Rolling bearing

A technology of rolling bearings and rolling elements, applied in the direction of bearings, bearing components, shafts and bearings, which can solve problems such as complex working steps and post-processing steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

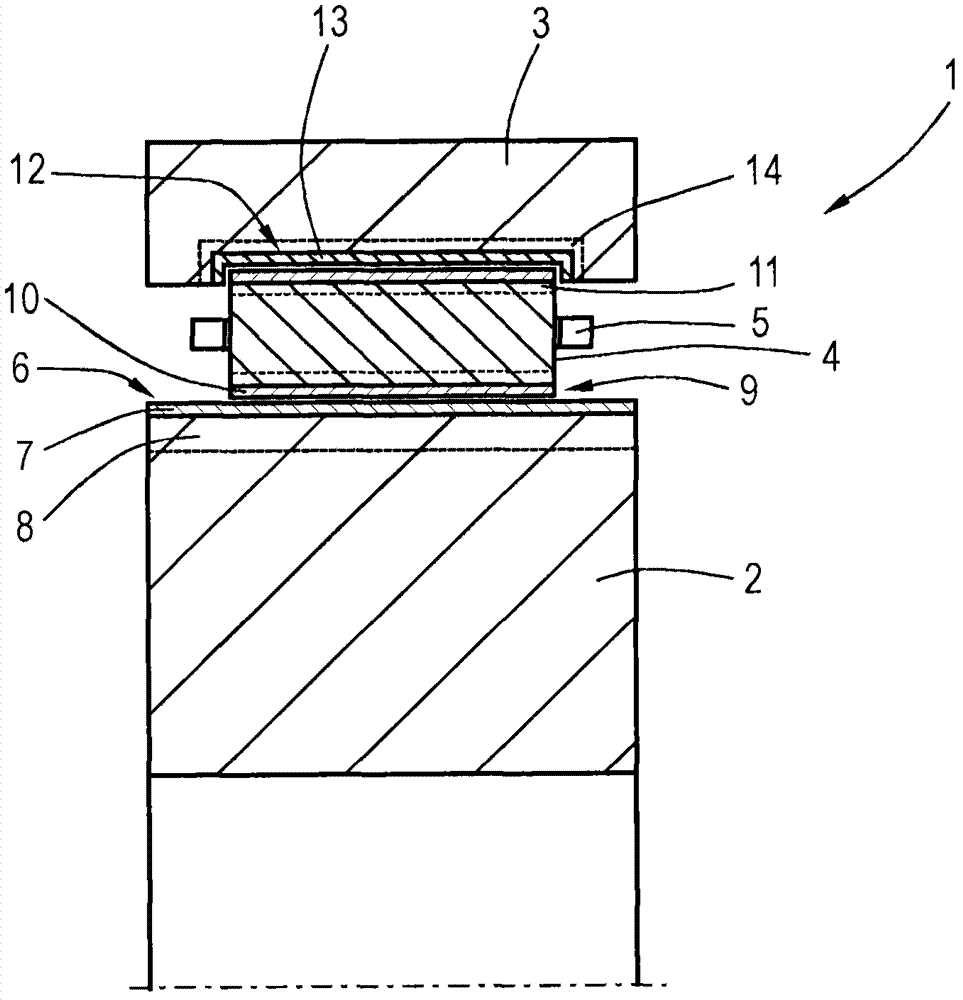

[0027] A cross-sectional view of a rolling bearing 1 according to the invention is shown as an example in the drawing. The rolling bearing 1 is composed of an inner ring 2 , an outer ring 3 and rolling elements 4 arranged between the inner ring 2 and the outer ring 3 , the rolling elements 4 being held in a cage 5 .

[0028] The inner ring 2 has an outer raceway 6 on which a polishing layer 7 is arranged. An edge region 8 is formed below the polishing layer 7 , in which an increased nitrogen and carbon content is given by the carbonitriding method. The nitrogen content is between 0.03-0.8%, wherein at least 0.02% of the nitrogen is dissolved in the steel substrate. In addition, the steel substrate contains a small nickel component of ≤0.4%, a silicon content of 0.2%-1.0%, a chromium content of ≥1.0%, a sulfur content of ≤0.008%, an oxygen content of ≤15ppm and an oxygen content of ≤50ppm Titanium content.

[0029] The surfaces 9 of the rolling bodies are also provided with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com