Production method for improving graphite form of spheroidal graphite cast iron

A production method and technology of ductile iron, applied in the direction of casting mold, casting mold composition, casting molding equipment, etc., can solve the problem of large fluctuation of punching method, improvement, technology, equipment reliability, and quality of cored wire. and other problems, to achieve the effect of high reliability and simple processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

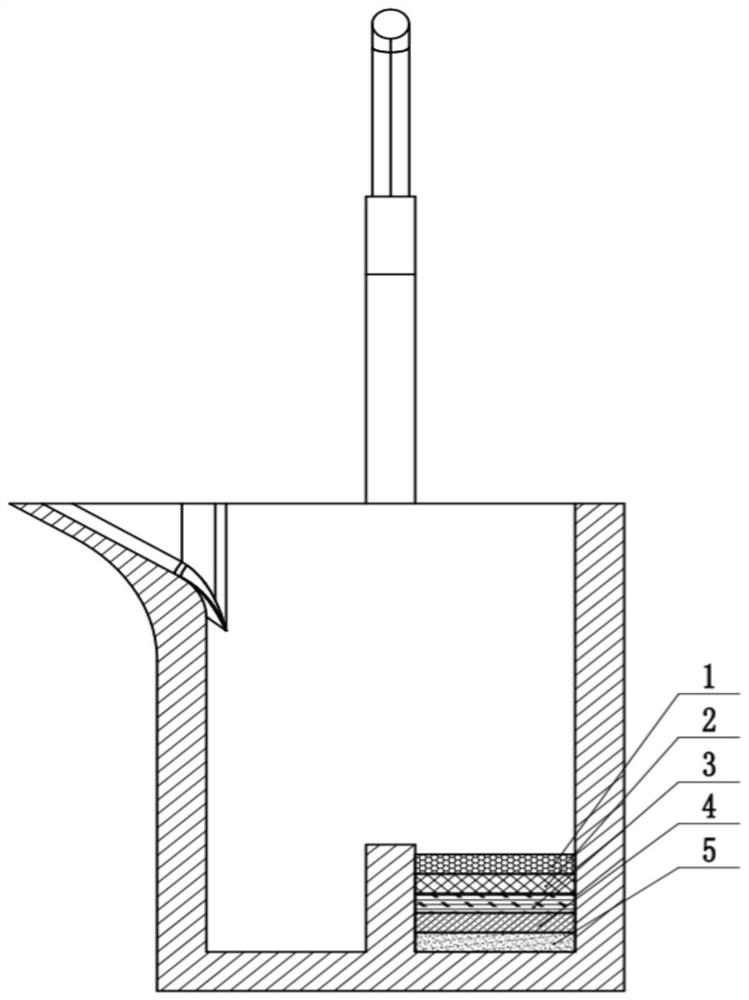

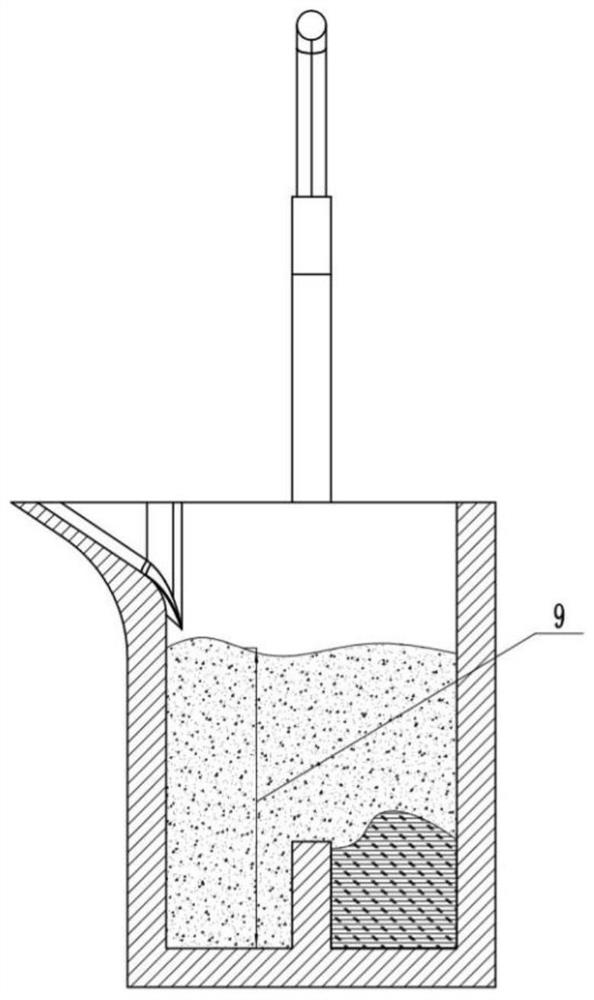

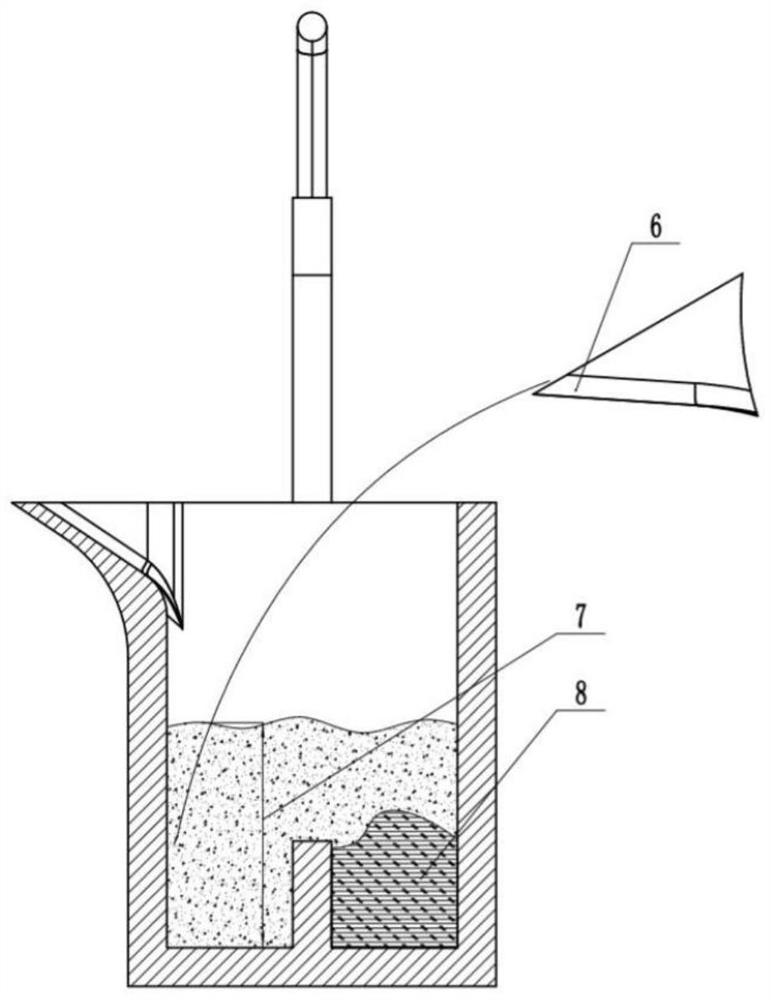

Method used

Image

Examples

Embodiment 1

[0048] Example 1: Using the prior art method to produce a single pearlite matrix ductile iron crankshaft

[0049] The weight of the part is 48Kg, the basic wall thickness is 25mm, and the outline dimension is 600*240*245mm.

[0050] (1) Use Q10 low-sulfur low-titanium pig iron 20%, carbon steel 55%, pearlite type reheating iron 25%; then add 0.18% of the total mass of the main charge of 75 ferrosilicon, 0.35% of 65 high-carbon ferromanganese, 0.4 % Electrolytic copper (low lead, 99.99% purity) and 2.45% graphite recarburizer. The composition of raw molten iron obtained by smelting is as follows: C: 3.85%, Si: 0.78%, Mn: 0.42%, Cu: 0.44%, S: 0.012%, Ti: 0.031%.

[0051] (2) Spheroidizing treatment: add 0.95% of the mass of molten iron with low rare earth 1-6 spheroidizing agent, 0.32% BS-1A inoculant, 0.21% BS-1SB, 0.4% 75 silicon Iron is used as an inoculant.

[0052] (3) The molten iron is tapped in 2 steps. In the first step, 85-90% molten iron is produced, and the tapping speed r...

Embodiment 2

[0055] Example 2: Production of a single pearlite matrix ductile iron crankshaft

[0056] The weight of the part is 48Kg, the basic wall thickness is 25mm, and the outline dimension is 600*240*245mm.

[0057] (1) Use Q10 low-sulfur low-titanium pig iron 20%, carbon steel 55%, pearlite type reheating iron 25%; then add 0.18% of the total mass of the main charge of 75 ferrosilicon, 0.35% of 65 high-carbon ferromanganese, 0.4 % Electrolytic copper (low lead, 99.99% purity) and 2.45% graphite recarburizer. The composition of the raw molten iron obtained by smelting is as follows: C: 3.85%, Si: 0.78%, Mn: 0.42%, Cu: 0.44%, S: 0.012%, Ti: 0.031%.

[0058] (2) Spheroidizing treatment: Add 0.95% of the mass of molten iron with low rare earth 1-6 spheroidizing agent, 0.32% BS-1A inoculant and 0.21% BS-1SB, and add 0.1% SiCaMn to deoxidize. As an inoculant, 0.4% of 75 ferrosilicon is used as an inoculant.

[0059] (3) The molten iron is tapped in 2 steps. In the first step, 85-90% molten iron...

Embodiment 3

[0061] Example 3: Production of a single pearlite matrix ductile iron crankshaft

[0062] The weight of the part is 70Kg, the basic wall thickness is 25mm, and the outline dimension is 800*250*250mm.

[0063] (1) Use Q10 low-sulfur low-titanium pig iron 20%, carbon steel 55%, pearlite type reheating iron 25%; then add 0.18% of the total mass of the main charge of 75 ferrosilicon, 0.35% of 65 high-carbon ferromanganese, 0.4 % Electrolytic copper (low lead, purity 99.99%) and 2.45% graphite recarburizer, smelted to obtain the following raw iron liquid: C: 3.8-3.9%, Si: 0.7-0.9%, Mn: 0.4-0.5% , Cu: 0.4-0.5%, S≤0.03%, Ti≤0.035%.

[0064] (2) Spheroidizing treatment: Add 0.95% of the mass of molten iron with low rare earth 1-6 spheroidizing agent, 0.32% of BS-1A inoculant, 0.22% of BS-1SB, and 0.1% of SiCaMn in the spheroidizing bag Deoxidizer, 0.4% of 75 ferrosilicon is used as an inoculant.

[0065] (3) The molten iron is tapped in 2 steps, the first time is 85-90% molten iron, the tap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com