Method for manganese alloying by using manganese ore and device for manganese alloying by using manganese ore

A technology of manganese alloying and application of manganese ore, which is applied in the field of iron and steel smelting, can solve the problems of low efficiency, large amount of final slag, and processing difficulties, and achieve the effects of convenient operation, zero CO2 emission, and simple composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

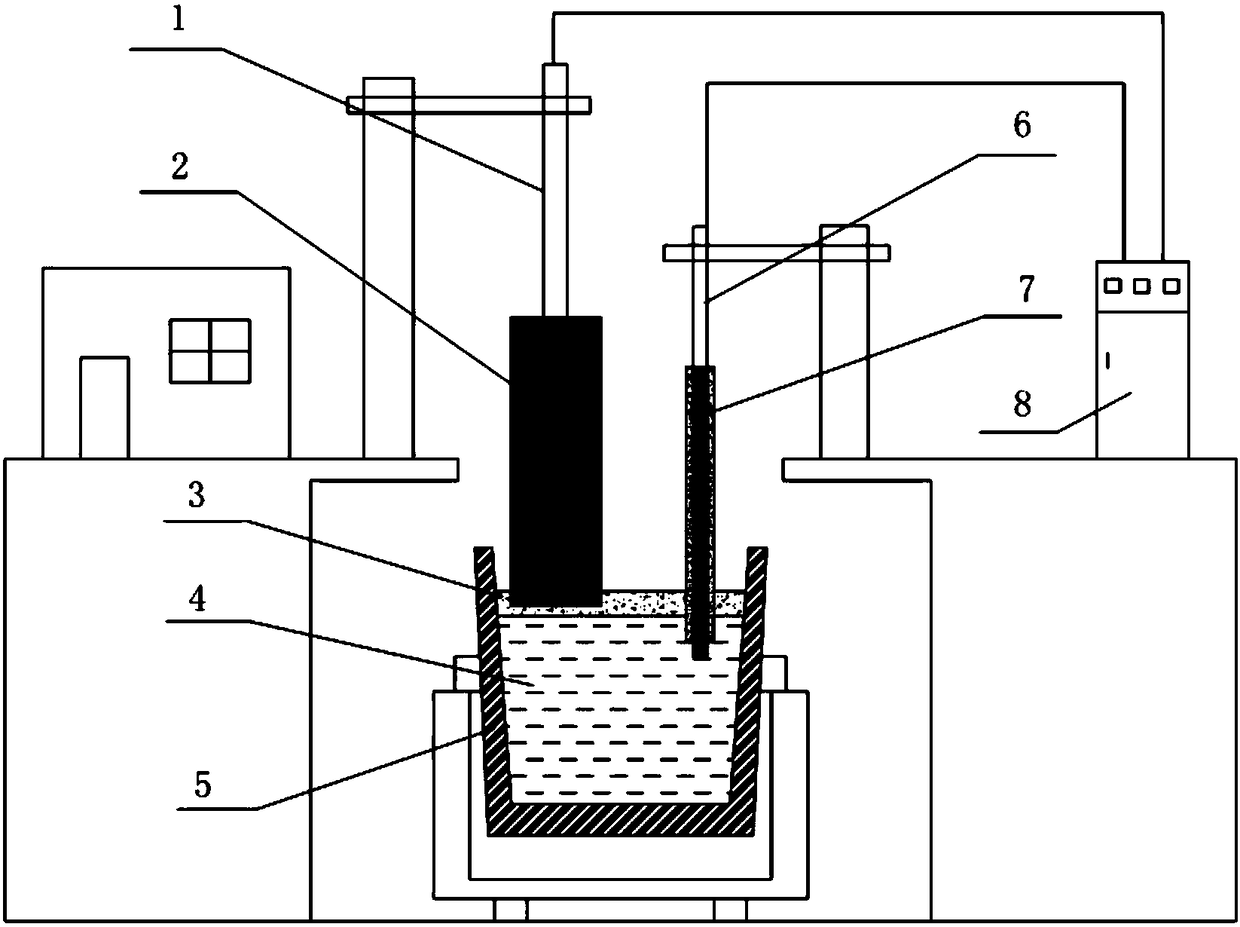

[0054] Such as figure 1 As shown, an anode lifting device 1 is arranged on the upper left side of the ladle 5; the anode lifting device 1 is equipped with a high temperature resistant metal molybdenum ceramic anode 2, the number is 4, and the anode 2 is inserted in the slag 3; the anode lifting device 1 The depth at which the anode 2 is inserted into the slag 3 can be adjusted to ensure that the anode 2 is in contact with the slag 3 and not with the molten steel 4; the other side above the ladle 5 is provided with a cathode lifting device 6, and the cathode lifting device 6 is installed with a Cathode 7, the cathode 7 is a round rod with a composite structure of two layers inside and outside, the outer layer is wrapped with high temperature resistant cement, and the inside is a graphite rod; the cathode 7 is inserted into the molten steel 4; the cathode lifting device 6 can adjust the lifting stroke of the cathode 7 , ensure that the cathode 7 passes through the slag 3 and con...

Embodiment 2

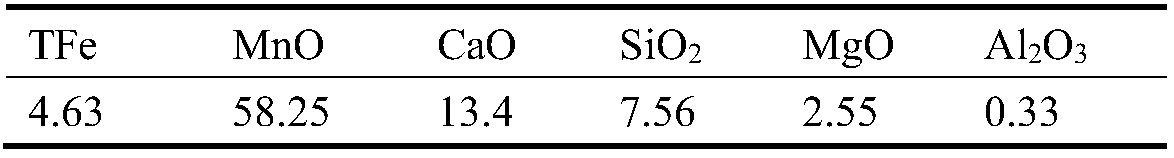

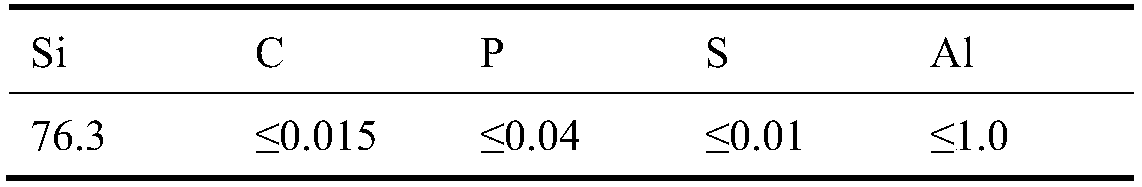

[0069] The electrolytic reaction control device in this embodiment is the same as in Embodiment 1; the composition of manganese ore is shown in Table 1, and the particle size is 5-50mm; the composition of white ash is shown in Table 3; the oxygen control agent is ferrosilicon, and the composition is shown in Table 2.

[0070] Apply this special electrolytic reaction control device on the 100t ladle to carry out manganese alloying with manganese ore metal. The overall control process is as follows: the weight of molten steel in the converter is 105 tons, the C content at the end of smelting is 0.073% (percentage by weight), the temperature of molten steel at the end of smelting is 1705°C; lime and manganese ore. The amount of white ash added is 8Kg / ton of steel; the oxygen content at the end point of molten steel is 0.038%, and the oxygen content is dropped into the oxygen control agent ferrosilicon according to this, and the added amount is 70kg; the added amount of manganese ...

Embodiment 3

[0073] The electrolytic reaction control device in this embodiment is the same as in Embodiment 1; the composition of manganese ore is shown in Table 1, and the particle size is 5-50mm; the composition of white ash is shown in Table 3; the oxygen control agent is ferrosilicon, and the composition is shown in Table 2.

[0074] Apply this special electrolytic reaction control device on the 100t ladle to carry out manganese alloying with manganese ore metal. The overall control process is as follows: the weight of molten steel in the converter is 101 tons, the C content at the end point of smelting is 0.066% (percentage by weight), the temperature of molten steel at the end point of smelting is 1710°C; lime and manganese ore. The amount of white ash added is 6Kg / ton of steel; the oxygen content at the end point of molten steel is 0.045%, and the oxygen content is dropped into the oxygen control agent ferrosilicon according to this, the added amount is 80kg; the added amount of ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com