Hard alloy stop block and compression molding process

A compression molding, hard alloy technology, applied in the direction of metal processing equipment, machines/engines, liquid fuel engines, etc., can solve the problems of instability, sintering cracking, high cost, etc., to reduce shrinkage, ensure uniform shrinkage, and ensure The effect of molding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A molding process of a hard alloy stop block, comprising the steps of:

[0042] S1: Mix 0.3kg of cobalt powder, 8.2kg of metal nickel powder, and 91.5kg of tungsten carbide powder; wherein, the particle size of tungsten carbide is 1-2μm, and the mass fraction of carbon in tungsten carbide is 5.9%;

[0043] S2: wet grinding the mixture obtained in step S1 to obtain a slurry with a particle size of less than 1 μm;

[0044] S3: drying, drying the slurry obtained in step S2, and then adding 140 mL / kg, 18% mass concentration of SBS emulsion to the dry matter, and stirring evenly;

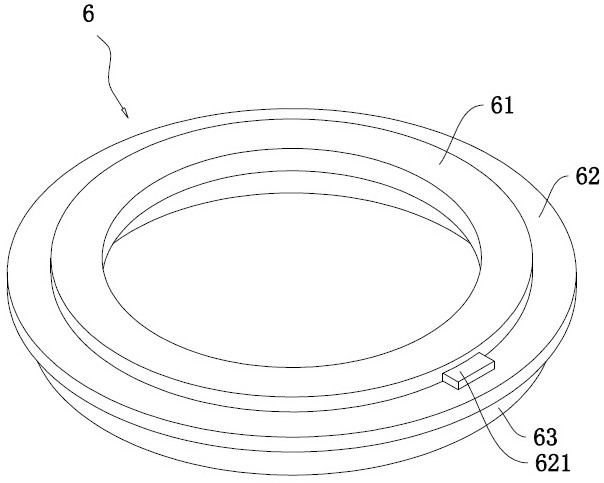

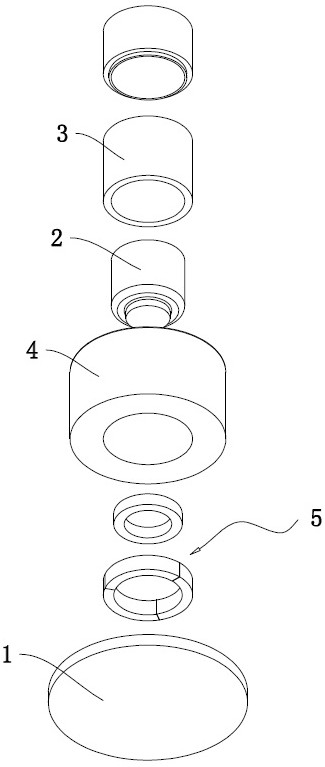

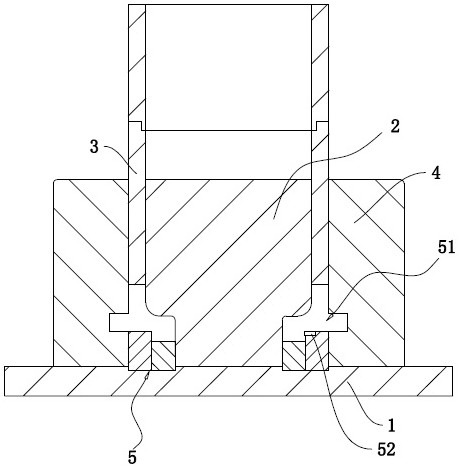

[0045] S4: Compression molding, at a pressure of 1.5t / cm 2 Under the condition that step S3 obtains the material granule press-molded to get the rough piece; In the process of press-molding, mold adopts announcement number to be that the mold disclosed by CN210817457U carries out press-molding, with reference to figure 2 and image 3, when in use, place the mandrel 5 on the lower die 1, then i...

Embodiment 2

[0055] A molding process of a hard alloy stop block, comprising the steps of:

[0056] S1: Mix 0.5kg of cobalt powder, 7.9kg of metal nickel powder, and 91.6kg of tungsten carbide powder; among them, the particle size of tungsten carbide is 1-2μm, and the mass fraction of carbon in tungsten carbide is 5.92%;

[0057] S2: wet grinding the mixture obtained in step S1 to obtain a slurry with a particle size of less than 1 μm;

[0058] S3: drying, drying the slurry obtained in step S2, and then adding 145 mL / kg, 16% mass concentration of SBS emulsion to the dry matter, and stirring evenly;

[0059] S4: Compression molding, at a pressure of 1.2t / cm 2 Under the condition that step S3 obtains the material granule press-molded to get the rough piece; In the process of press-molding, mold adopts announcement number to be that the mold disclosed by CN210817457U carries out press-molding, with reference to figure 2 and image 3 , when in use, place the mandrel 5 on the lower die 1, t...

Embodiment 3

[0069] A molding process of a hard alloy stop block, comprising the steps of:

[0070] S1: Mix 0.7kg of cobalt powder, 7.5kg of metal nickel powder, and 91.8kg of tungsten carbide powder; among them, the particle size of tungsten carbide is 1-2μm, and the mass fraction of carbon in tungsten carbide is 5.95%;

[0071] S2: wet grinding the mixture obtained in step S1 to obtain a slurry with a particle size of less than 1 μm;

[0072] S3: drying, drying the slurry obtained in step S2, and then adding 130 mL / kg, 20% mass concentration of SBS emulsion to the dry matter, and stirring evenly;

[0073] S4: Compression molding, at a pressure of 1.5t / cm 2 Under the condition that step S3 obtains the material granule press-molded to get the rough piece; In the process of press-molding, mold adopts announcement number to be that the mold disclosed by CN210817457U carries out press-molding, with reference to figure 2 and image 3 , when in use, place the mandrel 5 on the lower die 1, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com