Low-hydrogen easy-to-weld alkaline flux-cored wire prepared from steel slag and used for structural steel

A technology of flux-cored welding wire and structural steel, which is applied in the direction of welding medium, welding equipment, welding/cutting medium/material, etc., can solve the problems of poor crack resistance of weld seam, reduce alkalinity, and fail to reach, and achieve weld formability Good, the effect of increasing the burning intensity and reducing the formation tendency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

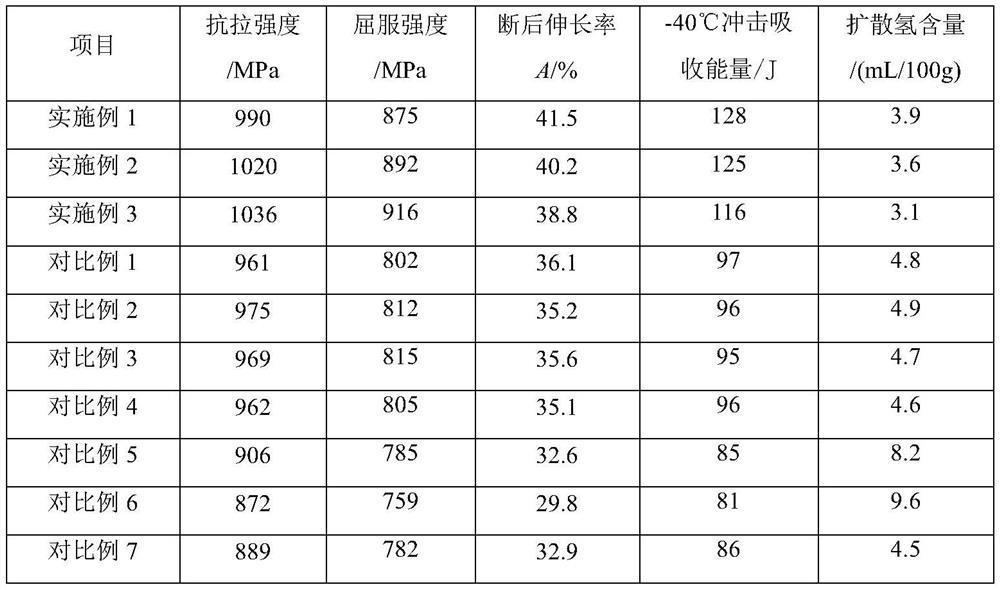

Examples

Embodiment 1

[0037] Low-hydrogen easy-to-weld basic flux cored wire for structural steel prepared from steel slag, including flux core powder and sheath, the chemical composition and dosage of flux core powder are calculated by mass percentage: 28% steel slag, 9.0% Mo40V40Al20 powder, FeMn60Si34C0.02 Powder 8.2%, FeTi80-A powder 5.0%, CaF coated with Ni 2 Powder 9.6%, Nano TiO 2 6.0%, 200 mesh nitrocellulose powder 3.8%, feldspar 3.0%, the balance is FHT100·25 reduced iron powder, CaF 2 The particle size of the powder without Ni plating is 5μm-10μm, the thickness of the Ni plating layer is 30nm-50nm, and the outer skin is made of low-carbon cold-rolled steel strip.

[0038] The chemical composition of steel slag is calculated by mass percentage: SiO 2 1.5%-3.0%, Al 2 o 3 32%-36%, MgO8%-12%, CaO49%-52%, FeO0.3%-0.5%, MnO0.5%-1.5%, S+P≤0.03%; Mo40V40Al20 powder, FeMn60Si34C0.02 powder, FeTi80 -The 100-mesh passing rate of A powder is 100%.

[0039] The thickness of the steel strip is 0...

Embodiment 2

[0050] Low-hydrogen easy-to-weld basic flux cored wire for structural steel prepared from steel slag, including flux core powder and sheath, the chemical composition and dosage of flux core powder are calculated by mass percentage: 22% steel slag, 7.5% Mo40V40Al20 powder, FeMn60Si34C0.02 Powder 5.6%, FeTi80-A powder 4.1%, CaF coated with Ni 2 Powder 7.8%, Nano TiO 2 4.2%, 200 mesh nitrocellulose powder 3.1%, feldspar 2.1%, the balance is FHT100·25 reduced iron powder, CaF 2 The particle size of the powder without Ni plating is 5μm-10μm, the thickness of the Ni plating layer is 30nm-50nm, and the outer skin is made of low-carbon cold-rolled steel strip.

[0051] The chemical composition of steel slag is calculated by mass percentage: SiO 2 1.5%-3.0%, Al 2 o 3 32%-36%, MgO8%-12%, CaO49%-52%, FeO0.3%-0.5%, MnO0.5%-1.5%, S+P≤0.03%.

[0052] The 100-mesh passing rate of Mo40V40Al20 powder, FeMn60Si34C0.02 powder and FeTi80-A powder is 100%.

[0053] The thickness of the steel...

Embodiment 3

[0058] Low-hydrogen easy-to-weld basic flux cored wire for structural steel prepared from steel slag, including flux core powder and sheath, the chemical composition and dosage of flux core powder are calculated by mass percentage: 25% steel slag, 8.3% Mo40V40Al20 powder, FeMn60Si34C0.02 Powder 7.0%, FeTi80-A powder 4.7%, CaF coated with Ni 2 Powder 8.6%, Nano TiO 2 5.0%, 200 mesh nitrocellulose powder 3.4%, feldspar 2.6%, the balance is FHT100·25 reduced iron powder, CaF 2The particle size of the powder without Ni plating is 5μm-10μm, the thickness of the Ni plating layer is 30nm-50nm, and the outer skin is made of low-carbon cold-rolled steel strip.

[0059] The chemical composition of steel slag is calculated by mass percentage: SiO 2 1.5%-3.0%, Al 2 o 3 32%-36%, MgO8%-12%, CaO49%-52%, FeO0.3%-0.5%, MnO0.5%-1.5%, S+P≤0.03%.

[0060] The 100-mesh passing rate of Mo40V40Al20 powder, FeMn60Si34C0.02 powder and FeTi80-A powder is 100%.

[0061] The thickness of the steel ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com