step 1. Tamping the magnesia crucible in the vacuum air atomization powder making equipment, and then heating and dehumidifying; the temperature of the heating and dehumidifying is 900° C., and the time is 10 hours;

[0046] Step 2. The raw materials are 29kg of Cu-CATH-2 electrolytic copper plate, 26.55kg of Ni9996 electrolytic nickel plate, 30kg of DJMnD electrolytic manganese, 6.0kg of Co998 electrolytic cobalt plate, 1.6kg of YT3 industrial pure iron, and 1.4kg of Si -2 Pure silicon and 3.75kg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com