Pouring method for large-scale vacuum steel ingot

A pouring method, vacuum steel technology, applied in the field of steel ingot pouring, can solve the problems of poor flow of molten steel, failure to achieve trickle pouring, low pass rate of forgings, etc., and achieve the effect of improving the purity of molten steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

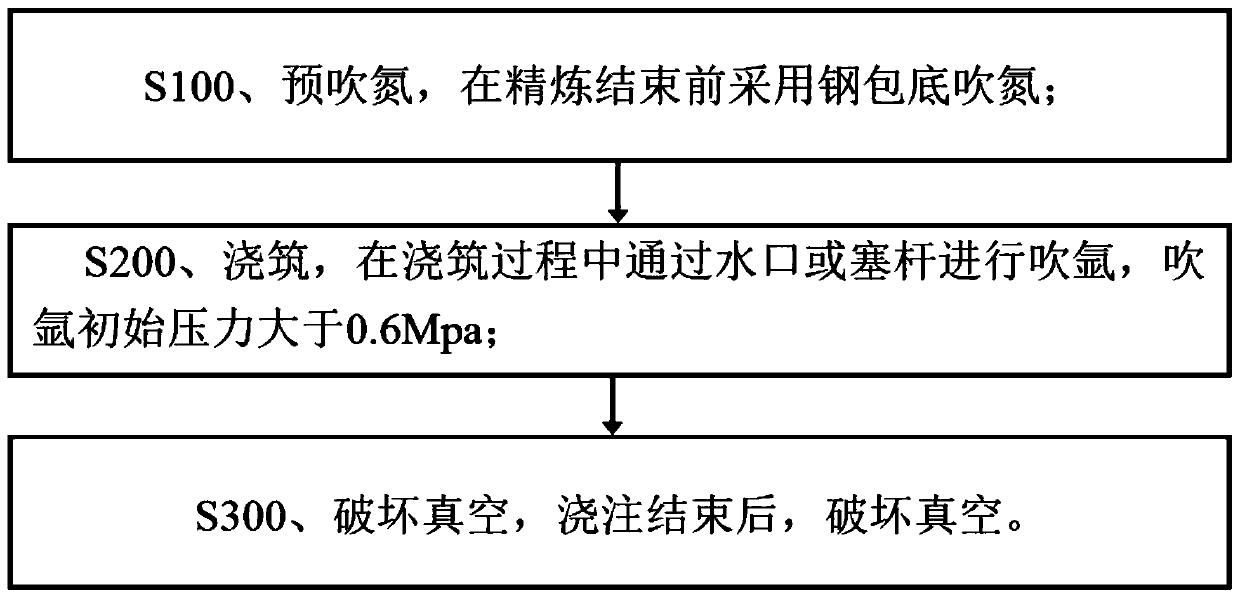

[0026] Refer to attached figure 1 , a pouring method for a large vacuum steel ingot in this embodiment, nitrogen blowing at the bottom of the ladle is used before the end of refining. Then break the vacuum. In the large-scale vacuum steel ingot manufactured by the manufacturing method of the present invention, the purity of molten steel is greatly improved, the content of C-type inclusions is reduced from 1-1.5 levels in the past to 0.5-1 level, and the contents of other types of inclusions are reduced from 0.5-1 level to 0-0. 0.5 level, some plate products, the pass rate of flaw detection has increased from less than 70% in the past to more than 95%.

[0027] Specifically include the following steps:

[0028] S100, pre-blowing nitrogen, using nitrogen blowing at the bottom of the ladle before refining;

[0029] S200, pouring, argon blowing is carried out through the nozzle or stopper during the pouring process, and the initial pressure of argon blowing is greater than 0.6M...

Embodiment 2

[0038] The steel grade SA508Gr.3Cl.1 of this embodiment has an ingot size of 300t and is hydrated with 3 packs of steel. The nitrogen content of the product is required to be controlled at 90-120ppm, and the target value is 105ppm. After vacuum treatment in the refining furnace, nitrogen is blown at the bottom, the nitrogen blowing flow rate is 200L / min, and the nitrogen blowing time is 25min. Samples are taken before pouring. The nitrogen content of 3 bags of molten steel is: 208, 215, 212ppm.

[0039] When pouring, the vacuum degree is 40Pa. When pouring starts, the argon pressure is 1.0Mpa, and the injection speed is controlled at 3t / min. After 2 minutes, the argon pressure is reduced to 0.2Mpa, and the pouring is at full speed. The whole pouring process is well diffused and the molten steel It drips into the ingot mold in the form of drizzle.

[0040] After the molten steel is poured to the target position of the riser, the nozzle is closed, the vacuum is broken, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com