Unkilled steel RH smelting method and temperature compensation method

A temperature compensation and smelting method technology, applied in the field of steelmaking, can solve problems such as pollution, affecting the quality of molten steel, waste of resources and the environment, and achieve the effects of avoiding environmental pollution, improving the purity of molten steel, and reducing the production of cold steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

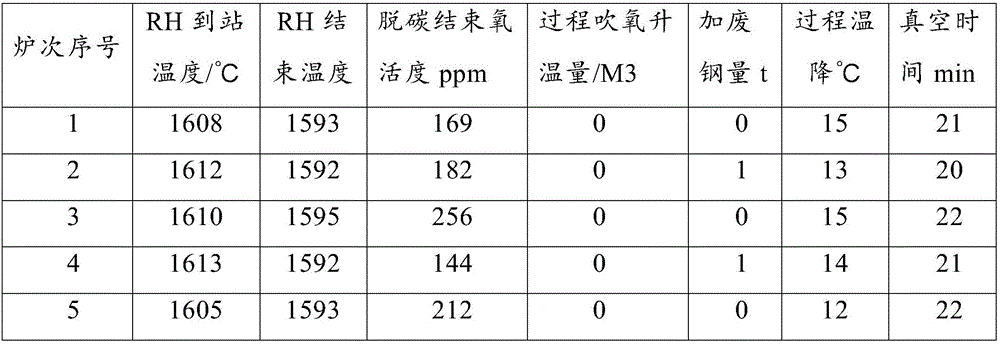

[0033] The embodiment of the present application provides a temperature compensation method for RH smelting based on exhaust gas combustion, which solves the problem of temperature drop in the RH refining stage in the prior art, which leads to the generation of cold steel and affects the quality of molten steel; at the same time, waste gas is discharged, causing waste of resources and environmental pollution. Technical problems; achieve the technical effect of reducing the temperature drop of molten steel, inhibiting the generation of cold steel, and ensuring the quality of molten steel; at the same time, improving resource utilization and avoiding environmental pollution.

[0034] In order to solve the above technical problems, the general idea of the technical solution provided by the embodiment of the present application is as follows:

[0035] A temperature compensation method for RH smelting based on waste gas combustion; comprising the following steps:

[0036] Execute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com