Method for smelting silicon manganese alloy through microwaves

A silicon-manganese alloy and microwave technology is applied in the field of microwave smelting silicon-manganese alloy, which can solve the problems of high volatilization rate and slag rate of manganese and silicon, poor control of furnace conditions, low silicon content in the furnace, etc. The effect of speeding up the restoration and increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

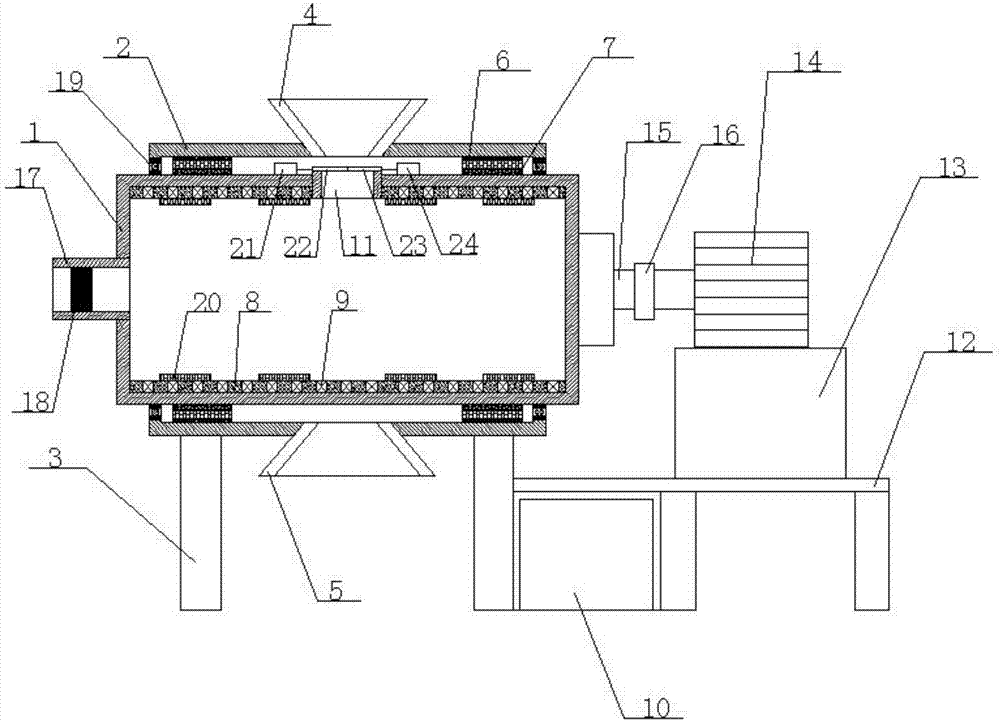

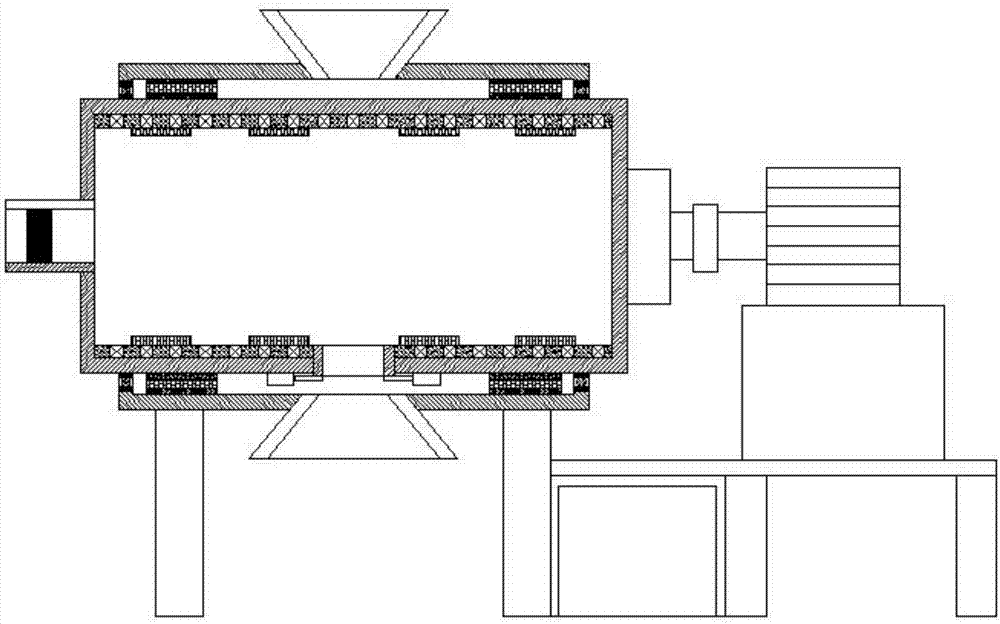

Method used

Image

Examples

Embodiment 1

[0041]A method for microwave smelting silicon-manganese alloys, comprising the following steps:

[0042] Step S10, putting manganese-containing raw materials into a microwave smelting furnace for smelting to obtain a liquid manganese mixture. Specifically:

[0043] Step S101, first crushing the manganese-containing raw materials, the processed manganese raw materials include manganese ore and manganese-rich slag, and screening to find out that the manganese-containing raw materials to be smelted have a particle diameter of 30 mm; take 130 kg of the manganese-containing ore after screening, Slag 80kg;

[0044] Step S102, put 130 kg of manganese ore and 80 kg of manganese-rich slag into the microwave smelting furnace, close the door of the microwave smelting furnace, and then start the motor, which drives the body of the microwave smelting furnace to rotate. After 15 minutes of rotation, the manganese ore and manganese-rich slag After the slag is fully mixed, start the microwav...

Embodiment 2

[0053] A method for microwave smelting silicon-manganese alloys, comprising the following steps:

[0054] Step S10, putting manganese-containing raw materials into a microwave smelting furnace for smelting to obtain a liquid manganese mixture. Specifically:

[0055] Step S101, first crushing manganese-containing raw materials, the processed manganese raw materials include manganese ore, manganese-rich slag and marble, and screening, screening out the manganese-containing raw materials to be smelted with a particle diameter of 40mm; take the manganese ore after screening 140kg, manganese-rich slag 130kg, marble 10kg;

[0056] Step S102, put 150kg of manganese ore, 130kg of manganese-rich slag and 10kg of marble into the microwave smelting furnace, close the door of the microwave smelting furnace, and then start the motor, which drives the furnace body of the microwave smelting furnace to rotate for 18 minutes. After the manganese ore and manganese-rich slag are fully mixed, th...

Embodiment 3

[0065] A method for microwave smelting silicon-manganese alloys, comprising the following steps:

[0066] Step S10, putting manganese-containing raw materials into a microwave smelting furnace for smelting to obtain a liquid manganese mixture. Specifically:

[0067] Step S101, first crushing manganese-containing raw materials, the processed manganese raw materials include manganese ore, manganese-rich slag and marble, and screening, screening out the particle diameter of manganese-containing raw materials to be smelted is 50 mm; take the manganese ore after screening 150kg, manganese-rich slag 150kg, marble 12kg;

[0068] Step S102, put 150kg of manganese ore, 150kg of manganese-rich slag and 12kg of marble into the microwave smelting furnace, close the door of the microwave smelting furnace, and then start the motor, which drives the furnace body of the microwave smelting furnace to rotate for 18 minutes. After the manganese ore and manganese-rich slag are fully mixed, the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com