A thin strip continuous casting cloth flow slag removal method

A continuous casting and thin strip technology, which is applied in the field of thin strip continuous casting cloth flow slag removal, can solve the problems of increasing quality influencing factors, failing to ensure slag retaining weir, and not specifying slag retaining weir, so as to reduce fluctuations and reduce temperature Decrease and increase the effect of anterograde

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

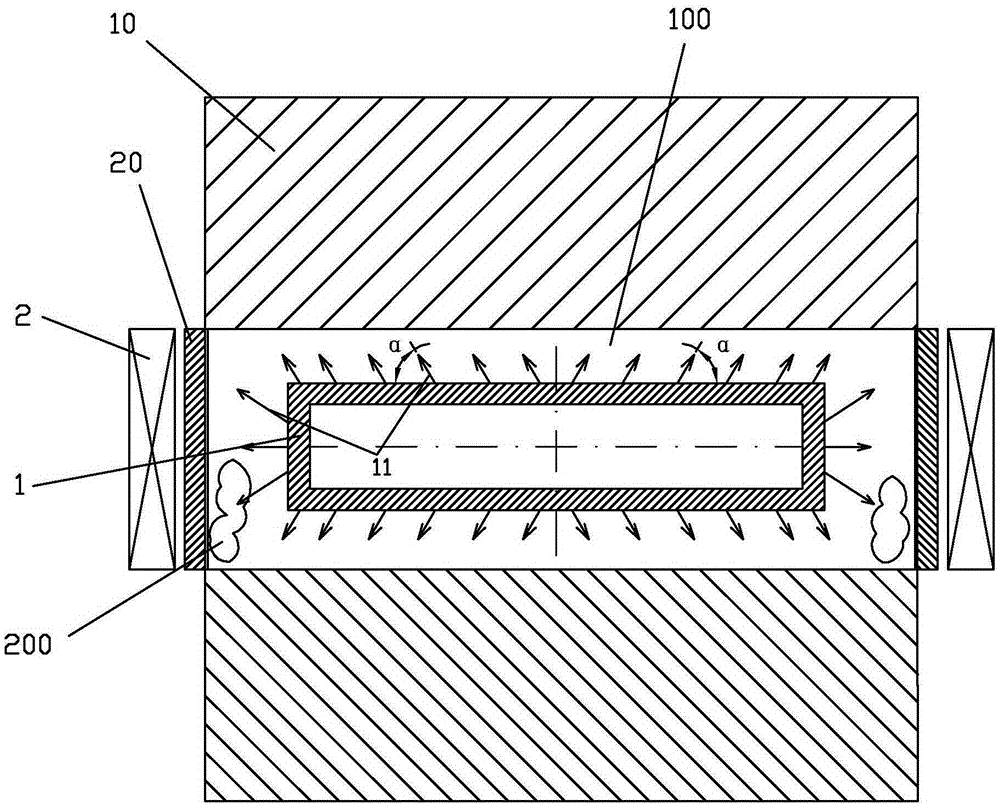

Embodiment 1

[0036] During the flow distribution process of twin-roll thin strip continuous casting, the pulling speed of the crystallization roll is 50m / min; the liquid level of the molten pool is 200mm; the distance from the upper edge of the discharge hole of the flow distributor to the liquid level is 4mm; The inclination angle is 65°; the electromagnetic intensity of the electromagnetic induction device is 0.09T.

Embodiment 2

[0038] During the flow distribution process of twin-roll thin strip continuous casting, the pulling speed of the crystallization roll is 70m / min; the liquid level of the molten pool is 220mm; the distance from the upper edge of the discharge hole of the flow distributor to the liquid level is 6mm; The inclination angle is 50°; the electromagnetic intensity of the electromagnetic induction device is 0.11T.

Embodiment 3

[0040] During the flow distribution process of twin-roll thin strip continuous casting, the pulling speed of the crystallization roll is 90m / min; the liquid level of the molten pool is 240mm; the distance from the upper edge of the discharge hole of the flow distributor to the liquid level is 7mm; The inclination angle is 40°; the electromagnetic intensity of the electromagnetic induction device is 0.13T.

[0041] Thin strip continuous casting technology is one of the most competitive technologies in the 21st century. It has advantages incomparable to conventional continuous casting in terms of energy saving and environmental protection, so it has attracted great attention from all over the world; There are many defects. Through the inclination of the discharge hole of the distributor and the control of the electromagnetic induction device on the molten steel, the removal of scum during the molten steel casting process is realized. On the one hand, the process is simple and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com