Polyether type fully synthetic compressor oil composition and preparation method thereof

A compressor oil, fully synthetic technology, applied in lubricating compositions, petroleum industry, etc., can solve the problems of polyalphaolefins such as poor lubricity, unfavorable low-temperature start-up, poor hydrolysis stability, etc., and achieve long service life, excellent oxidation stability and Thermal stability, excellent detergency and dispersibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The present invention also provides a preparation method of the above-mentioned polyether-type fully synthetic compressor oil composition, which includes the following steps: by weight percentage, adding 60% to 85% of polyether and 5% to 30% of alkyl aromatic hydrocarbon into the belt and stirring In the blending kettle of the device, heat to 60-70°C, and blend for 0.5-1 hour until uniform; then add 0.5%-8% antioxidant, 0.01%-1% sulfur-containing or phosphorus-containing extreme pressure anti-wear agent, 0.01%~1% rust inhibitor, 0.001%~0.5% metal deactivator and 0.001%~0.1% anti-emulsifier, adjust at 60-70℃ for 2~4 hours, until the mixture is uniform and transparent.

[0034] The technical scheme of concrete implementation of the present invention comprises:

Embodiment 1

[0036] A kind of polyether type fully synthetic compressor oil composition, its each component is distributed as follows by weight percentage:

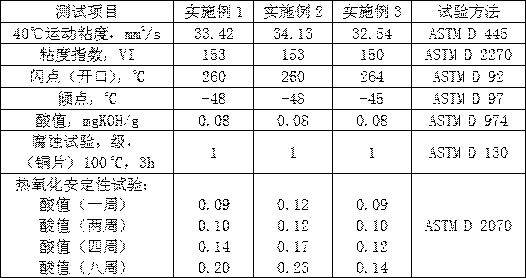

[0037] Polyether: 63.44%, alkyl naphthalene: 28%, amine antioxidant: 6.0%, phenolic antioxidant: 2.0%, antiwear agent: 0.5%, organic acid rust inhibitor: 0.02%, benzotriazole Derivatives: 0.02%, polyether anti-emulsifiers: 0.02%. The main test properties of the polyether type fully synthetic compressor oil composition obtained in Example 1 are shown in Table 1.

Embodiment 2

[0039] A kind of polyether type fully synthetic compressor oil composition, its each component is distributed as follows by weight percentage:

[0040] Polyether: 64.44%, alkyl naphthalene: 28%, amine antioxidant: 5.0%, phenolic antioxidant: 2.0%, antiwear agent: 0.5%, organic acid rust inhibitor: 0.02%, benzotriazole Derivatives: 0.02%, polyether anti-emulsifiers: 0.02%. The main test properties of the polyether type fully synthetic compressor oil composition obtained in Example 2 are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com